#textile dyes auxiliaries

Text

Innovative Textile Finishes

Are you Looking for eco-friendly fabric options and Innovative textile finishes supplier and manufacturer in India without compromising on quality?

Buy our textiles products from Colourinn textile auxiliaries. We provide sustainable service and products at affordable price range.

Our innovative textile finishes are sustainable, non-toxic, and designed to reduce environmental impact.

Experience the best of both worlds – superior textiles that are kind to the planet.

Contact: 8866868394

Email: [email protected]

Website

#textile dyes auxiliaries#textile finishing chemicals manufacturers#textile finishing chemicals#textile chemicals manufacturer#textile finishing chemicals suppliers

0 notes

Text

#textile dyeing auxiliaries in Delhi#textile dyes and auxiliaries in Delhi#textile finishing auxiliaries in Delhi

0 notes

Text

Textile Dyeing Chemicals & Auxiliaries | Dyeing Agent - Sarex

0 notes

Text

How Textile Chemical Dyes Impact the Environment?

In the vibrant world of fashion and textiles, colors play a pivotal role in capturing our imagination and defining our sense of style. The captivating hues of our garments owe their brilliance to a significant yet often overlooked aspect of the industry: chemical dyes.

These dyes have revolutionized the textile sector, making it possible to produce a wide array of colors and patterns that appeal to consumers' ever-changing tastes. However, amidst this rainbow of possibilities lies a dark truth - the environmental impact of textile chemical dyes.

In this blog, we delve into the consequences of using chemical dyes in textile production and explore sustainable alternatives that can help mitigate the ecological footprint of the fashion industry.

Water Pollution

One of the most significant environmental concerns associated with chemical reactive dyes in textiles is water pollution. Conventional dyeing processes often involve large amounts of water, which is used to rinse and treat fabrics. As a result, vast quantities of chemically-laden wastewater are discharged into rivers and water bodies, contaminating aquatic ecosystems. Many of these dyes are non-biodegradable and can persist in the environment for decades, disrupting the natural balance and threatening the health of aquatic organisms.

Energy Consumption

The process of digital textile sublimation inks requires substantial energy inputs, primarily during the dye application and fixation stages. Traditional dyeing methods may involve high-temperature dye baths and extended processing times, adding to the industry's carbon footprint. The energy-intensive nature of these processes contributes to greenhouse gas emissions, accelerating climate change and its devastating consequences.

Toxic Chemical Exposure

Chemical dyes used in textile auxiliaries manufacturers often contain hazardous substances such as heavy metals, formaldehyde, and volatile organic compounds (VOCs). Not only are these substances harmful to the environment, but they also pose significant health risks to the workers in the textile industry who are exposed to them daily. Moreover, consumers may experience allergic reactions and skin irritations when in contact with garments containing residual dye chemicals.

Biodiversity and Land Contamination

When dye wastewater finds its way into the soil, it can have severe consequences for terrestrial ecosystems. The toxic substances from the dyes can leach into the soil, affecting soil quality and disrupting the delicate balance of local flora and fauna. Moreover, the disposal of waste from dyeing processes can lead to the accumulation of harmful chemicals in landfills, further exacerbating the environmental impact.

Scarce Resource Consumption

Many chemical dyes rely on non-renewable resources for their production. For instance, some synthetic dyes use petroleum-based derivatives, placing additional strain on dwindling fossil fuel reserves. As these resources become scarcer, the textile industry must find more sustainable alternatives to safeguard the planet's future.

Embracing Sustainable Solutions

As we confront the ecological consequences of chemical dyes, the textile industry is gradually recognizing the urgent need for change. Embracing sustainable solutions can help mitigate the impact of dyes on the environment:

Natural Dyes: Traditional plant-based dyes, such as indigo, turmeric, and madder, offer a biodegradable and eco-friendly alternative. They can be sourced sustainably, reducing the strain on the environment.

Waterless Dyeing Technologies: Innovative technologies, like air dyeing and digital printing, minimize water usage and eliminate the discharge of wastewater, significantly reducing water pollution.

Biodegradable Dyes: Researchers are developing biodegradable dyes that break down naturally over time, circumventing the issue of persistent chemicals in the environment.

Eco-Friendly Dyeing Processes: Manufacturers can adopt low-impact dyeing techniques that consume less energy and minimize toxic chemical usage, ensuring a cleaner and safer environment for all.

The use of chemical dyes offers by textile printing ink exporter in the textile industry has undoubtedly made fashion more colourful and accessible. However, this innovation comes at a high cost to our environment. From water pollution to biodiversity loss, the impact of chemical dyes on the planet is far-reaching.

To ensure a sustainable future, it is imperative for the industry to embrace eco-friendly alternatives and implement responsible dyeing practices. By taking steps towards a more environmentally conscious approach, we can paint a brighter, greener canvas for the fashion world, where creativity and conscience coexist harmoniously.

#Textile Dyes Exporter#Textile Dyes Manufacturers#Textile Dyes Manufacturers in India#Digital Textile Reactive Inks#Digital Textile Printing Ink Manufacturer#Digital Textile Printing Ink Exporters#Textile Printing Ink Exporter#Digital Textile Sublimation Inks#Textile Auxiliaries Manufacturers#Textile Auxiliaries Exporter#Reactive Dyes Manufacturer#Reactive Dyes Exporter#Reactive Dyes Manufacturer in India#Textile Chemical Dyes

0 notes

Photo

Water sustainability is the major issue today; however, with Cosmo Speciality Chemicals' dyeing auxiliaries you can make a significant impact. Save water with Cosmo's eco-friendly dyeing auxiliaries.

0 notes

Text

0 notes

Text

The Role of Spectrophotometer in Color Management and Colorimetry

The spectrophotometer uses the grating spectrophotometer principle for color measurement. A grating is an optical element that is engraved with a set of parallel periodic lines or grooves (often inclined) on a plane.

When a beam of compound light is incident on the grating plane, its periodic structure will undergo diffraction, and the transmitted or reflected diffraction light will also interfere. The energy of the light will be redistributed, and different wavelengths of light will travel in different directions, forming a specific wavelength superposition extremum at a certain position, thereby achieving light splitting.

Spectroscopic colorimeters can produce spectral curves, which are equivalent to a color’s ID card and are unique. Therefore, the color data read by the spectrophotometer is absolutely accurate.

The role of spectrophotometer in colorimetry:

The chemical industries such as textiles, printing and dyeing, petroleum, and batteries often generate a lot of industrial wastewater during the production process. The national standards for detecting the chromaticity of wastewater mainly use platinum cobalt colorimetry and dilution multiple method.

The platinum cobalt chromaticity is expressed in Hazen units, with 1 milligram of platinum per liter of solution containing chloroplatinic acid and 2 milligrams of hexahydrate cobalt chloride solution having a platinum cobalt chromaticity of 1 unit. The general range of values is between 1 and 500. Suitable for measuring the color of liquid chemical products that are transparent or slightly close to the reference platinum cobalt color number, this color characteristic is usually brownish yellow.

Limitations of human eye colorimetry; The platinum cobalt colorimetric method is based on human eye judgment, and the color is influenced by environmental light sources, observation angles, and other factors. In actual visual colorimetry, there are certain differences.

Platinum cobalt chromaticity can not only be applied in water quality analysis, but also be used to measure the chromaticity of solutions of chemicals, petrochemical products, such as glycerol, solvents, plasticizers, carbon tetrachloride, petroleum alcohols, etc.

Given the shortcomings of the platinum cobalt colorimetric method in actual color comparison, a spectrophotometer can also be used to compare solution colors.

The use of a spectrophotometer for measurement has the following three major advantages:

1. There is no need to configure a solution and no need to consider material storage issues;

2. The instrument is easy to operate and can be directly measured;

3. Platinum cobalt data is clear at a glance.

The desktop spectrophotometer can measure the chromaticity indicators of platinum cobalt, Gardner, Saybolt, and ASTM.

The role of spectrophotometer in color management:

The spectrophotometer can display chromaticity information based on the internally set chromaticity space and calculation formula, and output it in digital form. In addition, spectrophotometer can also analyze potential spectral data information based on chromaticity data.

The spectrophotometer is designed for data comparison and simulation of visual chromaticity, and is also an important auxiliary tool for computer color matching, which can help major manufacturers complete the analysis, processing, and monitoring of spectral and chromaticity information perfectly.

In the use of spectrophotometer, a crucial data equation – the color tolerance equation – is involved. In fact, we usually refer to the tolerance range, and in industrial batch production, there are tolerances to control the product and qualification status, which is fast and reasonable.

The spectrophotometer wants to measure the color difference of the product and control it, which is the same as a regular color difference meter. Firstly, it needs to measure the information of the standard sample product, and then compare the color information of the measured sample to obtain color difference data.

Calculate whiteness. It can perform white measurement on the whitened sample according to relevant formulas, and then provide specific whiteness values to see if they can meet the standard requirements.

Calculate the strength of the dye. Different dye batches may result in dyeing differences. Therefore, a spectrophotometer can be used to read the relevant finished product samples, and then see the differences between the products produced by these two different batches of dyes. Then, the relevant differences can be filled in the correction coefficient, and the formula can be automatically adjusted to ensure consistent dyeing results.

Calculate the color depth. Because in the actual production process, there may be certain differences in color depth due to differences in formula or production process, and some of these differences cannot be judged by the naked eye. In this case, it is necessary to analyze them through professional equipment such as a spectrophotometer.

Application of spectrophotometer:

1. Food industry

The color of food has a significant impact on people’s appetite, so the food industry has very high requirements for color. The spectrophotometer can quickly measure the color of food to ensure good color and compliance with safety standards.

2. Cosmetics industry

The color of cosmetics is very important for consumers, and good colors can help consumers quickly distinguish different brands. A spectrophotometer can help cosmetic manufacturers ensure that their products have colors that match standard colors.

3. Textile industry

The color of textiles is also very important as it can affect consumers’ purchasing decisions. A spectrophotometer can help textile manufacturers ensure that their products have accurate color and chromaticity values.

4. Semiconductor industry

In the semiconductor manufacturing process, spectrophotometer can help detect the color of transistors, LEDs, and other electronic components. This is crucial for maintaining product consistency and quality.

Advantages of spectrophotometer:

1. High measurement accuracy

The spectrophotometer has high measurement accuracy and can achieve extremely high color accuracy. This is very important for applications that require high-precision color measurement, such as color identification, color matching, etc.

2. Overall measurement speed is fast

In traditional color measurement methods, multiple measurements are required to obtain high-precision results. The spectrophotometer can quickly complete the overall measurement, saving a lot of time.

3. With a recorder

The spectrophotometer has a recorder that can save measurement data during measurement. This is very convenient for later data analysis and comparison.

4. Easy to use

The spectrophotometer is convenient to use and easy to operate. There is no complex operation process, and color measurement can be completed in a few simple steps.

Benchtop Spectrophotometer (Transmittance) DSCD-910 is good performance and specially designed for testing the transparent material’s transmittance, absorbance, chromaticity value and other parameters.

DSCD-910_Benchtop Spectrophotometer (Transmittance)

Read the full article

0 notes

Text

Textile Auxiliaries Market to Reach US$ 11.7 Bn by 2031

The global textile auxiliaries market is poised for significant growth from 2023 to 2031, driven by the increasing demand for functional and sustainable textiles, technological advancements, and the expansion of the textile industry worldwide. Textile auxiliaries are specialty chemicals used in various stages of textile processing to enhance fabric properties, improve performance, and achieve desired finishing effects.

The wide range of use of textile auxiliaries chemicals in the processing of fabric underpins growth opportunities for firms in the textile auxiliaries market. Fabric producers are utilizing various textile auxiliaries to impart texture and colors to cater to the demands of the fashion and apparel industry. The value of the global textile auxiliaries market was pegged at US$ 8.0 Bn in 2021.

The textile auxiliaries market has been witnessing steady growth, propelled by the rising demand for innovative textile products with superior functional attributes. Textile auxiliaries play a crucial role in improving the quality, appearance, and performance of textiles, thereby catering to diverse consumer preferences and industry requirements.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=22580

Market Segmentation:

The textile auxiliaries market can be segmented based on several factors including service type, sourcing type, application, industry vertical, and region. Understanding these segments allows for a detailed analysis of specific market trends and dynamics.

By Service Type: Pre-treatment, Dyeing & Printing, Finishing

By Sourcing Type: Synthetic, Natural

By Application: Apparel, Home Textiles, Technical Textiles, Others

By Industry Vertical: Textile Manufacturing, Fashion & Apparel, Home Furnishings, Others

By Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

Regional Analysis:

North America: Dominant market share attributed to technological advancements and the presence of key market players.

Europe: Significant growth potential driven by the increasing demand for sustainable textiles and stringent regulatory standards.

Asia-Pacific: Emerging market with rapid industrialization, growing textile manufacturing sector, and favorable government initiatives.

Latin America: Growing adoption of advanced textile processing technologies and increasing investments in the textile industry.

Middle East & Africa: Rising demand for high-quality textiles and expanding fashion and apparel industry driving market growth.

Market Drivers and Challenges:

Drivers:

Increasing consumer demand for functional and sustainable textiles.

Advancements in textile processing technologies.

Growth in the fashion and apparel industry.

Challenges:

Stringent environmental regulations pertaining to chemical usage in textile processing.

Volatility in raw material prices.

Intense competition from alternative materials and processes.

Market Trends:

Shift towards eco-friendly and biodegradable textile auxiliaries.

Adoption of digital printing technologies for textile decoration.

Growing focus on performance-enhancing auxiliaries for technical textiles.

Future Outlook:

The future outlook for the textile auxiliaries market appears promising, driven by increasing consumer awareness regarding sustainable and functional textiles, technological innovations, and the growing demand for high-quality textile products across various industry verticals. Market players are expected to capitalize on emerging opportunities by offering innovative solutions and addressing evolving consumer preferences.

Key Market Study Points:

Analysis of market dynamics including drivers, challenges, and opportunities.

Assessment of market segmentation and regional trends.

Evaluation of competitive landscape and key market players.

Examination of recent developments and emerging trends shaping the market.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=22580<ype=S

Competitive Landscape:

The textile auxiliaries market is characterized by intense competition among key players striving to enhance their market presence through product innovation, strategic partnerships, and expansion strategies. Major players in the market include:

Archroma

Huntsman Corporation

Dow Chemical Company

BASF SE

Evonik Industries AG

Recent Developments:

Launch of eco-friendly and sustainable textile auxiliaries.

Strategic collaborations with textile manufacturers and brands.

Investments in research and development to introduce advanced textile processing solutions.

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll-Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Innovations in Textile Auxiliaries Chemicals: Enhancing Performance and Sustainability

The textile industry is undergoing a remarkable transformation driven by the demand for sustainable practices and improved performance. Central to this evolution are innovations in textile auxiliaries chemicals, which play a critical role in enhancing the properties of fabrics and optimizing manufacturing processes. In this article, we'll explore the latest advancements in textile auxiliaries chemicals and their role in enhancing both performance and sustainability in the textile industry.

Sustainable Raw Materials:

One of the most significant innovations in textile auxiliaries chemicals is the shift towards sustainable raw materials. Traditionally, many textile chemicals were derived from petroleum-based sources, contributing to environmental degradation and resource depletion. However, recent advancements in biotechnology and green chemistry have enabled the development of bio-based alternatives sourced from renewable materials. Enzymes, natural dyes, and biopolymers are examples of sustainable raw materials that offer comparable performance to conventional chemicals while reducing the industry's carbon footprint.

Eco-Friendly Processing Agents:

Innovations in textile auxiliaries chemicals have also focused on the development of eco-friendly processing agents that minimize water consumption, energy usage, and chemical waste in textile manufacturing processes. Enzyme-based biopolishing agents, for instance, are used to achieve a soft and smooth fabric finish without the need for harsh chemicals or excessive water and energy consumption. Similarly, bio-based dyeing auxiliaries and finishing agents help reduce water pollution and toxicity in textile dyeing and finishing processes, promoting a more sustainable approach to textile production.

Functional Finishes for Performance Enhancement:

Advancements in textile auxiliaries chemicals have enabled the development of functional finishes that enhance the performance and functionality of textiles. Nanotechnology-based finishes, for example, are used to impart water-repellent, stain-resistant, and antimicrobial properties to fabrics, making them more durable and easy to maintain. Additionally, phase change materials (PCMs) are incorporated into textiles to regulate temperature and improve thermal comfort, particularly in sportswear and performance apparel. These functional finishes not only enhance the performance of textiles but also contribute to their longevity, reducing the need for frequent replacement and waste generation.

Smart Textiles and Wearable Technology:

Another area of innovation in textile auxiliaries chemicals is the development of smart textiles and wearable technology. Conductive inks and coatings containing nanoparticles are used to create fabrics with electronic functionalities, such as sensors, actuators, and energy harvesters. These smart textiles have applications in various industries, including healthcare, sports, and fashion, where they can monitor vital signs, track physical activity, and provide personalized feedback to users. By integrating technology into textiles, these innovative solutions offer new possibilities for functionality, comfort, and interactivity in clothing and other textile products.

Regulatory Compliance and Certification:

As sustainability becomes increasingly important in the textile industry, regulatory compliance and certification have become essential considerations for manufacturers and brands. Innovations in textile auxiliaries chemicals include the development of eco-friendly formulations that meet stringent environmental and safety standards. Certifications such as OEKO-TEX® and bluesign® ensure that textiles and chemicals used in their production are free from harmful substances and manufactured in an environmentally responsible manner. By investing in certified textile auxiliaries chemicals, manufacturers can demonstrate their commitment to sustainability and meet the growing demand for eco-friendly products in the marketplace.

In conclusion, innovations in textile auxiliaries chemicals are driving significant advancements in performance and sustainability across the textile industry. By embracing sustainable raw materials, eco-friendly processing agents, functional finishes, smart textiles, and regulatory compliance, manufacturers can improve the environmental footprint of their products while meeting consumer demand for high-performance and environmentally responsible textiles. As the industry continues to evolve, these innovations will play a crucial role in shaping the future of textile manufacturing and promoting a more sustainable and resilient textile industry.

0 notes

Text

Archroma launches Super Systems+

Archroma, a global leader in specialty chemicals towards sustainable solutions, today introduced Super Systems+. These powerful end-to-end systems combine fiber-specific processing solutions and intelligent effects to help textile and apparel brands, retailers and mills positively impact their economic and environmental sustainability.

“The textile industry is being confronted with critical industry shifts, like resource savings and circularity, and the need for brands to find a new way to bring their products to life while remaining competitive and maintaining article aesthetics and functional performance,” Dhirendra Gautam, Vice President Product Marketing and Strategy, Archroma Textile Effects said. “Super Systems+ represents a major milestone, drawing on the industry’s most extensive product portfolio as well as our most innovative tools and programs. It reflects our ‘Planet Conscious+’ vision of delivering a deeper commitment to innovation and partnership for the textile industry. With a sharper focus on consumers and the environment, we want to deliver a more sustainable ecosystem.”

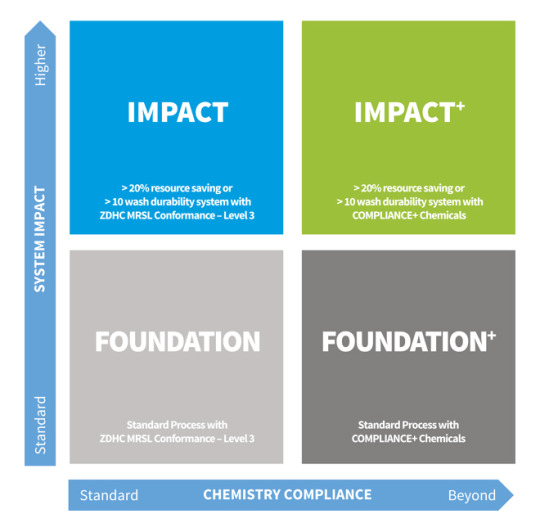

Archroma’s Super Systems+ suite encompass wet processing solutions that deliver measurable environmental impact; durable colors and functional effects that add value and longevity to the end product; and technologies that eliminate harmful or regulated substances. It will allow brands and mills to achieve their desired level of sustainability through measurable resource savings and cleaner chemistries. (Please refer to the Impact Matrix, below.)

Kerim Oner, Director of Strategic Marketing, shared, "Empowering a sustainable tomorrow, our Super Systems+ portfolio of solutions harnesses the power of cutting-edge technologies. Embracing eco-friendlier innovation, our offerings pave the way for a future where efficiency meets environmental consciousness, reducing processing time and conserving water and energy, all while achieving economic sustainability."

Breakthrough products and technologies that are be used in Super Systems+ solutions include: AVITERA® SE for significant resource savings, an improved cost-to-performance ratio for cotton and its blends and superior chlorine fastness; DIRESUL® EVOLUTION BLACK for unique shade and wash-down effects on black denim and an overall impact reduction of 57%; aniline-free DENISOL PURE INDIGO 30 LIQ for authentic blue denim; ERIOPON® E3-SAVE all-in-one auxiliary for resource-intensive polyester dyeing that significantly reduces processing time and conserves water and energy; and PHOBOTEX NTR-50 LIQ for bio-based, PFAS-free, formaldehyde-free and crosslinker-free durable water repellence.

With the industry’s most extensive product portfolio and a comprehensive global footprint, Archroma has the expertise and drive to lead the textile and fashion industry towards a more sustainable future. “Planet Conscious+” is a roadmap that will support textile brands and mills in charting their sustainability journey. It signifies Archroma’s augmented commitment to sustainability, progress and the positive evolution of the textile industry.

Super Systems+ is a core pillar of the “Planet Conscious+” vision. Super Systems+ are already available for popular end-use segments, from denim to performance wear, and casual wear to home textile. Discover our range of Super Systems+ solutions here.

0 notes

Text

Contact: 8866868394

Email: [email protected]

Website

#textile finishing chemicals manufacturers#textile dyes auxiliaries#textile finishing chemicals#textile dyes manufacturers#textile auxiliaries#textile finishing chemicals suppliers#aesthetic finish in textile

0 notes

Text

Our broad ranges of textile auxiliaries helps to ensure high performance on a wide variety of cellulosic and synthetic fabrics & blends.

0 notes

Text

Weaving the Future: Market Trends and Outlook for Textile Auxiliaries Chemicals

The textile industry is undergoing a transformative phase, driven by technological advancements, sustainability imperatives, and shifting consumer preferences. Within this dynamic landscape, the market for textile auxiliaries chemicals plays a crucial role in enhancing the efficiency and quality of textile processing. This article delves into the current market trends and offers insights into the future outlook for textile auxiliaries chemicals.

Current Market Trends:

1. Sustainability and Eco-Friendly Formulations:

A prominent trend shaping the textile auxiliaries chemicals market is the increasing demand for sustainable and eco-friendly formulations. Consumers are becoming more environmentally conscious, and this shift is reflected in the textile industry. Manufacturers are focusing on developing auxiliaries that minimize water consumption, reduce energy usage, and promote eco-friendly textile processing practices.

2. Bio-Based Textile Auxiliaries:

The rise of bio-based materials extends to the textile auxiliaries sector. Market trends indicate a growing interest in auxiliaries derived from renewable sources, such as plant extracts and bio-polymers. These bio-based alternatives not only align with sustainability goals but also offer performance advantages, contributing to the overall appeal of textiles in the market.

3. Digitalization and Smart Textiles:

The integration of digital technologies into textile manufacturing processes is another notable trend. From smart dyeing techniques to digitally controlled finishing processes, technology is enhancing precision and efficiency in the application of textile auxiliaries. Digitalization is also fostering innovations in the development of auxiliaries that enable the production of smart textiles with enhanced functionalities.

4. Focus on Specialty Auxiliaries:

Textile manufacturers are increasingly turning to specialty auxiliaries that cater to specific needs in textile processing. These can include auxiliaries designed for particular fabric types, applications, or desired properties. Specialty auxiliaries offer a tailored approach, allowing manufacturers to achieve desired outcomes in terms of color, texture, and performance.

Future Outlook:

1. Rise of Intelligent Textile Auxiliaries:

Looking ahead, the convergence of textiles and technology is likely to give rise to intelligent or "smart" textile auxiliaries. These intelligent auxiliaries may incorporate features such as self-monitoring, responsive to environmental conditions, and adaptive to various stages of textile processing. The integration of artificial intelligence and machine learning could revolutionize how these chemicals are applied, ensuring optimal results with minimal wastage.

2. Increased Emphasis on Circular Economy:

The textile industry is increasingly embracing the principles of the circular economy, and this trend is expected to influence the future development of textile auxiliaries. Manufacturers are likely to focus on auxiliaries that facilitate easier recycling, reduce the environmental impact of waste, and contribute to a more sustainable and circular textile production process.

3. Regulatory Compliance and Safety:

Anticipated changes in regulatory frameworks, particularly related to chemical usage and safety standards, will influence the future of textile auxiliaries. Manufacturers are likely to invest in research and development to create formulations that comply with evolving regulations, ensuring the safety of both workers and end-users.

4. Global Market Expansion:

The demand for textile auxiliaries is not limited to established textile-producing regions. Emerging economies are becoming significant players in the textile industry, and this will likely drive the expansion of the global market for auxiliaries. Manufacturers may need to adapt to diverse regulatory environments, consumer preferences, and manufacturing practices as they seek to capitalize on opportunities in new markets.

Conclusion: Navigating the Textile Frontier

As the textile industry evolves, so too does the landscape of textile auxiliaries chemicals. Market trends indicate a shift towards sustainability, digitalization, and specialized solutions. Looking ahead, the future of textile auxiliaries will be shaped by innovation, regulatory considerations, and the industry's commitment to creating textiles that align with environmental and consumer expectations.

Manufacturers, researchers, and stakeholders in the textile auxiliaries sector are poised to navigate this frontier by embracing new technologies, fostering sustainability, and responding to the ever-changing demands of the global textile market. The weaving of the future involves not just threads and fibers but also intelligent, sustainable, and innovative solutions that enhance the fabric of the textile industry.

0 notes

Text

Sustainability and Eco-friendly Solutions in the Asia Textile Chemicals Market

Definition: The Asia Textile Chemicals Market refers to the industry that produces and supplies various chemicals used in the textile manufacturing process. These chemicals play a crucial role in enhancing the quality, appearance, and performance of textiles, including fabrics, clothing, and other textile products.

Market Overview & Scope: The Asia Textile Chemicals Market encompasses a wide range of chemical products designed to improve different aspects of textiles. This includes dyeing and finishing chemicals, coating chemicals, and others used in the textile industry. The market caters to the needs of textile manufacturers across Asia, a region known for its significant contribution to the global textile industry. With a focus on improving textile properties such as color, durability, and texture, these chemicals are indispensable in the production of high-quality textiles.

Market Growth: The Asia Textile Chemicals Market has witnessed substantial growth in recent years, driven by the increasing demand for textiles in the region and the desire for better quality and performance. Factors such as population growth, rising disposable incomes, and changing fashion trends have contributed to the expansion of this market. Additionally, the adoption of sustainable and eco-friendly textile chemicals is gaining traction, aligning with the global emphasis on environmental sustainability.

Market Industry: The textile chemicals market industry in Asia is highly diverse, encompassing various subsectors. These include chemicals for dyeing and printing, finishing chemicals, colorants, and auxiliary chemicals used in processes like pretreatment, desizing, and scouring. Major players in the market include chemical manufacturers, textile mills, and garment producers, making it an integral part of the textile supply chain.

Trends: Several noteworthy trends are shaping the Asia Textile Chemicals Market. One prominent trend is the increased focus on eco-friendly and sustainable textile chemicals. Manufacturers are investing in research and development to create products that have minimal environmental impact. Furthermore, the digitalization of textile manufacturing processes, including the use of smart textiles and nanotechnology, is on the rise, transforming the industry and offering new opportunities for growth and innovation. As consumer awareness of sustainable and high-performance textiles continues to grow, the market is likely to see further advancements in these areas. Additionally, regulations and standards related to chemical usage in textiles are becoming more stringent, prompting the industry to adapt to evolving compliance requirements.

In conclusion, the Asia Textile Chemicals Market is a dynamic and evolving sector that plays a vital role in enhancing the quality and sustainability of textiles. With the region's continued growth in the textile industry and the adoption of innovative solutions, this market is poised for ongoing development and transformation.

#Asia Textile Chemicals Market#Asia Textile Chemicals Market Growth#Asia Textile Chemicals Market Trends

0 notes

Link

Soaping agent plays an imperative role in the manufacturing process of dyed or printed textile. So, if you want to learn about soaping agents and want to know how it impacts textile manufacturing process, then this is the post for you.

0 notes

Text

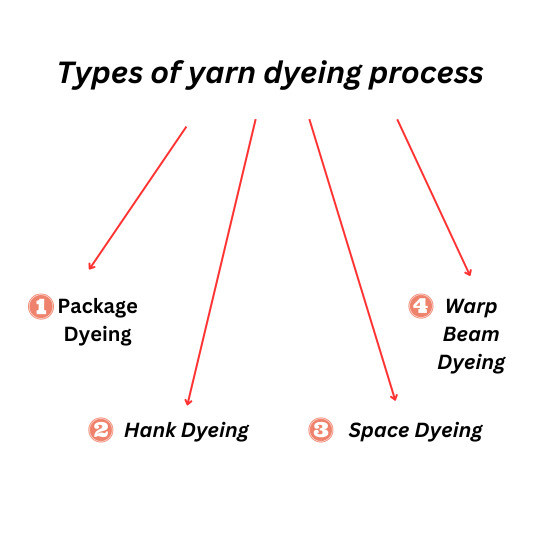

Types of Yarn Dyeing Process

The Yarn dyeing Process is the 3rd process of t-shirt manufacturing. Dyeing comes after the ginning and spinning process. There are several types of dyeing processes in the textile industry such as package dyeing, hank dyeing, space dyeing and warp beam dyeing. Dyeing is a crucial stage as it gives color to the dull cotton which makes it appealing to the wholesalers and retailers to buy t-shirts in bulk.

Package Dyeing

This is the most commonly used dyeing process by the t-shirt manufacturers in Tirupur. In this process the yarn is transferred to perforated cones. They are stacked together and inserted in a boiler. Then in that boiler dyes, auxiliary chemical and water is transferred. This dye goes from inside to outside of the cones for 4 minutes and from outside to inside for 6 minutes and this process takes place 6 times. After they are taken out of the boiling machine it is washed with softener to maintain the softness.

Hank Dyeing

Hank dyeing starts with losing the yarn and hanging it on a coil. The skein [Loosed Yarn] is washed to open the fibers to dissolve dye. The skein is immersed in the dye bath for 48 hours to dissolve the dye properly. This process is repeated several times until the desired results arrive. Then the skein is steamed in order to stick the dye to the yarn. In this process of dyeing the yarn remains soft and the dye gets properly dissolved with the yarn as it is loosen up. This dyeing process gives rich results and this dyeing process is used in making carpet, acrylic yarn and lofty wool.

Space Dyeing

Space dyeing is the process where multiple colors are dyed on a yarn. This multiple color is dyed throughout the length of the yarn. This dyeing method is referred as dip dyeing yarn. Space dyeing is used in making plaids, stripes and iridescent. This dyeing process is only possible because of a chemical named mordant. This chemical holds the dye in its place and makes it possible to dye multicolor. There are 3 ways to apply this chemical pre mordanting, meta mordanting and post mordanting.

Warp Beam Dyeing

The yarn is loosen up and they are wrapped on a warp beam. Then this beam is inserted inside a boiling machine where auxiliary chemicals, water and dyes are inserted at the time of high temperature. The time span is dependent on the end result. Once the yarn is taken out it is rinsed properly. Softening agents are applied to make the fiber soft and rich. They are stored either in the form of a hank or cone.

#manufacturing#textile#textiles#yarn#dyeing#pattern#fiber art#fiber#fabric#sewing#business#entertainment#clothing#clothes

1 note

·

View note