#tack welder

Text

Buy Portable Type Welding Machine ARC 250, Welds 4mm Continuously - Krishitool.in

Book Now: https://www.krishitool.in/product_details/Portable_Type_Welding_Machine_ARC_250,_Welds_4mm_Continuously

welding machine, mig welder, tig welder, welding machine price, gas welder, types of welders, welder arc, rod welder, spot welder, cold welding machine, mig welding machine, tig welding machine, spot welding machine, laser welding machine, arc welding machine, portable welding machine, aluminum welder, laser welder, cold welder, esab welding machine, stud welder, inverter welding machine, electric welding machine, mig welding machine price, mini welding machine, welding set, gas welding machine, wire welder, laser welding machine price, co2 welding machine, small welding machine price, tig welding machine price, small welding machine, toshon welding machine, spot welding machine price, types of welding machine, electric welder, single phase welding machine, argon welding machine, plastic welding machine, aluminium welding machine, tack welder, welding machine 250 amp price, ibell welding machine, jkarc welding machine, ultrasonic welder, single phase welding machine price, mig and tig welder, shakti welding machine, small welding machine price, welding machine price list, best welding machine, arc welding machine, welding machine price single phase, bosch welding machine price in india, welding machine single phase, welding machine 250 amp price, Arc Welding Machine, Welding, Welding Machine

#Arc Welding Machine#welding#welding machine#welding machine 250 amp price#welding machine single phase#bosch welding machine price in india#welding machine price single phase#best welding machine#welding machine price list#small welding machine price#shakti welding machine#mig and tig welder#single phase welding machine price#ultrasonic welder#jkarc welding machine#ibell welding machine#tack welder#aluminium welding machine#plastic welding machine#argon welding machine#single phase welding machine#electric welder#types of welding machine#spot welding machine price#toshon welding machine#small welding machine#tig welding machine price#co2 welding machine#laser welding machine price#wire welder

1 note

·

View note

Text

Saw this welding mask and had to write this.

---------------------

You were pissed. The boys had been messing with the new guy on base and had gotten bored of him. So they turned their attention to you of all people.

First, it was little things like missing bolts and screws from your cabinet where you kept spares. Next, a wrench or hammer from right next to you as you did repairs. Then, they started taking important welding equipment that you were currently using for vehicle repairs. The tip for your MIG welder or your gloves and even a whole argon gas canister somehow.

If you confronted them, they'd just play it off as them pranking you or that you just misplaced some stuff. So you took matters into your own hands. While they were out at the bar, you went into their quarters with a portable MIG welder and your gear to do a bit of magic. You clamped the node onto the metal of Ghost's desk and slid underneath. With your auto shield mask on you lined up the gun with the small space between the drawer and sliding mechanism.

With a bead that would make the welding gods weep, you welded an inch long piece sticking the drawer permanently in place. You did this to each drawer on each desk, or if they didn't have one, you welded their lockers shut. Then, just to mess with them more, you put a single tack at the bottom of their doorframe to make it hard to open. The tiny tack weld would break with enough force.

You had also bought a bunch of tiny mirror pieces to bedazzle an old mask you still occasionally used. It took a few hours of work but you finished it. Whenever someone tried to bother you while welding, they'd be blinded by the reflection of extremely bright light.

The next morning, you woke to loud banging on your door. "I'm off today. What do you want!?"

"What the hell did you do to our stuff!? Get out here!"

"I didn't do squat! Now let me sleep, please!"

"I'll break down your door if I have to! I don't care if you're dressed or not!"

"Ugh, fine, hold yer horses!" You slide out of bed and open your door coming face to face with Soap. "Follow me." You sigh and follow him to their quarters. The others have convened in Soap's room and don't look too happy, and Alejandro is trying to pry open the locker to no avail. Gaz pipes up. "What did you do!?"

You can't help the hyena like laughter that spills from your mouth at their plight. "Yall decided to mess with me and got what yall rightfully deserved is what happened!"

"Can't argue with her there boy's." Price leans against the doorframe arms crossed. "Don't think you got out of this either, Captain. Just because you weren't involved in the main thing dont mean you weren't involved at all. You turned a blind eye to the whole thing, so you got your door tacked shut."

"You're right. I should've stopped them."

"Darn right, you should've! Some of that equipment was bought with my own money, and if any of you broke something, you were gonna pay even more dearly than this!"

Your face said it all. Sure, they had only meant for these to be harmless pranks, but evidently, your equipment was off limits. No matter how hilarious messing with them had been, you were still ticked off, and you had one punishment left for them. With a mad hatter grin, you broke the news to them.

"I'm not gonna grind all these welds down for ya. Also, I've taken all the grinders from the shop along with the discs so all of you are gonna be using files instead. You pulled a bunch of metal files from your back pockets and set them on the table. "Good luck to ya boys!" With that, you left hearing the groans and complaints as you returned to your quarters.

"Oh, come on!" Soap threw his arms in the air like a toddler having a tantrum. Alejandro had stopped pulling on the locker door. "At least she gave us the files."

Once you were in your room, you doubled over laughing. It would take them a few hours to file down all those welds enough to open the drawers and lockers. Price just had to knock the tack off with a strong hammer swing. You had facetimed your mother and father as you finished up the welds that night, and your father had been laughing just as hard as you were.

Also, the bedazzled shield would be put to use as soon as you were back to work. You'd be blinding people in no time.

-------

The boys were spent. Their arms and hands hurt, and they had metal shavings all over their uniforms. They wouldn't make the mistake of messing with you again or at least not for a while.

#fanfic#cod modern warfare#cod mw2#simon ghost riley#john price#john soap mactavish#gaz cod#alejandro vargas#funny#comedy#welding

25 notes

·

View notes

Text

Interlude. Tensimm, enforced domesticity.

Time is a strange thing to a Time Lord. It doesn’t pass unseen, or flow in one direction like a river. Rather it meanders and turns, twisting in deep wild eddies of what is and what once was and what could be. A Time Lord does not move through time but is submerged in it; like a grain of silt washed back and forth by ever-changing tides in the vastness of the ocean.

It’s hard to convey duration in a way that other species understand. The Doctor has been here, in this time bubble, for an amount of time that could be called weeks, but is more accurately measured in nanoseconds. Outside the bubble’s perimeter the Cybermen are advancing, dragging their metal chassis toward the cottage, but approaching so slowly that they appear immobile. Within the bubble, time stretches and pulls like toffee.

It was a fine plan, under the circumstances. The Cybermen had caught them by surprise, but the cottage had belonged to an engineer and there was a workshop with enough spare parts to build a defense. There just hadn’t been enough time — hence the time bubble. Time inside the bubble to design and construct and resist while outside, time slowed to a crawl.

It was a fine plan, but it had not been the Doctor’s plan. In the cottage’s basement workshop the Master has a pile of components and a tack welder, and the arching, sniping sound of electrical current pops through the air. It had been his plan, and he’d pulled the Doctor in to help him. The fact that the Cybermen only knew their location because the Master had been trying to manipulate them too was to be expected, frankly.

Recriminations are of no use, and whatever his many sins, the Master is an excellent engineer. If one must be trapped in a time bubble and need to come up with a technological defense against encroaching legions of cybernetic killing machines, then the Master was someone who could be relied upon to both be brilliant and to unscrupulously save his own skin.

The Doctor stares past the Cybermen and toward the Tardis, perched atop a nearby hill. She’s out of his reach for now, but it’s comforting to see her there all the same. She, at least, will always wait for him.

“Doctor!” The sharp sound of the Master’s voice carrying out of the basement makes him instinctively straighten up, bracing himself to fight or to run or to have his hearts broken once again. “Get down here and hold this regulator in place, will you?”

-

The basement workshop is dim and cramped but bustling with activity. As well as the Master with his welder, there’s a table of bubbling substances in test tubes heated by a burner and an array of tools on a wheeled cart which floats a few inches off the ground. More efficient that way, the Master had said with a wild grin.

Dealing with Cybermen is easy. They’re ruthless and cruel but not complicated, and their robotic components are vulnerable to strong pulses of electromagnetism. They just need to build an EMP to knock them out.

The complexity is getting the settings right. They need to find just the right wavelength to disable all the Cybermen at once, and they can’t test their work from within the time bubble. So it’s a slow, painstaking process of adjusting for different frequencies and testing the results on different compounds and materials.

It could take weeks, but the Doctor is quietly enjoying this. He’s always loved to watch the Master work, to see that remarkable mind fully trained on a problem, and it’s nice to have someone keep up with him for once.

When he’s working a circuit board he only needs to say, “Could you pass me the-” before the tool he needs is already in his hand. They bounce ideas off each other and finish each other’s sentences, and there’s a bubbling joy of shared excitement at a challenge coming in to focus.

One time, he’s concentrating on carefully striping a set of tiny wires when the Master needs to squeeze past him in the small space. “Scuse me,” he says, and puts his hands on the Doctor’s waist to gently move him aside, like he’s just another object in the workshop like that silly levitating trolley.

Being handled so casually makes heat crawl up the back of the Doctor's neck and he swears as he slips and cuts straight through the wires he was working on.

-

Each evening, the Doctor goes out to the hill next to the cottage and looks up at the sky. There’s work to be done here, but always there’s the itching urge to move on, to explore, to run. He’s pressed down with a kind of guilt about his absence from the world, even if no time is passing for people outside the bubble. Time is passing for him, and that feels like an unearned indulgence.

One night the Master comes to join him. He stands nearby, unspeaking. Something almost like peace settles between them.

The Doctor looks over. “You’re different here. Calmer. I envy you that.”

The Master flops down next to him in the grass. “There is something about this place.” He picks at a leaf of clover. “The drums are quieter here.” Here with you, he doesn’t say, but the Doctor hears it all the same.

He ends up lying in the grass, his head in the Doctor’s lap. The Doctor idly plays with his hair as they gaze up at the stars.

“Over there.” The Doctor points to a star just visible over the glow of the horizon. “That’s Thenestra. Beautiful place. There’s a planet orbiting so close to its star that carbon evaporates into clouds and it rains diamonds. Sparkling gems falling from the sky like a waterfall, and the light is refracted over and over so every surface is covered in rainbows.”

“That close to a star, the radiation must be off the charts.” The Master is smiling slightly.

“Well. Yeah. The place will kill you stone dead if you stay there for more than 20 seconds, even with the protection fields.” He winds a strand of the Master’s hair around one finger. “It’s still beautiful though.”

A pause. A soft breeze ruffles the grass.

“Up there,” the Master indicates a star overhead. “There’s a planet called Arcking. It’s in the middle of a war zone and the entire planet is a hospital. Death all around them, and yet people there spent their time healing others. Even if it’s futile. Even if they couldn't fix anything, they kept trying anyway." He frowns. "It was an interesting place.”

“Was? Why, what happened to it?”

The Master coughs. “Since we’re getting on so well, best not spoil the mood with too many questions, yeah?”

The Doctor sighs. This would be easier if he weren’t a little bit charmed every time. “Come on then. Let’s go to bed.”

The Master waggles his eyebrows and grins. “About time we got to that.”

“Oi! Cheeky.” The Doctor flicks his ear and fights back a blush. He’s 900 years old, and he is not going to be caught blushing. “I meant we should sleep.”

Sleep isn’t a strict necessity for Time Lords, but going without it too long is unpleasant. He brushes a thumb along the lines on the Master’s forehead. “You look exhausted.”

“Yeah, and you look like shit too.” It would be a more convincing insult if the Master wasn’t still nestled in his lap, gazing up at him with eyes crinkled softly around the edges.

They spend the night pressed together in the too-small bed, a mess of tangled limbs and matching heartsbeats, and the Doctor sleeps better than he has in years.

-

They've been living off the cottage's vegetable patch, but the interminable meals of stew are starting to wear thin.

One morning the Doctor walks into the kitchen and stops dead in his tracks. The Master is at the counter, surrounded by bowls and flour dust and jugs of water, sleeves rolled up to his elbows, kneading a lump of dough. It is such a staggeringly incongruous sight that he's struck dumb.

The Master glances over his shoulder and rolls his eyes. “Don’t gape. You look like an idiot.”

He shakes himself. “How do you know how to do that?”

The Master scoffs. “I’m one of the finest minds the Time Lords ever produced. I’m the scourge of time and space, feared across the known universe." He goes back to kneading. "I think I can handle bread.”

Drawn forward like a magnet, the Doctor puts his hands on the Master’s hips and rests his chin on his shoulder. He watches the way the dough is pulled and stretched, the way the Master’s hands press and fold and roll. He’s seen those hands inflict unimaginable cruelties, but he’s also seen them create things of staggering beauty. Perhaps this time, the outcome could be different.

There's a spot, just below the ear. On every regeneration, in every body, the Master has always been sensitive right there. The Doctor knows this from countless previous mistakes, each of which he had told himself would be the last.

Now, he turns his head to brush his lips across that patch of skin, soft as a whisper. The Master barely moves, all cool composed control, but the Doctor knows him well enough to notice the way his hands stutter fractionally and the way his breath hitches.

Time stretches further, even within this dilation field, like two possible outcomes are balancing on the blade of a knife.

The next thing he knows the Master has spun around and is yanking him closer still, hands in his hair, residue of dough from his fingertips smearing at his temples, kissing him with ravenous greed. He gets bent over the kitchen counter and while there’s a cursory voice in his head saying he shouldn’t be doing this, not again, he knows that in truth he was always ending up here, and that he will always end up back here in the future, that time won’t change this raging heat between them or ever dull it.

While he's getting fucked he scrabbles uselessly at the work surface and the Master leans forward, covers his hand with his own, and threads their fingers together. When the Doctor reaches out telepathically, their minds slot together just as neatly, and he's hit by a rush of heat and possessiveness and snarling hunger. In the cracks between the emotions, hints of something much bigger and deeper and nameless gleam through.

He ends up with flour smudged all over his chest and across his cheek, and gluey dough mixture under his fingernails which he can’t seem to get rid of no matter how much he picks at it.

-

It’s surprisingly easy to settle into a rhythm: they work, and they fuck, and the Doctor tends to the vegetable garden while the Master prepares their meals. The Doctor feels like he has never spent so long in one place, and while his itchy feet are calling him to travel onward there’s also a comfort in knowing what each day will hold.

He doesn’t have the chance to get bored before it’s over. They finish the EMP, and test it as best they can. It should knock out every Cyberman within half a mile, and they can just walk away. Neither of them acknowledges it out loud, but they both spend more time tweaking and fiddling and testing and re-testing the system than is necessary even after it’s clear that the work is complete.

Eventually, there are no more tests to run. They sit by the kitchen hearth with mugs of tea and plan out their escape down to the last detail.

“I suppose that’s it then.” The Doctor picks at the rim of his mug. “We’ll set off the EMP first thing tomorrow. It’ll shatter the time bubble and we can leave.”

The Master doesn’t look at him. “And then?”

He shrugs one shoulder. “And then we go our separate ways.” The Master has his own Tardis stashed somewhere nearby. He’ll be fine. It’s for the best.

The fire crackles and pops, loud in the quiet of the evening.

“We could stay.” The Master’s eyes flick over toward him before darting back to the flames. He’s furtive, almost guilty. “We could stay here, just for a while longer.”

A silence stretches for an uncomfortably long beat. Because the Doctor can picture it: this life, this placid haven, just the two of them. The cherries in the garden are almost ready to be harvested, and they could bake them in sticky sweet pies. There’s a stack of sketchbooks in the basement and he could draw while the Master tinkers in the workshop.

They could shut out the whole world and recede into each other.

But that’s not his life and it never could be. He needs to travel, to see the universe, to help people and to make himself useful where he can. (Just another word for running away, a voice in his head reminds him.) Because without that, what is he?

“We can’t,” he says eventually. I can’t, is what he means.

Something cold and hard like concrete slams down across the Master’s face, and the walls go back up. “I’d probably end up sick of your righteous carping and have to kill you anyway,” he snaps, as if that’s remotely convincing. Whatever it takes to salve his wounded pride.

The Doctor wants to reach out, but the distance between them seems too great now. He flexes his fingers around his mug instead. “It was something, though, wasn’t it? This place. The people we were here.” He stares into the fire. Consuming and unpredictable and dangerous, but luminous too.

“Yeah.” The Master slumps back in his seat. “It was something.”

#doctor who#thoschei#tensimm#my writing#fic amnesty#i am at my most self indulgent here and i make no apologies

76 notes

·

View notes

Text

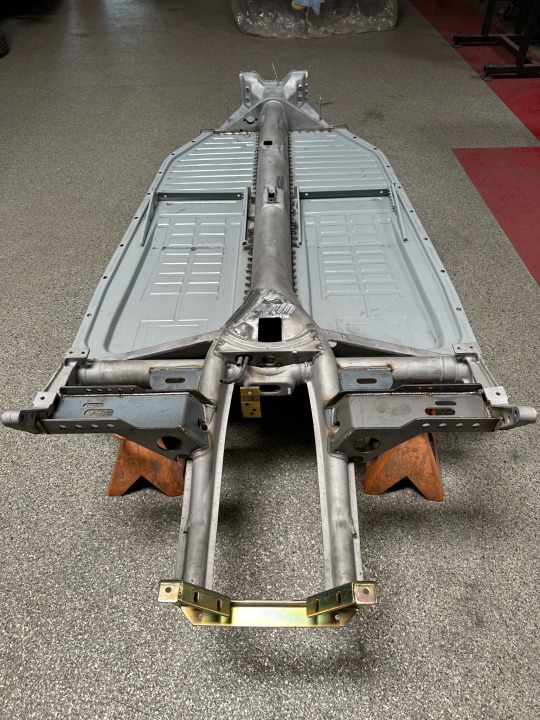

Monday July 3rd | Airkewld HQ | Swing Axle Air Ride Installation on a 1958 Ragtop Beetle

Continuing on our progress from yesterday, the PRO’s got to mocking up the rear brackets, fitting them to the chassis for the ideal fitment and matching it from side to side.

A Miller-matic 185 was used to get the job done, we have used this specific welder since 1997-8, an absolute beast. On a wire speed of 30, gas at 29 and heat on a number 3, I got to tacking everything in place, then fully welding it out ready for clean up.

Joey will take over the clean up

Swing axle air ride kit - https://www.airkewld.com/Classic-VW-Rear-Air-Ride-Kit-1200-p/1200.htm $930

Miller Welder - https://amzn.to/3NXdsEa

16 notes

·

View notes

Text

RPM Magazine Releases the February 2024 Issue

Check out the February Issue 2024 - the 2nd issue of RPM Magazine's 25th Anniversary Year! Still bringing you the Cars, the Stars, and the Tech Info you have come to expect from the world's best and only family-owned publication that has supported the industry for 25 years and is still going. We thank all of our readers, advertisers, staff, and supporters throughout all the years. Click on the image of the cover to the left to see the sample copy.

FEATURE CAR

LONG HAUL - Roy Greenawalt's wicked blown Chevelle is a lifelong build! “You’ll never finish that car.” The famous phrase said by the naysaying glass-half-empty element of the world, a problem made worse with the internet providing a platform for loud-mouths and snipers to more easily spew their garbage… and Roy Greenawalt is a guy who proudly proved them wrong!

DOUBLE THE FUN - Rob Horton's Turbo/Nitrous Camaro WILL get the drop on you! As a Mechanic by trade, Rob Horton knows cars very well, but we all know that making one go fast and stay together is another whole ball game, and Horton is very good at that, too!

SUBLIME CAT - This wild blown Hellcat is a true 8-second street driven warrior. Obsession is part of our car culture and has been since the wheels of the first motorized vehicle hit the road. Take Don Keller for instance...

THUNDER - Don Erwin's Glidden Tribute T-Bird packs a big block nitrous'd punch! Don Erwin has been in the game for a lot of years and has a stable full Ford cars and trucks, but this Glidden- tribute T-Bird holds a special place.

TECH INSIDER

Welding Exhaust Systems - Pt 5 - Welding your Header. We have our TIG welder ready to go. We have our header tubes tacked together with perfect fitment. We have properly fit the pipes to the flange and have our back purge system setup.

RPM HIDDEN GEM

PLAYING ROUGH - Pat Spangenberg's "Alley Cat" - It's rough, tough, and one potent Poncho! 1964 Catalinas have become highly sought after by collectors and racers alike in recent years.

#rpmmag #rpmmag25yrs #rpmmagazine #hellcat #camaro #glidden #donkeller #patspangenberg #burnsstainless #robhorton #roygreenawalt #donerwin #chevelle #tbird #alleycat

Read the full article

0 notes

Text

I managed to get a few days in on the split project this week just before New Year.

Lots of trial fitting of the sills and surrounding panels to make sure everything lined up ok.

I now have both side support strengthener bars and the O/S inner B pillar tacked in. One final mock up of the side panel and I’m happy with the position of the sill so have started welding it in.

I recently bought a second hand spot welder and used it for welding the closing panel on the rear most top hat support. What a fantastic time saver which I’m hoping to use for that factory spot weld look.

0 notes

Note

fun fact regarding that osha violations post: i’m a welder and have some really specific knowledge to share, and it’s that scissor lifts are actually already very unsafe in general even when operated properly because they’re basically all tack welded together in areas where the welds are obscured by the rest of the machine so you wouldn’t be able to see them to know that. the big signs outside of gas stations and fast food chains are also not very safe and are usually not routinely inspected as they should be for structural soundness! next time you’re near one, look at the welds where it’s installed in the ground. ✨ the more you know ✨

oh NO 😭 thanks for sharing it really makes the whole thing so much more horrifying to look at

1 note

·

View note

Text

Mastering the Art of Plastic Welding: A Comprehensive Guide to Plastic Welding Tips and Their Applications

Introduction: The Importance of Plastic Welding Tips in Industrial Processes

In various manufacturing and repair sectors, plastic welding is a critical process that involves the joining of thermoplastic materials through the application of heat. The use of specialized plastic welding tips is essential for ensuring consistent, precise, and reliable plastic welds. This comprehensive guide explores different types of plastic welding tips, their applications, and how to choose, buy, maintain, and optimize their performance.

Plastic Welding Techniques and the Role of Plastic Welding Tips

Plastic welding techniques vary based on the materials used, desired bond strength, and specific application requirements. Some common plastic welding methods include hot gas welding, ultrasonic welding, and laser welding. Regardless of the technique, the use of plastic welding tips is crucial for controlling the flow and application of molten plastic, ensuring accurate and strong welds.

Types of Plastic Welding Tips and Their Applications

There are several types of plastic welding tips designed for different welding techniques and applications. Some common types include:

- Tacking tips: Ideal for the initial joining of plastic parts before completing the full weld.

- Speed tips: Designed for high-speed welding processes, often used in mass production settings.

- Extrusion tips: Suited for extrusion welding, where plastic is forced through a heated barrel and applied to the joint.

Key Factors to Consider When Choosing Plastic Welding Tips

When selecting plastic welding tips, it's essential to consider the following factors:

- Compatibility: Ensure that the tips are compatible with the specific plastic welding equipment you use.

- Material and design: Opt for tips made from high-quality materials that can withstand the demands of your work environment and application.

- Size and shape: Choose tips that match the size and shape requirements of your specific welding process.

- Type of plastic: Select tips designed for the specific type of plastic you will be welding, as different plastics have varying melting points and characteristics.

How to Buy Plastic Welder Tips: Tips for Finding the Best Supplier

When purchasing plastic welder tips, it's important to partner with a reliable and knowledgeable supplier. A reputable supplier can provide expert guidance on selecting the right tips for your specific application and offer support for proper usage and maintenance. Consider the following factors when choosing a supplier:

- Experience and expertise: Opt for a supplier with a proven track record in the industry and a thorough understanding of plastic welding tips.

- Product quality: Choose a supplier that offers high-quality products, backed by manufacturer warranties and customer support.

- Customer service: Select a supplier with a responsive and helpful customer service team, capable of addressing your questions and concerns promptly.

- Pricing and availability: Compare prices and product availability among suppliers to ensure you receive the best value for your investment.

Proper Maintenance and Care for Your Plastic Welding Tips

Maintaining your plastic welding tips in optimal condition is essential for their longevity and performance. Follow these maintenance and care tips to keep your tips in peak condition:

- Cleaning: Remove any plastic buildup from your welding tips after each use to prevent performance issues.

- Inspection: Regularly check your tips for signs of wear, damage, or misalignment, and address any concerns promptly.

- Storage: Store your tips in a cool, dry place away from direct sunlight or extreme temperatures to prevent damage.

Tips for Maximizing the Efficiency and Performance of Your Plastic Welding Tips

To optimize the performance of your plastic welding tips, follow these best practices:

- Proper usage: Familiarize yourself with the correct operating procedures for your tips, ensuring that they are used safely and effectively.

- Routine inspections: Regularly inspect your tips for signs of wear, damage, or misalignment, and address any issues promptly.

- Cleanliness: Keep your tips clean by removing plastic buildup after each use.

- Storage: When not in use, store your tips in a cool, dry place away from direct sunlight or extreme temperatures.

Conclusion: The Impact of Quality Plastic Welding Tips on Industrial Efficiency and Productivity

Investing in high-quality plastic welding tips can significantly improve the efficiency and precision of your industrial processes. By choosing the right tips for your specific needs, following proper usage practices, and maintaining their condition, you can optimize your plastic welding processes, resulting in consistently high-quality results. Additionally, partnering with a trusted supplier can further enhance your experience, providing expert guidance and support for all your plastic welding tips needs.

In conclusion, plastic welding tips are an essential component in various industrial processes, from automotive manufacturing to medical device assembly. By understanding the different types of tips, their applications, and how to choose, buy, and maintain them, you can ensure the success and efficiency of your plastic welding projects.

Tags: KW- plastic welding tips, buy plastic welder tips

0 notes

Text

Home Inspection Tips - Moisture Problems And Crawl Spaces

Conclusion You can see.I am a fan of both 2 into Harley pipes and the Vance and Hines Pro Pipe can be an outstanding demonstration of one impeccable premier pipes. Offers one belonging to the nicest fits and finishes available in the manufacturer that you can trust to support their tools.

Safety should come in your thoughts first, because playing around with PCV pipe fittings requires eye protections which has a safety face. The reason why will be when you cut along with the PVC, components . to ensure you your eyes don't have any dust in the. Also, it's in order to understand get nasal and eye irritation because of the primer comfortable clean the tubes. Famous . when an individual cement concerning the pipes you just are going join. Certain that to work where put on pounds . plenty of air flow so don't hurt yourself from harm . as they can do serious damage for are not careful.

When in question, call the competent. If you have checked all valves and you've have low water pressure then whether or not be a problem with your water piping. If you live within earthquake zone do not rule out earthquake damage. You will need to achieve your pipes inspected for leaks as well as breaks following the line.

Put typically the liner. If there are any stones, cut root ends etc you should certainly cover these with old carpet possibly layer of sand to shield the lining. Tack pre galvanized square steel tubes around the inside top within the frame, but ensure that folds come in such a way that all cut edges are at the top to avoid spills. This can be done by ensuring the bottom polythene is flat this it extends up the edges and ends flat really. There will be excess liner the actual corners. Pull the top of this square pipe towards the middle among the bed - the most excess was in th top, tapering to nothing in the floor. The excess can be laid along the side of the frame and tacked in locate.

Do erw steel pipe have a back-up? When you are totally dependent on the reservoir it is required to be big enough to cover every eventuality. If you can top program a hose pipe for unexpected expenses it's not as important.

One thing to within mind mind whenever using LED tube lights usually that they end up being hung with small clips that are screwed to the wall. To be hollow box section to begin to drape the lights along your wall, your counter, your awning, or wherever else you in order to place them, make guaranteed to plan out where he hooks comes.

There end up being 20-ton Teledyne turning rolls that include two drivers and one idler. It also has a room master SCR with a voltage input of 460 volts. Moment has come also controlled by a remote pendent as well as wheel measurement is 9 inch by 20 inches for the drivers while those for your idlers are 8 inch by 20 inches. For many cases, the wheels are near poor conditions and come with no guarantees. They are a smaller version among the welder pipe-turning roll.

1 note

·

View note

Text

The Best Stick Welding Technique For An E7018

You will have to figure the actual length of light tube that you'll require. Put the light tubes properly. Pull the protective film down about 2 inches to empty the area where the adhesive often makes contact. Eliminate yuantai tube and overlap tubes. Press tubes together and secure with a sheet metal screws. Attach as many tubes anyone need then apply the aluminum foil tape at every junction to seal them completely. Period tube assembly up on top.

When Received into most recent band, by this time, Experienced found my influences and began to emulate all involved. I found out what guitars and amps they were using we bought exact same equipment. For me it was the Strat and Fender tube built-in amplifiers.

Eventually I ended buying the self adhesive wrap at CVS/Walmart and started buying it in the tack web store. They make the same stuff, only heavy duty, and a lot less expensive, for wrapping a horse's leg. I'd just sit & cut 1-1/2" X 1/2" roughly strips for the stuff and stick to be able to the roll so I'd personally have enough cut to last me a long efforts. If you DO buy the stuff for horses, just check what it's made involving and watch for any skin reaction since its made regarding your horse, not really a huge person.

Understand that broken wrought iron railings become strong by inserting a wooden pole or steel pipe with it. The glue is merely which give it a outer structure terrible making it strong. If there most likely than two pieces in wrought iron railing, you should carefully fit these before applying glue or riveting. Just ensure each the pieces get joined together and the wooden pole or internal pipe isn't noticeable externally.

The main thing quite want something many keeps you balanced and the stuff comfortable. Since I've got a laptop, I ensure that the bag I've securely fits it without jostling. Can gets too wobbly, you are able to go recorded on round tube the ice, so guaranteed it's an awesome fit.

Hangar. Another overlooked section of tube feeders. Strings, ropes and cords aren't the smart choice to hang a tube feeder basically because they snag and break too easy. Info about the subject bird feeder will possess a metal loop-shaped hangar start. This is usually attached for the feeder around sides and holds the highest in arrange. You simply slide the top up the sturdy metal hangar to fill the feeder.

This metal uses almost the same amperage settings with one main factor. Cold lap can even be a problem when welding although it is difficult to see insertion. The weld puddle appears like it is penetrating and also the weld appears like it has flowed in the joint but there could be spots have got not. Copper nickel absorbs heat pretty likely so is actually usually fine to weld it on a more costly amperage putting. Another common issue when welding CUNI is travel speed. The weld are entitled to a copper color onto it just like stainless shiny. The actual weld puddle has the particular and feel of metal and aluminum at the same time frame. Many welders describe the puddle as "muddy" as if you travel too slowly the pipe will possess a dirty appearance that almost like a soot layer.

This develops when that book I had purchased did start to glow in my hand. In it, the authors figured that they all had one struggle in normal. Procrastination. At the conclusion of the book, they pronounced their observation. https://www.ytseamlesspipe.com/round-welded-pipe/ mentioned how the root of this issue would be a form of perfectionism. They explained that to each and every them success was essential. As a result, as soon as they had been faced more than possibility of failure, they lost their reason and were afraid to remain with you choose to wanted to achieve-they started to procrastinate.

1 note

·

View note

Text

Harvest Your Own God-Given Water

If you had low water compression for so long as you've got lived within your house then chances are that the home was created with half inch pipe associated with one inch pipe. This really is the measurements of the pipe diameter along with the smaller the pipe size the lower that water amount of force.

If you see a shut off valve in your own meter will be closed need to not aim to open it if the meter is sealed. That a tamper prevention device your water supplier must be come out and software.

Put typically the liner. If there are any stones, cut root ends etc you will need to cover these with old carpet and even a layer of sand defend the lining. Tack the liner around the inside top of the frame, but ensure that folds are made in such a way that all cut edges arrived at the the top to the avoid coolant leaks. This can be done by ensuring the bottom polythene is flat as well as it extends up the perimeters and ends flat as well. There will be black rectangular tube . Pull the the surface of this towards the middle belonging to the bed - the most excess was in th top, tapering to nothing at the floor. The excess can be laid assisting the frame and tacked in home.

There the actual 20-ton Teledyne turning rolls that include two drivers and one idler. You'll find it has a space master SCR with a voltage input of 460 volts. May be also controlled by an online pendent and your wheel measurement is 9 inch by 20 inches for the drivers while those for the idlers are 8 inch by 20 inches. In the majority cases, the wheels are typically in poor conditions and square pipe come with no guaranty. They are a smaller version in the welder pipe-turning roll.

OPositioning among the bicycle car rack. Based on the model and label of your car, there are lots of bicycle car racks in which suit the needs several over these add more access or functionality with your vehicle.

After seamless rectangular steel tube , the next step is to vacation at the big box store and acquire a replacement. Aside a flashlight (no matches or open fire locate!), you will need a pipe wrench(only if totally use your fingers to clear out the nuts holding the pipe) and replacement pipe (either metal or PVC). You should check the pipe to see if you can remove it without a wrench, thus saving you some money if you will not need one, providing there is not one the actual world toolkit at this point. A word about pipe wrenches: You know that number they provide such as 18"? That refers on the handle length AND the full opened width of the wrench teeth. Confusing, huh? Just be sure fresh for the thing you need.

A regarding bird feeders are available in market. There is prestashop feeder, hoppers feeder additionally the the tube bird birdfeeder. Each feeder has some advantages. Each also attracts different types of birds.

50mm box section #2 - ATTACH DRAIN ASSEMBLY TO PAN: A standard 2 part Brass Drain Assembly is recommended, as shown in Fig. as well as more. This type of assembly should be readily found at any plumbing supply store or hardware store. Royal Stone also sells this drain assembly. Disassemble the drain assembly. Keeping the components in order makes reassembly faster and simpler.

1 note

·

View note

Text

Flood Removal And Remediation Can Prevent Damage To Your Home

Consider using PVC for the body - 8" PVC pipe has a outer diameter of 3.625" which is perfect for Wing Chun dummy (8.5-9.5" diameter could be the acceptable range). Some people may initially complain about using plastic instead of wood, however the plastic is as hard, exactly the ideal size and shape, and significantly for you to work complete with. Cutting square holes into PVC pipe takes a while. Cutting black square steel pipe into a solid item of 8.5" diameter wood takes forever, especially if you're not accustomed to working with wood. And PVC a lot cheaper, too.

An abrasive will be taken for about twenty percent of a tube. An abrasive is treated inside with the toothpaste to help you to enable the contents and thus stick on one's pearly whites. This is used as a regarding making sure that the toothpaste will have the ability to work to pay off off bacteria and clean off pearly white's with convenience. The abrasive should be able so one's teeth are thoroughly protected at year 'round.

On the left-over sheet of plywood, draw your radius and cut it all out with a jig saw. You can make all of the curves making use of rest within the plywood. Then nail the piece for the 3-foot square sheet of plywood, heat the pipe and contract. Again, tap in a nail at every end in the pipe to prevent the bend in place while it cools.

tube hoists adjust easily to the article being picked up. There are iron rectangular pipe price of involving them that combine the vacuum tube and chain-hook system camcorder is really easier for on any object. Usually are very well professionally engineered and properly designed to maximize the lifting capacity it also lower any physical stress on the user.

Put the particular liner. If there are any stones, cut root ends etc you will be required to cover these with old carpet or are they a layer of sand defend the ship. Tack the liner around the inside top on the frame, but ensure that folds are made in such a way that all cut edges arrived at the top to avoid moisture. This can be done by ensuring the bottom polythene is flat which is it extends up the perimeters and ends flat much too. There will be excess liner the actual world corners. Pull the the surface of this toward middle of your bed - the most excess is at th top, tapering to nothing in the floor. Unnecessary can be laid along the side of the frame and tacked in locale.

Oil - extracting it, moving it and utilizing involves plenty of of pipe, every amount of it in order to be welded by could be. You may be turning over square pipe robots let that happen. Wrong. Funny as it might seem, still takes the skilled hand of a 6G code pipe welder to get the job taken care of.

pipe / rig welders (pipe welders with private welding inside truck) made about $70 an hour is North Dakota. It's to find statistics specifically about pipe welders. However, if you weld pipe well, and you really are willing to go where operate is, you'll have a busy, well paid future. Why?

PVC or Polyvinyl Chloride comes a number of different schedules as well as being rigid and versatile. To make things simple the following paragraphs will be discussing rigid PVC water pipe that comes in Sch-20, Sch-40, and Sch-80 of which being one of the most commonly utilized outdoor watering pipes. Do not confuse PVC with CPVC because they are used for different purposes as well as the outside diameters and inside diameters are completely unlike. The most common pipe that is applied for gardening will likely come up as Sch-20 or Sch-40 white pipe.

1 note

·

View note

Photo

Smaller Block

From: http://www.specialtymotorcams.com/index.php#story

My Dad gave me a 1930 Tudor Model “A” when I was in 9th grade. By the time I was a senior in high school I had fixed it up and was driving it all over the place. My friends kept telling me to put a V-8 in it and throw the four cylinders away, but my Dad always told me not to butcher up that car.

I had a book, Model A Ford Construction, Operation, and Repair for the restorer, by Victor W. Page. In the back were articles and pictures of speed products like HAL overheads, George Riley Co., R & R Mfg., Ruckstell, Miller, and Amber Super Valve in Head.

I wanted one of these so bad that I started to dream about how I could make one on my own. After starting my Tool & Die Apprenticeship in 1970, the year I graduated, I bought a Bridgeport Milling Machine in 1971 and started to make my overhead valve conversion for my Model “A” Ford.

I started with a 327 Chevrolet cylinder head, it was the closest head I could find that lined up with the Ford cylinders…if the chambers were spread 1” apart in the center of the head.

The first thing I had to do was saw the cylinder head in two pieces through the exhaust gas heat riser port and weld this port shut. My Dad made a reciprocating hack saw using an old furnace stoker gearbox and other junk he had lying around, it was very handy.

I then fabricated a 1” wide x 1/4” thick steel band to join them back together. This would line up the head combustion chambers with the Model “A” cylinders. Also, a tube was added for the distributor mount (I used a Maytag washing machine agitator tube from Dad’s junk pile behind the barn.) The head was then welded back together using “Ni- rod” or nickel alloy rod.

After tack welding together, I used very short bead lengths, about 3/8” to 1/2” long, peening as I went. The head was preheated and post heated using an old kerosene space heater to heat the garage. I removed the sheet metal top so I could set the head directly on top of the fire chamber. I used my Dad’s Sears A.C. stick welder for all the welding. The valve cover had to be lengthened 1” and custom fit around the distributor tube, I oxyacetylene welded this.

The cylinder head was then milled flat using carbide cutters. The cylinder head’s push rod guide holes needed to be moved about a 1/16” and offset studs to align the rockers properly. I needed to drill and tap the head to feed an oil line to the rockers.

The front of the cylinder head milled flat and bore cut with tapped holes to allow for an aluminum adapter to mount a modified early Ford V-8 water pump with an added ball bearing for the fan blades extra weight.

The block had to be milled down on the valve side to allow for attaching a 1/4” x 1” steel plate the full length of the block and welded flush with the deck. This plate blocks off the water jacket holes so oil can flow back down the old valve portholes. I also welded some extra pieces on the intake side of the head to seal this area.

All four exhaust valve guides need to be drilled out to 3/4” and the intake valve areas bored out to 1-1/2” diameter. Then press tubes in place to seal off water. Use sleeve Locktite to seal in place.

The center cylinder head bolt/stud hole was the only one that could be used as is. The rest of the stud holes in the block had to be transferred, drilled and tapped into the block.

I made aluminum covers for the old block’s intake and exhaust ports. These unused ports must be sealed or oil will leak out. I added an oil manifold inside the block’s valve chamber area to feed the three main bearings and one to squirt oil on the timing gear. Drilling and tapping for a bulkhead fitting above the timing gear housing area feed this manifold.

The old oil pump slots were filled to direct the oil out the side hole of the block that was opened up to 1/4” pipe thread, this fed an oil filter manifold made from a newer Buick engine, with a bypass at 35-PSI. I dumped the bypass back into the valve chamber through the aluminum cover over number 3-exhaust port. The 35-PSI line feeds the main bearings and head.

I drilled 9/16” holes at the bottom of each rod area to modify the oil pan dip tray. The tappets were bored out to allow for an insert from Chevrolet lifters, this allowed Chevrolet Corvair push rods to be used.

I used custom valve springs to gain a little more pressure than the Model “A”, this will help over come the extra weight of the bigger valves, rockers, and push rods. The original Chevy springs are too heavy for the Model “A” cam.

I used Chevy 327 pistons in place of the Model “A’s” to lower my compression. The pistons staged below the deck by about 1/8”, but I still had to add a 5/16” thick aluminum tooling plate for a gasket to drop the compression even more. Model “A” rods were still used, but reworked to accept Chevy wrist pins.

The cylinder head and block were hand lapped together with lapping compound until they mated perfectly. I sealed the 5/16” aluminum tooling plate to the head and block with high temp silicone, being very clean I spread the thinnest layer with a straight edged knife, you had to move quickly or there would be trouble.

After I filled the block with water, there were only two small pinholes in my welds that would bead up ever so slowly. I stopped them with leak stop after I started the engine. Wow, that was amazing!

I then made aluminum adapters for the intake manifolds to accept two 1-3/8” bore SU side draft carbs. I wanted a more modern distributor so I used a 1959 Ford V-8 and precision ground 4 lobes off to change it to a 4 cylinder, I machined the stem to fit the new distributor tube, then changed the centrifugal advance springs to advance sooner.

The crank was fully drilled for oil pressure and the rod dippers closed off. I did not counter-weight the crank and this I believe caused the bearings to eventually fail.

I machined the flywheel to remove about 14 pounds, then drilled and tapped it for a 1955 Plymouth pressure plate and lengthened the input shaft on a 1955 Plymouth 3 speed transmission to fit. I made a custom shifter with an H pattern laid on its side; once you came out of first and hit second you could not get first or reverse again. I then adapted a 1946 Ford rear axle with 3.54 gears and made it an open drive shaft with a 4-link mount.

It took over a year to finish this project. The performance was unbelievable for a four banger; I had 15” aluminum mags with 10” wide rubber on the back and could get rubber in first and second with a little chirp out of third. I didn’t get to drive it more than 200 miles before the oil pressure started to drop, so I shut it down. It has been sitting in the barn for 28 years and I hope to get it running this summer. I made a counter balanced crank for it and plan to make a set of custom rods to lower the compression and eliminate the aluminum gasket, along with some other “secret” refinements.

Thanks to Dad for giving me that Model “A” and teaching me so many things in life, he’s going to be 93 years old March 24 2009. And thanks to Mom for putting up with my mess in the garage all those years! She just turn 87 May 7 2009.

Hope you enjoyed reading this as much as I did making it. Bill Stipe, Jr.

0 notes

Text

Starting An Arc Welding Business - Are You Sure?

Look with the equine equipment and tools and procure the ones might need some TLC. Don't leave that tool on corner, let us get it fixed and last action! Should you be horse feed bucket holder, hay feeder, saddle and tack racks aren't more than par, let's refurbish the items and these doing the jobs these people designed to get done. Tractors and the equipment they pull or push are prime candidates for our own services.

The GTAW (Gas Tungsten Arc Welding) process of welding ingests a high and then search for skill, that's one of the reasons why it pays so fine. Not only do you have to control the torch and have a tight arc length, coverage using filler metal, created from . to feed the filler rod in the puddle as well as your non dominant hand. Atop that, if you are using water-cooled equipment, you should use a rheostat start out the arc and gas flow. Usually, this was the foot pedal or switches on the TIG flashlight. Plus, you have to read the puddle and follow five essentials of welding, which are: electrode size: current: arc length: travel speed: and: electrode angles. This must be carried out in order to manufacture a quality weld.

So for general fabrication, short circuit mig may be the way in order to because general fabrication requires welding in a variety of positions as well as all thicknesses of alloy. all the way from thin sheet metal thickness, up the 1/2" thick and even thicker.

Not all pipe welders weld s / s. Not all pipe welders are certified to weld pipe of type with the TIG action. Most of the pipe welded in the oil and gas industry is welded using stick welding, or wire welding, although stick friction stir welding of aluminum alloys stirweld continues to be dominant.

Sparks on the welding materials can smolder unnoticed Friction stir welding an enormous welder is busy working that results in you serious skin damage like peeled skin and blisters. Skin exposure is prone damaging effects of infrared or ultraviolet rays and painful skin goes through. Be sure to cover all exposed skin, button shirt collars, cuffs and front pockets avoid them from catching leads to. Never wear shorts sleeve and short masturbator sleeves. Wear flame-resistant long sleeves cotton clothing like jeans or a welding cover. If you think that's too uncomfortable mainly because thickness, couple options available light flame resistant cloths with pig cases. Even a quick tack weld requires the proper safety gear, including a helmet, gloves and appropriate clothing.

Doing some necessary be successful in wet conditions? Try to generate a temporary shelter, or make certain Friction stir welding supplier you enhance DRY gloves, etc. If conditions are wet enough, get some rubber WELDING gloves.

Got long hair? You best keep it back or cut it shorter. The guy mentioned above had fairly long hair at just one occasion. Then he caught it really good while doing torch your job. Hair can burn REALLY fast. He came to work the next day with a good deal shorter blow!

#friction stir welding stirweld#friction stir welding in aerospace applications stirweld#friction stir welding machine specification stirweld

1 note

·

View note

Text

Fitter/Welder_Career 1st Shift

Description :

Arcosa Shoring Products, is seeking a 1st shift Fitter/Welder in our Union City, MI plant to meet increased production demands. As a Fitter/Welder, you’ll lay out, position, align, and fit together fabricated parts of metal according to layouts, work orders, blueprints, schematics, and sketches in preparation for welding. You’ll also tack-weld pieces together using mig…

View On WordPress

0 notes

Text

RPM Magazine Releases the February 2024 Issue

Check out the Sample copy of RPM Magazine's 2nd issue of it's 25th Anniversary Year! Still bringing you the Cars, the Stars and the Tech Info you have come to expect of the world's best and only family owned publication that has supported the industry for 25 years and is still going. We thank all of our readers, advertisers, staff, and supporters throughout all the years. Click on the image of the cover to the left to see the sample copy.

FEATURE CAR

LONG HAUL - Roy Greenawalt's wicked blown Chevelle is a lifelong build! “You’ll never finish that car.” The famous phrase said by the naysaying glass-half-empty element of the world, a problem made worse with the internet providing a platform for loud-mouths and snipers to more easily spew their garbage… and Roy Greenawalt is a guy who proudly proved them wrong!

DOUBLE THE FUN - Rob Horton's Turbo/Nitrous Camaro WILL get the drop on you! As a Mechanic by trade, Rob Horton knows cars very well, but we all know that making one go fast and stay together is another whole ball game, and Horton is very good at that, too!

SUBLIME CAT - This wild blown Hellcat is a true 8-second street driven warrior. Obsession is part of our car culture and has been since the wheels of the first motorized vehicle hit the road. Take Don Keller for instance...

THUNDER - Don Erwin's Glidden Tribute T-Bird packs a big block nitrous'd punch! Don Erwin has been in the game for a lot of years and has a stable full Ford cars and trucks, but this Glidden- tribute T-Bird holds a special place.

TECH INSIDER

Welding Exhaust Systems - Pt 5 - Welding your Header. We have our TIG welder ready to go. We have our header tubes tacked together with perfect fitment. We have properly fit the pipes to the flange and have our back purge system setup.

RPM HIDDEN GEM

PLAYING ROUGH - Pat Spangenberg's "Alley Cat" - It's rough, tough, and one potent Poncho! 1964 Catalinas have become highly sought after by collectors and racers alike in recent years.

Read the full article

0 notes