#Digital Textile Printing Ink Manufacturer

Text

How Textile Chemical Dyes Impact the Environment?

In the vibrant world of fashion and textiles, colors play a pivotal role in capturing our imagination and defining our sense of style. The captivating hues of our garments owe their brilliance to a significant yet often overlooked aspect of the industry: chemical dyes.

These dyes have revolutionized the textile sector, making it possible to produce a wide array of colors and patterns that appeal to consumers' ever-changing tastes. However, amidst this rainbow of possibilities lies a dark truth - the environmental impact of textile chemical dyes.

In this blog, we delve into the consequences of using chemical dyes in textile production and explore sustainable alternatives that can help mitigate the ecological footprint of the fashion industry.

Water Pollution

One of the most significant environmental concerns associated with chemical reactive dyes in textiles is water pollution. Conventional dyeing processes often involve large amounts of water, which is used to rinse and treat fabrics. As a result, vast quantities of chemically-laden wastewater are discharged into rivers and water bodies, contaminating aquatic ecosystems. Many of these dyes are non-biodegradable and can persist in the environment for decades, disrupting the natural balance and threatening the health of aquatic organisms.

Energy Consumption

The process of digital textile sublimation inks requires substantial energy inputs, primarily during the dye application and fixation stages. Traditional dyeing methods may involve high-temperature dye baths and extended processing times, adding to the industry's carbon footprint. The energy-intensive nature of these processes contributes to greenhouse gas emissions, accelerating climate change and its devastating consequences.

Toxic Chemical Exposure

Chemical dyes used in textile auxiliaries manufacturers often contain hazardous substances such as heavy metals, formaldehyde, and volatile organic compounds (VOCs). Not only are these substances harmful to the environment, but they also pose significant health risks to the workers in the textile industry who are exposed to them daily. Moreover, consumers may experience allergic reactions and skin irritations when in contact with garments containing residual dye chemicals.

Biodiversity and Land Contamination

When dye wastewater finds its way into the soil, it can have severe consequences for terrestrial ecosystems. The toxic substances from the dyes can leach into the soil, affecting soil quality and disrupting the delicate balance of local flora and fauna. Moreover, the disposal of waste from dyeing processes can lead to the accumulation of harmful chemicals in landfills, further exacerbating the environmental impact.

Scarce Resource Consumption

Many chemical dyes rely on non-renewable resources for their production. For instance, some synthetic dyes use petroleum-based derivatives, placing additional strain on dwindling fossil fuel reserves. As these resources become scarcer, the textile industry must find more sustainable alternatives to safeguard the planet's future.

Embracing Sustainable Solutions

As we confront the ecological consequences of chemical dyes, the textile industry is gradually recognizing the urgent need for change. Embracing sustainable solutions can help mitigate the impact of dyes on the environment:

Natural Dyes: Traditional plant-based dyes, such as indigo, turmeric, and madder, offer a biodegradable and eco-friendly alternative. They can be sourced sustainably, reducing the strain on the environment.

Waterless Dyeing Technologies: Innovative technologies, like air dyeing and digital printing, minimize water usage and eliminate the discharge of wastewater, significantly reducing water pollution.

Biodegradable Dyes: Researchers are developing biodegradable dyes that break down naturally over time, circumventing the issue of persistent chemicals in the environment.

Eco-Friendly Dyeing Processes: Manufacturers can adopt low-impact dyeing techniques that consume less energy and minimize toxic chemical usage, ensuring a cleaner and safer environment for all.

The use of chemical dyes offers by textile printing ink exporter in the textile industry has undoubtedly made fashion more colourful and accessible. However, this innovation comes at a high cost to our environment. From water pollution to biodiversity loss, the impact of chemical dyes on the planet is far-reaching.

To ensure a sustainable future, it is imperative for the industry to embrace eco-friendly alternatives and implement responsible dyeing practices. By taking steps towards a more environmentally conscious approach, we can paint a brighter, greener canvas for the fashion world, where creativity and conscience coexist harmoniously.

#Textile Dyes Exporter#Textile Dyes Manufacturers#Textile Dyes Manufacturers in India#Digital Textile Reactive Inks#Digital Textile Printing Ink Manufacturer#Digital Textile Printing Ink Exporters#Textile Printing Ink Exporter#Digital Textile Sublimation Inks#Textile Auxiliaries Manufacturers#Textile Auxiliaries Exporter#Reactive Dyes Manufacturer#Reactive Dyes Exporter#Reactive Dyes Manufacturer in India#Textile Chemical Dyes

0 notes

Text

Exploring the Screen Printing Mesh Market: Ink & Weave

The screen printing mesh market involves the manufacturing and supply of woven or synthetic mesh materials used in screen printing processes. These meshes serve as a crucial component in the creation of screen printing screens, enabling the transfer of ink onto various substrates such as textiles, paper, plastics, metals, and more. The adoption of mesh screen printing is widely rising among various end-use industries such as electrical, packaging, ceramics, and electronics are driving the market revenue. The growth and evolution of these sectors, including changes in consumer preferences and packaging trends, can influence the demand for screen printing meshes.

Increasing printing of mesh materials used for fabric print is eye-catching for beautiful printing designs in the textile sector, which is gaining immense popularity. Manufacturers offer polyester screen printing technologies in the textile industry to strengthen the cloth without affecting or upsurging the market growth. On the other hand, construction and architecture sectors are choosing advanced and cutting-edge technologies to reduce additional costs of printing methods and capture end users' needs. Advancements in digital printing technologies and the adoption of alternative printing methods may impact traditional screen printing processes, potentially influencing the demand for screen printing meshes.

Demand for custom-made screen printing meshes to suit specific applications or industries, such as high-resolution graphics or unique substrate printing, could drive market growth in specialized niches. Consumers are looking for effective and high-quality printing solutions for special event presents, increasing the market revenue. Manufacturers are focused on shifting consumers' preferences, changing lifestyles, and enhancing product quality with printing technologies. Manufacturers are developing new technologies to strengthen touchscreen production for electronic components to boost the global market.

3 notes

·

View notes

Text

TEXTILE DESIGN IN 2023-24

Overview of top textile importer, exporter countries & manufacturing industries.

Textile design is the art of creating designs for woven, knitted, or printed fabrics. It is an integral part of the textile industry, which encompasses the production of fibers, yarns, fabrics, and finished textile products. Textile design is a vast field that encompasses a wide range of techniques and processes, including drawing, painting, printing, weaving, and embroidery. In this article, we will explore the history of textile design, the various techniques used in textile design, and the current trends in the field.

History of Textile Design

Textile design has a long and rich history that dates back to prehistoric times. The first textiles were made by hand using natural fibers such as flax, cotton, and wool. These fibers were spun into yarn and woven into fabrics using simple looms. Textiles were used for clothing, bedding, and household items such as curtains and tablecloths.

Over time, textile design became more complex as new techniques and materials were developed. The introduction of the spinning wheel in the Middle Ages allowed for the production of finer and more even yarns. The invention of the Jacquard loom in the 18th century enabled the production of intricate patterns and designs. The Industrial Revolution in the 19th century brought about significant changes in the textile industry, with the introduction of mechanized production methods.

In the 20th century, textile design became an art form in its own right. The development of new synthetic fibers such as nylon and polyester allowed for new possibilities in textile design. The Bauhaus school, founded in Germany in 1919, played a significant role in the development of modern textile design. The school's emphasis on functional design and the use of new materials and techniques had a profound influence on the field.

Techniques Used in Textile Design

Textile design encompasses a wide range of techniques and processes. Some of the most common techniques used in textile design include:

Drawing and Painting: Many textile designs begin as drawings or paintings. Designers use a variety of media, including pencil, pen, ink, and watercolor, to create designs that are then transferred to fabric.

Printing: Printing is a common technique used in textile design. Designs are created on paper using a variety of techniques, such as block printing, screen printing, and digital printing. The designs are then transferred onto fabric using heat or pressure.

Weaving: Weaving is the process of interlacing two or more sets of yarns or threads at right angles to create a fabric. Weaving can be done by hand on a loom or by machine.

Knitting: Knitting is a technique used to create fabrics by interlocking loops of yarn. Knitting can be done by hand or by machine.

Embroidery: Embroidery is the art of decorating fabric or other materials with needle and thread. It is often used to add texture and dimension to textile designs.

Current Trends in Textile Design

Textile design is a constantly evolving field, with new techniques and materials being developed all the time. Some of the current trends in textile design include:

Sustainability: The textile industry is one of the most polluting industries in the world, and there is a growing trend towards sustainable textile design. This includes the use of organic and recycled materials, as well as the development of eco-friendly production methods.

Digital Printing:

Digital printing is a relatively new technique in textile design that allows designers to create complex designs with a high level of detail. It is also more environmentally friendly than traditional printing methods, as it uses less water and produces less waste.

3D Printing:

3D printing is a cutting-edge technology that is being used in textile design to create innovative fabrics with a variety of textures and shapes.

Smart Textiles: Smart textiles are fabrics that are designed to be interactive and responsive.

Smart Textiles:

Smart textiles are fabrics that are designed to be interactive and responsive. They incorporate electronic components such as sensors, actuators, and microcontrollers to enable the fabric to sense and respond to its environment. Smart textiles can be used in a wide range of applications, from fashion to medical devices. For example, smart textiles can be used in clothing to monitor vital signs and adjust temperature, or in bedding to monitor sleep patterns and adjust the bed's firmness.

Innovation in Materials:

There is a growing trend towards innovation in materials in textile design. Designers are exploring new materials, such as sustainable and bio-based materials, to create fabrics with unique properties. For example, fabrics made from bamboo, soy, or hemp are becoming more popular due to their sustainable and eco-friendly properties.

Mixing of Textures and Prints:

There is a trend towards mixing different textures and prints in textile design. Designers are using contrasting textures and prints to create bold and visually striking designs. This trend is evident in fashion, where designers are using a combination of textures such as silk and velvet or prints such as stripes and florals to create unique and eye-catching garments.

Digital Fabrication:

Digital fabrication is the use of digital tools such as computer-aided design (CAD) and 3D printing to create textiles. This technique allows designers to create complex designs with a high degree of precision and accuracy. Digital fabrication is particularly useful for creating one-of-a-kind textiles or small production runs.

Collaboration and Interdisciplinary Work:

Collaboration and interdisciplinary work are becoming increasingly important in textile design. Designers are working with scientists, engineers, and other professionals to develop new materials and technologies. This collaborative approach is leading to innovative solutions and new possibilities in textile design.

Textile design is a dynamic and constantly evolving field. From the early hand-woven textiles to the cutting-edge smart textiles of today, textile design has come a long way. The field encompasses a wide range of techniques and processes, from drawing and painting to digital fabrication and smart textiles. With the growing focus on sustainability and innovation, textile design is poised to continue to evolve and shape the future of fashion, interior design, and other related industries.

TOP TEXTIL EXPORTER COUNTRY

The textile industry is a global industry, with many countries producing and exporting textiles. The top textile exporting countries in the world are:

- China: China is the world's largest exporter of textiles, accounting for around 35% of global textile exports. The country has a strong manufacturing base and is known for its production of cotton, silk, and woolen textiles.

- India: India is the second-largest exporter of textiles in the world, with a share of around 12% of global textile exports. The country is known for its production of cotton textiles, including handloom textiles, and is also a significant exporter of silk and woolen textiles.

- Bangladesh: Bangladesh is the third-largest exporter of textiles, with a share of around 6% of global textile exports. The country is known for its production of low-cost cotton textiles and is a major supplier to many western clothing brands.

- Vietnam: Vietnam is the fourth-largest exporter of textiles, accounting for around 5% of global textile exports. The country has a growing textile industry and is known for its production of cotton and synthetic textiles.

- Turkey: Turkey is the fifth-largest exporter of textiles, with a share of around 4% of global textile exports. The country has a well-established textile industry and is known for its production of high-quality cotton textiles and home textiles.

Other significant textile exporting countries include Pakistan, Italy, Germany, Indonesia, and the United States. The textile industry plays an important role in the economies of these countries, providing employment opportunities and contributing to the overall economic growth.

TOP TEXTILE IMPORTER COUNTRIES

The global textile trade is driven by demand from textile importing countries that rely on textile imports to meet their domestic demand. The top textile importing countries in the world are:

- United States: The United States is the world's largest textile importer, accounting for around 16% of global textile imports. The country has a significant textile industry but also relies on imports to meet the demand for a wide range of textile products.

- Germany: Germany is the second-largest textile importer, with a share of around 9% of global textile imports. The country has a well-established textile industry but also imports a significant amount of textiles to meet the demand for high-quality fabrics.

- Japan: Japan is the third-largest textile importer, accounting for around 8% of global textile imports. The country has a significant textile industry but also imports textiles to meet the demand for a wide range of consumer products, including clothing and home textiles.

- United Kingdom: The United Kingdom is the fourth-largest textile importer, with a share of around 6% of global textile imports. The country has a significant textile industry but also imports a significant amount of textiles to meet the demand for a wide range of products.

- France: France is the fifth-largest textile importer, accounting for around 4% of global textile imports. The country has a significant textile industry but also imports textiles to meet the demand for high-quality fabrics and luxury goods.

Other significant textile importing countries include Italy, Spain, Canada, Russia, and China. The textile industry plays an important role in the economies of these countries, providing employment opportunities and contributing to the overall economic growth.

TOP TEXTIL MANUFACTURING COMPANY

The textile manufacturing industry is a highly competitive industry with many companies vying for market share. The top textile manufacturing companies in the world are:

- China National Textile and Apparel Council (CNTAC): CNTAC is the world's largest textile manufacturing company. It is a state-owned enterprise that has a dominant position in the Chinese textile industry. CNTAC operates a large number of textile mills and produces a wide range of textile products, including cotton, silk, wool, and synthetic fabrics.

- Indorama Ventures: Indorama Ventures is a global chemical and textile manufacturing company with a presence in more than 30 countries. The company produces a wide range of textile products, including polyester, nylon, and spandex fabrics.

- Luthai Textile: Luthai Textile is a leading textile manufacturing company based in China. The company produces a wide range of cotton and polyester fabrics, including high-quality shirting fabrics.

- Vardhman Textiles: Vardhman Textiles is one of the largest textile manufacturing companies in India. The company produces a wide range of cotton and synthetic fabrics, including home textiles, garments, and yarns.

- Hyosung Corporation: Hyosung Corporation is a South Korean company that produces a wide range of textile products, including polyester, nylon, and spandex fabrics. The company has a significant global presence and operates textile mills in several countries.

Other significant textile manufacturing companies include Toray Industries, Inc., Teijin Limited, Milliken & Company, and Arvind Limited. These companies are known for their high-quality textile products, innovative technologies, and sustainable manufacturing practices.

TOP 10 BEST DIGITAL TEXTILE DESIGN COMPANIES

The textile industry has rapidly adopted digital technologies, leading to the emergence of several digital textile design companies. The top 11 best digital textile design companies are:

- Mahashankh Design: Mahashankh Design is a India-based company that offers world most complex & convertible digital designs services in two format 1. Shared Design : in Shared Design copyright of design will remains to mahashankh design before the payment & After the payment only they have right to use in personal projects. 2. Dedicated Design : in Dedicated Design all rights will be goes to customer after payment .

- Spoonflower: Spoonflower is a US-based company that offers digital printing services for custom fabric, wallpaper, and gift wrap designs. The company's platform allows customers to upload their designs and have them printed on a range of fabrics.

- Printful: Printful is a Latvian-based company that offers on-demand printing and fulfillment services for custom apparel, home decor, and accessories. The company's platform allows customers to upload their designs and have them printed on a range of products.

- Patternbank: Patternbank is a UK-based company that provides trend forecasting and digital textile design services to the fashion and textile industries. The company's platform offers a range of design tools and resources to help designers create unique and innovative designs.

- Kornit Digital: Kornit Digital is an Israeli-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints.

- Lectra: Lectra is a French-based company that offers software and hardware solutions for the fashion and textile industries. The company's platform includes design software, cutting machines, and automation tools designed to help manufacturers improve their production efficiency.

- Epson: Epson is a Japanese-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints.

- EFI: EFI is a US-based company that offers software and hardware solutions for the textile industry. The company's platform includes design software, printers, and automation tools designed to help manufacturers improve their production efficiency.

- AVA CAD/CAM Group: AVA CAD/CAM Group is a UK-based company that provides digital textile design and print solutions to the fashion and textile industries. The company's platform includes design software, color management tools, and production planning tools designed to help textile manufacturers and designers improve their efficiency.

- Mutoh: Mutoh is a Japanese-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints.

- HP: HP is a US-based company that offers digital printing solutions for the textile industry. The company's platform includes a range of printers and software tools designed to help textile manufacturers and designers create high-quality digital prints.

These digital textile design companies are known for their innovative solutions and their ability to help designers and manufacturers create unique and high-quality textile products.

Read the full article

3 notes

·

View notes

Text

Xaar’s drupa presentation on textile inkjet printing

Xaar, an inkjet innovator, providing printheads and technologies for OEM and UDI customers worldwide, is inviting visitors at drupa to hear how the latest inkjet technologies are rewriting the rulebook for textile printing in a presentation to be made as part of the show’s touchpoint textile forum.

Speaking on June 3 in hall 4, Karl Forbes, the Xaar group’s R&D director, will show how its Aquinox printhead, utilizing Xaar’s Ultra High Viscosity printing and patented High Laydown Technology, is transforming productivity in digital textile printing.

Chemists at Nazdar were able to produce a new fluid technology that can deliver clarity and high pigment loading while simultaneously reducing the use of raw materials and energy costs. Vibrant, color-rich textiles can now be achieved by using half the traditional amount of ink and printhead passes, delivering significant machine productivity savings.

Notably, Nazdar’s new HighV Aqua Series includes a high viscosity white ink, which when coupled with the TF Technology embedded within Xaar’s Aquinox printhead, provides customers with quality textile printing at an efficiency that was previously unmatched.

Drupa will also see Xaar technology across the show – including its recent collaboration with Koenig & Bauer Kammann (Kammann) to create personalized embossed effects on glass bottles, plastic and metal containers at a build height of up to 3mm. Utilizing Xaar’s Nitrox printheads with new high viscosity fluids developed by global ink manufacturer Marabu, Kammann’s machines can jet at greater viscosity and carry a significantly increased pigment load, delivering more color vibrancy and capturing fine details with up to 50 per cent less ink.

Colors no longer need pinning, delivering significant savings in the time required for printing, as well as reductions in energy and material use. Overall, the speed of production can be more than doubled, making inkjet printing a greater reality for a much wider variety of decorative applications.

Commenting on the exhibition, Karl Forbes said, “drupa is the perfect show for visitors to hear how Xaar’s inkjet technology is enabling the development of new fluids and providing access to the many potential benefits of digital printing.

“From UV inks requiring less curing energy to aqueous inks containing high pigment loading and a lower ratio of water, inkjet is now able to deliver the performance, sustainability and innovation demanded, rewriting the rulebook for textile printing and many other applications.”

0 notes

Text

Digital Inks Market to Reach USD 7.6 billion by 2031, at 9.5% CAGR

The global digital inks was estimated to have acquired US$ 3.4 billion in 2022. It is anticipated to register a 9.5% CAGR from 2022 to 2031 and by 2031, the market is likely to gain US$ 7.6 billion.

Digital textile printing is becoming more and more popular, which in turn is increasing demand for digital inks like textile printing inks, since it can now print on a wider range of materials, including synthetic and natural fibers.

Download PDF Sample Report @ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=48210

The growing focus of the textile industry on sustainability is contributing to the widespread use of digital inks. Green initiatives within the business are supported by environmentally friendly ink formulations that are devoid of toxic chemicals and volatile organic compounds (VOCs). Companies in the industry are moving more and more toward digital inks that adhere to strict environmental regulations, which helps to make production processes more environmentally friendly.

Market Segmentation

The digital inks market can be segmented based on service type, sourcing type, application, industry vertical, and region.

By Service Type

Inkjet Inks

Electrophotographic Inks

By Sourcing Type

OEM (Original Equipment Manufacturer) Inks

Compatible Inks

By Application

Advertising and Promotion

Textile Printing

Packaging

Publications

Ceramics

Others

By Industry Vertical

Printing and Packaging

Textiles

Electronics

Ceramics

Others

Regional Analysis

The digital inks market is geographically segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

North America: Dominates the market due to high adoption of digital printing technologies in advertising and packaging.

Europe: Strong growth driven by the textile printing sector and increasing demand for sustainable printing solutions.

Asia-Pacific: The fastest-growing region, attributed to the expanding electronics industry and rising consumer demand for printed textiles.

Latin America and the Middle East & Africa: Emerging markets with growing investments in digital printing infrastructure.

Market Drivers and Challenges

Drivers

Technological Advancements: Continuous innovations in ink formulations and printing technologies enhance print quality and reduce costs.

Environmental Concerns: Increasing preference for eco-friendly inks with low VOC emissions.

Demand for Customization: Growing need for personalized and short-run printing in various industries.

Challenges

High Initial Costs: The setup costs for digital printing equipment can be prohibitive for small and medium-sized enterprises.

Technical Limitations: Issues related to print head compatibility and ink performance on different substrates.

Market Trends

Sustainable Inks: Development of biodegradable and water-based digital inks.

Smart Inks: Integration of functional properties such as conductivity and color-changing capabilities.

Growth of E-commerce: Boosting the demand for digitally printed packaging solutions.

Future Outlook

The digital inks market is poised for robust growth, supported by technological advancements and expanding applications across various industries. The shift towards sustainable and smart inks will further drive market evolution, offering new opportunities for innovation and development.

Key Market Study Points

Competitive Analysis: Assessing the market position of leading players and their strategies.

Technological Innovations: Tracking advancements in ink formulations and printing technologies.

Consumer Preferences: Understanding the demand dynamics in key application sectors.

Competitive Landscape

The digital inks market is highly competitive, with key players including HP Inc., Canon Inc., DIC Corporation, Sun Chemical, and Epson. These companies are focusing on research and development, strategic partnerships, and acquisitions to strengthen their market positions.

Buy this Premium Research Report @ https://www.transparencymarketresearch.com/checkout.php?rep_id=48210<ype=S

Recent Developments

HP Inc. has launched a new range of eco-friendly inks suitable for various printing applications.

Epson introduced a series of high-performance digital textile printers to cater to the growing demand in the fashion industry.

DIC Corporation announced a collaboration with leading packaging companies to develop sustainable ink solutions.

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

DuPont to showcase new innovative artistri digital printing inks at drupa 2024

To commemorate 35 years of delivering innovation and being a global leader in digital inkjet inks with its Artistri ink products, DuPont announced the launch of its PN 1000 ink series at Drupa 2024. The new product series is a set of low-viscosity water-based pigment inkjet inks for commercial printing, formulated with proprietary DuPont technology and compatible with industry-standard drying technologies.

This new ink set is suitable for book, direct mail, and transactional printing applications and prints a rich black alongside delivering a large color gamut with minimal to no drying, allowing printers to achieve higher speeds to be more productive. The key benefits also include:

high optical density on various paper substrates

high image quality

high durability

reliable jetting sustainability.

“We believe that Drupa 2024, the most important printing show in the world, is the perfect place for presenting the newest ink series, said Tucker Norton, Global Business Director, DuPont Printing & Packaging.” With the growth in digital printing, we will continue to innovate, bringing more sustainable solutions that will elevate commercial and textile printing to a higher level.”

On the packaging front, DuPont will showcase its water-based inks for corrugated, folding cartons and flexible packaging printing, responding to the emerging demand from conscious converters looking for safer ink alternatives. Developed for the OEM project needs, these products are ideal for indirect food contact and comply with the Swiss Ordinance and EuPIA (European Printing Ink Association). The Artistry water-based pigment inks for packaging printing are manufactured under Good Manufacturing Practices (GMP) standards and in ISO 9002-2015 certified facilities.

Sustainability is a key element in DuPont’s portfolio innovation. The company aims to not only offer more environmentally friendly products that will allow printers to choose processes with a lower carbon footprint but also develop products that are safe and sustainable by design.

DuPont’s recent 2024 Sustainability Report, published last month, highlights the success case of DuPont scientists completing a three-year effort to replace 2-pyrrolidone solvent in inks with safer, non-regulated alternatives while maintaining equivalent performance and shelf life. “We are proud to see that this work supports the overarching trends of printers moving to digital printing for consumer products and demonstrates DuPont’s commitment to being ahead of the curve about substances of concern across our portfolio”, said Gabriela Kim, Global Brand and Marketing Manager, DuPont Artistri Digital Inks.

DuPont will also exhibit other products from the Artistri portfolio at Drupa 2024, such as P1600, the premium pigment inkjet inks for Direct-to-Film (DTF) textile printing. “Within textile printing, there’s a boom with the DTF technology over the last few years due to its versatility and DTF is here to stay, added Kim.” The P1600 ink series was specially designed for this technology, delivering bright images while giving the consistency and reliability for printers to spend less time with maintenance.”

0 notes

Text

DuPont's new Artistri digital printing Inks at drupa 2024

To commemorate 35 years of delivering innovation and being a global leader in digital inkjet inks with its Artistri ink products, DuPont has announced the launch of its PN 1000 ink series at drupa 2024. The new product series is a set of low viscosity water-based pigment inkjet inks for commercial printing, formulated with proprietary DuPont technology and compatible with industry standard drying technologies.

This new ink set is suitable for book, direct mail, and transactional printing applications and prints a rich black alongside delivering a large color gamut with minimal to no drying, allowing printers to achieve higher speeds to be more productive. The key benefits also include – high optical density on various paper substrates; high image quality; high durability; and reliable jetting sustainability.

“We believe that drupa 2024, the most important printing show in the world, is the perfect place for presenting the newest ink series, said Tucker Norton, global business director, DuPont Printing & Packaging.” With the growth in digital printing, we will continue to innovate, bringing more sustainable solutions that will elevate commercial and textile printing to a higher level.”

On the packaging front, DuPont will showcase its water-based inks for corrugated, folding carton and flexible packaging printing, responding to the emerging demand from conscious converters looking for safer ink alternatives. Developed for the OEMs project needs, these products are ideal for indirect food contact, and are compliant with Swiss Ordinance and EuPIA (European Printing Ink Association). The Artistri® water-based pigment inks for packaging printing are manufactured under Good Manufacturing Practices (GMP) standards and in ISO 9002-2015 certified facilities.

Sustainability is a key element in DuPont’s portfolio innovation. The company aims to not only offer more environmentally friendly products that will allow printers to choose processes with a lower carbon footprint, but also develop products that are safe and sustainable by design.

DuPont’s recent 2024 Sustainability Report, published last month, highlights the success case of DuPont scientists completing a three-year effort to replace 2-pyrrolidone solvent in inks with safer, non-regulated alternatives while maintaining equivalent performance and shelf life. “We are proud to see that this work supports the overarching trends of printers moving to digital printing for consumer products and demonstrates DuPont’s commitment to being ahead of the curve with regard to substances of concern across our portfolio,”said Gabriela Kim, global brand and marketing manager, DuPont Artistri Digital Inks.

DuPont will also exhibit other products from the Artistri portfolio at drupa 2024, such as P1600, the premium pigment inkjet inks for direct-to-film (DTF) textile printing.

“Within textile printing, there’s a boom with the DTF technology over the last few years due to its versatility and DTF is here to stay, added Kim.” The P1600 ink series were specially designed for this technology, delivering bright images while giving the consistency and reliability for printers to spend less time with maintenance.”

DuPont will be at Hall 8b, stand B13 at drupa 2024

DuPont is a leading manufacturer and innovator of digital inkjet printing inks with its Artistri inks for commercial, packaging, textile, office, and home printing applications.

0 notes

Text

Cotton Digital Printed Sports Towel

Elongated 200mm x 1100mm sports towel that is manufactured from heavy 400gsm cotton. lt is branded on one side with stunning high-definition digital printing which is colorfast, using imported ink. Fast sampling speed, the fastest 3 days out of the sample. Fast delivery, the fastest 10 days to deliver large goods.

1 note

·

View note

Text

Revolutionizing Industries: The Marvels of Rubber Rollers Technology

In the expansive realm of industrial innovation, certain technologies often lurk in the background, silently but significantly contributing to the smooth operations of various sectors. One such unsung hero of industrial efficiency is rubber rollers technology. While its name might not immediately evoke awe, the impact of rubber rollers in revolutionizing manufacturing processes across diverse industries is truly remarkable.

Rubber rollers, as the name suggests, are cylindrical tools made primarily of rubber, though they can also incorporate other materials such as metal or plastic, depending on the specific application. These rollers serve a multitude of purposes, ranging from facilitating material handling to providing essential functionalities in printing, laminating, conveying, and more. What makes rubber rollers indispensable in these processes is their unique properties, including resilience, durability, and adaptability to various surfaces and materials.

One of the most prominent applications of rubber rollers is in printing. Whether it's offset, flexographic, gravure, or digital printing, rubber rollers play a crucial role in transferring ink from the plate to the substrate with precision and consistency. In offset printing, for instance, rubber rollers, also known as offset blankets, are responsible for transferring ink from the printing plate to the printing surface, be it paper, cardboard, or another substrate. The elasticity of the rubber ensures uniform ink distribution, resulting in high-quality prints.

Similarly, in the field of laminating, rubber rollers contribute significantly to the bonding of multiple layers of materials, such as films, foils, papers, or textiles. The pressure exerted by the rollers ensures proper adhesion, creating laminates with desirable properties such as strength, barrier protection, and aesthetic appeal. Whether it's packaging materials, decorative laminates, or industrial composites, the reliability of rubber rollers is paramount in achieving consistent lamination quality.

Beyond printing and laminating, rubber rollers find extensive use in various manufacturing processes, including web handling, embossing, coating, and more. In industries ranging from textiles and plastics to food and pharmaceuticals, these rollers facilitate the movement, processing, and finishing of materials with efficiency and precision. Their ability to grip, transport, and manipulate different substrates makes them indispensable components in modern manufacturing machinery.

Moreover, the versatility of rubber rollers extends to specialized applications such as corrugated cardboard production, where they play a critical role in shaping, pressing, and transporting the corrugated medium and liners to create the final product. The robustness of rubber rollers allows them to withstand the rigorous demands of high-speed corrugators while maintaining consistent performance over prolonged usage.

In recent years, advancements in materials science and manufacturing technologies have further enhanced the capabilities of rubber rollers. Innovative formulations and manufacturing techniques have led to the development of rollers with superior wear resistance, chemical compatibility, and temperature stability, expanding their applicability across a broader range of industries and operating conditions.

Furthermore, the integration of automation and digitalization has enabled precise control and monitoring of rubber roller systems, optimizing performance, reducing downtime, and enhancing overall productivity. With features such as predictive maintenance, remote diagnostics, and real-time adjustments, modern rubber roller solutions empower manufacturers to achieve higher efficiency and reliability in their operations.

The environmental sustainability of rubber rollers technology is also worth noting. Unlike some alternative solutions that rely on consumable parts or generate excessive waste, rubber rollers are inherently durable and reusable. With proper maintenance and refurbishment, they can provide years of reliable service, contributing to resource conservation and waste reduction efforts in manufacturing processes.

In conclusion, while often overlooked, rubber rollers technology represents a cornerstone of modern industrial manufacturing. From printing and laminating to material handling and beyond, these unassuming cylindrical components play a pivotal role in ensuring the efficiency, quality, and reliability of diverse manufacturing processes. As industries continue to evolve and innovate, the role of rubber rollers is poised to remain indispensable, driving progress and efficiency across the industrial landscape.

0 notes

Text

Unlocking the Potential: Exploring Textile Printing Machines Market Trends

Introduction

In the dynamic world of textiles, printing plays a crucial role in adding value, enhancing aesthetics, and enabling customization. From apparel and home furnishings to automotive interiors and signage, printed textiles are ubiquitous in our daily lives. Behind the scenes, textile printing machines are at the forefront of innovation, driving the industry forward with advanced technologies, sustainable practices, and innovative applications.

In this comprehensive article, we will delve deep into the trends shaping the textile printing machines market, exploring digital transformation, sustainability initiatives, global market dynamics, and the future outlook.

According to the study by Next Move Strategy Consulting, the global Textile Printing Machines Market size is predicted to reach USD 17.78 billion with a CAGR of 5.2% by 2030.

Request a FREE sample, here: https://www.nextmsc.com/textile-printing-machines-market/request-sample

Digital Transformation: The Rise of Digital Printing Technologies

Digital printing has emerged as a game-changer in the textile industry, offering unparalleled flexibility, speed, and quality. Unlike traditional printing methods such as screen printing and rotary printing, which involve lengthy setup times and limited design capabilities, digital printing allows for the on-demand production of highly intricate designs with minimal setup requirements. This shift towards digitalization is transforming the way textiles are printed, enabling faster turnaround times, reduced waste, and enhanced customization options.

One of the key advantages of digital textile printing is its ability to accommodate short print runs and rapid design iterations, making it ideal for fast fashion brands and niche markets. With advancements in inkjet technology and software solutions, digital printers can achieve vibrant colors, sharp details, and smooth gradients, replicating complex designs with precision. Additionally, digital printing enables variable data printing, allowing manufacturers to personalize products with individualized text, graphics, or images.

In recent years, the adoption of digital printing technologies has surged across the textile industry, driven by factors such as increasing demand for customized products, growing e-commerce penetration, and advancements in digital ink formulations. Today, digital textile printers are capable of printing on a wide range of substrates, including cotton, polyester, silk, and even synthetic fabrics such as nylon and spandex. As digital printing continues to evolve, we can expect further improvements in print speed, color accuracy, and substrate compatibility, expanding the possibilities for innovation and creativity in the textile industry.

Sustainability Focus: Driving Environmental Responsibility in Textile Printing

Sustainability has become a key priority for stakeholders across the textile supply chain, from raw material suppliers to garment manufacturers and retailers. In response to growing environmental concerns and regulatory pressures, the textile printing industry is increasingly adopting sustainable practices and eco-friendly technologies to minimize its ecological footprint.

One of the primary areas of focus for sustainable textile printing is the development of water-based inks as an alternative to traditional solvent-based inks. Water-based inks contain lower levels of volatile organic compounds (VOCs) and hazardous chemicals, making them safer for both workers and the environment. Additionally, water-based inks are more easily recyclable and biodegradable, reducing the impact of printing waste on landfills and waterways.

Another sustainability initiative gaining traction in the textile printing industry is the use of eco-friendly substrates and materials. Manufacturers are exploring alternative fibers and fabrics derived from renewable sources such as bamboo, hemp, and organic cotton, which require fewer pesticides and chemicals in their production. Additionally, advancements in textile recycling technologies are enabling the reuse and repurposing of post-consumer and post-industrial textile waste, closing the loop on the circular economy.

Beyond ink and substrate choices, textile printing companies are also implementing energy-efficient manufacturing processes and investing in renewable energy sources to reduce their carbon emissions. From energy-efficient digital printers to solar-powered production facilities, sustainable energy solutions are helping textile printers minimize their environmental impact and contribute to a greener future.

Innovative Applications: Exploring New Frontiers in Textile Printing

The versatility of textile printing machines extends far beyond traditional applications such as apparel and home textiles. Today, printed textiles are finding innovative uses across a wide range of industries, from automotive and aerospace to healthcare and architecture. Advances in printing technologies and materials are unlocking new possibilities for creativity, functionality, and customization in diverse sectors.

In the automotive industry, printed textiles are increasingly used for interior upholstery, seat covers, and decorative trim, offering designers the flexibility to create unique patterns, textures, and color schemes. Digital printing enables automotive manufacturers to produce custom interiors tailored to individual preferences, enhancing the overall aesthetic appeal of vehicles, and differentiating them in the market.

Inquire before buying, here: https://www.nextmsc.com/textile-printing-machines-market/inquire-before-buying

Similarly, in the field of architecture and interior design, printed textiles are being employed for wall coverings, window treatments, and acoustic panels, transforming spaces with visually stunning and acoustically functional designs. Digital printing allows architects and interior designers to collaborate with textile printers to create bespoke solutions that meet their project requirements, whether it's a corporate office, hospitality venue, or residential space.

In the healthcare sector, printed textiles are playing an increasingly important role in patient care and medical device manufacturing. Antimicrobial fabrics, printed with specialized inks containing silver nanoparticles or other antimicrobial agents, are being used for hospital linens, uniforms, and wound dressings to help prevent the spread of infections and improve hygiene standards. Additionally, 3D-printed textile structures are being explored for applications such as tissue engineering, drug delivery, and wearable medical devices, opening up new possibilities for personalized healthcare solutions.

Global Market Dynamics: Exploring Regional Trends and Opportunities

The textile printing machines market is a dynamic and diverse landscape, shaped by regional trends, economic factors, and cultural preferences. While established markets such as North America and Europe continue to drive innovation and technological advancements, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth and market expansion.

In North America and Europe, the textile printing industry is characterized by a high level of automation, advanced digital printing technologies, and a strong emphasis on sustainability and product innovation. Manufacturers in these regions are investing in research and development to stay ahead of the curve and meet evolving consumer demands for eco-friendly and customizable products. Additionally, strategic partnerships and collaborations between textile printing companies and fashion brands are driving market growth and brand differentiation.

In contrast, Asia-Pacific and Latin America are emerging as key growth markets for textile printing machines, fueled by factors such as urbanization, rising disposable incomes, and a growing middle-class population. Countries including China, India, Brazil, and Mexico are witnessing a surge in demand for printed textiles driven by the booming fashion and apparel industries, increasing consumer awareness of fashion trends, and the growing popularity of e-commerce platforms. As a result, textile printing companies in these regions are ramping up production capacity, investing in infrastructure, and adopting advanced printing technologies to capitalize on market opportunities and gain a competitive edge.

Conclusion: Charting the Course for Future Success

As we look ahead to the future of the textile printing machines market, one thing is clear: innovation, sustainability, and globalization will continue to shape the industry landscape and drive market growth. Digital transformation will revolutionize the way textiles are printed, enabling faster turnaround times, greater customization, and enhanced creativity. Sustainability will remain a top priority for stakeholders across the supply chain, driving the adoption of eco-friendly materials, energy-efficient processes, and responsible manufacturing practices. And global market dynamics will present both challenges and opportunities for textile printing companies, as they navigate evolving consumer preferences, regulatory requirements, and competitive pressures.

By staying abreast of the latest trends and developments in the textile printing machines market, businesses can position themselves for success in this dynamic and competitive industry. Whether it's investing in digital printing technologies, implementing sustainable practices, or exploring new applications and markets, textile printing companies must adapt and innovate to thrive in an ever-changing business environment. As we unlock the full potential of textile printing machines and harness the power of innovation and sustainability, we can create a brighter future for the industry, our customers, and the planet.

0 notes

Text

Unleashing Creativity: Exploring Fabric Printing in the UK

In the realm of design and personal expression, fabric printing stands as a vibrant canvas for creativity. From bespoke fashion pieces to unique home décor, the possibilities are endless when it comes to bringing ideas to life on fabric. In the United Kingdom, a rich tapestry of fabric printing services and artisans exists, catering to individuals and businesses alike. Let's embark on a journey to discover the world of fabric printing in the UK, where innovation, craftsmanship, and artistic flair converge.

The Art of Fabric Printing

Fabric printing is an age-old craft that has evolved significantly with technological advancements and modern techniques. Today, artists and designers have access to an array of methods for transferring designs onto fabric, including screen printing, digital printing, block printing, and sublimation printing. Each method offers unique characteristics, allowing creators to achieve different textures, colors, and effects on various types of fabric.

Tailored Creations: Custom Fabric Printing

One of the hallmarks of fabric printing in the UK is the emphasis on customization and personalization. Whether you're a fashion designer seeking to bring your vision to life or an individual looking to create bespoke gifts or home textiles, custom fabric printing services abound in the UK. From small boutique studios to large-scale printing facilities, artisans and manufacturers offer tailored solutions to meet the unique needs and preferences of their clients.

Sustainable Solutions: Eco-Friendly Printing Practices

As environmental consciousness continues to grow, so does the demand for sustainable fabric printing solutions. Many printing companies in the UK prioritize eco-friendly practices, using water-based inks, organic fabrics, and energy-efficient processes to minimize their environmental footprint. By embracing sustainability, these printers not only reduce their impact on the planet but also cater to eco-conscious consumers who value ethically produced textiles.

Collaborative Ventures: Supporting Local Artists and Designers

The UK fabric printing industry thrives on collaboration between printers, artists, designers, and entrepreneurs. Many printing studios actively collaborate with local talent, providing them with a platform to showcase their designs and reach a broader audience. Whether through partnerships with independent designers, collaborative pop-up events, or curated online marketplaces, these collaborative ventures foster a sense of community and support within the creative ecosystem.

Innovation in Technology: Digital Fabric Printing

Digital fabric printing has revolutionized the way designs are transferred onto textiles, offering unparalleled flexibility, speed, and precision. In the UK, digital printing facilities equipped with state-of-the-art machinery enable artists and designers to unleash their creativity without limitations. From intricate patterns and vibrant colors to photographic prints and custom gradients, digital fabric printing opens up a world of possibilities for textile innovation.

Preserving Heritage: Traditional Printing Techniques

While digital printing has gained prominence, traditional printing techniques still hold a special place in the fabric printing landscape of the UK. Artisans skilled in methods such as screen printing, block printing, and hand-dyeing continue to preserve these time-honored crafts, infusing their creations with a sense of authenticity and heritage. Through workshops, exhibitions, and cultural events, the UK celebrates its rich tradition of textile craftsmanship and keeps these ancient techniques alive for future generations.

Conclusion

In conclusion, fabric printing in the UK is a dynamic and multifaceted industry that celebrates creativity, innovation, and collaboration. Whether through cutting-edge digital technologies or time-honored traditional techniques, artisans and designers across the UK are pushing the boundaries of textile design and production. From custom creations to sustainable solutions, the fabric printing landscape in the UK offers something for everyone, inviting individuals to unleash their imagination and adorn the world with their unique creations. So, dive into the vibrant world of fabric printing in the UK and let your creativity run wild on the canvas of textiles.

0 notes

Text

Unlocking the Potential: A Comprehensive Overview of the Printing Ink Market

Introduction:

The printing ink market is a crucial component of the printing industry, supporting various sectors such as packaging, publishing, commercial printing, and more. As technology continues to evolve and environmental concerns gain prominence, the printing ink market is experiencing significant shifts. This comprehensive overview delves into the key aspects shaping the printing ink market landscape.

Market Analysis:

The printing ink market is witnessing steady growth, driven by advancements in printing technology and the increasing demand for printed materials across industries. With the rise of digital printing, there is a growing need for high-quality, versatile printing inks compatible with diverse printing processes.

Industry Trends:

Several trends are influencing the printing ink market, including:

Shift Towards Digital Printing: Digital printing technologies are gaining traction due to their efficiency, customization capabilities, and reduced setup times. This trend is driving the demand for digital inks tailored for various substrates.

Sustainability: Environmental concerns are driving the development of eco-friendly printing inks formulated with renewable resources and fewer volatile organic compounds (VOCs). Manufacturers are focusing on sustainable ink formulations to meet regulatory requirements and consumer preferences.

Innovation: Continuous innovation in ink formulations is enhancing print quality, durability, and compatibility with different substrates. Nano-based inks, UV-curable inks, and specialty inks are among the innovations driving market growth.

Emerging Markets: Emerging economies are witnessing rapid industrialization and urbanization, leading to increased demand for printed materials across sectors such as packaging, textiles, and advertising. This presents lucrative opportunities for ink manufacturers to expand their presence in these regions.

Ink Types:

Printing inks are categorized based on their formulation and application, including:

Lithographic Inks: Used in offset printing for high-quality commercial printing applications such as magazines, catalogs, and brochures.

Flexographic Inks: Ideal for packaging printing due to their ability to adhere to various substrates and withstand the rigors of packaging processes.

Gravure Inks: Commonly used in high-speed printing processes for packaging materials, labels, and flexible packaging.

Digital Inks: Specifically designed for digital printing technologies such as inkjet and electrophotography, offering quick drying times and vibrant colors.

Market Size and Regional Analysis:

The printing ink market is geographically diverse, with key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific dominates the market due to the presence of major manufacturing hubs and the growing demand for printed packaging in countries like China and India. North America and Europe are also significant markets, driven by technological advancements and sustainability initiatives.

Growth Drivers:

Key factors driving the growth of the printing ink market include:

Rise in Packaging Industry: The booming packaging industry, driven by e-commerce, food & beverage, and consumer goods sectors, is fueling the demand for high-quality printing inks for packaging applications.

Technological Advancements: Continuous innovation in printing technology, including digital printing and inkjet technology, is expanding the scope of applications for printing inks and driving market growth.

Increasing Demand for Customization: Consumers are increasingly seeking personalized and customized products, driving the need for printing solutions that offer flexibility and customization capabilities.

Conclusion:

The printing ink market is undergoing a transformation, driven by technological advancements, sustainability initiatives, and evolving consumer preferences. As the industry embraces digitalization and environmental consciousness, ink manufacturers are innovating to meet the demands of a dynamic market landscape. By staying abreast of industry trends and investing in research and development, stakeholders can unlock the full potential of the printing ink market.

#Printing Ink#Market Analysis#Industry Trends#Printing Technology#Ink Types#Growth Drivers#Market Size#Regional Analysis#Sustainability#Digital Printing#Packaging Industry#Environmental Regulations#Innovation#Emerging Markets

0 notes

Text

Revolutionizing Textiles: Exploring the Digital Textile Printing Machines Market

In the dynamic world of textile manufacturing, digital textile printing machines are ushering in a new era of innovation, efficiency, and creative possibilities. These advanced machines leverage digital technology to transfer designs directly onto fabric, offering manufacturers greater flexibility, customization, and speed compared to traditional printing methods. In this article, we delve into the dynamics of the digital textile printing machines market, exploring key trends, innovations, and considerations driving the industry forward.

Digital textile printing machines have revolutionized the textile industry by streamlining the printing process and enabling on-demand production of high-quality fabrics with intricate designs and vibrant colors. Unlike conventional printing techniques such as screen printing or rotary printing, which require separate screens or cylinders for each color and design, digital printing allows for direct printing from digital files, eliminating the need for costly setup processes and reducing lead times.

One of the defining trends in the digital textile printing machines market is the shift towards sustainability and eco-friendliness. As consumers become increasingly aware of the environmental impact of textile production, there is a growing demand for greener printing technologies that minimize water consumption, chemical usage, and waste generation. Digital textile printing machines offer inherent sustainability advantages, such as reduced water usage, minimal setup waste, and the ability to print on demand, thereby reducing overproduction and excess inventory.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS25064

Moreover, digital textile printing machines enable greater design freedom and customization options, allowing manufacturers to produce unique, personalized fabrics tailored to individual preferences and market trends. With digital printing, designers can create intricate patterns, photorealistic images, and complex color gradients that would be difficult or impossible to achieve with traditional printing methods. This versatility and flexibility open up new opportunities for product differentiation and market segmentation in the textile industry.

Another key trend driving the digital textile printing machines market is the integration of advanced technologies such as inkjet printing, dye sublimation, and reactive dye printing. These technologies offer advantages such as fast printing speeds, high-resolution output, and compatibility with a wide range of fabric types, including natural fibers like cotton and silk, as well as synthetic materials like polyester and nylon. Additionally, ongoing advancements in ink formulations and printhead technology are enhancing print quality, durability, and colorfastness, further expanding the application potential of digital textile printing.

Furthermore, the digital textile printing machines market is witnessing innovations in automation, workflow optimization, and software integration to streamline production processes and enhance operational efficiency. Integrated software solutions for color management, file preparation, and print job scheduling enable manufacturers to achieve greater consistency, accuracy, and productivity in their printing operations. Additionally, robotics and automation technologies are being deployed to automate tasks such as fabric loading, printing, and unloading, reducing labor costs and minimizing human error.

In conclusion, digital textile printing machines are driving a paradigm shift in the textile industry, offering manufacturers unprecedented flexibility, efficiency, and creativity in fabric production. With advancements in sustainability, customization, and technology integration, digital printing is poised to become the preferred method for textile printing in the years to come. As manufacturers embrace digitalization and invest in state-of-the-art printing solutions, the digital textile printing machines market will continue to thrive, unlocking new possibilities for innovation and growth in the global textile industry.

0 notes

Text

Epson’s talks about innovative printing solutions at pre-drupa meet

At the pre-drupa press conference held in Dusseldorf from 25-27 March, Duncan Ferguson, vice president of Epson Europe’s commercial and industrial printing division, offered a glimpse into the company’s anticipated showcase at drupa 2024. Epson will be present in Hall 5, Stand D20, at the printing and packaging show scheduled to be held from May 28 to June 7 in Dusseldorf.

Titled ‘Changing the Model for Localised Production,’ Ferguson outlined Epson’s commitment to manufacturing, focusing on compact, efficient printing solutions, and emphasizing personalization and on-demand production technology.

His presentation covered several key areas:

Advanced Printhead Technology: Epson’s latest industrial printhead, the D3000, is tailored for various applications including packaging, labels, textiles, and décor. Special features include high speed, single-pass, 1200 dpi resolution with nozzle-level re-circulation.

Innovative Product Design: Epson’s new product design concept features space-saving designs, replaceable printheads, enhanced environmental standards, and improved user interfaces. The new platform will be easier to use with a large 4.3-inch user interface display, low profile and flat top design, media cleaner and a media lifter allowing for a single-person set-up.

Next-Generation Label Press: Epson’s new SurePress labeling concept promises increased productivity and image quality through real-time nozzle detection and additional enhancements.

Direct-to-Fabric Printing: Ferguson introduced the Monna Lisa 13000, a new digital fabric printing solution offering in-line printing with sustainable pigment inks and enhanced print durability. The innovation aims to revolutionize textile printing by eliminating the need for post-treatment equipment, making it more accessible to commercial printers.

Productivity Breakthroughs: The SureColor F10000, Epson’s most productive dye-sublimation printer, features jumbo roll capabilities and self-replaceable parts for minimal downtime. The dye-sublimation printer delivers productivity up to 255m2/h, 10L hot-swap inks (LcLm/FyFp) and has self-replaceable parts for easy maintenance.

Personalization Solutions: Epson’s range of printers targeting the personalization and micro-production market, including hybrid DTG/DTFilm printers and UV flatbed printers. This included the recently launched hybrid DTG/DTFilm SureColor F1000 and the A4 UV flatbed SureColor V1000. Ferguson introduced the A3 UV flatbed SureColor V2000 and new micro-production SureColor F2200 and showed the complete range of mini-lab (D1000, D500) and smaller dye sublimation printers (SureColor F500 and F100).

Supporting Software and Tools: Epson’s software and process management tools, including the SD-10 Scanning Table and Edge Color Lite software, which enhance color management and consistency. Also launched was the new SD-10 scanning table along with mentions of Epson’s Edge Color Lite and Edge Print software that further the capability to manage distributed printing at the highest quality and consistency.

Focus on services

Ferguson also explained how Epson is delivering successful product reconditioning programs to extend the life of Epson printers and create a more sustainable business model. He talked about Epson’s reconditioning program, which aims to repair, repurpose and upgrade products on its customers‘ premises. He mentioned how Epson has established a central facility for technical refurbishment work and is collecting and returning customer products; how it reuses cartridges and printer parts and collects cartridges that can be refilled with genuine Epson ink.

Future developments

Finally, Ferguson revealed future developments, including support for more sustainable fashion using Epson’s Dry Fiber Technology (DFT). DFT produces durable printable fabric from used garments without any water. He said that the Japanese fashion designer Yuima Nakazato is using DFT to experiment with batches of cotton, polyester and silk and plans to commercialize his range in 2024. Some examples of Dry Fibre fabric fashion items were on display at the presentation.

He discussed Epson’s new direct-to-shape technology and explained how the company is developing its expertise with inkjet technology to print on complex shapes using automation with its robots.

0 notes

Text

Unleashing Imagination: Exploring the Potential of Silk Making Equipment

Silk printing, also referred to as monitor printing, has been a cornerstone of fabric style for centuries. From their modest beginnings in ancient China to its modern-day software in industries world wide, cotton printing has undergone an amazing evolution. Key to the evolution are the silk making devices that have continuously advanced in technology, detail, and efficiency. In this information, we search to the amazing trip of cotton making models, discovering their history, improvements, and impact on fabric design. دستگاه چاپ سیلک

The Roots of Silk Making:

The origins of cotton printing may be traced back once again to historical China, where the approach was developed around 1000 AD. Originally, cotton making was a labor-intensive method, involving the painstaking hand-stenciling of types onto cotton cloth applying silk mesh screens. This technique, while efficient, was slow and restricted in their capabilities.

The Industrial Innovation and the Birth of Cotton Printing Machinery:

The introduction of the Professional Revolution in the 18th century caused substantial developments in production and printing technology. It absolutely was during this time period that the first silk making machines started initially to emerge. These early devices mechanized the method of cloth printing, allowing for faster production and greater reliability in design. However, these were however relatively raw in comparison to contemporary standards, requiring manual operation and missing the detail of later innovations.

Technological Inventions in the 20th Century:

The 20th century found a flurry of technical inventions that changed silk making machinery. One of the most significant developments was the release of circular screen making, which changed the original flatbed printing process. Rotary screen making machines permitted for continuous making on a move of cloth, significantly raising production rates and efficiency.

Another landmark in cotton making technology was the creation of the computerized silk screen making machine. These models automated the making method, reducing the requirement for guide job and increasing productivity. Furthermore, improvements in ink formulations and drying methods increased the product quality and toughness of produced materials, expanding the options for developers and manufacturers.

The Digital Age and the Rise of Electronic Cotton Printing Models:

In new years, the electronic revolution has altered virtually every facet of our lives, including cloth printing. Digital cotton making devices symbolize the latest frontier in material design, offering unmatched detail, usefulness, and customization. Unlike traditional silk making practices, which count on displays and stencils, digital printing uses computer-controlled engineering to utilize ink right onto fabric. This allows for elaborate designs, lively colors, and photo-realistic designs with minimal setup time and waste.

Moreover, digital silk printing devices are eco-friendly, as they require fewer substances and less water than standard making methods. Additionally, they provide on-demand production capabilities, enabling manufacturers to generate small-batch or custom-printed fabrics without the necessity for expensive startup charges or minimal buy quantities.

The Potential of Silk Printing Devices:

As technology continues to improve, therefore also may cotton making machines. Improvements such as for instance 3D printing and intelligent textiles are actually beginning to restore the landscape of fabric design, providing new opportunities for creativity and expression. Furthermore, the integration of synthetic intelligence and unit learning algorithms promises to help expand optimize the making method, reducing waste, and raising efficiency.

In conclusion, cotton making devices have played an important role in the evolution of fabric design, from their ancient roots to their modern-day applications. With each scientific advancement, these models have pushed the limits of what is probable, allowing makers to produce spectacular and revolutionary textiles that captivate the imagination. As we look to the long run, it is distinct that silk making machines will keep on to drive innovation and encourage imagination in the world of cloth design.

0 notes

Text

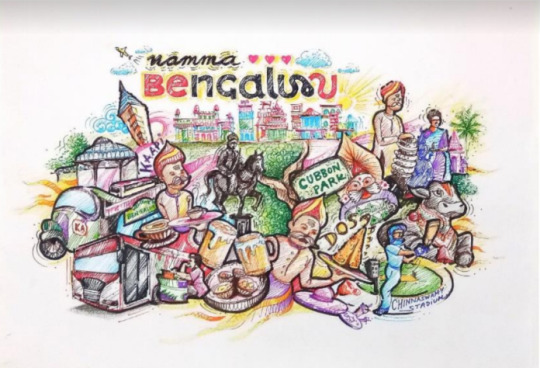

Bengaluru to host the premiere edition of Bharat Print Expo!

The Total Print and Package Converting exhibition will be held from 24-26 April 2025

at Bangalore International Exhibition Centre, Bengaluru.

"This is not just another printing exhibition," declares Anil Arora, President of ReEnvision

Events Private Limited. "India is poised to become the world's third-largest economy

within the next five years, and we acknowledge that specific sectors as well as regions of

the country have played a crucial role in driving this growth. It is essential that we feature

them prominently on our event calendar."

Bharat Print Expo is inspired by the county’s adoption of new Print and Converting technologies, coupled with the surge in e-commerce, evolving lifestyles, urbanization, and heightened awareness about personal health, that has significantly fuelled the expansion of the Print and Packaging sectors. Bengaluru is a city that mirrors its diversity, combining a rich cultural tapestry with advanced technologies. According to the Bengaluru Innovation Report, among the 780 major cities globally, 17 of the 20 fastest growing cities will be in India. Among them, Bengaluru is projected to have the world's fastest GDP growth at 8.5%, maintaining this pace until 2035. The vibrant city will hold the first edition of Bharat Print Expo, driving participation from all across the country along with a global brand presence. The venue selection was made based on a survey conducted among the exhibitors of our current show.

Exhibitor Profile

Bharat Print Expo 2025 will delve into the growing demand and prospects within South India and its surrounding areas. Exhibitors hailing from various parts of the nation will showcase cutting-edge products and solutions spanning the print and related industries, including- Printing Equipment: Offset/ Screen/ Digital/ Flexo/ Gravure; Prepress Equipment; Post-press & Packaging Converting Equipment; Label Converting & Printing Press; Paper Converting Machines; Adhesives & Consumables; Binding & Lamination; Paper, Films, Foils; Ink & Chemicals; Dies, Cutters, Rollers; Corrugated Box Making Machinery; Carton Folding Equipment; Testing Equipment, Inspection Systems & Accessories; Textile Printing Machines; 3D Printers; Wide Format Signage Printers; Plant Automation; Infrastructure, Trade Associations & Financial Organisations and Services & Software.

Visitor Profile

The exhibition will attract visitors from the entire Southern region, with extensive promotional activities planned to reach a wide audience. Targeted visitors from all over Bharat and Sri Lanka will also attend the Show. The profile will broadly include: Commercial Printers, Package Printers & Label Printers; Brand Owners & Print Buyers; Package Converters & Corrugated Box Manufacturers; Textile Printers & Professionals; Signage & Graphic Arts Specialists; Retailers, Manufacturers & Industry Suppliers; Packaging Professionals, Design Houses, Art Directors & Consultants; Trade publications, Advertising, Marketing, Media & PR Agencies; Government Bodies and Trade Associations.