#plastic welding machine

Text

The Application of Ultrasonic Welding Technology in Cosmetic Hose Sealing

Hose is a common item in our daily life, the tail of the hose is usually sealed up, cosmetic hose sealing machine is used to seal the tail of plastic products, the use of ultrasonic welding process to complete the pressing part of the tooth.

The principle of cosmetic hose sealing machine: the ultrasonic energy is transmitted to the welding area through the upper welding parts. Because the welding area is the sound resistance at the interface of two welding, local high temperature will be generated. And because of the poor thermal conductivity of plastic, it can not be timely distributed, gathered in the welding area, resulting in the rapid melting of the two plastic contact surface, plus a certain pressure, so that the fusion into one. When the ultrasonic wave stops, let the pressure continue, there is some time to hold the pressure, so that it solidifies, so as to form a strong molecular chain, to achieve the purpose of welding, welding strength can be close to the strength of the raw material body

Weldable materials such as: polyvinyl acetate, polyoxyethylene, polystyrene, polypropylene, polyvinyl chloride, nylon, polyethylene, nylon, polytrifluorovinyl chloride, nylon, polybutene, polyvinylidene, polycarbonate, plexiglass, poly4-methylpentene, cellulose acetate, nylon , polyacrylonitrile, polyethylene terephthalate, etc.

The features of cosmetic hose sealing machine: The cosmetic hose sealing machine is mainly used for all kinds of plastic welding, compared with the previous adhesive old method, it is convenient, clean, fast, firm, no deformation. It is easy to operate, the welding process is clean and eco-friendly. Besides, the working efficiency is high, a cosmetic hose sealing process can be finished with 1 second. It can be matched to the automatic production line to make the working efficiency even higher.

The application in cosmetic packaging industry :It is widely used in cosmetic packaging industry: cosmetic hose end sealing, toothpaste hose end sealing, hose welding, cosmetic plastic bottle welding, acrylic bottle welding, ointment bottle welding, dressing mirror welding and so on.

This article is from our website: https://www.minyangsonic.com/

#cosmetic hose sealing machine#cosmetic hose sealing process#ultrasonic welding machine#plastic welding machine

3 notes

·

View notes

Text

Best Plastic Welding machine manufacturer & Supplier in India

DK Machine Services is the leading manufacturer and supplier of plastic welding machine in India. Based in New Delhi, we offer best product and service related to it

Website:- https://dkmsplasticwelding.com/index.php

1 note

·

View note

Text

Plastic Welding Machine Manufacturers in Delhi, India

In a world that strives for innovation and sustainability, plastic welding has become a game changer in various industries. It allows the assembly of plastic materials, allowing the creation of strong, sustainable products in the environment. As the demand for quality plastic welding solutions increases, so does the need for high quality plastic welding machine manufacturers in Delhi. In this blog, we will take a closer look at some unique market players that are changing plastic welding technology.

1. EcoWeld Industries: Pioneering Sustainable Welding Solutions:

The EcoWeld Company stands out among plastic welding machine manufacturers for its consistent commitment to sustainability. They have come up with a variety of machines that not only deliver welding performance, but also bring environmental awareness. Their welding machines use energy efficient technology, reducing energy consumption and carbon footprint.

Moreover, EcoWeld's dedication to sustainability extends beyond their products. They have implemented a green manufacturing process, incorporating recycled materials into their machines and adopting eco-friendly practices throughout their production facilities. By choosing EcoWeld, customers not only invest in top-notch welding equipment but also contribute to a greener planet.

2. PrecisionBond Tech: Pushing the Boundaries of Precision

When it comes to tough welding jobs that require extreme precision, PrecisionBond Tech leads the way. This manufacturer has earned a reputation for producing high-quality plastic welding machines for industries such as medical devices, aerospace and electronics. What sets PrecisionBond Tech apart is its advanced technology that allows micron level control during the welding process. Their machines use advanced sensors and computer vision to ensure accurate alignment and alignment, resulting in flawless welds on even the smallest components. With a focus on perfection, PrecisionBond Tech helps companies reach new heights in reliability.3. RoboFusion Systems: Embracing Industry 4.0

In the era of Industry 4.0, where automation and integration dominate, RoboFusion Systems is leading the way in the plastic welding machine industry. They have successfully integrated robotics and artificial intelligence into their welding machines, bringing unparalleled efficiency and flexibility to the welding process. RoboFusion welding machines can monitor welding parameters in real time, making automatic adjustments to increase efficiency and maintain stability. In addition, they provide seamless connectivity to the production network, enabling visual monitoring and control of welding operations. With RoboFusion's advanced technology, companies can streamline production, reduce downtime and improve overall productivity.

4. InnoMelt Solutions: Revolutionizing Hot Plate Welding

Although there are various plastic welding techniques, Hot-Plate Plastic Welding Machine a special place in some applications. Dk Machine Services, Solutions has taken this welding process to a new level, making it a benchmark among Analog Ultrasonic Plastic Welding Machine manufacturers in Delhi, India. The InnoMelt machine features a new temperature control system, ensuring proper heating of components for reliable fusion. They have introduced customizable options, allowing customers to tailor the welding process to their needs. With their expertise in hot plate welding, InnoMelt Solutions serves industries such as automotive, piping, and packaging, where solid and flexible joints are critical.

5. NoviWeld Robotics: Advancing On-Site Welding

In the sections like the construction of the resources, shipping site becomes important. Noviwildd Robotics respond to this request and request showing the plastic light plastic. Their machines are designed for mobility and ease of use without compromising performance. Equipped with advanced battery technology, the NoviWeld machine offers long run times, reducing the need for frequent recharging. Additionally, their user-friendly space and remote support capabilities make on-site welding a seamless and efficient process.

As plastic welding continues to grow in importance across all industries, manufacturers of specialty plastic welding machines are leading the charge with their innovative approaches and developing technologies. open. From durability and precision to automation and portability, each manufacturer brings something unique to the table. Their contributions not only improve the plastic welding process, but also play an important role in shaping a sustainable and advanced future. From medical devices to automotive components to consumer electronics, the world's leading manufacturers of plastic welding Welding Machine in Delhi, India, are at the forefront of innovation and advancement.

#Plastic Welding Machine#Plastic Welding Machine Supplier in delhi#plastic welding Welding Machine in Delhi

1 note

·

View note

Text

Ultrasonic Hand Gun Manufacturers/Suppliers/Exporters in Pune, Maharashtra

SMAK Industries is one of the trusted Ultrasonic Hand Gun manufacturers, suppliers, exporters in Pune, Maharashtra.

We have been in this field for more than 8 years now and have an excellent reputation for quality products that we can deliver on time as promised.

0 notes

Text

Buy Portable Type Welding Machine ARC 250, Welds 4mm Continuously - Krishitool.in

Book Now: https://www.krishitool.in/product_details/Portable_Type_Welding_Machine_ARC_250,_Welds_4mm_Continuously

welding machine, mig welder, tig welder, welding machine price, gas welder, types of welders, welder arc, rod welder, spot welder, cold welding machine, mig welding machine, tig welding machine, spot welding machine, laser welding machine, arc welding machine, portable welding machine, aluminum welder, laser welder, cold welder, esab welding machine, stud welder, inverter welding machine, electric welding machine, mig welding machine price, mini welding machine, welding set, gas welding machine, wire welder, laser welding machine price, co2 welding machine, small welding machine price, tig welding machine price, small welding machine, toshon welding machine, spot welding machine price, types of welding machine, electric welder, single phase welding machine, argon welding machine, plastic welding machine, aluminium welding machine, tack welder, welding machine 250 amp price, ibell welding machine, jkarc welding machine, ultrasonic welder, single phase welding machine price, mig and tig welder, shakti welding machine, small welding machine price, welding machine price list, best welding machine, arc welding machine, welding machine price single phase, bosch welding machine price in india, welding machine single phase, welding machine 250 amp price, Arc Welding Machine, Welding, Welding Machine

#Arc Welding Machine#welding#welding machine#welding machine 250 amp price#welding machine single phase#bosch welding machine price in india#welding machine price single phase#best welding machine#welding machine price list#small welding machine price#shakti welding machine#mig and tig welder#single phase welding machine price#ultrasonic welder#jkarc welding machine#ibell welding machine#tack welder#aluminium welding machine#plastic welding machine#argon welding machine#single phase welding machine#electric welder#types of welding machine#spot welding machine price#toshon welding machine#small welding machine#tig welding machine price#co2 welding machine#laser welding machine price#wire welder

1 note

·

View note

Text

Angle Fusion Machine DWH315

Pipe fitting angle fusion machine,hydraulic operation.This machine is suitable for PE/PP/PVDF fittings,standard model make elbow from 90-315mm,90 degree equal tee and cross from 90-315mm.If want make 45 and 60 degree “Y”shape fitting 90mm to 315mm,have to choose Y clamp as optional.

Pipe fitting angle fusion machine,hydraulic operation.This machine is suitable for PE/PP/PVDF fittings,standard model make elbow from 90-315mm,90 degree equal tee and cross from 90-315mm.If want make 45 and 60 degree “Y”shape fitting 90mm to 315mm,have to choose Y clamp as optional.This machine work principle is same as butt fusion machine.Easy way to understand angle fusion machine is this machine make butt fusion tee,elbow,cross and y shape fittings.Butt fusion machine is connect plastic pipes.

Pipe fitting angle fusion machine,one year warranty

Optinal parts

Y clamp

Technical Data

IIf you want to know how much an angle fusion machine costs, or to know about different pipe fusion machines models/prices/picture information, please visit the DSL official website.

1 note

·

View note

Text

AABTools offers a range of HDPE and plastic pipe welding machines suitable for various types of welding processes such as socket welding, electro-fusion welding, and butt-fusion welding. We distribute ROTHENBERGER brand machines, which are among the leading choices for professional users in plumbing, HVAC, and pipeline sectors. These machines are designed for the reliable operation and welding of PE, PP, and PVDF pipes and molded bodies, providing complete solutions for pipe installation and associated service and maintenance work

0 notes

Text

Fully automatic mask making machines

Fully automatic mask-making machines have revolutionized the production of masks in China, addressing the global demand for reliable and high-quality protective gear. These machines have improved efficiency, ensured consistent quality, reduced labor costs, and demonstrated technological advancements.

#catheter flaring machine#high frequency hot-melting machine#thermocouple welding machine#plastic pipe extruder#automatic brazing machine

0 notes

Text

Principle of ultrasonic plastic welding machine

The ultrasonic plastic welding machine is a machine that uses ultrasonic waves to weld. It is commonly used for plastic welding and it completely replaces the traditional industry of glue bonding. The process of ultrasonic welding is not combined with materials such as bolts, nails, clips, welding materials or adhesives. There are various methods of welding with ultrasonic plastic welding machines, such as fusion welding, riveting and spot welding.

When the ultrasonic wave acts on the contact surface of the thermoplastic plastic, it produces high frequency vibrations of several tens of thousands of times per second, which reach a certain amplitude. Because of the poor thermal conductivity of the plastic, a moment can not be timely distribution, gathered in the welding area, resulting in the rapid melting of the two plastic contact surface, coupled with a certain pressure, so that it is fused into one. When the ultrasonic waves stop working, the pressure is allowed to continue for a few seconds to solidify and form a solid molecular chain, thus achieving the purpose of welding, and the welding strength can be close to the strength of the raw material.

Ultrasonic plastic welding depends on three factors: the amplitude of the transducer head, the pressure applied and the welding time, etc. The welding time and head pressure can be adjusted, and the amplitude is determined by the transducer and the variable amplitude rod. These three quantities interact with a suitable value, the energy exceeds the appropriate value, the amount of plastic melting is large, the weld is easy to deform; if the energy is small, it is not easy to weld firmly, the added pressure can not be too large. This optimal pressure is the best pressure per 1mm of the edge of the welded part and the edge.

Ultrasonic welding is commonly used for plastic welding, it completely replaces the traditional industry of gluing, there are no bolts, nails, clips, welding materials or adhesives to bind the materials together in the ultrasonic welding process, it is faster than traditional adhesives or glues and the drying time is also very fast, the welding process can be easily automated and can be easily customised to suit the specific specifications of each type products are welded.

0 notes

Text

We Avni Industries is a leading manufacturer and supplier of Ultrasonic Plastic Welding Machine in Ghaziabad, Uttar Pradesh.

For more Information Please Contact us!

+91-9716178631

#Ultrasonic Plastic Welding Machine#Ultrasonic Plastic Welding Machine Manufacturer#Ultrasonic Plastic Welding Machine Manufacturer in Ghaziabad#Ultrasonic Plastic Welding Machine Supplier

0 notes

Text

How Businesses Will Save A Lot Of Clutter In Office Space With HF PVC Machines

Businesses are constantly in the efforts or quest to save money and space. Therefore, they look for a bigger workspace and even a limited number of people. However, with time and better sales, there will be a need to expand, and that is also when you as an entrepreneur might have to invest in the automatic myclear bag making machine. These are more than just a staple in any office space from companies like Packweld. Let’s see how.

Best Packing and Storing Solutions

When you look for the best materials to store away or throw away materials, boxes and bags come in handy. However, you will need an H.F. PVC Stationery making machine when you have a business that also deals with supplying or exporting. It would create anything from bags, button bags, report files, and even pouches.

Each of these has a different utility and purpose. All that you have to do is to get a machine that makes these bags. Many would disagree and state that investing in a plastic stationery making machine. However, if you look at it from several standpoints, you will realize that it makes a lot of sense.

Highly Efficient: You may have a local supplier of bags, but there might be times when his supplies have gone down, or he has shut his business. In that case, you must not wonder about how to run your business, package it, and sell it. That should continue without any problem. It will be possible only if you are self-sufficient. Buying and setting up these plastic bag-making machines in your firm will be the most cost-efficient idea that you have ever had.

Timely Solution: For businesses with logistics playing a crucial part, you should not miss on having a P P button bag making machine. It is easy to create a batch of these button bags, and you can have them ready ahead of any delivery you have to make. Also, it is time-efficient and will not allow you to wait for a long time just for the same.

Better Management: Many firms buy these bags in lesser numbers or major quantities. They are not aware of exactly how much they might need them later on. It is where having a machine for making these in your facility might give you a better and an appropriate number as per the requirement.

#Plastic Stationery Making Machine#P.P. Doctor File Welding Machine#H.F.PVC Stationery Making Machine#Automatic Myclear Bag Making Machine.

0 notes

Text

i typed this out absentmindedly while working on like 4 different things so it may not be up to my usual standards but whatever, y'all seem to like particularly violent robot smut here

cw lesbian robot violence

--

i only got to her place about thirty minutes ago, yet she already seems to have taken a liking to me. she's been gently caressing my soft silicone skin, talking about how lovely it feels, and how pretty the clean white looks on me. she's getting a little more excited by now, growing more touchy, pressing her fingers between my panels, holding me tighter, breathing heavier

before i know it i find my comparatively tiny 150cm chassis shoved against a wall, not even attempting to resist as she effortlessly picks me up by the neck, giving me a little smooch in the middle of my glass display of a face; giggling as she sees me grow more and more flustered

"you'd make such a good toy, you know~" she whispers directly into one of my microphones, "and you'd love that, wouldn't you?~"

i can't help but nod nervously in agreement as her slightly raspy voice echoes in my head. she giggles a tiny bit again, grabbing me into a bridal carry, my flustered mind too overwhelmed to pick up on my surroundings, or where she's taking me

the next thing i know, i get roughly slammed down on a metal table, squealing as i feel some of the plating on my back crack from the impact. i stare up at her as she sits on top of me, grinning slightly

she leans down, essentially laying down on top of me, pinning me down as she starts peeling off some of my paneling. she nonchalantly tosses the bits of plastic aside, ripping out the connectors for my touch sensors

"last chance to turn back, cutie~" she warns, but the both of us already know the answer

--

she sits up slightly, picking up a hammer from underneath the table, flipping it around carelessly. she gives me another little kiss, prompting me to flash a little heart pattern on my display.. which is promptly shattered into tiny little crystals of glass by her hammer, my screaming mixing with her giggling

she then proceeds to slam her hand through the hole, seemingly not even noticing the shards of glass scratching her up as she feels around inside my head

before long she grabs onto some cables, yanking out one of my camera arrays, my servos clicking frantically before the connectors fail to hold on, one of my delicate optical modules dead in her hand, before i get to see it discarded like a piece of e-waste with my remaining two

then go my lidar and other cameras, taking a hammer right in the lenses, leaving me blind, squirming underneath her

"stay still." i hear her command as she grabs onto my neck, holding me down. i don't even get to ask what she's doing before feeling an intense heat near my back. that, combined with finding myself unable to move tells me everything. she giggles as i finally pick up on the fact that i've been welded to the table, and am not going anywhere anytime soon

--

"by the way.." she mentions, "hope you didn't think you're stuck to just a table~"

"wait, w-what is this then?"

"you'll know~" she answers, right as i hear the unmistakable whine of large stepper motors from somewhere above me, moving closer

then a piece of metal tapping on me, followed by some typing, and then the turbine-like whir of a large motor

i still have no idea what is happening, until i feel metal blades dig into the surface of my arm's plastic skin, prompting a little squeal out of me

then again, and again, and again, and again; taking out minuscule slices at a time, slowly but surely digging their way through

my squeals shift to screams as what i now recognise is a milling machine tears through my arm, shaving off layer after layer of the whole thing

as the machine cuts into my frame and wires, my mind gets flooded by erratic signals from the wiring shorting out on itself, getting interpreted as pulses of every feeling imaginable. my mind getting overwhelmed by feelings, i start to shift into weak moans, finding myself enjoying the whole process

--

"well someone is enjoying itself, isn't it?~" i hear her say as she steps closer to me, most of my arm in shreds of metal and plastic by now. and as if the sensory overload wasn't bad enough, she proceeds to lean in to kiss what's left of my face again

and she doesn't go easy, her saliva dripping through the cracks, causing minor faults in even more systems as i struggle to even maintain consciousness

--

i wake up an unknown time later in her bed, the only thing i'm able to reliably feel being her warmth and weight on top of me

she slowly wakes up as well

i try to look up at her, forgetting that i have no more visual sensors. she laughs sleepily at my attempt

"hope you enjoyed last night", she says, "…because i'm not at all done with you, toy~"

i only manage to nod slightly in agreement, not like i have a choice

…not that i'd choose otherwise even if i did

13 notes

·

View notes

Text

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

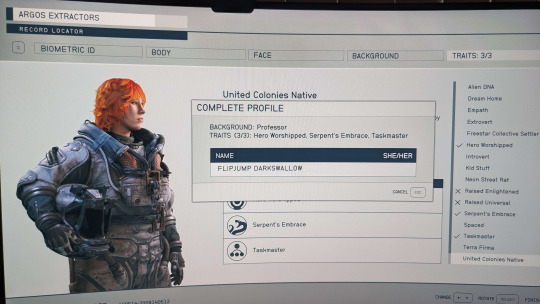

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

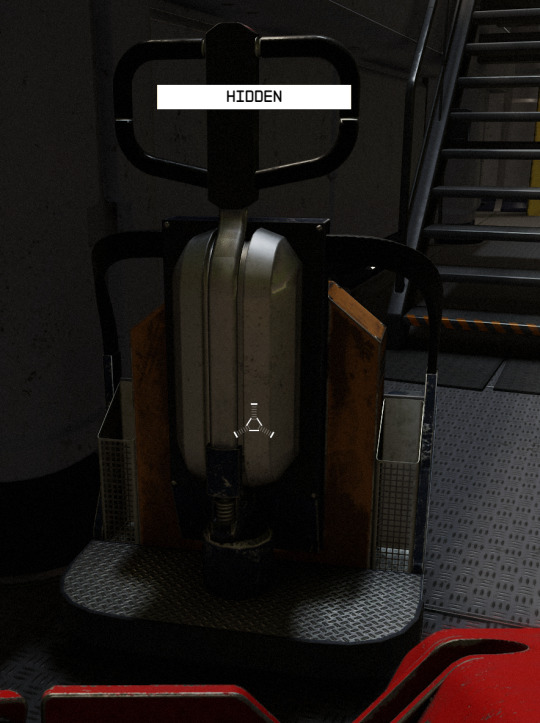

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

43 notes

·

View notes

Text

man i really am but a machine with a cluttered code. my circuits don't work as they must. some wires are plugged into the wrong ports. my folders are too full and need to be put in the trash. i am but a laptop that should have stopped working about 30 coffee spills ago, yet it still keeps moving on forward. my ventilator no longer spins as fast as it could. my parts are overheating and frying themselves. my plastic and my metal are at skin burning temperatures. the glow of my screen is fading in and out. i can't fully boot up anymore. some parts aren't welded properly. there is dust in my motherboard that has been there for lord knows how long. i am but a machine with a cluttered code.

11 notes

·

View notes

Text

What is Electrofusion Welding Machine?

Welding is a technique that uses heat, high temperature or high pressure to achieve atomic fusion of metals.In this article, the editor will tell you what an electrofusion welding machine is and the principle and instructions of an electric fusion welding machine.

The welding principle of electrofusion welding machine

The principle of electrofusion welding machine is as follows: the electric welding machine rectifies and filters the alternating current, inverts it, reduces the voltage, and then rectifies it, and finally outputs a low-voltage DC voltage suitable for welding (there were also some welding machines that output alternating voltage in the early days). Generally, the welding metal is used as the base material. One of the two poles of the welding machine is connected to the welding wire or electrode (TIG is self-fusion, generally tungsten electrode). When the welding machine outputs voltage, a loop is formed between the welding wire and the base metal to generate an arc, and the arc energy melts and fuses the base metal and the welding wire, and finally achieves fusion at the atomic level.

The instructions of electrofusion welding machine

1. Prepare the electrofusion welding machine, PE pipes and fittings that need to be welded.

2. Remove the oxide layer on the insertion end of the PE pipe and insert it into the electrofusion pipe fitting. The pipe fittings inserted into the pipe fittings should be easily inserted. Do not force the pipes into the pipe fittings. The pipe fittings are inserted too tightly. During welding, the electric heating is easily displaced during the expansion process of the PE material after heating, thereby changing the temperature change caused by heating. It is easy to cause the local heating temperature to be too high and cause failures such as welding smoke. In special cases, such as the insertion of the pipe into the pipe fitting is not in a straight line, that is to say, the pipe and the pipe fitting are not coaxial. In this case, a special linear device is required to fix the pipe and the pipe fitting to reduce the stress of the pipe inserted into the pipe fitting.

3. When ready, insert the output electrode of the electric fusion welding machine into the electrode column of the pipe fitting.

4. Start the electric fusion welding machine, scan the barcode or input the voltage and time parameters to be welded to start welding.

After the welding countdown is over, the output cable can be removed without affecting the cooling and welding of the pipe, and the next welding can be started.

Electrofusion Welding Machine supplier - DSL

DSL will build one stop solution for full range of plastic pipe fusion equipment.The products of DSL contain butt fusion machine, HDPE fabricated machine, band saw, hand extruder, socket fusion machine, electrofusion coupling, pipe tools and so on. Electrofusion welding machine EF250 is one of our hot products, more product details as follow:

If you want to know more about our products, you can contact us or visit our website anytime.

1 note

·

View note