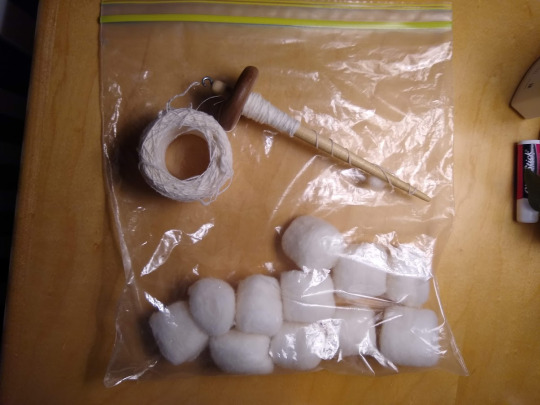

#(was spun as a singles on a supported spindle)

Text

Made a ply ball to make this plying less annoying. I still have fiber left to spin, but I've decided to get started on plying anyway.

This is the suffolk/hampshire blend I've been working on, on and off, for the last couple months.

Nearly there.

Also, some snowdrops for your trouble.

#plying on a drop spindle from a ply ball has been my preferred method for plying supported spindle spun singles#work is so hard today#i have like 10 things to do and instead i reorganized the towels drawer and made a ply ball and am gonna go#walk around and ply it and smoke some weed#no idea if i can ply on my rollator#ive been rolling myself around in it/getting pushed by my partner despite knowing not to#its so hard to walk and stand and support my own weight haha.#really need that wheelchair.#anyway...#supported spindle#spinning#handspun yarn#ply ball#suffolk hampshire blend

44 notes

·

View notes

Text

Fiber arts update: lots of WIPs

2 out of 3 singles for the weft of my next weaving project are done:

this is Polwarth/Silk/Yak. Very nice and chill spin, all things considered. Not as easy as that amazing grey merino I spun before that, but honestly still pretty harmless by luxury fiber standards. Bit fuzzy, somewhat prone to slight clumps, but generally very fun.

Before starting the third single, I got my next bunch of fibers in, so I elected to experiment for a bit:

This is a sample of roving that I bought 100g of ages ago and haven't yet figured out what to do with:

The bigger thing is 3-ply with the fiber split into thirds by color, the smaller one is just the whole thing spun with a short forward draw as a 2-ply. I actually prefer the uncontrolled blending over the more controlled, barber-pole look, I think; the surprisingly small amount of green should keep the spin from getting too muddy. It's gonna be a royal pain in either case: There's silk in this one, and it's in two big strands. So, so impossible to work with.

Then, I got myself some cotton:

just slapped on the supported spindle overtop of a red merino practice spin because I'm lazy. Honestly, on the supported spindle it's the easiest spin I've done so far, because the short fibers are actually manageable with an unsupported long draw. I'll give it a try on the wheel at some point, too, just in case it works and is faster, but I wouldn't mind relegating it to the supported spindle if it doesn't; fuck knows the thing isn't getting enough use right now anyway.

And, the highlight of the haul, a baby camel/silk sample:

This stuff is beautiful. A wonderful light caramel kind of color, shimmery as anything, and soft as heck.

it spins up into an almost violently shiny single that looks just as expensive as the fiber is:

Unfortunately, I'm now also 56% tiny, fine, short silk fibers by volume, and I'm pretty sure I have camel hair stuck up my nose.

I'll have to get the second half of this sample spun quickly, before my entire room gets covered in silk fuzz.

35 notes

·

View notes

Text

[ID: Three photos of a purple to pink to orange gradient yarn sitting on weathered wood planks in direct sunlight. In the first, the yarn is a single, unplied twist wrapped into a ball around a disc shaped core (the cardboard of an empty masking tape roll).

In the second, it is a loosely tied hank of three-ply yarn; it has been chain-plied, so neighboring segments of yarn are wrapped together, preserving the color change with minimal variegation.

The third photo features the hank laid with the opposite side up next to a shallow dark-orange mug with a spindle resting in it at a 40 degree angle. The spindle was 3D printed horizontally with a rainbow colored filament, from a spot of orange on one side through red, purple, blue, and to green on the other side. It is about nine and a half inches or twenty-four and a half centimeters long. The spindle is a supported Russian style, its base an inverted teardrop shape before a waist and the shaft of the spindle that's widest just above the waist and tapers down to as thin a spike at the top as possible. End ID]

I spun yarn! And plied it! This spindle and spinnable fluff were an incredibly generous gift from @dangerphd amid excess from 3D printing experiments! I'd previously spun one skein on a drop spindle in high school -- and I loved it for the process and made a chunky shawl of the Stephen West Spectra scarf design with it, but boy was it an uncontrolled thick and thin mess. Whether due to actually carrying over that learning more than a decade later, or the lighter (supported) spindle, or marginally more patience with age, this went way better!

I was definitely struggling with repeated breaks at the start and compromised my intention to go as thin as possible, but by the end I felt like I got decent control and consistency in my single's weight. And seeing how much less fragile those once-broken sock-weight singles are once plied should help me keep up the confidence with future fiber to really push for the thinner threads that I want to use. I had just learned about chain plying and wanted to try it when Danger sent the gradient fluff, so it wasn't a problem when there were several spots that I was sure would need plying for strength--and overall it's still less chunky than the thicker parts of the single I had made before! And much more even than I expected.

I haven't been brave and tried fulling it yet, just barely dampened and hung with a minor weight (a thick flannel shirt on its hanger) while drying. (It smells like wool once wet, though less strongly than some and I don't actually know its fiber contents.) But it's already pretty well behaved. It's a bit less than 20 feet of yarn, and I have to get into and through a different project right now, but I'll find something that lets me use it soon enough.

#thank you again dangerphd! it was such a cute package y'all#and it arrived while i was out for a very long day so it was like returning to a little dragon's horde of treasure in my mailbox#except a little more mad science themed than fantasy because 3D printing and spinning experiments#until i get some straw to become gold spun on the rainbow that is#spinning#fiber art#cj gladback#ramblings

18 notes

·

View notes

Text

After seeing @orchardknit 's beautiful handmade supported spindles I decided I had to make my own! One thing led to another, and before long I realized maybe I could knit a wedding ring shawl with the alpaca fiber I had sitting around at home. Alas, this spindle is not a handwhittled creation because I only was able to go home for a brief period for Easter so modifying my cheap little homemade turkish spindle was faster, but once the semester ends I'm definitely trying my hand at the whittling!

This spindle didn't spin for very long at the beginning but it's getting better with more weight and better flicking technique! The spindle fills up so slowly with yarn this fine *pauses to measure wpi, loses count repeatedly* I think it's around 80 wpi though? Maybe more, my eyes were struggling.

*realizes I could have just marked out an inch long segment of the spindle shaft (bamboo kitchen skewer) and counted the wraps as I put them on to fill the inch segment*

I'm really enjoying the portability of spindling, I was able to pull out my little spindle and espresso cup spindle bowl while I was waiting around at my mock audition yesterday in studio class and I also cannot wait to spend some time in the sunshine spinning because we're having lovely weather this week!

I intend to make the Queen Susan Shawl, which is a lovely free pattern on ravelry with a great story behind it's creation, so 8 miles of singles, lovingly spun, here I come!

Edited to include hashtags bc I totally forgot those are a thing lmao

#support spindle#hand spinning#Cobweb yarn#Spindle making#I don't know what I'm doing but I'm having a great time

95 notes

·

View notes

Text

Some more spinning stuff from today/yesterday!

- I finished plying yarn from a small hank of multicolored merino that I spun up into really skinny singles and then turned into a plying bracelet for a class I taught. No one had a catastrophic failure in Andean plying so I didn't have to give the bracelet away. It's been soaked and is drying in my bathroom now.

- Some rough purple sparkly roving that came with one of my spindles got turned into practice with long draw on a supported spindle, then more practice with chain plying. It puffed up really nicely after wet finishing but I think it's too rough to use for anything worn on the body. I saw some little crocheted baskets this weekend that were cute - I might try one of those.

- More finished Dory yarn. It's very soft and feels like the physical manifestation of a shitpost.

19 notes

·

View notes

Text

Tour de Fleece - Day 06

First full day of my vacation. First thing I did was sleeping in! Then I had some urgent chores and finally after 4 p.m I could dedicate my time to my fibre arts.

As I had planned I made my flat smell like wet sheep again and washed/steamed all the stuff I finished last month:

The blue yarn is spun on the supported spindle, the pink and dark blue is wheel-work merino/silk/linen the blue with a little red was the first braid of my Moonlight shadow (Merino/silk/help) fibres I got last month. I spun it in a long draw on my wheel. The black stuff is from my drop spindles, Merino/neon coloured silk. The two little skeins are test plies for the TdF.

When the yarns were drying in top of my other laundry I took my wheel outside for some balcony spinning as it was finally warm and dry enough again. And I followed mr. Baggins inside the Lonely Mountain. He now has the Arkenstone and his Mithril shirt. And I love having dinner on the balcony. It's a little break from everything.

Then I wanted to watch Dracula Untold again (somehow I remember it to be better... well it wasn't that great...) and do some supported spinning. And when the movie was done I decided the spindle was full enough and I directliy chain plied the single on it. Not the easiest task directly after spinning but it went okay.

Result of today.

Plan for tomorrow: I'll visit my dad until saturday morning so i'll only do some spindle work. Prepared the new fibres for the drop spindles so that i have stuff to spin and I got the supported spindle empty so that I can take it with me as well. Let's see how far I'll get.

#fibre arts#hand spinning#spinning wheel#emotional support spindle#tour de fleece 2023#tour de fleece#the hobbit

9 notes

·

View notes

Note

I want to spin but shipping anything here is really expensive. Would it be possible to just spin the big rolls of cotton like the kind they use in hospitals

It's definitely possible to spin cotton! I haven't tried it before, but I had a look around and found a video that demonstrates making cotton slivers/punis for spinning from surgical cotton:

youtube

Cotton is a very short fiber, and that can make it more difficult to spin than wool, especially if you're just starting out: It needs a lot of twist to hold together, and it breaks very easily if you put too much weight/pull too hard on it before it's properly twisted. You may want to look into using a supported spindle rather than a drop spindle (both should be easy to make yourself and to find tutorials for). The channel above also has a tutorial for spinning a single with just a pencil.

The only cotton I have in the house right now (that isn't yarn or fabric) is cotton pads, so as a quick experiment I just tore one up, floofed it up a bit, and spun directly from the floof with a supported spindle. Definitely not the ideal fiber preparation, but it can make a thread:

(Here I was using the lid of my mini scale to set the spindle in - normally you would use a little bowl.)

Alternatively, if you rather want to look for wool to spin: Depending on where you live, sometimes you can find wool for felting at craft stores - any wool like that also works fine for spinning. I've also seen people spin from very thick unspun yarns (wool/acrylic) that were sold for arm knitting, but I've never seen those yarns in a store where I live. And if you happen to have sheep nearby, you can sometimes buy unprocessed wool directly from the shepherd for relatively little money (but then you would need to wash and prepare it yourself, of course).

Good luck, and happy spinning!

#hand spinning#spinning cotton#brarb talks#fiber crafts#i don't normally spin supported or cotton#so please feel free to comment/reblog with more advice for anon#long post

1 note

·

View note

Text

So my top whorl suspended spindle broke while I was trying to ply a newbie attempt at spinning, so I treated myself to a new spindle, a supported bottom whorl spindle because I I get pain in my arms from holding things up.

And despite having successfully-ish spun a single before I cannot manage the drafting, instead of pulling on the fibre a little over and over and it just keeps coming (like I see in the tutorial videos) the fibres slip out of the roving and then I reattach it, and then it happens again.

I thought the problem might be the fibre I was using, so I swapped to a different fibre, then I thought maybe the problem was that it needed pre drafting, but I still couldn’t get it to work.

Maybe I’m just not a good enough spinner for my new spindle? Is is a lightweight centre mass one because I want to spin thin plys.

I wish I could try it out with the fibre I was using when my last spindle broke, but I don’t have any more of it, and it was unlabelled in a starter kit so I don’t know what fibre it was.

I am feeling very frustrated and like maybe I am going to fail at this hobby

Pictured above: proof that have successfully spun a single before, despite my inability to do it now.

Any ideas on what I am doing wrong?

1 note

·

View note

Text

there are so many specific jobs in the process of making even a single garment theres no way one person could be in charge of everything alone. like the process of making a linen shirt:

step 1 is growing. this has numerous sub steps of plowing, sowing, watering, weeding, pruning, checking for illness etc

step 2 is harvesting. flax is pulled from the ground roots and all in order to obtain the longest fiber. this is extremely strenuous and often injurious. a very specific kind of person pulls flax.

step 3 is drying. if water is present the flax will rot so drying must be done quickly and evenly. this is also called stooking (very cute word) and is done by gathering flax into bundles and standing it upright

step 4 rippling (the first combing) this is done to remove the seeds

step 5 controlled rotting away of the inner pectin core by a bacterium (retting). this is done to remove the fibers that will become linen from the outer stalk without damaging them. however if the rot isnt carefully monitored it will rot the fibers too and then the whole things fucked. also this process takes several days.

step 6 manually breaking the remaining stalk so it can be removed from the fibers by bashing and smashing the shit out of it with wooden blocks

step 7 breaking 2! with a knife to really break up any stalk left

step 8 hackling (the second combing) this one makes it soft. dragging the fibers through progressively finer combs to remove the remaining stalk bits, make the fibers shiny and fine. broken fibers that get stuck in the combs still get spun into thread just shittier

step 9 spinning the fibers into thread (distaff, wheel, drop spindle, whatever)

step 10 weaving on the loom

step 11 bleaching. traditionally done by leaving it out in the sun but peroxide works too unless you really like the natural colour of your flax.

(optional step 12 is dyeing. for purest colour this follows bleaching)

step 13 pretreating your linen (wash it, preshrink it, size it, starch it, iron it, whatever)

step 14 measuring the wearer

step 15 preparing the pattern

step 16 tracing the pattern onto the fabric itself

step 17 cutting out the pattern pieces

step 18 actually sewing it up (sewing the body together, sewing the sleeves, attaching the collar)

step 19 finishing (finishing the seams, adding buttons, embroidery, pockets)

and this is just a linen shirt. scale this up to 3 shirts. 5. 10. now skirts. pants. jackets. boots. gloves. socks. bifurcated underwear. bust support. scale that up too. now picture the cotton fabric process. wool. leather. knit fabrics instead of plain woven. different styles of weaving (satin, jacquard, twill). do you understand yet

4 notes

·

View notes

Text

Tour de Fleece Day 8

The one with pictures @swords-n-spindles ;)

I actually managed to surpass my goals from yesterday, which makes me happy. However, I also forgot to take a picture of my full cotton spindle, so it comes out as a wash.

I spun my 13th cotton ball, and then used the ball winder to pull the singles off my spindle, because it was getting very full, and because now I can do a fairly simple 2 ply once I finish this half of the cotton balls. Then I spun a cotton ball on the newly empty spindle once again. Today I’m going to match this again, and spin 2 cotton balls.

Gratuitous pic of my pretty pretty yarnbowl, which I am using as a base for my faux supported spindle.

As for my alpaca, I managed to spin five rolags (instead of four yesterday). The green bin, as you can see, is about 2/3 of the way full still, and the shoe box with teased fiber is overflowing. I don’t think I’ll be carding today because I have a 2 hour exam that I need to take, but I think I can still manage 4 rolags (each rolag takes about ten minutes, so it shouldn’t be too difficult to fit around my day).

The mega alpaca skeins, compared with one of my bubble nebula skeins, which I wound on my 1 yard niddy noddy. You see why I call them mega, especially in comparison. Each mega skein came from one very large spindle.

When I prepped the bubble nebula roving, I split it into four pieces, first lengthwise, and then widthwise, and then split each of those in half, with the intent of plying them together. The roving had a blue grey blue gradient that I wanted to preserve, and in the skein on the right, you can see that. The skein on the left is the one that I plied during the Tour, and you can see that it is very much marled grey. This is because I split the roving by eye, not by weight. All of the other three skeins were decently balanced where some judicious fiddling could preserve the color sequence. This one wound up with one longer and one shorter single that after the first color change, switched colors in opposition. One would be blue, the other grey, and then the grey one would be blue for an inch and then the blue one would be grey. It was very frustrating. But it’ll make a nice accent skein for whatever project I use this up with.

Finally, at the end of this very long post. I offer you all a question. Do you use old stash first? Or do you use up the things you bought recently? Because I want to add a third project back in rotation, now that the buble nebula is done and now that I’m halfway done with my cotton spinning. I have three choices, two new batts (pictured at the top), and one old braid (pictured at the bottom). They’re all pretty, and all very nice fiber contents. Any thoughts?

(Apologies for glare in this picture, I don’t want to open the batts yet, for fear of mucking with them, so they’re all pictured in their plastic sleeves)

(Also, can you tell I like the color blue?)

14 notes

·

View notes

Text

Cotton Buds Making Business

The cotton swab making machine business is rapidly progressing in India. Cotton is the staple fiber made from the natural fibers of cotton plants. The cotton made from the genus Gossypium is primarily composed of cellulose, which is an insoluble organic compound that is a soft and fluffy material. Cotton is the most important fiber crop, which provides the basic raw material to the cotton textile industry. Cotton is grown in tropic and sub-tropic parts and requires uniformly high temperature and is a Kharif crop; it is sown and harvested in different parts of India depending upon the climatic conditions.

China, the USA, and India are the world’s major cotton-producing countries, accounting for about 60% of the world’s production. China alone consumes around 40% of the world’s cotton, and it is a significant export revenue source for major cotton-producing countries of the world.

Cotton is cultivated around 117 lakh hectares in India and accounts for about 37.5% of the global cotton area, and contributes to 26% of the global cotton production. Cotton holds an essential place in the Indian textile mills, and it is used as a primary raw material of India. Cotton provides livelihood to around 60 million people of India by means of cotton cultivation, processing, marketing, and exports.

Cotton buds are the most common item which is used for cleaning the ear, first-aid, cosmetic application, cleaning, and arts and crafts. The cotton buds are composed of small wads of cotton which are wrapped around a rod made of wood, paper, or plastic. The cotton buds were developed in 1923 by a Polish-American Loe Gerstenzang which later became the most widely sold brand name of cotton swabs.

The cotton bud with a single tip on a wooden handle is mostly used in medical settings and is the traditional cotton buds. The cotton buds used for domestic purposes are usually short, about 3 inches long, and double-tipped. Traditionally, the handles of the cotton buds were made of woods while later it was made of the rolled paper and sold in large quantities. The cotton buds are available in a wide variety of colors, such as blue, pink, or green. The manufacturing of the test swabs in a record time of seven days is a dream come true under the ”Make in India” initiative which has conceptualized the production and provided employment to so many unemployed people in India.

The cotton buds are most commonly used for cleaning the ear by removing earwax. The cotton buds are used for domestic purposes such as cleaning and arts and crafts purposes. The medical buds are used to take microbiological cultures which are usually rubbed into the affected area and wiped where the bacteria grows across the culture medium. They can also be used to apply medicines to selective areas targeting to remove substances or clean them. They can be used as an applicator for applying cosmetics, ointments, or other substances.

The cotton buds are also used to take the DNA samples by scraping cells from the inner cheek in the case of humans. The cotton swabs are also often used in the construction of the plastic model kits while paintings. They are also frequently used for cleaning the laser diode lens of an optical drive in conjunction with rubbing alcohol. In addition to his, they are used to clear the large parts of the computer such as video cards and fans and also used widely to clean video games cartridges in the past.

With so many uses, the demand for cotton buds in the market is growing at a rapid rate and is an essential tool for the healthcare of all individuals irrespective of age, race, culture, or religion, etc. keeping this in mind, the idea to start the automatic cotton swab making machine business is a golden opportunity for the young and aspiring entrepreneurs.

With the increased diversity of product ranges from adult-centric to baby and child-centric and increased popularity of cotton buds in the modern as well as in traditional retailing has increased the sales of the cotton buds to grow. With the rising demand, the locally produced cotton buds have become popular across rural India. it has also become popular in small as well as in metropolitan cities because of the availability of the cotton buds at a much lower price as compared to the branded products have been a key focus for the small manufacturers in India. Therefore, it is an ideal business for employing in the Rural areas as well as it will promote the ‘Make in India” initiative of the Modi Government.

The Government of India is promoting all the manufacturing units, especially in the areas where China enjoys a big share in the global market. The government to achieve the Atma Nirbhar Bharat is pushing the exports by giving various aids to the small and marginal businessmen and it aims to reduce the dependency of the country on the imported goods.

The government through various joint ventures and supporting the local businesses is expanding India’s share in the global market. Keeping this in mind, the government has announced various production-linked incentives for manufacturing the earbuds. This is a great opportunity for Indian earbuds manufacturers to raise their business. It is a big step towards making India self-reliant and manufactures their products. Almost 260 schemes are contracted by the Tri-services at an approximate cost of Rs. 3.5 lakh crores and with the latest embargo on the import of 101 items, the contracts worth Rs 1, 30,000 crore is expected to be placed upon the domestic industries in India.

Registration:- To start the buds manufacturing business in India, the first and foremost thing is the registration of your firm either as a proprietorship company or as a partnership firm. One must register the company as a Proprietorship firm if he has to start his buds manufacturing business as One Person company. To start a partnership firm, one must get registered with the Registrar of companies (ROC) and register as a Limited Liability Partnership (LLP) or the Private Limited Company.

GST Registration:- To start a business, it is now mandatory for any business to obtain a GST number, tax identification number, and an insurance certificate.

License for Trade:- Trade license is very important to be acquired to start a buds manufacturing business. It can be obtained from the local bodies of the respective states.

MSME or SSI Registration:- To avail of the government schemes and benefits, one must obtain the MSME or SSI registration. This will help the businessman to receive all the governmental benefits arising from various schemes.

Trademark:- It is required to make sure to register the buds manufacturing business with the trademark which will help in protecting the brand name.

Before starting a semi automatic cotton swab making machine business, one has to make sure to select the proper machines which are proper for operations suitable for your business.

Following are the description of machines used in the cotton buds making business-

Automatic Cotton Swab Packing Machine : –

The automatic cotton bud making machine is the machine that uses the computer PLC process control and warm wind drying technology is used to help to absorb the coating layer. The microcomputer servo motor aids feed the cotton layer and wrap the absorbent material. In this technology, there is no requirement for a different packaging machine separately.

Spindle Fabrication Machine : –

The paper spindles are processed with the help of a dyeing cutting machine from a heavy grade paper and then a thin layered paper is rolled around it to make it light. While a wooden spindle is developed with the help of a lathe machine process. The plastic spindle is made from the extrusion molding process machine, where the plastic is melted and extruded through a die and sent to a hopper machine.

Packaging Machine : –

The cotton buds are sent through the packaging wheels where the buds are rolled with the pouch. A sensor is attached to the packaging wheel which counts the buds and places them into the packaging bag which is packed with the packaging wheel.

The automatic cotton swab packing machine does not require a lot of space for its operation and it can be started from home. Anyone can start the business even from home this will reduce the cost of investment. The cotton buds making business has the potential to give a good place in the market by becoming a high profit earning business in a short period. With the increased demand for cotton buds, the business is very ideal for start-ups and young entrepreneurs.

In the times like this where the pandemic has left no nation in a mess, India has started the manufacturing of indigenous swabs or cotton buds for the testing of Covid-19. A Mumbai based Micro, Small and Medium Enterprise (MSME) and Tulips has got a green signal from the Indian Council for Medical Research (ICMR) and the National Institute for Virology in Pune. These firms have started manufacturing the polyester-spun swabs which are way cheaper than the imported swabs from the US and China. This has helped various small and indigenous manufactures to retain their livelihood and it has also resulted in producing cheaper testing kits at an affordable price.

We Indians have in reality converted the deadly pandemic into an opportunity and the government through various initiatives has been aiding the cotton buds making business. The government is also being aided by various Non-governmental Organisations like Aatmnirbhar Sena is working very hard to provide finances and cheap credit to aspiring and innovative minds and fulfilling their dream of starting the business.

Therefore, the growth and development of cotton and cotton made products has a vital role in the overall development of the Indian economy.

2 notes

·

View notes

Text

I haven't blocked this yet--so far the other two puffed up a ton, so I wanted to get a picture first, because I'm very happy with it. It's chain plied, but so much more even than my chain plied yarns usually are. I think it's only a bit thinner than the 4 ply main yarn, so I still couldn't get this singles as thin as the 4 ply yarn. Glad I stopped trying to 4 ply it, I guess.

It's also got subtle stripes, which is always appreciated.

Unfortunately though it's only 22 yards, which is not very long. I am hoping to do a small black sheep on the heel since I'm working it flat, so I could do fair isle instead of intarsia. I'm not sure if I'll have enough for that but I could also just put it on the ankle or leg and use the thicker yarn (earlier failed attempts to spin the dark southdown locks fine enough) to knit the body of the sheep so it's a bit bigger. Please nobody suggest I embroider or duplicate stitch it on, I'm not doing that to myself

#at a certsin point i might have to admit that i am becoming a fine spinner simply out of a zest for 4 ply sock yarns#spinning#handspun yarn#supported spinning#(was spun as a singles on a supported spindle)#drop spindle#hand combed top#southdown babydoll#sock yarn

40 notes

·

View notes

Text

Quick fiber arts update:

I've been working on the fine Merino! It still feels weird to spin and this is probably going to be one of the most uneven yarns I've done recently, but it's also super soft, so.

One single done, two to go:

I figured I'd spin up a sample in the midst of all the white stuff:

From the fold again, so the tweedy bits stay in. I enjoy the color, but the combed top refuses to stay together when spun from the fold and it's really annoying, so I'm not sure if I want a proper braid of this one. I'll see how it goes!

I also did a fair chunk of supported spindle spinning, but didn't get around to snapping a picture. Maybe tomorrow!

23 notes

·

View notes

Text

Broken Chain

The sound of a simple wooden spindle hitting the floor echoed loudly in the dead-silent battle-scarred hall.

“It’s gone,” Haroun said, and even though his voice was barely over a whisper, the echos seemed to come from everywhere. He wore a stricken expression, and one hand was pressed to his heart as if he was feeling for something no longer there. “The prophesy. How...?”

“You taught me that the High Magic is vulnerable to the low,” Raeca said, and sat on the bloodstained floor, completely worn out from the fear of the last few days, and the battle that still lay spread around them. “And magic likes to spin. Anything that likes to spin can be unspun.”

“You broke our prophesy...?” Brendis stared at her with wonder like the dawning sun in his eyes, and then he swept her into his arms, laughing breathlessly. “We- we’re free?”

“You’re free!” Raeca laughed with him and flung her arms around his shoulders as he spun her. “For better or worse, this will be your last life.”

“No!”

Calliope lunged off the floor, tattered, bloodstained white silk flying as she threw herself at them, her fallen blade bright in her hand. Brendis brought up his shield and the crystal-hilted dagger threw sparks as it glanced off spelled steel.

“Calliope, it’s over,” Brendis told her, one arm around Raeca’s waist as he protected them both from the mad queen. “The prophesy is done. We don’t have to do this anymore.”

“I chose,” Calliope screamed at him, and blasted them with a spell-bolt that was, again, caught on the hero’s battle-tried shield. “I chose to be queen! I chose to murder you over and over to keep my reign! I chose to build my temple and my castle and you stole it from me!”

“We stole nothing!” Raeca shouted back and wondered if she had the power to put the woman to sleep. When she reached for her magic, there was nothing there but faint, weak glimmers. “I broke the chains that bound you to this toxic fate. Your life is your own, and so are theirs!”

“I will kill you,” Calliope seethed, radiating icy sunlight as she gathered her power, far from defeated even yet now that she was back on her feet. “For all you stole from me, for defying me, you wretched country wench!”

“I think not,” Haroun snarled, and brought hai magic up in a whirl of golden flames that solidified into shields around himself, and Raeca and Brendis. Just in time, as sun-white burst around Calliope in an expanding ring of destruction. “You’ve wrecked enough harm!”

“You stole my immortality!” Calliope hissed like a cornered cat, insanity bright in her eyes. “You stole my everything. If I cannot live forever, none of you will!”

With that, she reached for the white marble ceiling, fingers curled into claws.

The castle trembled and screams came from everywhere even as great cracks crawled through the polished stone, and chunks of rock began to fall like heavy rain.

“She’s trying to bring this place down on us!” Haroun yelled over the roar of collapsing stone. “We have to get out!”

But even as he spoke, a huge pillar trembled furiously and fell, blocking the entrance under tons of stone.

“Can you portal?” Brendis yelled back, his shield over their heads as he did his best to keep the worst of the stone off himself and Raeca. “We need a fast way to get clear!”

“I’m out,” the mage admitted, and joined their huddle, the last of his magic supporting Brendis and his shield. “I could take myself and one other, maybe, but not all of us.”

“Take Raeca and go,” Brendis said without hesitation. “Get her out of here!”

“Don’t you dare,” Raeca ducked under Haroun’s hands and looked up at Brendis even as the walls shook harder, and great chunks of polished ceiling began to fall. “Brendis, we can go together! There must be a way!”

“I love you,” he told her, and bent for a slow, sweet kiss that belied the violence thundering down around them. Raeca tasted tears mixed with marble dust and clung to him desperately. “I wish we could have had a life together. Roun?”

“Goodbye, old friend. You will be remembered,” Haroun said, voice heavy with grief. Before Raeca could stop him, he wrenched her away from Brendis and backwards.

The walls blurred around them, ripples of water-shadows and rainbow as reality softened for three long heartbeats, and went solid again.

Cold air blew harsh against Raeca’s face.

They were outside, on a hilltop looking down at the castle.

“I’m sorry,” Haroun choked out, grey with exhaustion, and heedless of the years cutting through the white dust on his cheeks. Raeca tried to run for the castle, but the ground bucked under her and she fell almost on top of the probe mage. “I’m sorry- I’m s-sorry.”

Below them, the castle shook one last time, and collapsed, plumes of white dust spraying high into the air as it caved in on itself until not a single tower stood one stone atop another.

A fitting tomb for a queen, and a hero.

“No,” Raeca sobbed as her hand found Haroun’s and he fought to sit up. “No that can’t be- he can’t be dead. He- he can’t!”

“I’m sorry,” Haroun whispered brokenly as she turned to cry into his torn shirt. He wrapped his arms around her and held on. “It was you or him, and he chose to stay.”

Raeca barely heard him, lost in torrent of tears and recriminations. Maybe, if only she had been faster, or more clever. Maybe if she had escaped before they walked into Calliope’s castle, ready to die.

Maybe there could have been a happy ending.

Maybe there could have been a life in a small house, for a healer and a hero to learn what came after the adventure.

She could still feel his kiss on her lips, and could hardly face a future where there would never be another.

Magic breezed through the air, so weak it was barely even there, and Raeca might have missed it if not for Haroun’s gasp.

“What-“ He said, and stretched out a hand, as drained as she was, but still willing to fight if he had to. “How-“

“What is it?” Raeca asked through the haze of thick mourning that made her chest hurt and her eyes sting. “What could come for us now?”

“It can’t be,” Haroun muttered, and narrowed his eyes. Raeca felt the moment he started to burn his own life-force, attention fully on that barest tremble in the air. “Link with me!”

Baffled, but willing, Raeca fed him what little magic she had left and hoped it was enough.

A lesser master of magic couldn’t have done it, but Haroun had three thousand years of experience, and a will of honed steel.

He sent the remains of their joined Magic into the shiver, and Raeca felt the bone-snap as their magic found whatever was reaching for them.

A portal tore through the air, a ragged, half-formed thing that blazed with instability.

Brendis tumbled out, as grey as Haroun, and too sick to even stand.

But his eyes were open, and he managed the faintest smile for them even as the portal imploded in on itself.

Raeca scrambled for him with Haroun on her heels. His arms felt like coming home, and she was crying again, this time with the raw sort of relief that didn’t feel real.

“She saved me,” Brendis told them as he lay back in the grass, too weak to stand. Raeca went with him, tucked into the curve of his side and unwilling to let go of him even for a moment. “At the last moment, a portal opened under my feet as the ceiling came down on her.”

“A fitting last act of a queen,” Haroun murmured, smiling, half-dead, but shoulder-to-shoulder with Brendis. The flat mage didn’t even try to sit up. “I’m glad you’re not dead, brother. Raising the dead is not one of my skills.”

“I’m glad you’re not dead too,” Brendis replied, and punched Haroun’s shoulder weakly. “I need someone to do the runes on Raeca’s new house, after all.”

“Our new house,” Raeca corrected him, and pressed a kiss to his throat, which was all she could reach without trying to move. “Now sleep. I refuse to make plans for our future until none of us are dying of magic shock.”

“Always bossy,” Haroun mumbles, smiling and already half asleep in the grass. “Must be a healer thing.”

“She’s your granddaughter,” Brendis snickered back, and kissed the top of Raeca’s head. “Do I have to ask your permission to marry her?”

“I don’t know. Ask her.”

“She says yes,” Raeca told them both, and wiggled until she was comfortable. “Go to sleep and dream of a future without prophesies.”

+++

Never Free:

A warrior, a sorcerer, and a queen reincarnate each time they die. Doomed to kill each other over and over until their prophesy is fulfilled, each battles to keep their sanity as the centuries drag on with no end in sight.

Their healer thinks all three of them are being just a little bit ridiculous.

Round and Round Again

Mistaken Step

Spinning Wheel

Stronger Together

Tea and History

Girl Talk

History Past

Dizzy Spell

Herbs and String

Burning Oil

Ancient Alliance

The Queen’s Hall

Circle Challenged (Free on Patreon!)

UnSpun

Broken Chains

+++

More Stories!

+++

Support me on Patreon

#love#romance#fantasy#magic#death#mentioned death#mentions of violence#violence#fight#fighting#spell#spells#mage#mages#queen#warrior#healer#healing#happy ending#spilled ink#writing inspiration#spilled thoughts#spilled words#spilled writing#writing#writing prompt#writers#writing prompts#writer

45 notes

·

View notes

Photo

I sat in a chair one night, spinning alpaca yarn with a supported spindle, the white cloud of fluff trailing from my hand, when disaster struck. Something caught on my spindle, ripping the top from my hand, sending meticulously combed fiber spinning around the shaft of my spindle, tangling with the singles and invoking unbridled rage. Reversing the spin can allow you to try and salvage the top, but it's never quite the same. I'd gotten so sick of this happening to me that I grabbed a dried yucca shoot, sanded it down, cut a notch in the top end, and started using it as a hand distaff. And I'll never go back. Not wanting to use alpaca as 'practice' fiber, I instead started using wool top. I arranged strips of top into a batt, and rolled it onto the distaff so that the fibers run along the length, which I refer to as vertically dressed. Then you wind a cord or ribbon around to secure it, and draft from the bottom. What I didn't really think about at the time was that, because short draw requires both hands, and because I was using a supported spindle and had both hands occupied, I would only be able to do long draw. But, I found that allowing the yarn to draft itself by pulling the distaff away resulted in a beautiful single magically emerging from my cloud of fluff. And so, I learned long draw on accident. I wasn't even thinking about it. But now that I've started using long draw, I might not go back to short draw either. If you use a fiber with a long staple length, arranged vertically on the distaff, and put in lots of twist, your yarn will end up more worsted than woollen. I joined the facebook page Evangelical Church of Distaff Spinning, and found that the methods of spinning that most people on the page use were much more portable than supported spinning. I wanted to move to a setup that was variable; where I could go from suspended to supported if the need arose. So, in spite of this likely never being used with a distaff, I made myself a turkish spindle. Now there are three things that I will never not use when spinning. One is the distaff, two is continuous chain plying, and three is a turkish spindle. Because of the chain plying, I end up with finished, plied yarn on my cop. So when I'm done, I remove the spindle, and am left with a wonderful ball of finished yarn. There was just one improvement to make to the spindle - a spiral notch. Using a half hitch to secure the spindle works, and it's fast, but it's not fast enough. If you have a well-cut spiral notch in your spindle, the single can wrap around it and hold the spindle up without a knot. So, with my determination and my arguable dremel skills, I somehow managed to cut a working spiral notch into the end of my spindle. That's where I am now. Over the course of about a month, I made and started using a distaff, made and started using a turkish spindle, switched the direction in which I spin (for ergonomics), and made and started using a spiral notch. All of those changes have been an improvement. Now my spinning is much more portable than it's ever been, I don't get unspun fluff tangling into my yarn, I've spun ~130 grams of wool in seemingly no time at all, and there's almost no downtime between emptying a spindle and starting a new batch. Sorry this was such a longass post, but the distaff, above all else, needs to be pulled from its place in obscurity, because spinning without one is just insane.

13 notes

·

View notes

Text

Tour de Fleece - day 04

I'm not done spinning for today but have a SIP (Spin in progress) pic nonetheless.

'On the right: plied from the drop spindles. I like the outcome. One single had rested for a few weeks the second... less than 24 hours. I noticed a difference while plying. Let's see how it develops after a nice hot bath.

On the left: Ply test of the 50/50 merino/silk from the supported spindle. Since I spun quite a bit on it last night I did a chain ply. I initially planned to do a 2 ply test as well but the stuff gets so incredibly fine, I will chain ply all 60g I have. It will probably be used for sth lacey.

And now up to a nice shower and then to the sofa with more emotional support spindeling and finally getting to watch Nimona.

#hand spinning#fibre arts#drop spindle#emotional support spindle#nimona#tour de fleece 2023#tour de fleece

8 notes

·

View notes