#Textile Dyes Manufacturers

Text

Innovations in Textile Chemicals: What to Expect in 2024

1. Eco-Friendly Mixtures

Innovation in textile chemicals is still fueled by sustainability, with an increasing focus on environmentally friendly formulations and procedures.

Bio-based dyes, biodegradable softeners, and water-saving treatments that reduce environmental effect without sacrificing performance should be available by 2024.

2. The use of nanotechnology

The textile sector can benefit greatly from nanotechnology, which presents chances to improve the functions and qualities of fabrics.

We predict that in 2024, the use of nanoparticles into textile chemical compositions will allow for enhancements in moisture management, stain resistance, and durability.

3. Intelligent Textile Finishes

The need for intelligent coatings that provide textiles new functionality is being driven by the advent of smart textiles.

By 2024, smart textile coatings with antimicrobial, self-cleaning, and UV protection qualities should be more advanced, improving customer comfort and performance.

4. Technologies for Digital Printing

Rapid prototyping and customization are made possible by digital printing technologies, which are transforming textile design and production.

We expect more developments in digital printing technologies in 2024, such as increased compatibility with a wider variety of textiles, faster printing rates, and better color fidelity.

5. Antimicrobial Interventions

Antimicrobial treatments are becoming more and more important in textile industry as sanitation and hygiene become more and more important.

We anticipate the introduction of sophisticated antimicrobial treatments in 2024, which will guarantee textile items that are safer and more hygienic by offering enduring defense against bacteria, viruses, and other pathogens.

In summary

By 2024, textile chemistry innovations should propel previously unheard-of improvements in fabric functionality, sustainability, and performance.

With an emphasis on smart coatings, digital printing, sustainability, nanotechnology, and antimicrobial treatments, the textile industry is ready for new changes that will influence textiles for years to come.

Visit site

Contact: 8866868394

Email: [email protected]

#textile dyes auxiliaries#textile finishing chemicals#textile finishing chemicals manufacturers#textile chemicals manufacturer#textile dyes manufacturers#textile auxiliaries#textile finishing chemicals suppliers

0 notes

Text

How Textile Chemical Dyes Impact the Environment?

In the vibrant world of fashion and textiles, colors play a pivotal role in capturing our imagination and defining our sense of style. The captivating hues of our garments owe their brilliance to a significant yet often overlooked aspect of the industry: chemical dyes.

These dyes have revolutionized the textile sector, making it possible to produce a wide array of colors and patterns that appeal to consumers' ever-changing tastes. However, amidst this rainbow of possibilities lies a dark truth - the environmental impact of textile chemical dyes.

In this blog, we delve into the consequences of using chemical dyes in textile production and explore sustainable alternatives that can help mitigate the ecological footprint of the fashion industry.

Water Pollution

One of the most significant environmental concerns associated with chemical reactive dyes in textiles is water pollution. Conventional dyeing processes often involve large amounts of water, which is used to rinse and treat fabrics. As a result, vast quantities of chemically-laden wastewater are discharged into rivers and water bodies, contaminating aquatic ecosystems. Many of these dyes are non-biodegradable and can persist in the environment for decades, disrupting the natural balance and threatening the health of aquatic organisms.

Energy Consumption

The process of digital textile sublimation inks requires substantial energy inputs, primarily during the dye application and fixation stages. Traditional dyeing methods may involve high-temperature dye baths and extended processing times, adding to the industry's carbon footprint. The energy-intensive nature of these processes contributes to greenhouse gas emissions, accelerating climate change and its devastating consequences.

Toxic Chemical Exposure

Chemical dyes used in textile auxiliaries manufacturers often contain hazardous substances such as heavy metals, formaldehyde, and volatile organic compounds (VOCs). Not only are these substances harmful to the environment, but they also pose significant health risks to the workers in the textile industry who are exposed to them daily. Moreover, consumers may experience allergic reactions and skin irritations when in contact with garments containing residual dye chemicals.

Biodiversity and Land Contamination

When dye wastewater finds its way into the soil, it can have severe consequences for terrestrial ecosystems. The toxic substances from the dyes can leach into the soil, affecting soil quality and disrupting the delicate balance of local flora and fauna. Moreover, the disposal of waste from dyeing processes can lead to the accumulation of harmful chemicals in landfills, further exacerbating the environmental impact.

Scarce Resource Consumption

Many chemical dyes rely on non-renewable resources for their production. For instance, some synthetic dyes use petroleum-based derivatives, placing additional strain on dwindling fossil fuel reserves. As these resources become scarcer, the textile industry must find more sustainable alternatives to safeguard the planet's future.

Embracing Sustainable Solutions

As we confront the ecological consequences of chemical dyes, the textile industry is gradually recognizing the urgent need for change. Embracing sustainable solutions can help mitigate the impact of dyes on the environment:

Natural Dyes: Traditional plant-based dyes, such as indigo, turmeric, and madder, offer a biodegradable and eco-friendly alternative. They can be sourced sustainably, reducing the strain on the environment.

Waterless Dyeing Technologies: Innovative technologies, like air dyeing and digital printing, minimize water usage and eliminate the discharge of wastewater, significantly reducing water pollution.

Biodegradable Dyes: Researchers are developing biodegradable dyes that break down naturally over time, circumventing the issue of persistent chemicals in the environment.

Eco-Friendly Dyeing Processes: Manufacturers can adopt low-impact dyeing techniques that consume less energy and minimize toxic chemical usage, ensuring a cleaner and safer environment for all.

The use of chemical dyes offers by textile printing ink exporter in the textile industry has undoubtedly made fashion more colourful and accessible. However, this innovation comes at a high cost to our environment. From water pollution to biodiversity loss, the impact of chemical dyes on the planet is far-reaching.

To ensure a sustainable future, it is imperative for the industry to embrace eco-friendly alternatives and implement responsible dyeing practices. By taking steps towards a more environmentally conscious approach, we can paint a brighter, greener canvas for the fashion world, where creativity and conscience coexist harmoniously.

#Textile Dyes Exporter#Textile Dyes Manufacturers#Textile Dyes Manufacturers in India#Digital Textile Reactive Inks#Digital Textile Printing Ink Manufacturer#Digital Textile Printing Ink Exporters#Textile Printing Ink Exporter#Digital Textile Sublimation Inks#Textile Auxiliaries Manufacturers#Textile Auxiliaries Exporter#Reactive Dyes Manufacturer#Reactive Dyes Exporter#Reactive Dyes Manufacturer in India#Textile Chemical Dyes

0 notes

Text

Dyes widely used in the textile, food and pharmaceutical industries pose a pressing threat to plant, animal and human health, as well as natural environments around the world, a new study has found.

Billions of tons of dye-containing wastewater enter water systems every year, and a group of researchers from the UK, China, Korea and Belgium say that new sustainable technologies including new membrane-based nano-scale filtration are needed to solve the issue, adding that legislation is needed to compel industrial producers to eliminate colorants before they reach public sewage systems or waterways.

Published today in Nature Reviews Earth & Environment, the study Environmental impacts and remediation of dye-containing wastewater was written by academics from the University of Bath, the Chinese Academy of Sciences, the Fujian Agriculture and Forestry University, the Korea Institute of Energy Technology (KENTECH), and KU Leuven, Belgium.

The research highlights that currently, up to 80% of dye-containing industrial wastewaters created in low- and middle-income countries are released untreated into waterways or used directly for irrigation. The authors say this poses a wide range of direct and indirect threats to human, animal and plant health

Continue Reading

124 notes

·

View notes

Text

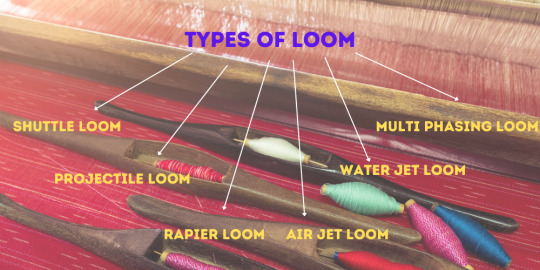

“Discover: Types of Loom in Textile Manufacturing”

Loom? What are They? What Do They Manufacture?

Looms is the weaving machine which converts the yarn into a fabric. There is no history of when looms were discovered but one thing is clear that it was before the birth of Jesus christ. There are 2 types of looms: Shuttle Looms and Shuttleless Looms. Below we are going to learn about various types of looms. The end result of this machine is fabric and wholesalers and retailers buy t-shirts in bulk made out of those fabric.

Learn About Shuttle Looms

This is the most primitive loom in the history of loom. In this machine there is a shuttle which contains bobbins and around bobbins there are yarn wounded. In this weaving machine the shuttle travels from one corner to the other and hence the fabric is made. The speed of this machine is 110-225 ppm [Picks Per Minute]. It is quite noisy and inefficient.

Fabric Weaving Without a Shuttle in the Loom Is It Possible?

Projectile Loom

Projectile loom is a shuttleless loom, in this looms instead of a shuttle projectile are there. Projectiles are made out of stainless steel and hence it was light weight. As the projectile lightweight this saves lots of energy and increases the efficiency of the machine. This loom speed was 300 ppm. The weaving takes place when the projectile goes across the width of the loom with the yarn.

Rapier Loom

This loom is also shuttleless. In this loom the weft is carried by a rapier which is a long rod like structure. Many kinds of fabric could be made using this loom and it is highly efficient. The range of GSM things loom could weave is 20-850 GSM. From home fabric to industrial fabric can be made using this loom. There are 4 types of rapier loom in the market.

Single Rigid Rapier Loom

Double Rigid Rapier Loom

Double Flexible Rapier Loom

Telescopic Rapier Loom

Air-Jet Loom

In this loom the yarn is transferred from the force of air, it does not have any shuttle. This loom is highly efficient and versatile. This loom does not make noise because it does not have many moving parts. As the moving parts are less then the floor space requirement and maintenance is low. The weft travels with the help of air pressure and once it reaches the shedding area interlacement takes place. This machine can be used in manufacturing Denim fabric, polyester dress material and cotton shirting fabric.

Water Jet Loom

Water pressure is used in this loom to transfer weft from one end to the other. It is a shuttleless loom machine. The speed of this machine is 600 ppm. This machine is highly efficient but we can use yarn which is hydrophobic, like polyester, polyamides etc. Hydrophilic yarn can not be used.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

8 notes

·

View notes

Text

RK Industries | Leading Dye Manufacturers in Colorant Solution

RK Industries is a dye manufacturer known for its innovative & quality controlled products, ensuring customer satisfaction & trust across various industries

#About us#dyes product#dyes product manufacturer industry#dyes product supplier company#Textile product supplier and manufacture in India#Vietnam#Brazil

0 notes

Text

Fabric manufacturing companies in Ludhiana

Get the best quality fabrics with PI Cottex Pvt Ltd. We possess various varieties of fabrics which are high in quality. Contact PI Cottex one of the best fabric manufacturing companies in Ludhiana. Visit our store today.

E-638, Phase 7, Focal Point, Dhandari Kalan, Ludhiana, Punjab 141010

0161 278 2400

1 note

·

View note

Text

Fabric dyeing services

Applying dyes or pigments to textile materials, such as fibers, yarns, and fabrics, is the process of dying, which aims to produce color with the appropriate color fastness. Typically, dyeing is carried out in a unique solution made up of certain chemicals and colors. Get the best fabric dyeing services with PI Cottex. Visit us today!

0 notes

Text

Sustainable Cotton Fabrics in India: Sri Shakthi Tex, Your Eco-Friendly Partner

Looking for top-quality, sustainable cotton fabrics in India? Look no further than Sri Shakthi Tex, a leading cotton fabric manufacturer dedicated to ethical and environmentally responsible practices. Founded in 1994, we offer a wide range of high-quality cotton fabrics wholesale, perfect for businesses seeking eco-friendly solutions.

Why Choose Sri Shakthi Tex?

Sustainable Practices: We source our cotton from responsible farms and use eco-friendly dyes and chemicals, minimizing our environmental impact.

Diverse Selection: From plain fabric and shirting fabric to duck canvas and stain fabrics, we have the perfect material for your project.

Superior Quality: We are committed to providing the best possible fabrics at competitive rates, never compromising on quality.

Eco-Friendly Products: Beyond fabrics, we offer cotton bag fabric for sustainable packaging and white dhoti made with ethical practices.

Reliable Supplier: With over 28 years of experience, we are a trusted partner for businesses across India.

More Than Just Fabric:

At Sri Shakthi Tex, we believe in responsible textile production. We are committed to:

Ethical Labor Practices: We ensure fair wages and safe working conditions for all our employees.

Community Development: We actively support our local community through various initiatives.

Reducing Waste: We minimize waste throughout our production process and promote sustainable practices.

Join the Sustainable Movement:

By choosing Sri Shakthi Tex, you are not just buying high-quality cotton fabrics, you are supporting a company that is committed to a sustainable future. Contact us today to learn more about our products and services and how we can help you achieve your sustainability goals.

#handloommagic#srishakthitex#sri shakthi tex#sustainable cotton fabrics india#cotton fabric manufacturer india#high-quality cotton fabrics wholesale#eco-friendly textile supplier india#white dhoti manufacturer#organic cotton india#ethical textile production#sustainable fashion india#eco-friendly clothing#responsible sourcing#fair trade cotton#GOTS certified fabric#natural dyes#ethical labor practices

0 notes

Text

#apparels#manufacturer#supplier#textile#fabrics#knitting#woven#denim jeans#dyes#chemical industry#mensfashion#women's fashion#bangladesh#elpra21

0 notes

Link

#fabric printing services in Kuwait#digital fabric printing services in Kuwait#Fabric Dyes manufacturers in Kuwait#fabric printing kuwait#Fabric Printing or Textile Printing in Kuwait#Customized Fabric Printing services in kuwait#The Odd Factory

0 notes

Text

Textile auxiliaries manufacturer in India

Colourinn Auxiliary is a leading dyes and auxiliaries manufacturing company founded in the year of 1983. Colourinn is an ISO:2015 certified textile chemicals supplier company known for its amazing products and wonderful services. Since Colourinn is a textile chemical manufacturer, it has everything you need for your textiles. Growing as the best textile chemicals manufacturer around the world is all the result of the hard work of our team and the continuous efforts we all have invested.

Contact Us : +91 94265 16868

Visit : https://www.colourinn.in/

#textile auxiliaries#textile dyes auxiliaries#textile dyes manufacturers#reactive dyes manufacturers#textile finishing chemicals#reactive dyes#Industrial dye#Textile auxiliaries manufacturer in India#Textile auxilaries exporter in India#Textile auxiliaries suppliers in India#dyes exporter#dyes suppliers

0 notes

Text

0 notes

Text

Natraj Chemicals . is one of the largest manufacturers & exporter of dyestuff, intermediates and chemicals worldwide. Natraj Chemicals has a plant located in Gujarat with a daily capacity of producing 1000 MT of dyes & dyes intermediates which includes , Para-Amino azobenzene 4 Sulfonic Acid (paabsa) ,DASDA, Sulphanilic Acid Aniline 2,5

#dye sublimation perth#acid dyes#chemical & dyes news#dyes and pigments market#chemical suppliers#chemical industry#basic dyes#export from india#dyes and pigments companies#manufacturing#dyed locs#natural dye#mason dye#box dye#jarastyle#fleece#fine chemicals#textiles

0 notes

Text

Learn About 2 Types of Circular Knitting Machine and Their Advantages

Comprehensive Guide of Single Jersey Circular Knitting Machine and Its Advantages

Single jersey knitting machine has one cylinder of around 30 inches. This machine can knit fabric with less GSM [gsm in fabric how to calculate] compared to a double jersey knitting machine. Knitting is done in one direction in this machine. The knitting in this machine takes place by the coordination of needle and sinker, where needle makes the loop and sinker push it toward the fabric. Sinker plays an important part in this machine. Using this fabric we can manufacture plain fabric which is used in the production of t-shirts, blouses, tops and casual dress. Since the invention of knitting plain fabric is being made. Plain fabric can be made using hand and machine both. Wool production is limited to 20 gauge using this fabric. The fabric made out of this machine has curling ends.

Advantages of Single Jersey Circular Knitting Machine

A- This machine is a good choice for mass production

B- This machine can manufacture a variety of products from lightweight to heavy-weight fabric.

C- Single jersey machine is easy to maintain and repair

D- Less expensive compared to double jersey knitting machine ]

E- It can switch between colors easily

Introducing Double Jersey Circular Knitting Machine and Its Advantages

A double jersey circular knitting machine is nothing but a single jersey knitting machine; the only difference in this type of knitting machine is that it has an extra set of needles which moves horizontally. In this machine there are 2 sets of needles adjacent to each other. This machine knit in 2 directions perpendicular to each other. Sinker is not required in this machine. The final product that is made out of this machine are sweaters, sweatshirt, hoodies, etc. The final product of this machine does not curl unlike a single jersey circular knitting machine.

Advantages of Double Jersey Circular Knitting Machine

A- Can produce fabric with different textures such as terry and pique

B- It can produce multiple patterns, such as stripes and jacquards

C- It can produce thicker fabric with higher insulated properties

Fabric is an important part of t-shirts or any garment manufacturing. We as a t-shirt manufacturer see that when a wholesaler buy t-shirts in bulk from us they check the quality of the fabric.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

5 notes

·

View notes

Link

Soaping agent plays an imperative role in the manufacturing process of dyed or printed textile. So, if you want to learn about soaping agents and want to know how it impacts textile manufacturing process, then this is the post for you.

0 notes