#small welding machine price

Text

Buy Portable Type Welding Machine ARC 250, Welds 4mm Continuously - Krishitool.in

Book Now: https://www.krishitool.in/product_details/Portable_Type_Welding_Machine_ARC_250,_Welds_4mm_Continuously

welding machine, mig welder, tig welder, welding machine price, gas welder, types of welders, welder arc, rod welder, spot welder, cold welding machine, mig welding machine, tig welding machine, spot welding machine, laser welding machine, arc welding machine, portable welding machine, aluminum welder, laser welder, cold welder, esab welding machine, stud welder, inverter welding machine, electric welding machine, mig welding machine price, mini welding machine, welding set, gas welding machine, wire welder, laser welding machine price, co2 welding machine, small welding machine price, tig welding machine price, small welding machine, toshon welding machine, spot welding machine price, types of welding machine, electric welder, single phase welding machine, argon welding machine, plastic welding machine, aluminium welding machine, tack welder, welding machine 250 amp price, ibell welding machine, jkarc welding machine, ultrasonic welder, single phase welding machine price, mig and tig welder, shakti welding machine, small welding machine price, welding machine price list, best welding machine, arc welding machine, welding machine price single phase, bosch welding machine price in india, welding machine single phase, welding machine 250 amp price, Arc Welding Machine, Welding, Welding Machine

#Arc Welding Machine#welding#welding machine#welding machine 250 amp price#welding machine single phase#bosch welding machine price in india#welding machine price single phase#best welding machine#welding machine price list#small welding machine price#shakti welding machine#mig and tig welder#single phase welding machine price#ultrasonic welder#jkarc welding machine#ibell welding machine#tack welder#aluminium welding machine#plastic welding machine#argon welding machine#single phase welding machine#electric welder#types of welding machine#spot welding machine price#toshon welding machine#small welding machine#tig welding machine price#co2 welding machine#laser welding machine price#wire welder

1 note

·

View note

Video

A welding machine by SupplyVan that is a versatile tool that can be used for a variety of welding tasks. With the convenience of a supply van, welding machines can be easily transported to job sites, saving time and money. Benefits include increased productivity, improved quality control, and the ability to work in remote locations. Visit our site to know more.

0 notes

Text

RE:BOOTING, Awakening.

Part one-> Here.

Have fun!

———————

There are three things John believes in. The divine, The machine, and The flesh.

His own body has been over, under, twisted around this conglomerate of parts for months. People have called, texted, mailed him for Christ's sake. But there's nothing more important than feeling unforgiving metal bend under his human hands.

Ghost is a machine so broken and tragic, John cries when he's alone with it.

he forgets there's a human inside of there, forgets though always passively aware of the chip in the machine's name where he works around it. When he's welding metal together, wiring it, staring into its chassis with adoration and wonder, he neglects the fact there is a human ‘soul’ in there, waiting to wake up.

John's never been dead, he doesn't know what the real man inside the metal feels.

But he longs, he wants to shove more than his hands inside this robot. This Replicant, he wants to become one with it, in a body he's created himself. In his hazy mind he believes there's god inside this machine, because there is some god in everything and in him, and he is inside this machine, bits of himself- his handiwork, his blood, his sweat, the tears from drunk nights sobbing over a machine while he tells it things he could never admit to himself.

It takes his time, his sleep, his awareness away from the world. There's a bottle of medication right by his night stand and everyday he avoids it, he's so focused now. There's never been anything else like this, like peeling the synthetic skin away from metal and improving what couldn't fix itself. John doesn't want to lose any attention he has on this machine.

Days and nights pass, he prolongs the inevitable, making tiny worthless upgrades, small details, painting back some of Simon Rileys tattoos onto the cold dark grey metal, they barely show up unless in the right lighting but who cares? Anything but turning it back on, anything but having the man inside look upon John and see what he's done, to see him, see inside John's head and every thought he's had while inside him.

John hopes robotic bodies don't hold memories, he hopes when a Replicant's body is turned off that they can't see anything, can't hear anything, he hopes Simon is sleeping well in whatever realm of data his soul is in now. He doesn't want to be seen, he just wants to work. Free to love and care for things that feel nothing at all.

When he turns this machine on it will cease to be just that, it'll be a person. A person who will look down at themselves, call it good, and never see him again.

He'll be letting go of the best thing he's ever made, he'll be letting go Ghost.

[«»]

Time catches up anyway. He sends the email and they respond in kind. A week from now John Price, Kyle Garrick, and Kate Laswell will arrive at his office, So it's time. John will turn the ‘key’ and Simon will wake up.

When he does, for a brief moment he considers a gift from god- there is silence. Those brown eyes blink open, the synthetic skin on his face and neck pull when he turns his head, scrunches when he sniffs the air. John has never felt so… unsure of what he's done.

“Where am I?” Simon's head pulls up, he rattles against the metal table, john looks down in shame and purses his lips- unable to really make anything of his own doing.

“Where the hell am I?!?” Simon rattles again, John looks away from the restraints on him in guilt.

Simon continues his questioning, his flailing, John can only hope it'll end soon so he can get a word in- maybe explain. But in truth, how could he explain being reborn into a machine?

The sounds grow closer and John makes nothing of it until a towering figure blocks every inch of his vision.

Of course, he would make Ghost inhumanly strong, and of course he would fail to make proper restraints.

“Who are you, what orders were you given?”

Simon's face looked down at him, that face he had painfully put onto a plate he 3D printed just so he could keep it as accurate to what few pictures he was given. Scars and everything, even those tiny freckles he hand painted on- exactly where they should be.

Orders, right, orders are much easier to explain.

“You're aware of what a replicant is, yea?”

God let him keep his eyes anywhere but on the man in front of him.

“Captain Price, your superior; found you dying in Texas of all places- put you in a very old Replicant soldier body that was beat up and declared a spare.”

John thanked whatever gods out there that Simon had taken steps back to sit on the table, the table with broken leather straps- Christ above.

“He came to me to fix you up the best I could, so I did. Fix you, I mean.”

He felt… tired, John didn't bother explaining even more. couldn't really think beyond the sudden wave of exhaustion. Instead he sat down at his closest chair and bemoaned some of the papers and parts Simon had stepped on.

There's a giant silent expanse between them, John yearns for cold metal with no gaze to freeze him solid.

“When am I on active duty.”

John bites his tongue, goes for a cup of coffee on his desk he knows is cold.

“Price is coming around with the rest of the squad in three days, presumably he'll move you and you'll be in their care.” He can't keep the bitterness out of his voice.

Simon is prone to one word responses and direct questions, John shouldn't blame him for it. He doesn't, not really, he blames himself most of all. For getting involved with a Replicant, for spending what little sleep he got at its bedside, for whispering his secrets into a hollow skull.

“And you?”

Oh, John doesn't know. What does anyone do when losing a part of themselves?

“I'll move on to other projects- military always has issues with something, once someone gets word about who patched you up, i'll get more orders. I do good for myself.”

He wants to brag, he wants to brag and act like Ghost isn't the best thing he's worked on in his life.

“Right.”

[«»]

In the end those three days are spent in silence. Simon only needs to recharge really, so John goes back to sleep in his bed. The world has never felt colder.

He's not listening to their reunion, not really. Price is happy to see Simon again and Garrick makes his introduction- he's charming and John finds he likes the people in this squad, it's certainly better then some.

Laswell is who he spends most of the time with, there's papers and documents of all kinds. John wants to poke fun at them using ancient methods like a paper contract but he's still so tired.

In truth, the only thing that really catches his attention is when Price turns to him and asks him, John Mactavish, to join the one-four-one.

It's been years since he'd been on a military base, he shriveled at the thought of shitty “laboratories” and rec rooms full of people that became uninterested in him once he spoke about what he was truly passionate about.

He lays down his clauses, he'll work here, loath to change his environment.

There's a secret glee inside of him though. Proper gym equipment, maybe the opportunity to work on more specialized robotics then just his usual contract allows. When he says yes, Kate slides his contract from under the one he just signed.

Quietly it feels like fate.

——————

👍I take my leave.

#mw2 2022#cod modern warfare#call of duty mw2#simon ghost riley#ghost mw2#ghostsoap#johnny soap mactavish#cod mw2#very badly written sifi#call of duty modern warfare#modern warfare#modern warfare 2#modern warefare ii#cod mw3#ghost cod#cod mwii#ghoap#I swear the religious stuff wasnt supposed to be there#you can blame it on me letting my partner talk about preachers daughter by Ethel Cai#I think it screwed those last two tags I dont know because im on mobile life is such joy :)

27 notes

·

View notes

Text

cw: slavery, dehumanization, noncon strip/nudity (nonsexual), adult language, alcohol mention

previous ///// masterlist ///// next

×××

The sun was rising when they reached the slavers' camp. The journey has dampened Judd's unwanted hangover enough for him to focus, and he made an effort to determine their direction of travel.

East. Right into the fucking sun.

He angled his head to avoid the light, doing anything he could to lessen the pounding in his skull.

Fucking wine. He almost wished Skye would've just kicked his ass instead of resorting to creativity. It had been almost a whole day since he'd had any water, and the booze only served to rush the dehydration process.

Water first, he thought. Then I'll get the hell out.

The slaver camp was a lot smaller than the site Judd called home, just a few makeshift buildings and a public area protected from the sun by a tarp. There was a weapons rack, and a pile of what looked like spare speeder parts. Tools he could use to escape, or fight his way out when the time was right.

He tried to ignore the other objects in the area. Shackles. Whips. A metal pole with a length of chain welded to it, and a small rusted cage a foot away from that. Cage and manacles were both empty. He'd find no allies here, but there didn't seem to be many enemies either. Aside from the two that had snatched him, there were only a handful others, coming out of their huts or getting up from cleaning their weapons to see what their buddies had returned with.

Judd was dumped just shy of the shade, struggling to lift his head as a pair of boots came into view. They were attached to a woman, well-muscled and covered in freckles.

"Brought me back a treasure, eh?" she said, lifting his chin with the toe of her boot. He jerked away, falling back onto the cracked dirt, and wincing as the movement drove a fresh spike of pain through his head.

"Wreck was deserted by the time we got there, but this idiot made the mistake of sticking around," Rika replied.

Sticking around? Yeah, picking on the kid had been a mistake, but Judd wasn't fucking stupid.

"What do you think, Sonora?" Rika's partner said. "Good haul?"

"Should make us a pretty penny," the other woman said, approval in her voice. "Get it settled in."

It. He was already written off as an object to them, something that had no value aside from a price tag.

The pair moved to obey her, dragging Judd under the tarp and into the marginally cooler shade. His arms—by now well past aching—were freed at last from Skye's bindings. Rope was swiftly replaced with metal cuffs, each one connected to a long chain that trailed upward, wrapping around a beam that sat a few feet above his head.

Not just a beam, he saw, noticing gears on either side of it, interlocking all the way down to hip height, where a handle jutted out. Some kind of mechanism, probably designed to shorten his leash whenever they saw fit.

Clearly the group had way too much time on their fucking hands, but if nothing else, the machine told him this was their permanent base.

Good. When he got out, he'd come back here with a hoard of scavs. Burn it down.

"Let's get a look at it," Sonora said, and Rika moved to the handle, confirming his suspicions as she cranked it until the chains were taut and his arms were suspended above his head. Maybe it was procedure, maybe she'd just made up her mind to give him misery, but she didn't lock the mechanism in place until Judd's feet were barely touching the ground.

He cursed through the gag, shooting her a hateful glare that was pointedly ignored.

Sonora selected a knife from the weapons rack and closed the distance on him. He did his damnedest to jerk back as she set the blade against his chest, but she didn't cut him, instead slicing through the fabric of his shirt.

Judd let out a muffled yell of protest as she moved to his jacket, a fancy sun-reflecting thing he'd paid out the ass for. She didn't seem to care what it was, cutting it away without hesitation and discarding it at his feet.

His pants and boots followed it, but Sonora didn't stop there, slicing away in cool-eyed silence until he was stark naked.

Judd tried to reign in his pride and breathe steady through the gag. If he let the frustration, the humiliation, get to him, it would just make his headache that much worse.

Nudity didn't bother him. Water was too scarce for showering to be a private affair, and scavs were generally too pragmatic to find a lack of clothes taboo.

This was different. This was being put on display, stared at by his captors while they figured out how much he was worth.

I'll break out. Pick the locks. They'll be sorry.

"Hm," Sonora said, and he flinched as she ran a finger across his abdomen. "Strong enough for the pits, pretty enough to be a pet. What do you think?"

Rika snorted. "I think it's the highest bidder's choice."

"So it is." She stepped back, kicking away the remains of Judd's clothing. "Go ahead and let it down. Can't put it up for auction half-dead."

Rika pulled back on the lever, and the chains went slack. Judd cried out as he hit the ground, pain shooting through his knees as they took most of the impact. It was becoming more and more difficult to want to get up, but he did, pushing himself to a sitting position with a groan.

Sonora had reappeared beside him, a canteen in her hand.

Water.

She was close enough that he could probably grab her. Get her weapon, use her as a bargaining chip. But he was too thirsty to try.

She reached behind his head, untying his gag and removing it from his bone-dry mouth.

Despite the burning urge to start cussing her out, Judd held back. Drink first. He reached for the canteen, but Sonora took a quick step back.

"Ah ah. You get what I give you or you get nothing," she chided. "And I only give what is earned."

Because of fucking course she did.

"Kneel," Sonora continued. "Hands on your knees, head bowed. Show me you can be obedient."

As debasing as it was to follow her commands, Judd wasn't about to give up the water. He moved to his knees, glaring up past sweat-damp hair.

"That snarl could use some work, but we have time," Sonora said. "Good boy."

All reason fled his body at her words, his head snapping up. "The fuck did you just call me?"

Behind him, Rika let out a short laugh. "Told ya it had a mouth."

"It just needs to learn some respect," Sonora said, looking vaguely annoyed.

"My name is Judd," he spat.

"You don't have a name anymore," she replied, not flinching as he lunged forward, the chains halting his movement before he got within a foot of her. The sudden stop, combined with his bound ankles, unbalanced him, and he landed gracelessly on his side.

He saw Rika reach for a whip, but Sonora held up a hand to stop her.

"It has enough scars as is. We don't need any new marks before auction."

"My name is—" He was cut off by a boot to the gut from Rika.

"Bruises will heal," she said, in response to the stern look from Sonora, who sighed and shook her head.

"I'm sure they will. You and Bo go ahead and get some sleep. I'll take it from here."

As Rika and her partner disappeared into one of the huts, Sonora moved to the mechanism Judd was attached to, adjusting the upper bar until it was level with the ground, then reeling in the chains until he had no room to move, arms once again restrained behind him. Once that was done, she left.

Judd let his head drop, drawing his knees up to his chest. Maybe he was stupid. Letting his anger get in the way of fucking survival.

She'd be back, wouldn't she? They'd gone through the trouble of taking him, they wouldn't just let him die and miss out on their payday.

He pulled at the cuffs. Just needed to wait until Sonora tried again. He'd choke down his pride and comply. Get her to drop her guard.

It hadn't been long before she returned, still holding the canteen. She knelt in front of him, much closer now that he was locked up tight.

"Good boys get water," she said, but held the canteen to his lips anyway.

He drank so quickly he almost choked, feeling relief wash over him as the liquid ran down his throat. It wasn't until he'd drained the entire thing that he noticed the strange aftertaste.

Sickly sweet, like something on the verge of rotting.

He knew what was coming then, the kind of bullshit these people would resort to in order to keep him down. Sonora smiled at him as she capped the canteen.

"Bad boys get Compliance."

×××

tag list:

@kira-the-whump-enthusiast

#whoops forgot to add tags#whump#whump writing#judd harlow#tw slavery#tw alchohol mention#tw noncon drugging#nonsexual nudity#tw violence#tw adult language#forced stripping#tw dehumanization#defiant whumpee#it as a pronoun

28 notes

·

View notes

Text

Boiler Not Firing Up For Central Heating

Orders positioned after 9pm on Thursday, and up to 5pm on Sunday, might be out there for assortment on Monday. Once you could have placed your order on-line, we’ll have it prepared for you on the store you have chosen in as little as 5 minutes. We will hold your order for 14 days, after which we'll automatically generate a refund to the cost type you used to place the order. No need to drain down the entire system best for small, single-use DIY or home plumbing jobs. Until you log in, your list might be saved temporarily and might solely be accessed from the system you are utilizing now. For an uncovered pipe, you presumably can attempt making use of heat to the pipe itself.

At PLS , our quadrina drilling and tappings may be done with out interruption to product circulate or disruption to service. At Pipeline Services , we pride ourselves on with the ability to supply the absolute best service to our prospects for all sectors of the business. In-house fabrication and machining services permits us to provide the business with both mechanical and welded fittings globally. Open up cupboards underneath sinks or basins and depart your loft hatch open in a single day to permit warm air to flow into.

If regardless of taking precautions to minimise threat, the pipes in your vacation cottage do freeze, here’s what you should do to attempt to prevent a burst. If unsure, always seek the advice of a registered plumbing and heating engineer for help. If your boiler runs on oil or LPG fuel, guarantee that you have sufficient gasoline to heat your property over winter. You don’t need to run out and discover your provider is unable to deliver because of extreme winter climate. If you run out of oil, make certain that the water is turned off at the mains stopcock and the water system is drained down.

district heating services

To compliment this, we provide a great vary of pipe freezing equipment with capacities as a lot as 100mm. In difficult conditions pipe freezing can provide a versatile resolution to project completion. In the kitchen, depart cabinet doorways open overnight to allow warmer air to circulate spherical pipes, or take away kickboards beneath kitchen models. If you’re planning on being away from residence, look at ways of preserving a minimal temperature inside to stop temperatures dropping too low and pipes freezing. Pipefreezing eliminates the time and price of drain downs, chemical waste elimination and refilling. New pipe work, plant or gear could be strain tested in situ by isolation, saving further delays and expense.

The most important industrial utility for Polybutene-1 (PB-1) is subsequently in plumbing pipe for residential and industrial use. With superior temperature and thermal capabilities compared to different supplies, it endures and continues to perform both in low and high temperature purposes. The flexibility of Polybutene-1 pipe assists installers and eliminates water hammer noise.

The webpage above also consists of data on the method to find a cease tap outside a house or business. Have the name and telephone variety of your nearest WaterSafe qualified plumber to hand. As direct heat may trigger everlasting harm to the pipes and could also result in a hearth within the home.

It is really helpful to depart the heating completely on to maintain a minimum temperature of 13 degrees C. There are many rooms in your house that may undergo from pipe freezing. However, the coldest areas of your property are more probably to undergo the most.

Once you've shut off the availability, open the faucet to let water drain out and air flow in. This air provide will be certain that any water that does stay in the faucet after it's been shut off has room to increase. For this cause, it is crucial to shut off the valve that lets water circulate into the tap over the cold winter months – before the primary frost. Typically, an out of doors faucet could have a shut-off valve contained in the property, and it is water remaining in the pipe leading up to this valve that's the problem.

Locate the bottom of the bib on the other facet of the wall, most likely within the basement or crawl house, and wrap the realm with towels and rags. Remove any garden hoses from the spigot, drain the line, and wipe down the hose. Coil it, and store it in a clear, dry, indoor house, corresponding to a shed or storage. Keeping hoses away from spigots also keeps relations or pals from reattaching them and leaving them to freeze on accident.

#district heating services#leak detection systems#hot tapping#pipe freezing#district heating pipes#district heating pipe#pre insulated pipework#hot tapping contractors

2 notes

·

View notes

Text

Stainless Steel Forkable Square Tank with Insulation

| Product Description

Presenting our Square Wine Tank – a specialized solution meticulously designed to meet the demands of small-capacity requirements. This tank is an ideal choice for the storage, transfer, and fermentation of limited quantities of pressed grapes, grape juice, and wine.

The square configuration of this tank optimizes space utilization, ensuring efficient handling and transportation. Engineered to be safely operated with forklifts, pallet jacks, and trailers, it offers convenience for storing, processing, and transporting full tanks of wine.

Crafted with precision and meticulous attention to detail, our Square Wine Tank adheres to the highest industry standards. Its robust construction guarantees durability and longevity, safeguarding your valuable wine throughout the storage and fermentation journey.

Whether you're a small winery aiming to enhance production capabilities or a wine enthusiast in search of a reliable storage solution for your collection, our Square Wine Tank stands as the perfect choice. Rely on its professional design and functionality to elevate your wine-making experience.

Make the investment in our Square Wine Tank today and elevate your wine storage and fermentation to unparalleled heights.

| Certificate

Over 100 patents including utility,invrention and industrial design.

Pass through ISO certificates of ISO9001/22000/ 45001, and other export certificates of CE, PED, API650, AS1210, AS1692, CSA.

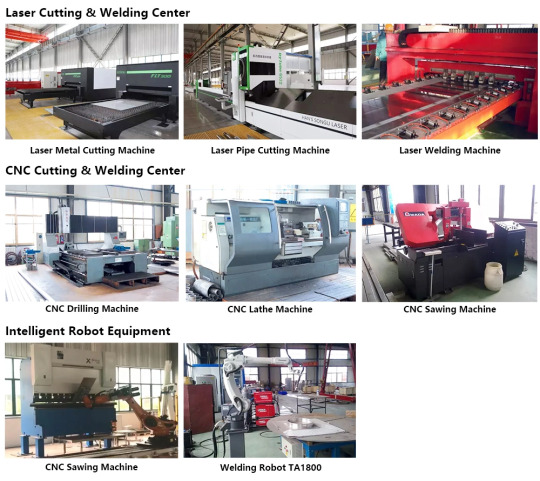

| Processing Machinery

Pretank use advanced processing machines to fabricate our stainless steel tanks,including auto Robbot welding machine,laser cutting/welding machine,CNC lathe,plasma cutting and automatic welding machines.

The machines replace labor working and minimize the human fault& tanks defects,improve tank quality, shorten construction period.

| About Company

Pretank is established in 1971, it's the largest-scale and longest-history stainless steel vessels manufacturer in China,with 4000 staff, 666,000 m㎡ floor space and US$240 million annual sales. We have the most advanced technology, R&D capability in the industry,adopt solidworks and AutoCAD to design vessels, Engaged in formulation of National Standard in designing, producing, inspection and transportation.

53-Year History in Tank Fabrication

Prettech stainless steel tanks already used in 40 classifications,gather rich experiences and precipitate skills in varied industries,win 100,000 client’s trust

Guarantee Quality

- Ensure no leaks no rust, easy cleaning.

- All tanks are over engineered and heavy-duty made, lengthen tank service life.

- Stainless steel tanks produced by automatic and laser machines, reduce labor fault.

- Each tank is strictly tested and inspected before delivery.

- We pass through ISO certificates CE, PED, API650, AS1210, AS1692, CSA, supply 2-year warranty.

Competitive Price

Scale production and automatic machines reduce cost, Pretank always perseus the most reasonable price policy to share the profits with our consumers and distributors. With same quality our price are more strong competitive.

Customize Service Free of Charge

Our bespoke tanks are tailor-made for each project, considering material, strength calculations, dimensions, fittings, and ports.We listen carefully to your needs and provide humane designs.

Lifetime Engineering Service

At pretank family, you will get lifetime engineering service! Installation service on your site, making all the AutoCAD drawings for you, completely free parts replacement in the warranty date, low cost parts supplied out of the warranty, technology support door to door, lifetime consult support.

| FAQ

1. Can you produce tanks with S.S.316L?

A: Yes we can, the wetted-parts are produced by S.S.316L to guarantee the corrosion resistance, the non-wetted parts are produced by S.S.304 to reduce cost.

2. What’s the lead time?

A: 35-50 working days depend on the order quantity.

3. How do you ship the goods?

A: We usually ship by sea in containers or flat rack.

4. Do you supply door to door shipping?

A: Yes we do, Pretank do ocean shipping, customs clearance, import procedures and deliver products to the appointed place.

5. What inspections will you do before delivery in your factory?

A: All tanks would be tested by static pressure test, dye penetration or X-ray test if requested.

0 notes

Text

wmass exclusive agent in KSA

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a reputable manufacturer of Carbon Steel Flanges based in India. Our extensive line of flanges encompasses various types and material grades, meticulously engineered to meet diverse requirements. Each flange is precisely crafted with a blend of carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium, tailored to specific material grades as indicated in our Carbon Steel Pipe Flange Price List.

Renowned for their unique dimensions and strengths, our WMASS Carbon Steel Flanges boast a minimum tensile strength ranging from 485MPa to a minimum yield strength of 250MPa. Among our offerings, the Flange ANSI B16.5 Class 150 represents a medium-pressure class within the B16.5 standard. We carefully select materials and pressure classes based on nominal bore sizes and wall thicknesses to ensure optimal performance.

Covering nominal bore sizes from ½ inches to 48 inches and classes such as WMASS Carbon Steel Flanges Rating with varying pressure ratings, our flanges cater to a wide range of applications. Whether it's for permanent or temporary termination of pipe connections, our Carbon Steel Blind Flange is a versatile choice, with permanent connections welded and temporary ones secured with bolts and nuts. Additionally, our CS Lap Joint Flange stands out with its lap joint design, offering added flexibility.

Renowned for their durability and high wear resistance, our carbon steel flanges provide reliable solutions across industries. For detailed information on Carbon Steel Weld Neck Flange Dimensions, pricing, and any further inquiries, please do not hesitate to reach out to us.

Specifications of WMASS Carbon Steel Flanges Companion Flanges:

Sizes: Ranging from 1/2" (15 NB) to 48" (1200NB) DN10~DN5000

API Flanges Standards: ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092

API Flanges Pressure Rating ANSI: Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS

API Flanges Pressure Calculation in DIN: 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64

JIS: 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K

UNI: 6Bar 10Bar 16Bar 25Bar 40Bar

EN: 6Bar 10Bar 16Bar 25Bar 40Bar

Coating: Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized

Most Common Types of API: Forged / Threaded / Screwed / Plate

Test Certificates: EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc.

Production Technique: Forged, Heat treated, and machined

Connect Type/Flange Face Type: Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove

Special Design: As per your drawing, AS, ANSI, BS, DIN, and JIS, 15 NB (1/2") to 200 NB (8"), Equal and Reducing Configurations

Test: Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector

Equipment: Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine, etc.

Origin: Indian / West Europe / Japan / USA / Korean

Manufacturer of: ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE, etc.

API: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

API Flanges Uses & Application: Bitumen upgraders, Heavy oil refineries, Nuclear power (mostly seamless), Petrochemicals, and acids

Export to: Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc.

Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175

For More Information:

Visit Our Website: https://www.merakimetals.ae

Contact No: +971-523973687

E-Mail ID: [email protected]

#Carbon Steel Flanges in UAE#CS Flanges in UAE#Carbon Steel Flanges Stockist in UAE#WMASS Carbon Steel Flanges#WMASS Carbon Steel Flanges UAE#WMASS Carbon Steel Flanges Manufacturers

0 notes

Text

Welding Machinery

The global welding machinery market has an estimated value exceeding USD 19.5 billion in 2019, with a projected Compound Annual Growth Rate (CAGR) of 2.4% until 2028, resulting in a 1.2X increase in revenue opportunity. This growth is primarily fueled by external macroeconomic factors such as construction and automotive sales.

Welding machinery finds application across a wide spectrum of industries, including chemical, metal fabrication, construction, and automotive sectors, thus presenting lucrative market opportunities. This diverse end-use landscape has attracted numerous companies to operate within the segment, facilitated by lower operational costs and robust demand.

The global welding machinery market is characterized by high fragmentation, with players predominantly relying on direct distribution networks for agility. Despite being price-intensive, particularly with numerous small-scale players in the Asia Pacific region, the industry is gradually moving towards consolidation, driven by evolving business structures in heavy industries and increased industrial automation. Leading players are actively embracing advanced technologies to maintain competitiveness.

The industry experienced a slowdown between 2010 and 2015 due to economic recession, particularly affecting the manufacturing sector, with construction being hit the hardest. However, the construction industry witnessed a significant rebound in 2017, especially in North America, where several infrastructure projects have been initiated. This growth trend is mirrored globally, with Asia Pacific exhibiting the fastest growth rate.

The automotive sector represents another significant market for welding machinery players, given the substantial volume of car sales and the rapid adoption of automation technologies. A shift from manual to automated welding machinery is anticipated during the forecast period, presenting substantial sales opportunities, albeit with higher initial operational costs.

Global Welding Machinery Market Size and Forecast: Regional Analysis

Asia Pacific accounted for over 35.7% market share in 2018, driven by extensive infrastructure projects and robust automotive sales. China, in particular, has emerged as a key hub for industrial players, supported by its substantial manufacturing output and investments in green mobility initiatives. With manufacturing contributing significantly to China's GDP, the country holds a dominant position in global electric vehicle (EV) sales, further bolstering the welding machinery market.

Global Welding Machinery Market Size and Forecast: Competition Landscape

Key players in the welding machinery market include:

Panasonic Corporation

Denyo Co. Ltd.

Daihen Corporation

Illinois Tool Works Inc.

Carl Cloos Schweisstechnik GmbH

Manufacturing Technology Inc.

Hobart Brothers Company

Fronius International GmbH

Coherent Inc.

IDEAL-Werk

IGM Robotersysteme AG

Kemppi, Kiefel GmbH

Kobe Steel Ltd.

ESAB

KUKA AG

Industry Segmentation

By Type:

Arc Welding Machines

Gas Welding Machinery

Laser Welding Machinery

Ultrasonic Welding Machinery

Resistance Welding Machinery

Others

By Level of Automation:

Manual

Semi-Automatic

Automatic

By Application:

Automotive

Construction

Metal Fabrication

Marine

Aerospace

Others

0 notes

Text

Bareer supply parent line price | Supplier | Quotes (the top ten manufacturers in Jiangxi Copper Volleyball Team)

Our company insists on giving back to the majority of new and old customers with high -quality parent processing machine products and satisfactory after -sales service. I sincerely welcome friends and friends of merchants to come to the guidance and discuss cooperation matters.

The copper row processing machine is generally composed of three industrial stations: punching, bending and shearing. The hydraulic driver is used to control the control of each process by PLC. , It is a high -efficiency small machine tool for the large -scale processing mother of the electrical industry. As one of the three major stations, the scissors station, its function is to cut off the copper row of 20 to 160mm and 3 to 15mm thick and ensure the smoothness of the incision and the vertical of the section. The focus and difficulty in design. Bareer supply Maternal Machine Price | Supplier | Quotes

The busbar machine is the main product of our company. We have been operating for many years, and strictly control the quality of the product. Because of this, we have been favored by consumers. Previously, this site also introduced some knowledge about the parent machine. Today we continue to continue Let me introduce the role of the parent line machine without contribution.

The parent line supply bus price | Supplier | Quotes Parallel placing mechanism from the literal understanding is that the direction of the line is in a parallel position. Under the processing mode of flat lines and multi -wire and wound, it is characterized by small space. The mechanism is equipped with a sliding brake or pneumatic brake as a tension generator, which is generally configured in the medium and large bus.

After mechanical transmission, the servo system also requires that the servo system has excellent static and dynamic load characteristics, that is, when the servo system changes in different load conditions or by winding conditions, the main axis is constant. Because the CNC bus has put forward strict technical requirements for the servo system, the servo system also puts forward strict requirements for its own specialized servo motor:

Cited with copper row, welded with special solder welding, such as triple welding wires, disadvantages: 1 welding is more expensive, 2 uses oxygen acetylene to heat the copper row, and stick copper aluminum together with melted welds. Low can only be hand -welded, and automatic production cannot be achieved. The parent supply of the parent line machine price | Supplier | Quotes

The precision parent line machine is generally equipped with a very high -precision servo control system, which can complete the winding system of the precision coil. The line effect is better than the CNC model. It is suitable for fine winding for fine lines. It can also complete a more complex winding process. Essence

0 notes

Text

How to Make a Bookmark With Cricut: A Stepwise Guide

Hey, Cricut enthusiasts! Are you in search of a tutorial on how to make a bookmark with Cricut? Be patient, as I have covered everything in this write-up. I always need a bookmark to keep track of my reading progress in books. Without it, I can’t continue reading books. Since I forget things a lot and can’t remember which page I read last time, it becomes essential for me to keep a separate bookmark for each book😅.

But don’t you think it costs so much to buy a new and small bookmark from the store🤑? Damn, its price is really high! I couldn’t afford that much, so I thought I’d create one myself. Yes, being a crafter, if we can’t make a bookmark using Cricut, then what’s the point of crafting? If you want to create a glitter bookmark with me, hop on a board with me!

Step 1: Start a New Project on the Cricut App

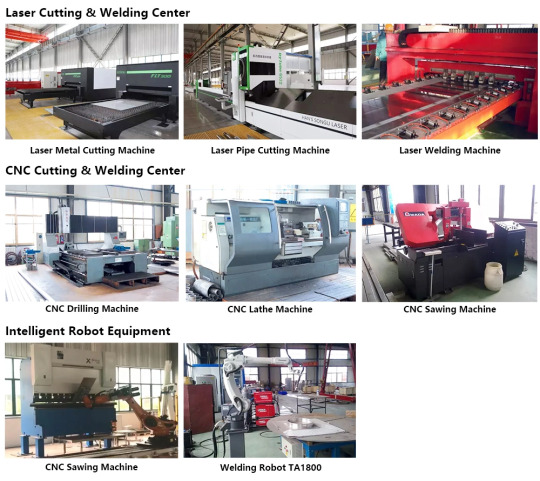

Before we delve into how to make a bookmark with Cricut, you need to ensure that Cricut Design Space is installed on your compatible computer device. After that, follow the steps in the section below:

You have to open up your Design Space app and start a New Project.

Go to the left toolbar menu and select Images.

Then, open the Art Type menu and choose Draw Only.

Afterward, you will need to type “Enjoy the Little Things” on the search bar and press Enter on the keyboard.

After that, you have to select the design that you are looking for and click on the Insert option.

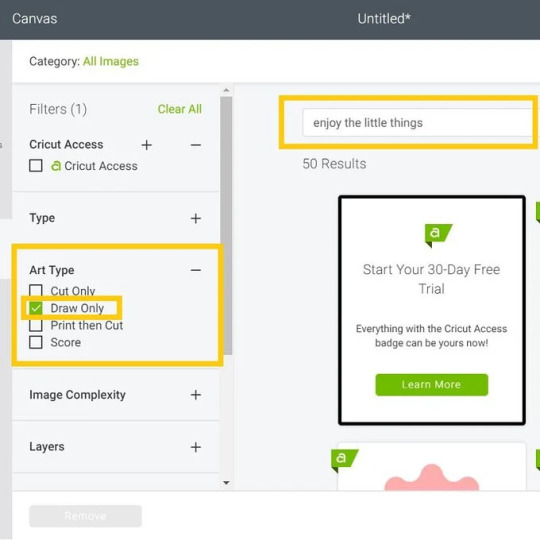

Step 2: Edit the Bookmark Image

Step 3: Adjust the Shape and Size

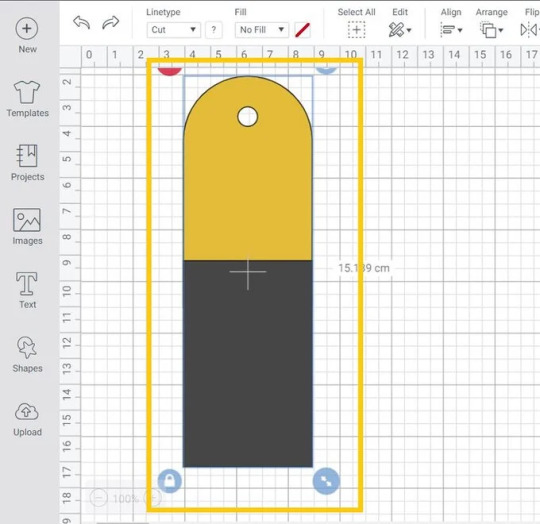

Now, we need to adjust the width of a rectangular bookmark as per the required size. For this, go to the Shapes menu, and you will need to insert a square. Hit the Padlock icon so that you can adjust the width and height of the shape.

Step 4: Arrange Your Shape

Once you are satisfied with the placement, you should drag the selection box over both shapes and select Weld to join both shapes together. Then, you need to weld the design to join both shapes together. Furthermore, you have to add color to the shapes.

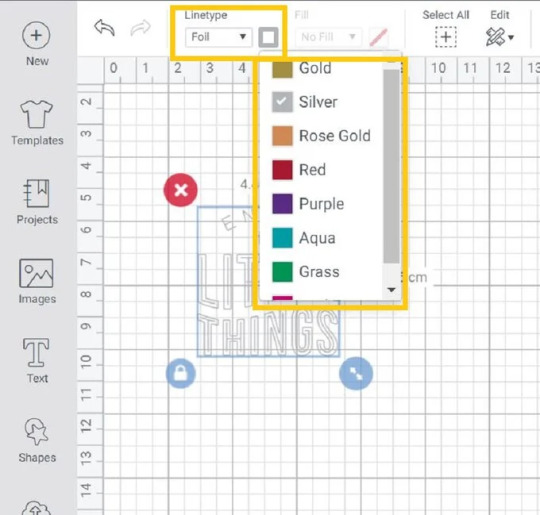

You have to go to the Shapes and then click the Score Line. After that, you have to change the line type to Foil and select the same line.

Step 5: Start Cutting Your Material

On the next screen, you will move to the Mat Preview screen. Then, hit the Continue button and proceed.

Place the faux leather on your cutting mat and then use a brayer to adhere it to the mat properly. Install the foiling tip into the housing. Move the white stars on the right side. Perform the instructions to cut the design. Before you unload the mat, you need to remove the foiling sheet.

After that, install the Fine-Point blade and cute bookmark shapes. Finally, you have learned how to make a bookmark with Cricut. Follow the instructions carefully to create your own.

FAQs

Question 1: What do I need to make a bookmark on Cricut?

Answer: Basic supplies are required for making bookmarks with Cricut. Besides, you must install your Design Space on a computer or mobile device. Here are the supplies needed for your bookmark:

● Cricut Machine (Maker or Explore or Joy)

● Brayer

● Faux Leather

● Foil sheet

● Tape

● Cricut StrongGrip Mat (Purple)

● Fine-Point Blade

Question 2: What materials can I use to make my bookmark on Cricut?

Answer: In my experience, you have various materials that you can try for making beautiful personalized bookmarks. For example, you can use

● Cardstock: It can be easily cut, engraved, embossed, or curled.

● Faux Leather: Available in multiple patterns and easy to cut on Cricut.

● Resin: Make decals and use resin to top them to seal them.

Question 3: Can I make bookmarks on Cricut Joy?

Answer: Yes, of course! In fact, the Cricut machine is the most suitable device for making small projects such as cards, bookmarks, and so much more. So, there is no doubt about it. The Cricut Joy is compatible with 50 materials, meaning it can cut up to 50 materials hassle-free. Moreover, you can use specialty papers to create an extraordinary bookmark.

Final Words

In this tutorial, I have explained how to make a bookmark with Cricut. From step-by-step instructions, I have tried to make it easier for everyone, including beginners. Making bookmarks with Cricut will require you to use some materials or supplies that I have already mentioned in this blog. Make sure you get all of them to make everything smooth. Start your journey to make a bookmark with me and keep tracking your reading progress.

Read more: install cricut design space app

cricut.com/setup

cricut.com/setup mac

Source: how to make a bookmark with Cricut

#design space signin#how to make a bookmark with Cricut#cricut.com/setup mac#install cricut design space app

0 notes

Text

This is what he's talking about and he's talking about making this RTA so it doesn't come welded and you would simply attach the corner pieces using inserts and that would be how the frame would go together and you saddles to put mounting hardware on and you can see where. And the gooseneck would have inserts on the plate and the gooseneck would be welded to the plate already and the parents would be packed in we start with no shock in the rear or shocks and we are going to make the frame so you can ship it the frame itself when it's not broken down the way he's talking about breaking it down is more than what we're thinking and the box would only be by 6 in by 3 ft by a foot and a half it was small and little bit bigger than the box or shelf came in but not much this would help a lot and we're going to do several tests of the frame and we're going to put it in research and development and have people test it out on the street and more and we have the design it's going to be nice this frame would be very very inexpensive $150 because of the metal well this is not cheap and the hard knock kicker 5150 frame the last price was like 15 years ago now they're just online and didn't nobody selling it was $500 that's how much it cost to make too but really you're just going to be cutting shapes and saying it out with the wild material because we decided to have people drill holes and use self tappers so I'm going to send a few high-speed drill bits and self tapping and you're working metal real well this is going to be awesome you're going to see a lot of happy faces and this comes out cuz we can make tons of these cutting this pipe is so easy and we just have machines to it and making the saddles is massively easy you just stamp them out and they make millions and millions in like a minute it's like hardware for a house just tons of it and the clue is easy as hell I mean this is just a very simple system it's going to be great so we are going to sell the frame and show people too what it is I'm probably so A stitch in the car and where they put it they put it like on the main beam I mean these things hold like really really well much better than the world so now we are going to go to it and get these prototypes going then testing and we want everybody who wants to be involved to get involved and to make a prototype I'm going to all have the same design and I would request at least one team captain from each of our areas

Thor Freya

We do respect that a lot and that's great it's good idea to get people up and involved up front and the design is rather simple and this metal is everywhere and it's very sturdy and strong and I'll say it would make a better bike than this other ideas cuz it looks normal and the stream is perfect and the size is great too especially with three different bikes I'll tell you what this is going to be famous he's going to be back on the chart again and it's so easy to go together that's ridiculous it's like our son putting together the PVC anything it's a good idea to put a line and you can put line up lines too this is great

Olympus

0 notes

Text

A small, adaptable tool for safely sealing a variety of plastic bags, packing materials, and pouches used in laboratory environments is the Effective Lab India, laboratory heat sealer. With the use of regulated heat, this apparatus fuses or welds the thermoplastic material of the bag to produce an enduring and airtight seal. It is frequently used in scientific research, medical laboratories, and other settings where it is essential to maintain sample integrity and avoid contamination. By preserving the integrity of samples and reagents, the heat sealer guarantees a prompt, effective, and reliable sealing procedure, which enhances the accuracy and dependability of experimental results. For inquiries or further information about our heat sealing machine price, please feel free to contact us at +91 9555515525 or via email at [email protected]. We look forward to assisting you with any questions or requirements you may have.

0 notes

Text

PinnacleMetalFab: Trailblazers in Metal Fabrication Tools and Equipment Manufacturing

Originally Published on: SpendEdge |Top 5 Metal Fabrication Tools and Equipment Manufacturers | SpendEdge

In the realm of towering skyscrapers and intricate machinery, metal fabrication tools play a pivotal role in crafting sheet metal, nuts, bolts, springs, and wires. These tools, utilized in metal fabrication shops, mold and structure metal components through cutting, burning, welding, machining, forming, and assembling. Lathes, boring machines, milling machines, and drilling machines are commonplace in this intricate process. The metal fabrication process, whether manual or automated, has undergone a transformative evolution, particularly post the fourth industrial revolution, witnessing a significant shift towards automation and the integration of IoT systems. The adoption of IoT is anticipated to propel the global metal fabrication equipment market's growth, creating synergy between manufacturing and information management systems.

##Pioneers in Metal Fabrication Tools and Equipment Manufacturing

###Trumpf A stalwart in metal fabrication equipment, Trumpf, a family-owned powerhouse, stands among the world's largest machine tool suppliers. With production facilities spanning Germany, France, the UK, China, Japan, and the US, Trumpf offers a diverse product and service portfolio, encompassing laser cutting machines, marking systems, punching machines, bending machines, and more. The company's commitment to Industry 4.0 solutions is evident through its $30 million investment in a technology center in Chicago in 2017.

###Shenyang Machine Tool As the largest machine tool and equipment manufacturer in China, Shenyang Machine Tool is a global leader in metal fabrication equipment. Boasting a comprehensive range of tools for cutting, milling, boring, and drilling, the company's annual production exceeds 80,000 small and large equipment. A Berlin-based R&D center ensures top-notch product design and performance accuracy.

###Amada Headquartered in Kanagawa, Japan, Amada is a global player in metal processing equipment and machinery, specializing in metal cutting, forming, punching, and shearing equipment. With over 8,000 employees worldwide, Amada not only provides metal fabrication tools but also offers software solutions for machine automation and training. Their innovative 3kW ENSIS product enables continuous processing of thin-to-thick materials without a lens change.

###Okuma Originating as Okuma Noodle Machine in 1898, Okuma has evolved into a renowned machine tool builder. Producing CNC lathes and machining centers, Okuma is recognized for excellence and groundbreaking technologies. Reporting revenues of $1.45 billion in 2016, the company continues to push the boundaries of CNC machine tools.

###DMG Mori Seiki Formed through a strategic partnership between Deckel-Maho-Gildemeister and Mori Seiki, DMG Mori Seiki has grown into one of the world's largest suppliers of machine and metal fabrication tools. Operating under the name DMG Mori, the Japanese company has developed over 200 models of CNC lathes and machining centers since its establishment.

Delve into comprehensive insights on key players in the metal fabrication tools and equipment market, along with dynamic market trends, pricing models, procurement challenges, and sourcing insights in SpendEdge’s forthcoming report on the global metal fabrication equipment market.

Contact us.

0 notes

Text

MS Pipes Distributors In Ghaziabad| Mild Steel Pipe Manufacturers

Ghaziabad, the bustling industrial hub of Uttar Pradesh, thrives on a robust network of infrastructure. At the heart of this development lies a crucial element: the humble MS pipe. And when it comes to sourcing reliable, high-quality MS Pipe Distributors in Ghaziabad, JRS Pipes And Tubes stands tall as a trusted name.

From Humble Beginnings to Trusted Supplier

Established in 2000, JRS Pipes And Tubes began its journey as a modest distributor of MS Pipe Dealers. Driven by a commitment to excellence and customer satisfaction, the company steadily expanded its reach, becoming a prominent distributor for leading steel manufacturers across India. Today, JRS Pipes And Tubes is a one-stop shop for all your MS pipe needs in Ghaziabad and beyond.

Beyond Distributors, Embracing Manufacturing

JRS Pipes And Tubes didn't stop at just distributing. Recognizing the growing demand for customized solutions, the company ventured into manufacturing in 2010. This strategic move allowed JRS to cater to specific project requirements and offer a wider range of products, including:

• MS Round Pipes: Perfect for plumbing, general engineering and construction purposes, MS Round Pipe come in a variety of diameters and thicknesses.

• MS Square Pipes: A specialty of JRS, MS Square Pipe are strong and aesthetically pleasing, and are extensively used for furniture, fencing and structural support. (Placement of keywords).

• MS rectangular pipe: Providing adaptability to a wide range of uses including industrial machines and construction structures.

MS Black Pipes: Reliable and cost-effective for conveying water, gas, and other fluids.

Spiral Welded Pipes: Durable and economical for large-scale infrastructure projects like pipelines and water treatment plants.

Unwavering Commitment to Quality

JRS Pipes And Tubes understands that quality is paramount in the construction industry. That's why they source their raw materials from renowned steel manufacturers and employ stringent quality control measures throughout the manufacturing process. Their products adhere to national and international standards, ensuring durability and reliability for years to come.

What Sets JRS Apart

In a competitive market, JRS Pipes And Tubes distinguishes itself through several key factors:

Extensive Inventory: JRS boasts a vast inventory of MS pipes in various sizes, thicknesses, and grades, ensuring prompt delivery and meeting diverse project requirements.

Value-Added Services: JRS goes beyond just selling pipes. They offer cutting, threading, and other value-added services to streamline your construction process.

Technical Expertise: Their team of experienced professionals provides technical guidance and support to help you choose the right MS pipes for your specific needs.

Competitive Prices: JRS maintains strong relationships with steel manufacturers, allowing them to offer competitive prices without compromising on quality.

Customer-Centric Approach: JRS prioritizes customer satisfaction, offering personalized service and prompt response to inquiries.

Building Ghaziabad's Future, One Pipe at a Time

JRS Pipes And Tubes is not just a supplier of MS pipes; they are partners in Ghaziabad's growth story. Their dedication to quality, innovation, and customer service has earned them the trust of countless builders, contractors, and engineers. From small residential projects to large-scale infrastructure developments, JRS pipes are playing a vital role in shaping Ghaziabad's future.

Looking Ahead

As Ghaziabad continues to evolve, JRS Pipes And Tubes is committed to adapting and growing alongside the city. They are constantly exploring new technologies and expanding their product range to cater to the ever-changing needs of the construction industry. With their unwavering commitment to quality and customer satisfaction, JRS Pipes And Tubes is poised to remain a leading force in Ghaziabad's infrastructure landscape for years to come.

#MS Round Pipe#MS Square Pipe#Construction#JRS Pipes And Tubes#Mild Steel#MS PIpes#JRS Pipes#MS Square Pipe Manufacturers#.MS Pipe Distributors#Pipe Dealers#business#tiktok#Unknown#motivation#quotes

0 notes

Text

Supplier of Industrial Flanges in Aurangabad

Luvana Metal Corporation, an ISO 9001:2015 certified company, serves as a leading Supplier of Industrial Flanges in Aurangabad, Maharashtra.

Renowned for top-quality stainless steel products, SS pipes, and tubes in Ankleshwar and Pune, India.

As a fully integrated forging and machining manufacturer, we specialize in stainless steel forged flanges.

Our extensive range includes small and large diameter flanges with various pressure classes, complying with international quality norms.

Equipped with advanced machines and a highly qualified research team, we cater to diverse specifications based on client needs.

Our reputation thrives on quality-assured tests and products, emphasizing a skilled workforce and stringent quality control.

Why Choose Our Industrial Flanges:

Manufactured from high-quality materials

Durable with efficient performance

Dimensional accuracy

Faster delivery with competitive pricing

In-house testing facility

Packaging and stock facility

Qualified technicians and dedicated quality controllers

We produce flanges in a wide range of materials, engineered to meet industry standards and service requirements, including:

Weldneck Flanges

Slip-On Flanges

Blind Flanges

Threaded Flanges

Lap Joint Flanges

Socket Weld Flanges

Long Weldneck Flanges

Reducing Flanges

Serving as a prominent Supplier of Industrial Flanges in Aurangabad, we extend our services to locations such as Ahmednagar, Akola, Amravati, Aurangabad, Bhandara, Bhusawal, Buldhana, Chandrapur, Daulatabad, Dhule, Jalgaon, Kalyan, Karli, Kolhapur, Mahabaleshwar, Malegaon, Matheran, Mumbai, Nagpur, Nanded, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal.

For an in-depth exploration of our product catalog, feel free to connect with us through the provided contact information.

Read the full article

0 notes

Text

mass flanges in Qatar

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a prominent manufacturer located in India, specializing in the production of Carbon Steel Flanges. Our comprehensive inventory comprises a variety of flange types and material grades, meticulously crafted with customized compositions tailored to specific material grades. These compositions incorporate essential elements such as carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium. The pricing of our Carbon Steel Pipe Flanges may fluctuate depending on the selected material grade.

Our WMASS Carbon Steel Flanges are distinguished by their unique dimensions and strengths, boasting a minimum tensile strength ranging from 485MPa to a minimum yield strength of 250MPa. Classified as Flange ANSI B16.5 Class 150, they represent a medium pressure class within the B16.5 standard flanges. Material choices and pressure classes for the flanges are determined by nominal bore sizes and wall thicknesses.

Nominal bore sizes range from ½ inches to 48 inches, encompassing classes such as WMASS Carbon Steel Flanges Ratings, each offering varying pressure ratings. Our diverse selection caters to specific requirements, with different flange types serving distinct functions. For instance, the Carbon Steel Blind Flange facilitates both permanent and temporary termination of pipe connections. Permanent connections are welded, while temporary ones are secured with bolts and nuts. The CS Lap Joint Flange, renowned for its lap joint, is highly esteemed for its durability and resistance to wear and tear.

Specification of WMASS Carbon Steel Flanges Companion Flanges:

WMASS CARBON STEEL FLANGES SIZES: Ranging from 1/2" (15 NB) to 48" (1200NB) DN10~DN5000

API FLANGES STANDARDS: Compliant with ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092

API FLANGES PRESSURE RATING ANSI: Including Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS

API FLANGES PRESSURE CALCULATION IN DIN: Covering 6Bar, 10Bar, 16Bar, 25Bar, 40Bar / PN6, PN10, PN16, PN25, PN40, PN64

JIS: Offering 5K, 10 K, 16 K, 20 K, 30 K, 40 K, 63 K

UNI, EN: Available in 6Bar, 10Bar, 16Bar, 25Bar, 40Bar

COATING: Options include Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized

MOST COMMON TYPES OF API: Forged, Threaded, Screwed, Plate

TEST CERTIFICATES: Compliance with EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third-Party Inspection Report, etc.

PRODUCTION TECHNIQUE: Forged, Heat treated, and machined to perfection

CONNECT TYPE/ FLANGE FACE TYPE: Offering Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove

SPECIAL DESIGN: Customization as per your specifications, adhering to AS, ANSI, BS, DIN, and JIS standards, catering from 15 NB (1/2") to 200 NB (8") in Equal and Reducing Configurations

TEST: Utilizing advanced equipment such as Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector

EQUIPMENT: Equipped with state-of-the-art machinery including Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine, etc.

ORIGIN: Sourced from reputable manufacturers in India, West Europe, Japan, USA, and Korea

MANUFACTURER OF: Covering ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE, etc.

API: Offering a diverse range including BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

API FLANGES USES & APPLICATION: Including applications in Bitumen upgraders, Heavy oil refineries, Nuclear power (mostly seamless), Petrochemicals, and acids

EXPORT TO: Countries spanning Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc.

MATERIAL TEST CERTIFICATES (MTC): As per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175

For comprehensive details on Carbon Steel Weld Neck Flange Dimensions, pricing, and any further inquiries, please do not hesitate to contact us.

For More Information:

Visit Our Website: https://www.merakimetals.ae

Contact No: +971-523973687

E-Mail ID: [email protected]

#WMASS Carbon Steel Flanges Manufacturers in UAE#WMASS Carbon Steel Flanges Suppliers in UAE#WMASS Carbon Steel Flanges Stockists in UAE#WMASS Carbon Steel Flanges Exporters in UAE#WMASS Flanges In UAE#Mass Flanges In UAE#WMASS Stockist In UAE#WMASS Exclusive Agent In UAE#WMASS Flanges Dealers In UAE

0 notes