#single phase welding machine

Text

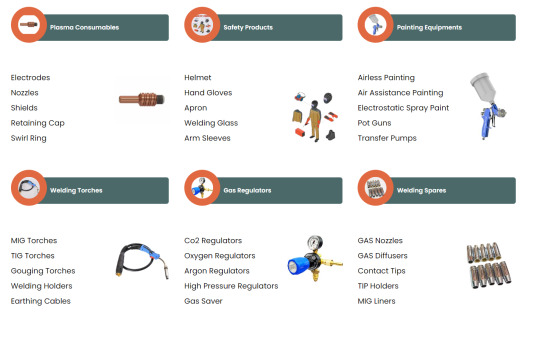

Need Welding Material at low cost in Ludhiana, We provide various types of Plasma Consumables and Safety Products, painting Equipment and Welding Torches, Gas Regulators, Welding Spares, etc. Free Shipping on the first order, Upto 50% Off on bulk order.

#Single phase welding machine#Mosfet welding machine#Small welding machine#jk welding machine#Iball Welding machine#Mag welding machine#Mig welding machine

0 notes

Text

industrial tools supplier in qatar

#construction tools suppliers in qatar#single phase welding machine qatar#wedge anchor suppliers qatar#cable crimping tool qatar

0 notes

Text

Buy Portable Type Welding Machine ARC 250, Welds 4mm Continuously - Krishitool.in

Book Now: https://www.krishitool.in/product_details/Portable_Type_Welding_Machine_ARC_250,_Welds_4mm_Continuously

welding machine, mig welder, tig welder, welding machine price, gas welder, types of welders, welder arc, rod welder, spot welder, cold welding machine, mig welding machine, tig welding machine, spot welding machine, laser welding machine, arc welding machine, portable welding machine, aluminum welder, laser welder, cold welder, esab welding machine, stud welder, inverter welding machine, electric welding machine, mig welding machine price, mini welding machine, welding set, gas welding machine, wire welder, laser welding machine price, co2 welding machine, small welding machine price, tig welding machine price, small welding machine, toshon welding machine, spot welding machine price, types of welding machine, electric welder, single phase welding machine, argon welding machine, plastic welding machine, aluminium welding machine, tack welder, welding machine 250 amp price, ibell welding machine, jkarc welding machine, ultrasonic welder, single phase welding machine price, mig and tig welder, shakti welding machine, small welding machine price, welding machine price list, best welding machine, arc welding machine, welding machine price single phase, bosch welding machine price in india, welding machine single phase, welding machine 250 amp price, Arc Welding Machine, Welding, Welding Machine

#Arc Welding Machine#welding#welding machine#welding machine 250 amp price#welding machine single phase#bosch welding machine price in india#welding machine price single phase#best welding machine#welding machine price list#small welding machine price#shakti welding machine#mig and tig welder#single phase welding machine price#ultrasonic welder#jkarc welding machine#ibell welding machine#tack welder#aluminium welding machine#plastic welding machine#argon welding machine#single phase welding machine#electric welder#types of welding machine#spot welding machine price#toshon welding machine#small welding machine#tig welding machine price#co2 welding machine#laser welding machine price#wire welder

1 note

·

View note

Video

youtube

Portable Table Top Spot Welding Machine, Table Top Pedal Operated Spot Welder.. Con : +91-8780499281

Gorang Welding Machine - Rajkot ( Gujarat ) #gorang @Gorang Welding Machine Portable Table Top Spot Welding Machine Table Top Pedal Operated Spot Welder. 5kva Spot Welding Machine. 8kva Spot Welding Machine. Jewellery Spot Welding Machine. imitation jewellery spot welding machine.. Model 5kva Table Spot Welding Machine Usage/Application Industrial Type of Spot Welder Table Mounted Spot Welder Model Name/Number 5kva table Spot Welding Machine Suitable For Welding Rod 1-2mm Material Steel, Metal Voltage 220v Max no load Voltage 220v Automation Grade Manual Phase Single Phase Frequency 50fz Weight 80kg Rated Duty Cycle 75% Duty Cycle Current Control Timer Base Guaranty 1 year full guaranty Product Code 5kva Table Timer Setting Range Weld 00 to 99 I Deal In New Only This Is 5 kva Table Spot Welding Machine. Most of use in jewellery prodects, decoration products, spects Manufactiring, And Small Meany Prodects in use this machine.. We are one of the largest manufacturer of Tabel spot welding Company In All India.. Additional Information: Item Code: 5kvaTableSpot Production Capacity: 5kva Table Spot Welding Machine Delivery Time: Ready in stock Packaging Details: Free Packaging and forwarding services. @Gorang Welding Machine #machinertandtools #manufacuters #machinery #gorangweldingmachine #gorangmachinery #rajkotmachine #machineguru #gorangspotweldingmachine #machinemanufacturer #trading #spotwelding #welding #weldingmachine #welder #weld #Handspot #copperwire #heavyequipment #industrialmachinery #gorang #shorts #machinery #machinery #handspotweldingmachine Spot-welding-machine @Gorang Welding Machine #nutweld #battery Gorang Welding Machine con : +91-8780499281 Mail : [email protected] : [email protected] Web : WWW.gorangweldignmachine.com : www.gorangwelidngmachine.in Gst No : 24AHYPJ4092N1ZJ Facebook Page : https://www.facebook.com/Gorangweldin... YouTube Chanel : https://www.youtube.com/machineguru Instagram : https://www.instagram.com/gorangweldi... WhatsApp : https://wa.me/message/YHMQYVW3EKUEO1 Web : www.gorangweldingmachine.in Mail id : [email protected]

#gorang#spot welding#spot weldin#spotwelding#spotweldingmachine#handspot#tablespot#table spot#table spot welding machine#gorang welding machine#8780499281#gorang machinery#jewellery#jewellery spot#manufacturing#manufaktura#manufcaturers#welding#weldingmachinery#machineryandtools

2 notes

·

View notes

Text

What Are the Different Types of Pipe Spools? |Metalforgeindia

Business piping structures, pipe spools play a critical position in connecting severa sections of piping to form a whole pipeline. Pipe spools are prefabricated additives that include pipes, fittings, flanges, and other vital additives welded together in a workshop earlier than being mounted on-website. They are used to streamline the set up method, lessen hard work fees, and ensure the integrity of the piping device. In this article, MetalForge India will give you the specific kinds of pipe spools usually utilized in diverse industries.

1. Straight Pipe Spools:

Straight pipe spools are the simplest shape of pipe spools and consist of a single direct phase of pipe with flanges or fittings welded at each end. They are used to attach sections of piping in an immediate line without any bends or adjustments in path. Straight pipe spools are commonly used in smooth piping structures in which the drift direction remains steady.

2. Elbow Pipe Spools:

Elbow pipe spools are designed to trade the path of drift in a piping machine with the useful resource of instantly connecting sections of piping at an altitude. They function one or extra bends or elbows welded onto the direct sections of pipe. Elbow pipe spools are to be had in diverse angles, inclusive of forty five ranges, 90 degrees, and one hundred 80 ranges, to accommodate awesome piping layouts and layout necessities.

3. Tee Pipe Spools:

Tee pipe spools are used to create branch connections in a piping gadget by means of the use of connecting 3 sections of piping collectively within the shape of a "T." They embody a at once segment of pipe with a tee turning into welded onto it, allowing fluid or gasoline to go with the glide in 3 considered one of a type commands. Tee pipe spools are generally used in piping structures that require branching or distribution of fluids to a couple of locations.

4. Reducer Pipe Spools:

Reducer pipe spools are used to transition among pipes of different diameters within a piping tool. They characteristic a tapered layout with one surrender large than the alternative, bearing in thoughts an easy transition in pipe size. Reducer pipe spools are typically used to preserve the drift charge and pressure of fluids or gases even as transitioning between extremely good sections of piping with varying diameters.

5. Cross Pipe Spools:

Cross pipe spools are much like tee pipe spools but characteristic an extra outlet perpendicular to the precept go along with the drift path, developing a "plus" form. They are used to create complicated piping configurations that require more than one department connection. Cross pipe spools are typically utilized in industrial procedures in which fluid or gasoline distribution desires to arise in more than one hints concurrently.

6. Custom Pipe Spools:

Conventional forms of pipe spools, custom pipe spools by MetalForge India can be fabricated to fulfill unique challenge necessities. These spools are designed and synthetic in line with the right specifications furnished through the patron and can consist of unique talents or configurations tailored to the software program. Custom pipe spools provide flexibility and flexibility in designing complex piping systems for severa industrial programs.

Conclusion:

Pipe spools are vital components in industrial piping structures, imparting a handy and efficient way of connecting piping sections while making sure structural integrity and fluid float performance. By statistics the only-of-a-kind forms of pipe spools available, engineers and assignment managers can pick out the maximum suitable spools for their particular application necessities, whether or not it entails smooth without delay connections, directional modifications, branching, or length transitions. Whether general or custom-designed, pipe spools play an important role in the successful implementation of piping tasks throughout diverse industries.

0 notes

Text

Unleashing Precision: The Laser Soldering Machine Revolutionizing Jewelry Making

Introduction: Redefining Jewelry Crafting with Laser Precision

The Alpha Laser Soldering Machine: An Overview

Crafted with the jeweler in mind, the Alpha Laser Soldering Machine offers pinpoint precision, expanding the horizons of assembly and repair applications while minimizing the risks of heat damage. Its ergonomic desktop/vertical design, coupled with strategically positioned operator controls, ensures optimal utilization with minimal operator fatigue.

Harnessing the Power of Hot Light

At the heart of the Alpha Laser Soldering Machine lies its electrical design efficiency, guaranteeing maximum hot-light energy transfer from the laser source. This is made possible by a specially designed laser enclosure system, delivering unparalleled power and efficiency without compromising on longevity, even during extended operation.

Unmatched Value for Jewelry Professionals

Our experts are committed to providing exceptional value for today’s jewelry professionals seeking to harness the power of hot light. With its compact, ergonomic design and cutting-edge technology, the Alpha Laser Soldering Machine ensures optimal performance across a variety of applications.

Applications: Transformative Capabilities for Jewelry Repair and Beyond

The versatility of the Alpha Laser Soldering Machine makes it ideal for a wide range of metal joining and repair applications in the jewelry industry. Its seamless integration with top-quality, efficient laser sources makes it the preferred choice for discerning jewelry artisans.

Precision Repairs with Ease

Whether it’s intricate repairs on delicate pieces or joining metals seamlessly, the Alpha Laser Soldering Machine delivers unparalleled precision and reliability. Its ability to support various materials, including gold, silver, platinum, and stainless steel, makes it indispensable for jewelry professionals worldwide.

Catering to Diverse Needs

From small-scale repairs to intricate designs, the Alpha Laser Soldering Machine caters to the diverse needs of jewelry artisans. Its versatility allows for precise adjustments, ensuring optimal welding results across different materials and designs.

Specifications: Powering Innovation with Cutting-Edge Technology

Model No.: SLW-100/SLW-200

Output Power: 100W / 200W — Based on requirement

Single Pulse Energy: 0–150 J

Machine Design Type: Desktop / Vertical

Laser Source: ND:YAG

Laser Wavelength: 1064 nm

Pump Lamp: Pulsed Xenon Lamp

Pulse Width: 0.1–20 ms adjustable

Pulse Repeated Frequency: 1 ~ 50 Hz adjustable

Welding Spot Diameter: 0.2 -1.3 mm adjustable

Observing System: Microscope / CCD — Based on requirement

Cooling System: Water Chiller

Power Supply: Single Phase AC 220V +10%, 50Hz/60 Hz, 4 KW

Running Environment: Temperature 5°C — 28°C Humidity 5% — 70%

Supported Application: Gold, Silver, Rose Gold, Copper, Platinum, Titanium, Argentine, Nickel, Aluminum, Stainless Steel, etc.

Conclusion: Elevate Your Craft with the Alpha Laser Soldering Machine

In conclusion, the Alpha Laser Soldering Machine stands as a testament to innovation in the jewelry industry. Its unparalleled precision, versatility, and efficiency empower jewelry professionals to push the boundaries of their craft. Experience the difference today and elevate your jewelry making process to new heights.

FAQs (Frequently Asked Questions)

Is the Alpha Laser Soldering Machine suitable for both small and large-scale jewelry repairs?

Absolutely! The machine’s versatility caters to the diverse needs of jewelers, whether it’s intricate repairs or large-scale projects.

What materials can the Alpha Laser Soldering Machine work with?The machine supports a wide range of materials, including gold, silver, platinum, stainless steel, and more, ensuring compatibility with various jewelry pieces.

How does the Alpha Laser Soldering Machine compare to traditional soldering methods?

Unlike traditional methods, the Alpha Laser Soldering Machine offers pinpoint precision, minimal heat damage, and enhanced efficiency, revolutionizing the soldering process.

Can the machine be customized to suit specific jewelry crafting needs?

Yes, our experts can tailor the machine’s settings to meet specific requirements, ensuring optimal performance for each project.

Is training provided for operating the Alpha Laser Soldering Machine?

Certainly! We offer comprehensive training and support to ensure jewelers can maximize the machine’s capabilities effectively.

0 notes

Text

"Empowering Customers: A Guide to Making the Right Purchase on XL Industri"

Purchasing welding machines and tools like MMA (Manual Metal Arc) welding and TIG (Tungsten Inert Gas) welding equipment is an important decision for anyone involved in metalworking or welding projects. Here are valuable tips and advice to help customers make informed decisions when purchasing these items from XL Industri's platform:

Determine Your Welding Needs:

Identify the specific welding processes and materials you'll be working with. Different welding machines are designed for different purposes.

Consider Your Skill Level:

Assess your welding experience and skill level. Some machines are more user-friendly for beginners, while others require advanced knowledge.

Research the Brand and Model:

Look for reputable brands known for producing high-quality welding machines and tools. Check customer reviews and ratings to gauge user satisfaction with a particular model.

Power Source:

Understand the power source options available (e.g., AC, DC, single-phase, three-phase) and choose one that suits your workshop's electrical infrastructure.

Amperage Range:

Ensure that the welding machine has an amperage range suitable for your welding projects. Different materials and thicknesses require different amperage settings.

Duty Cycle:

Check the duty cycle rating, which indicates how long the machine can operate continuously at a given amperage without overheating. Higher duty cycles are better for extended welding sessions.

Portability:

Consider the portability of the welding machine, especially if you need to move it frequently. Smaller, lightweight models may be more convenient for on-site work.

Welding Processes:

Understand the welding processes supported by the machine. MMA and TIG are different processes with distinct applications, so choose a machine that aligns with your needs.

Gas or Gasless Welding:

Determine whether the welding machine requires shielding gas for TIG welding or if it supports gasless welding options. Some models are versatile and allow both.

Welding Tools and Accessories:

Don't forget to purchase essential welding tools and accessories like safety gear (helmet, gloves, apron), electrodes, filler metals, tungsten electrodes (for TIG), and welding clamps.

Warranty and Support:

Check the warranty offered by the manufacturer and the availability of customer support. A good warranty provides peace of mind in case of defects or malfunctions.

Budget Considerations:

Set a budget for your welding equipment, but don't compromise on quality for the sake of saving money.

Training and Education:

If you're new to welding or using a different welding process, consider investing in training or online courses to improve your skills and safety.

Compare Prices:

Compare prices of the welding machines and tools on XL Industri's platform with other reputable retailers to ensure you're getting a competitive deal. Check the discounts on our welding products without compromising the quality.

Read Product Descriptions:

Carefully read the product descriptions, specifications, and compatibility details provided on the platform to ensure the selected equipment meets your requirements.

Ask for Recommendations:

Seek advice from experienced welders or colleagues who have used similar equipment. They can offer valuable insights and recommendations.

Check for Package Deals:

Some vendors offer package deals that include the welding machine, essential accessories, and safety gear. These can be cost-effective options for beginners.

By following these tips and advice, customers can make informed decisions when purchasing welding machines and tools from XL Industri's platform, ensuring they select the right equipment for their welding needs and skill level.

0 notes

Text

Aluminum Extrusion Companies Prototype & Custom Extrusion

It can additionally be used to enhance the sustainability of a design or project. Metalex provide a full vary of Aluminium Plate, Aluminium Bar and Aluminium Extrusion and course of and ship Aluminium to meet your particular necessities. This is a type of aluminium alloy mainly used in architectural aluminium. We hearken to the suggestions our prospects provide to assist us enhance the standard of our service. Whether you require 1 or 10,000 components, extrusion produces absolutely customised, prime quality, uniform cross sections.

GSM Aluminium Ltd is a specialist supplier and stockholder of high quality, bespoke extruded and fabricated aluminium profiles at a competitive cost. Our MiG and TiG crops are for welding aluminium so we can meet all your aluminium extrusion wants, Our bending specialists have a vast quantity of experience in bending aluminium profiles. We welcome the chance to work with our clients at the earliest stage of their aluminium extrusion design requirements. This permits us to incorporate the utmost advantages from the extrusion design and fabrication process.

You should also optimize the operations of the manufacturing machine to produce most aluminum extrusion profiles. Here are a number of the ways of decreasing the value of manufacturing the aluminum extrusion profiles. In the ultimate phases, you will reduce the aluminum extrusion profile to size according to customers’ specifications.

You can keep away from destruction of aluminum extraction profiles by cleaning the aluminum extraction profiles nicely. It can be necessary to avoid any form of contact between aluminum and different metallic sorts. You ought to have essentially the most suitable design that will not solely meet your specifications however also needs to be manufacturable. You will use a water tub or cool air to properly quench the extruded supplies. The high pressure will force the extruded materials to emerge through the die openings.

We are an internationally recognised aluminium extrusion supplier with a whole host of aluminium profile services. It produces aluminium profiles for both architecture and basic business. Their market sector together with Architectural, Automotive, Defence, Display, Electronics, Engineering, Furniture, Leisure, Marine, Product Design, Retail, Rail & Signage, Aerospace. Capalex is a bespoke aluminium extrusion manufacturer in Cumbria, United Kingdom. Aluminium extrusions are used within the building, automotive and aerospace industries for construction of rods and frames. Raptor Supplies provides a broad range of those aluminium extrusions from manufacturers like 80/20 and Faztek.

Whether you want a mass manufacturing or just a one-off custom extrusion, Get It Made has the potential and flexibility to ship on your project. In that point, we have constructed a portfolio of customers from blue-chip multinationals to single-owner businesses. Our numerous base of customers has come to rely on our popularity for honesty, integrity and sound monetary backing.

Complex cross-section designs can be created that are strong and have a wonderful surface finish. Aluminium extrusion products are utilized in many industries including building, aircraft, machinery, manufacturing, and client items. Using a strong hydraulic press, you can produce a variety of merchandise in numerous shapes.

aluminium extruded profiles

Alternatively, if you'd like to discuss your project earlier than submitting a quote, be happy to e-mail our engineers at [email protected]. Extruded Aluminium processed and equipped to your particular necessities. We’ve complied a helpful record of concerns for people who are new to sourcing a supplier of extrusions. Aluminium extrusion terminology can be complicated if you're new to sourcing profiles. Operating from our 35,000 square toes facility in Manchester, the birthplace of manufacturing and repair long established international markets.

#aluminium extrusions#aluminium extrusion#aluminium extrusion profiles#extruded aluminium profiles#aluminium extruded profiles#aluminium extrusions uk#aluminium extrusions profiles#aluminium extrusions online#aluminium extrusions uk suppliers#aluminium extrusion uk#aluminium extrusion profile#aluminium extrusion profiles uk

1 note

·

View note

Text

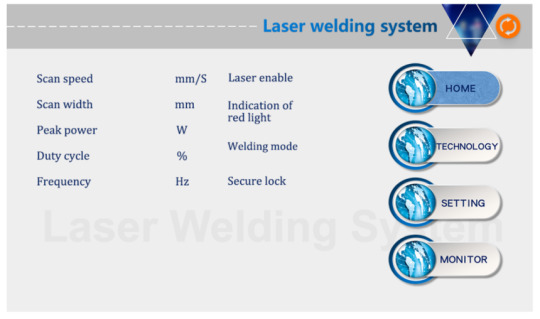

Remcor 3 in 1 laser welding machine and cleaning machine integrates three functions. One machine can get the multi-purpose, it's much more cost saving on machines, labors and spaces. Apply with a continuous laser source, which can have 3-5 times faster in welding speed and cleaning speed compared with pulse type. This fiber laser welding machine in china is widely used for precise welding and rust removal. Contact us and the latest portable laser cleaner price!

Remcor Technology is a professional supplier for laser solutions .which offers the most advanced manufacturing technology in the industry, specializing in all types of manufacturing technology for metals, aluminum, ferrous and none ferrous material fabrication. which have got high appreciations from the global customers.

The 3 in 1 fiber laser cutting welding and cleaning machine applies the latest laser technologies. Which integrate the laser cutting welding and cleaning in one system and head. Compared with the traditional welding or cleaning machine, the advantages are quite obvious for laser welding and cleaning application.

3 in 1 Laser Welding Machine Advantages

Triple functions with one system and head, Users can switch welding/cutting/cleaning mode according to the needs easily.

Super High efficiency. The welding speed can be up to 2m/min compared with traditional tig/mig 0.5m/min, which is 3-5 times faster. No need secondary polish or grinding.

Cost saving. No need certificate, normal people can do beautiful welding and cleaning finish with some practice.No need training.

Simple installation and operation. None maintenance.

More flexible in using, no need special places and machines and labors for different application.

Triple Function Welding Cutting And Cleaning In One System

Simple Installation

Only need to connect the power and gas can get to use.

Integrated Laser source and chiller

max/raycus laser source

The third generation single-module continuous fiber laser;

high-quality laser beam

Hanli chiller

Sufficient cooling, ensure the stable use

Triple Use Laser Head

Sup laser head, which is the best laser head with it's stable in using, none maintenance. Light weight and easy to handle.

Triple Use Controlling System

welding cutting and cleaning achine system

Sup laser controlling system, which is the best system with it's convinient in using. Support four contries' language. Touch screen, easy and quick to click and set. Can save and copy the technology easily. Simple to handle.

3 in 1 Laser Cutting Cleaning Welding Machine Features

Basic features: The product apply with a self-developed three-in-one control system can be flexibly switched the mode of welding, cleaning, and cutting. It sets up multiple security alarms and can be operated easily and flexibly.

More stability: All parameters are visible and the status of the whole machine will be monitored in real time, so that we can avoid problems in advance and troubleshoot and resolve issues easily to make sure that the system can work stably.

Technical parameters: technical parameters can be set, and various technical effects can be tried flexibly.

Stable parameters and high repeatability: Nozzle Air Pressure and Lens Status are determined, the power of the laser is stable, the craft parameters can be repeatable, which greatly improves efficiency

3 in 1 Laser Cutting Cleaning Welding Machine Parameter Details

Laser

Nominal output power

W

1000/1500/2000

Working mode

mm

CW/Modulated

Range of laser power

-

10-100 %

Modulation frequency

Hz

50-5000

Wavelength

nm

1080

Indicated output power of red light

mW

0.5-1

Hand-held optical cable length

m

8-10

Machine Size

Length*Width*Height

mm

800*530*900

Machine

Net

kgs

200

Weight

Electricity

Working voltage

-

220V single phase

Supply

0 notes

Text

Sheet Metal Welding

https://www.hsjfabrication.com/sheet-metal-welding/

Sheet metal welding has argon arc welding, laser welding, spot welding, carbon dioxide protection welding, stainless steel sheet welding, aluminium sheet welding manual arc welding, etc. With the advent of technology, the process of sheet metal welding has evolved over the years. As one of the professional sheet metal components companies, HSJ Metal Fabrication, understands the differences between the existing welding techniques. That’s why we can make a wise decision when it comes to picking the right welding technique for any projects from our customer.

What Is Sheet Metal Welding?

Sheet metal welding involves heating and melting sheet metal parts and joining them together to increase their strength or create a single integrated product. This process is widely used in various manufacturing industries, such as automotive, aerospace, construction, and equipment production. Common applications include welding metal frames, cabinets, HVAC systems, and other metal products.

At HSJ Metal Fabrication, we have expertise in different welding techniques, enabling us to make informed decisions when choosing the most suitable welding method for each project to meet our customer's requirements.

HSJ Sheet Metal Welding Highlights

Equipment List

5-Tig Welders, 300 amp, by Miller.

5-Tig Welder, 300 amp, by Airco.

2-Tig Welder, 250 amp, by Ltech.

2 Miller heliarc welder.

2-Tig Welder, 250 amp, Cobramatic for aluminum.

2-Tig Welder, 250 amp, Miller Syncrowave

2-Tig Welders, 330 amp, by Miller.

2-Mig Welder, Miller, 300 Amp.

2-Airco wire feed.

2-Miller CP300, wire feed.

2-Welder Airco.

2-Acme spot welder, 30" arm, water cooled, air timer.

2-TRW stud welding machine.

5-Gas powered field welder, Miller

5-Portable welder

Industry Area

Medical

Oil & Gas

Defense

Transportation

Packaging

Heating & Cooling

Building Materials & Construction

Engineering

Electrical Equipment & Electronics

Aerospace

Commercial Display

Industrial Equipment

Custom Sheet Metal Welding Tolerances

Size(mm)

Grade1

Grade2

Grade3

Grade4

Grade5

Gerneral Angle

0-30

±0.1

±0.2

±0.3

±0.4

±1

90degree, ±1

31-120

±0.15

±0.25

±0.4

±0.7

±2

121-250

±0.2

±0.3

±0.6

±1

±2

/

251-500

±0.3

±0.5

±1

±1.8

±2

Above 500

±0.5

±0.8

±1.5

±3

±3

HSJ Materials for Sheet Metal Welding

Aluminum (2A21/3003/5052/5083/6061/6082 /8011)

Carbon Steels(Q235,SPHC ,SPCC,SPCD ,SPCE ,ST,ST12,ST13,ST14,ST15,ST14-T )

Stainless Steel ( 304,304L ,312 ,316,317,321,347,904L,440,17-4ph,430 etc.)

Copper (C1020、C1100、C2100,2200,2300,2400)

Brass ( H62、H65、H68、H70、H80、H90、C2600、C2680、C2700、C5210、C5191、 C51000、QBe2.0、C1100、T2)

Other Non-Ferrous Alloys

Material

Features

Thickness(mm)

Electro-galvanised steel (SECC)

Fingerprint-resistant, with excellent corrosion resistance and good paintability, while maintaining the processability of cold rolled sheet

0.8, 1.0, 1.2, 1.5, 2.0

Cold rolled sheet (SPCC)

No rust resistance, surface plating or baking paint is required.

0.8, 1.0, 1.2, 1.5, 2.0, 3.0

Galvanised Steel Sheet (SGLD)

A multi-phase alloy containing aluminium and zinc rich material with beautiful appearance, scratch resistance, corrosion resistance and much higher capacity than SGCC.

0.8, 1.0, 1.2, 1.5, 2.0, 3.0

Aluminium sheet (AL)

Lower strength, excellent forming properties, good weldability and corrosion resistance, and good heat dissipation capability.

0.8, 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0

Hot-dip galvanized steel plate (SGCC

Beautiful appearance, there are two kinds of zinc flowers, small zinc flowers, it is difficult to see the zinc flowers; large zinc flowers can obviously see the kind of hexagonal flower blocks. It has corrosion resistance, paintability, formability, and spot welding.

0.8, 1.0, 1.2, 1.5, 2.0, 3.0

Benefits of Sheet Metal Welding

Save metal materials and reduce structural weight. Simplify processing and installation procedures and improve production efficiency.

The structural strength is high, and the joint sealing is good; it provides greater flexibility for structural design. The welding process is easy to realize mechanization and automation.

Custom Sheet Metal Fabrication Welding

HSJ Metal Fabrication Co., Ltd is a specialized sheet metal fabrication company located in Shenzhen, China. We offer industrial and commercial fabrication services, including OEM, ODM, and customized solutions for size, color, surface treatment, logo, assembly, or packing. Since 2015, we have been committed to providing dependable and excellent customer service for every project we undertake.

Choose HSJ for Sheet Metal Welding

Experienced and Reliable Sheet Metal Fabrication Company

Qualified Sheet Metal & Welding has been serving small and large clients for over 8 years. We have successfully completed thousands of projects for commercial, industrial, pharmaceutical, and aerospace clients from China and abroad. Our commitment to innovation and hard work has earned us a reputation as a reliable and experienced sheet metal fabrication company.

Customized Solutions for Your Sheet Metal Needs

At HSJ Metal Fabrication, we use the highest-quality materials, the best cutting-edge technologies, and the most efficient welding processes to ensure the accuracy and precision of our work. Our 20 years experienced engineer and professional service teams have successfully completed high-level customer requirements. We offer customized solutions for each client and ensure the most accurate and precise workmanship available in this field.

Associated with the Associated Builders & Contractors Association

We are affiliated with the Associated Builders & Contractors Association and are committed to providing the broadest range of sheet metal and welding services to the commercial, industrial, and pharmaceutical industries.

Contact us now for all your sheet metal needs!

Available Sheet Metal Welding Process

HSJ sheet metal welding comes with various types of sheet metal welding, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding.

Typical types of sheet metal welding processes including, MIG welding, TIG welding, resistance welding, projection welding, robotic MIG and TIG welding, and laser welding on various metallic and aluminum alloy surfaces as well as on stainless steel and iron.

MIG welding

MIG welding, also called MAG welding, is a continuous wire welding process where a shielding gas ensures firing bath protection. MIG or MAG welding is used where high productivity and high flexibility of use are required. While MIG welding requires the use of inert gas, MAG welding is carried out through an active gas. MIG welding can be also performed on thin metal, such as thin steel or aluminum.

TIG welding

TIG welding is one of the most popular welding methods since it provides high-quality components. Especially indicated to weld thin parts, it can be used for both continuous and spot welding.

Resistance welding

Resistance welding is a metal fusion welding technique where the material is heated by electrical resistance. Generally used to weld iron and steel, resistance welding guarantees high-quality standards on welded components while ensuring time and cost savings. If you want to learn more about resistance welding, we will explain everything to you.

Projection welding

Projection welding requires studs to be placed on the metals to be welded. During the metal welding process, the welding current is focused on the stud that heats to obtain complex welds, with final results that ensure excellent quality at low costs. Basically, projection welding is a type of resistance welding that uses projection.

Robotic TIG MIG MAG welding

Robotic welding is performed by programmable industrial robots. Mainly used in situations that require repeated welding, it guarantees repeated precision which is hard to achieve with manual welding. Greater precision and higher productivity are the main advantages of robotic welding.

Laser welding

Laser welding allows metals and metallic alloys to be welded, creating a thin and deep weld, with reduced heat deformations thanks to the reduced heat, even on materials that could not otherwise be welded. Precision, cleanness, minimal heat input, and fast manufacturing are just a few of the advantages of laser welding.

Welding metals: the metals that we process in Minifaber

The mentioned welding processes apply to a wide range of metals and sheet metal components that can be welded to create semi-finished and finished products. Through these processes, HSJ can provide welding of iron, aluminum, stainless steel, and copper.

Iron welding

Iron welding is widely employed in several industrial sectors. Thanks to a cutting-edge machinery and the extensive know-how raised through the years, Minifaber can provide iron welding services with the highest cleanness and precision. There are 5 different ways to carry out iron welding: HSJ can help you choose the right one!

Aluminum welding

Renowned for its ductility, lightness, and oxidation resistance, aluminum is employed in every sector in which these qualities are required, such as the aerospace sector and the transport sector. HSJ is focused on various types of aluminum welding: aluminum MIG welding, aluminum tig welding, and other welding processes to manufacture aluminum according to the desired output.

Stainless steel welding

Stainless steel is a special steel alloy that boasts important qualities such as rust resistance, corrosion resistance and high hygiene standards. For this reason, stainless steel is widely employed in the food industry. HSJ provides stainless steel welding services for any specific requirements and offers three different services of stainless steel welding.

Copper welding

Copper is employed in the electrical and electromechanical sectors for its high conductivity and ductility. Copper welding is among the services provided by Minifaber for national and international customers.

Metal Fabrication Welding Application

Computer enclosure

Electronic part

Sheet Metal Welding Related FAQs

How to weld thin metal?

TIG and MIG are both ideal when it comes to welding thinner metal sheets. However, for an extremely thin sheet of stainless steel and aluminum, the TIG method is preferred as it allows for better control over heat input.

What is the thinnest sheet metal that can be welded?

Which Weld Is stronger, MIG, TIG or Arc?

0 notes

Text

ElettroLaser Laser Welding Machine

GF 1100 N3D TILTING ELECTRIC FURNACE Electric furnace for melting precious metals, with manual tilting sistem. Complete with graphite crucible, graphite stirrer and clamp. Capacity. 3kg Au Power: 1700 W Maximum temperature: 1120 ° C Single-phase 220V, 110V available.

0 notes

Text

Weldmate is a top supplier of the best quality welding machine, plasma machines, mig tig torches, etc. We delivered at Ludhiana, Amritsar, Jalandhar, Ambala, Chandigarh, Mohali, Patiala (https://weldmate.in/)

#Single phase welding machine#Mosfet welding machine#Small welding machine#jk welding machine#Iball Welding machine#Mag welding machine

1 note

·

View note

Text

Best Mig Welding Machines | Electroweld

MIG Welding Machines (Metal Inert Gas Welding) has become a popular choice for metal fabrication, repair, and welding due to its usability and speed. If you’re thinking of getting into mig welding yourself, it’s important to choose the right machine for your needs. Here’s an overview of the best MIG welders on the market today from Electroweld.

1. Hobart Handler 210MVP MIG Welder – This portable welder is perfect for weekend hobbyists or working professionals looking to join two pieces of metal quickly and accurately. It can weld materials up to 3/8 inches thick in a single process without changing settings or gas cylinders. The included MVP plug lets you use 115V and 230V outlets with ease so you can take it anywhere without worrying about access to higher amperage outlets.

2. Lincoln Electric Power Wave 355M – This incredible machine provides 3-phase power at 480 volts while still allowing excellent portability due to its rugged yet lean design. With advanced features like Arc Force Control and pulse frequencies available, expect a great arc start as well as clean arcs whether welding thin sheets or thicker slots. Additionally, this model allows for specific adjustments to gas flow so that better conditions are created when joining aluminum or other alloy metals.

3.ESAB Rebel EMP 205ic AC/DC – This multi-process welder not only provides amazing MIG performance but also delivers outstanding TIG welding capabilities due to its AC balance control feature which maintains balanced current output even when welding thin materials like aluminum sheets, pipes and rods up 1/4 inch thick! It also incorporates burn back control so your electrode doesn’t warp when touched after being heated up by the arc during longer operations - making it ideal for automotive body work, furniture structural repairs and installation of kitchen appliance fixtures like dishwashers and refrigerators where precision is key! Remember that when purchasing any kind of welder, always purchase the consumables needed along with it in order to get maximum performance out of your machine!

When getting started with MIG welding projects it's important to find a reliable and affordable machine that compliments your needs - be sure to check out these great products from Electroweld today!

Contact Us:

Phone number: 1300 237 246 Email address: [email protected]

Follow us on Facebook and YouTube.

0 notes

Text

Electrical Engineering Objective Questions for Competitive Exams Pdf

Electrical Engineering Objective Questions MCQ

with Answer PDF Download

like GATE, IES, JTO, PSUs, RRB JE/AEN, RRB loco

pilot and technicians, SSC JE, DMRC, LMRC,

ISRO and other state level engineering exams.

GATE Study Material:

· GATE Exam Pattern, Syllabus, Best Books,

Previous Papers, Notes Download

You can also download Electrical Questions and

Answers Pdf these all electrical objective question

with answer key will be help you for yours electrical

exams preparation like GATE, IES, SSC JE and other

state and India level JE and AE exams. Below table

provides you Electrical Engineering Objective

Questions and Answers Pdf Free Download. This post

provides estimate 1000++ MCQ Electrical

Question which are help all country students. In this

article provide you all subjects MCQ or objective

question with answer categories wise.

Electrical Engineering Objective

Questions for Competitive Exams

Pdf

This article covers these subjects MCQ on Basic

Electrical, MCQ on Electrical Circuit Theory, MCQ

on Measuring Instruments, MCQ on Power

Generation MCQ on Switchgear and Protection, MCQ

on Machine, MCQ on Transmission and Distribution

Electrical Machine Objective MCQ PDF Download

This category all MCQ or objective question related to Electrical Machine. Below table provide you all

latest MCQ Electrical Machine topics D.C. Generators, D.C. Motors, Transformers, Poly Phase Induction

Motors, Single Phase Induction Motors, and Synchronous Motors. You can download free pdf

all Electrical Machine Objective MCQ PDF Download following download links.

Power System Objective MCQ PDF Download

This category all MCQ or objective question related to Power System. Below table provide you all latest

MCQ Power System topics Power Plant Engineering, Economics of Power Generation, switchgear and

Protection, Transmission and Distribution. You can download free pdf all Power System Objective MCQ

PDF Download following download links

Electrical Drives Objective MCQ PDF Download

This category all MCQ or objective question related to Electrical Drives. Below table provide you all

latest MCQ Electrical Drives topics Electric Traction, Industrial Drives, Electrical Machine Design. You

can download free pdf all Electrical Drives Objective MCQ PDF Download following download links

Analog and Digital Electronics Objective MCQ PDF Download

This category all MCQ or objective question related to Analog and Digital Electronics. Below table

provide you all latest MCQ Analog and Digital Electronics topics Digital Electronics, Analog Electronics,

Semiconductor Theory, Semiconductor Diode, Transistors, Transistor Biasing, Op-Amp Circuits,

GATE Exam Notes PDF:

Electrical Engineering Notes Pdf For GATE, IES, PSUs

Extra Electrical Engineering Objective MCQ PDF Download

This category all provide you Other Important MCQ Electrical Engineering. Below table provide you all

latest Other Important MCQ Electrical Engineering topics Electrical Engineering Materials, Measurement

and Instrumentation, Control Systems, Heating and Welding. You can download free pdf all Electrical

Machine MCQ following download links.

Your preparation for the exams will be helped by these Electrical Engineering Objective Questions MCQ

with Answers. For more Electrical Engineering study material, follow the above links. We hope all the

Electrical Questions and Answers Pdf study material here will help you crack your university exams and

also help you crack competitive exams like GATE, IES, SSC JE and other exams.

These all Electrical Questions and Answers Pdf here provide also useful for studying for other state and

national level exams like SSC Jen, BSNL Je and JTO Exams, Railways Jen and Section Engineers,

DRDO, DMRC, Metro, and many other state and national level engineering exams. If you like this

article, please share it with your friends and classmates, because sharing is caring.

0 notes

Text

DIFFERENT TYPES OF WELDING MACHINES?

Is it time to upgrade your welding closet? Then it is important to know the wide options available in the market. Welding is a manufacturing process using high temperature to melt and bridge or fuse parts together. Welding methods are evolving to give quality results with advanced welding equipments. As one of the best welding accessories suppliers in UAE, bright weld understands the importance of advanced technologies to meet different welding processes and requirements. Welding processes vary as MIG welding, TIG welding, stick welding, flux welding, energy beam welding, atomic hydrogen welding, gas tungsten welding, plasma arc welding and each one of it might demand different purpose with different welding machines that make the work simpler and efficient with the best welding accessories suppliers in UAE.

MIG welding machine

When you are working with large and thick materials, metal inert gas machine can be your buddy. Compared to TIG welding, it is faster and results in lower production costs. The welder uses a consumable wire as both electrode and filler material. Majorly MIG welding machines are used to weld stainless steels and aluminium metals. The machine is capable to work in single phase, three phase and all in one. It is ideal for small business, manufacturing industries and metal fabrication.

TIG welding machines

Tungsten inert gas machines are commonly used for thin metals and smaller projects as they produce precise and clean welds. It is ideal for pipeline, pipe welding, aviation, aerospace and sheet metal operations. A non consumable tungsten electrode is used to produce a weld.

Spot welding machine

Two or more metal sheets can be welded together by applying pressure and heat to the weld area with electric current by spot welding. Spot welding is popular for its effective power usage, high manufacturing rate, simple automation etc. it is ideal for automatic industry.

https://www.bwsme.com/different-welding-machines.php

0 notes

Text

Disposable Syringe Filter-GST Syringe Filter Automatic Production Line

GSTsyringe filter automatic production line equipment manufacturersbelieve that the small partners who do experiments have used disposable syringe filters. Any type of sample (food, soil, water sample, etc.) must be used once after pretreatment and before the sample is put on the machine. Filtered with a syringe filter to remove impurities and particles from the sample solution, so as not to block the instrument for long-term accumulation.

The shell of the needle filter is made of polycarbonate, polypropylene and polyethylene plastics. The upper and lower parts are welded together by ultrasonic waves. It is resistant to high pressure and there is no problem of product leakage.

The needle filter is widely used in the laboratory. It does not need to change the membrane and clean the filter, which saves the complicated and time-consuming preparation work. It is mainly used for sample pre-filtration, clarification and particle removal, and sterilization filtration of liquids and gases. It is the preferred method for filtering small samples by HPLC and GC.

Needle filter classification: liquid property classification: water phase filtration; organic phase filtration; filtration phase classification: gas phase filtration; liquid phase filtration; filtration purpose or process classification: sterile filtration; clarification filtration; pre-filtration; particle removal filtration; interface Form: female bayonet; formula socket; external dimensions: 4mm\13mm\17mm\25mm\30mm\33mm\50mm, etc.; filter layer structure: single-layer membrane structure; multi-layer membrane structure; capillary structure; hydrophobic polytetrafluoroethylene Vinyl Fluoride Membrane (PTFE): Used for filtration of air, gases and hydrophobic chemicals.

0 notes