#Microstructures

Text

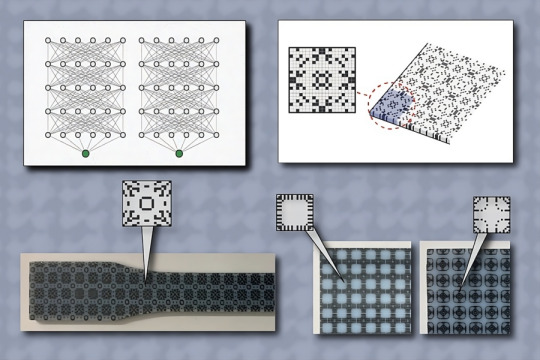

Using AI to discover stiff and tough microstructures

Innovative AI system from MIT CSAIL melds simulations and physical testing to forge materials with newfound durability and flexibility for diverse engineering uses.

Every time you smoothly drive from point A to point B, you're not just enjoying the convenience of your car, but also the sophisticated engineering that makes it safe and reliable. Beyond its comfort and protective features lies a lesser-known yet crucial aspect: the expertly optimized mechanical performance of microstructured materials. These materials, integral yet often unacknowledged, are what fortify your vehicle, ensuring durability and strength on every journey.

Luckily, MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) scientists have thought about this for you. A team of researchers moved beyond traditional trial-and-error methods to create materials with extraordinary performance through computational design. Their new system integrates physical experiments, physics-based simulations, and neural networks to navigate the discrepancies often found between theoretical models and practical results. One of the most striking outcomes: the discovery of microstructured composites — used in everything from cars to airplanes — that are much tougher and durable, with an optimal balance of stiffness and toughness.

Read more.

#Materials Science#Science#Microstructures#Artificial intelligence#Computational materials science#MIT

13 notes

·

View notes

Text

@maderilien you... broke me.....

#i'm halfway through il.lu.mi.nate ch4 and i'm literally incapable of putting words together in a god obiding and coherent fashion#to make a comment#i think you fundamentally altered the microstructure of my DNA i'll never be the same person again#in which Maddie is less of a fic writer and more of a godtier alchemist#I'M NOT EVEN FINISHED YET!!! AND AND!!!!!!!!#''do you remember the chocolate?'' “i can get you another box'' HEY HEY WATCH HOW HARD I CAN CRY!!!!!!

3 notes

·

View notes

Text

la fin is located in an abandoned cathedral, and i think about all the ways nature creeps in, how it ultimately takes over something that was man-made, and how that connects to the vampires that inhabit its halls, how nature has found a way to creep into their humanness and reclaim the body as its own; yes, vampires are abnormal from a human perspective, but to nature? aren't they part of the cycle?

#macrostructures mimicking microstructures#everything is interconnected & interrelated#patterns are always repeated in an infinite cycle#anw hello i will be here soon#finally seeing the end of the semester#TBT.

1 note

·

View note

Text

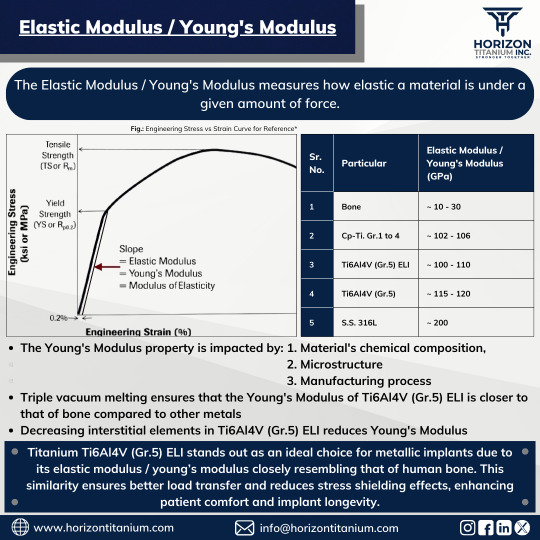

Metal implants play a crucial role in biomedical engineering, offering durability and reliability for bone reconstruction.

With superior mechanical properties compared to ceramics and polymers, metals like Titanium Ti-6Al-4V (Gr.5) ELI are preferred for handling heavy loads. In fact, 80% of implants are made from metal, with Titanium Ti-6Al-4V (Gr.5) ELI being the major choice, especially due to its higher fatigue strength and fracture toughness.

The value of the Elastic Modulus / Young's Modulus, should closely match that of the bone to minimize the stress-shielding effect between the bone and the implant. We will delve into more details about the stress-shielding effect in our next post.

Ti-6Al-4V ELI closely matches bone's Young's modulus as compared to other metallic implantable materials, making it a top choice for bone replacements.

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#ElasticModulus#YoungsModulus#ModulusofElasticity#Elasticity#StressStrainCurve#EngineeringStressStrainCurve#BoneYoungsModulus#TitaniumYoungsModulus#StainlessSteelYoungsModulus#StressShieldingEffects#CPTitanium#Ti6Al4V#Ti6Al4VELI#SS316L#ChemicalComposition#Microstructure#3VAR#ELI#TitaniumImplant#OrthopeadicImplant#PatientComfort#ImplantLongevity#HorizonTitanium#StrongerTogether

1 note

·

View note

Text

Metal Manufacturing as the Smart Specialization of the Regions

Metal manufacturing has emerged as a shining beacon of innovation and economic progress, transforming from a conventional heavy industry into a smart specialization that drives regional development. This article aims to shed light on the intricate world of metal manufacturing, encompassing its evolution, significance, technological advancements, and its pivotal role as a smart specialization strategy across diverse regions.

METNMAT RESEARCH AND INNOVATION

1. Introduction: From Tradition to Transformation

At the heart of industrial evolution lies the remarkable journey of metal manufacturing. Once associated with the imagery of smoke-filled factories and manual labor, this sector has undergone a revolutionary metamorphosis. Today, it stands tall as a vanguard of innovation, steering the course of regional development toward new horizons. The transition from tradition to transformation is a testament to the resilience and adaptability of metal manufacturing in the face of changing times.

2. The Significance of Metal Manufacturing

Metal manufacturing occupies a pivotal position in the tapestry of industries that shape the modern world. From the towering structures of urban landscapes to the intricate components within electronic devices, its significance is omnipresent. The products of metal manufacturing serve as the backbone of diverse sectors, breathing life into everything from automobiles to advanced medical equipment. This significance underscores its role not only as an economic driver but also as an enabler of technological progress and societal advancement.

"From forges of tradition to the frontier of technology, metal manufacturing stands as a beacon of progress." - [METNMAT RESEARCH AND INNOVATION]

3. Evolution of Metal Manufacturing Techniques

The annals of metal manufacturing are adorned with a story of relentless innovation and technological prowess. The evolution of techniques from labor-intensive processes to precision-driven methodologies is a captivating journey that mirrors humanity's quest for perfection. Gone are the days of hammer and anvil as digital fabrication technologies have taken center stage. The marriage of computer-aided design (CAD) and computer-aided manufacturing (CAM) has birthed a new era of digital craftsmanship, where intricate designs come to life with unparalleled accuracy and speed.

4. Technological Advancements Driving Smart Metal Manufacturing

The dawn of the fourth industrial revolution has cast a transformative spell on the realm of manufacturing. Metal manufacturing, in particular, has been a willing participant in this digital renaissance. The infusion of sensors, Internet of Things (IoT) devices, and data analytics has given rise to a new era of smart metal manufacturing. This paradigm shift empowers manufacturers with real-time insights, predictive maintenance capabilities, and the ability to fine-tune processes for optimal efficiency. The convergence of technology and metallurgy has bestowed upon us a realm where precision meets intelligence, and where waste is minimized through data-driven decision-making.

5. The Role of Skilled Workforce in Metal Manufacturing

While technology orchestrates the symphony of modern metal manufacturing, it is the skilled workforce that wields the baton. Behind the curtain of automation and innovation, there exists a cohort of talented individuals whose expertise ensures the seamless orchestration of complex processes. Engineers, technicians, and designers collaborate harmoniously to breathe life into raw materials, sculpting them into works of art that power our modern world. The symphony of metal manufacturing requires not only the instruments of technology but also the virtuosity of skilled human hands.

6. Sustainable Practices in Metal Manufacturing

Amidst the backdrop of escalating environmental concerns, the concept of sustainability has permeated virtually every facet of human endeavor. Metal manufacturing, with its historical reputation for resource-intensive processes, has not been impervious to this shift. However, the sector has responded with remarkable ingenuity, embracing sustainable practices that echo a commitment to both innovation and environmental stewardship.

The adoption of sustainable practices in metal manufacturing spans various dimensions. One notable avenue is the recycling of scrap metal. In an era where responsible resource utilization is paramount, the recycling of scrap metal not only conserves precious resources but also curtails the environmental impact of mining and extraction. The metamorphosis of discarded metal into raw material breathes new life into the production cycle, reducing energy consumption and minimizing waste.

Moreover, energy efficiency has become a cornerstone of sustainable metal manufacturing. From the optimization of heating and cooling systems to the deployment of energy-efficient technologies, manufacturers are meticulously recalibrating their processes to minimize energy consumption. This not only translates into cost savings but also contributes to a greener and more environmentally conscious industry.

7. Regional Smart Specialization: Boosting Economic Growth

In an era characterized by unprecedented globalization and interconnectedness, regions seek strategies that can catapult them onto the global stage. Enter the concept of smart specialization. This strategic approach involves concentrating resources and efforts on areas of expertise, thereby fostering economic growth and innovation. Metal manufacturing emerges as an alluring candidate for smart specialization, harnessing its multifaceted applications and demanding technological landscape.

The synergy between regional strengths and metal manufacturing is a symbiotic relationship that begets economic prosperity. By aligning a region's existing industrial prowess with the demands of metal manufacturing, a unique competitive advantage is forged. This advantage, coupled with strategic investments in research, development, and education, positions regions as formidable players in the global market. The allure of specialized metal products, coupled with a technologically adept workforce, becomes a potent recipe for attracting investment, generating employment, and fueling economic expansion.

8. Case Studies: Successful Implementation of Metal Manufacturing Specialization

The theoretical underpinnings of smart specialization find tangible expression in real-world case studies. Several regions have harnessed the potential of metal manufacturing specialization, leading to transformative outcomes. One such compelling example is the resurrection of a declining industrial town through the establishment of a cutting-edge metal research and production hub.

This case study highlights the transformative power of deliberate specialization. By identifying and capitalizing on latent potential, this region was able to transition from the throes of economic decline to becoming a thriving center of innovation. The infusion of research institutions, collaboration between academia and industry, and the cultivation of a skilled workforce converged to breathe new life into the region. The success story underscores the significance of strategic metal manufacturing specialization in rejuvenating stagnant economies and fostering resilience.

In the upcoming segments of this article, we will delve into the challenges that underlie the path to metal manufacturing specialization, gaze into the crystal ball to discern future prospects, and ultimately, draw our conclusions from the symphony of insights presented.

9. Challenges and Future Prospects

While the journey of metal manufacturing as a smart specialization is marked by resounding successes, it is not without its share of challenges. These challenges, however, are not roadblocks but rather stepping stones that beckon the industry toward an even brighter future.

Challenge 1: Global Competition and Innovation In a world characterized by seamless connectivity, metal manufacturing faces the challenge of global competition. As regions vie to establish themselves as hubs of specialization, the competition intensifies. To remain at the vanguard, continuous innovation becomes imperative. The industry must relentlessly push the boundaries of technology, embracing novel processes, materials, and design paradigms. Innovation not only sustains competitiveness but also kindles the spark of differentiation that sets pioneers apart.

Challenge 2: Skilled Workforce Development The symbiotic relationship between technology and skilled human capital is pivotal in the realm of metal manufacturing. However, nurturing and maintaining a skilled workforce is a multifaceted challenge. The industry must bridge the gap between academia and industry, ensuring that educational curricula align with the demands of modern metal manufacturing. Furthermore, the allure of other sectors and the aging workforce pose recruitment challenges. A concerted effort toward attracting and retaining talent is imperative to keep the wheels of specialization turning.

Challenge 3: Sustainability Imperatives While sustainable practices have found a home in metal manufacturing, the journey toward comprehensive environmental stewardship is ongoing. Striking a balance between resource utilization, energy efficiency, and waste reduction remains a complex endeavor. Technological innovations will play a pivotal role in overcoming these challenges, enabling the industry to ascend to new heights of sustainable production.

Challenge 4: Regulatory Landscape The metal manufacturing sector operates within a regulatory framework that demands compliance with environmental standards, safety protocols, and labor regulations. Navigating this intricate landscape can be arduous, particularly for smaller enterprises. Adaptation to evolving regulations and the proactive embrace of compliance becomes paramount to ensure the industry's sustained growth.

Future Prospects: A Vision of Promise The path ahead for metal manufacturing as a smart specialization is imbued with promise and potential. As technology continues to advance, the industry stands on the precipice of transformative breakthroughs. Additive manufacturing, nanotechnology, and advanced materials hold the keys to unlocking new frontiers of possibility. The fusion of these innovations with sustainable practices not only bolsters the industry's competitive edge but also paves the way for a more environmentally conscious and socially responsible future.

Conclusion

In conclusion, metal manufacturing has evolved into a smart specialization strategy that propels regions toward economic prosperity. Its fusion of traditional craftsmanship with cutting-edge technology exemplifies human ingenuity at its finest.

"In the crucible of smart specialization, metal manufacturing reshapes regions into hubs of innovation." - [METNMAT RESEARCH AND INNOVATION]

FAQs

What is smart specialization in the context of metal manufacturing? Smart specialization in metal manufacturing refers to the strategic focus on this sector to drive regional economic growth and innovation.

How does technology contribute to sustainable metal manufacturing? Technology enables energy-efficient processes, waste reduction, and the use of eco-friendly materials in metal manufacturing.

What role does a skilled workforce play in metal manufacturing? A skilled workforce is essential for operating advanced machinery, designing innovative products, and driving continuous improvement.

Can regions with limited metal resources benefit from metal manufacturing specialization? Yes, regions can leverage technology, innovation, and collaboration to overcome resource limitations and create a successful metal manufacturing specialization.

What does the future hold for metal manufacturing as a smart specialization? The future looks promising as technology advances, enabling more efficient, sustainable, and globally competitive metal manufacturing practices.

SIGNUP NOW

#Advanced Technology#Alloying#Future of Materials#future trends#Future Trends#Materials Science#Microstructure Analysis

0 notes

Text

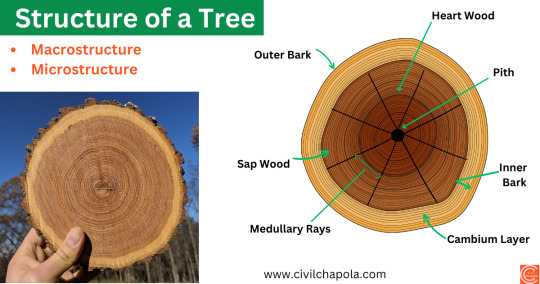

The Structure of a Tree: Understanding the Macrostructure and Microstructure of Timber

Trees have been an important resource for human civilizations for thousands of years, providing building materials, fuel, and other essential products. In civil engineering, timber is one of the most commonly used materials, thanks to its strength, durability, and versatility. Understanding the structure of trees is therefore crucial for civil engineers who work with timber.

Structure of a…

View On WordPress

#branches#building materials.#cambium layer#environment#function#heartwood#inner bark#leaves#macrostructure#medullary rays#microstructure#outer bark#pith#roots#sapwood#structure#structure of tree#timber#tree#trunk

1 note

·

View note

Link

#Weld Tensile Testing#Weld Bend Testing#Weld Microstructure Testing#Welder Qualification#Welding Failure Analysis

0 notes

Text

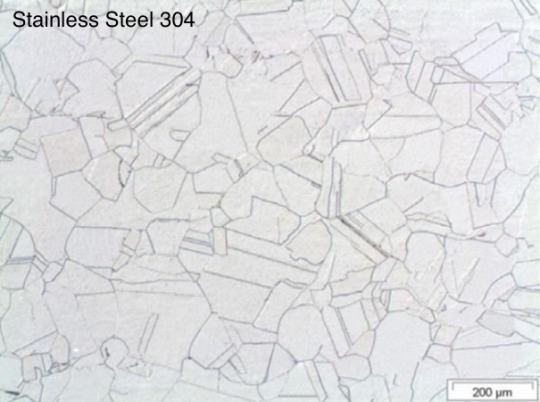

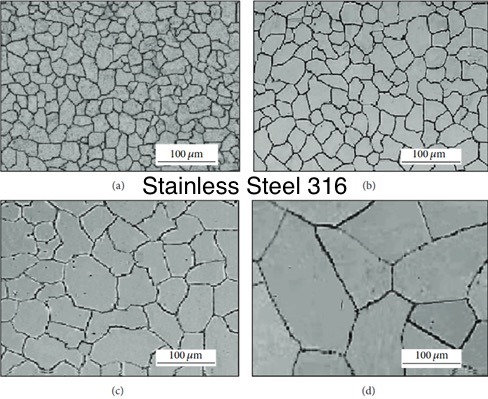

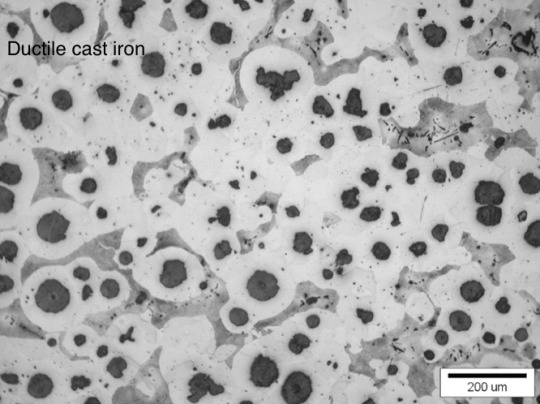

Microstructures

Stainless steel has larger grains compared to cast iron as seen in the figures. The formation of such grains results in a lower tensile strength. Therefore, stainless steel is more ductile than cast iron. As a result, the tank can absorb a certain amount of shock from the repeated colliding of the mixture upon the rotation of the tumbler mixer without fracturing.

1 note

·

View note

Text

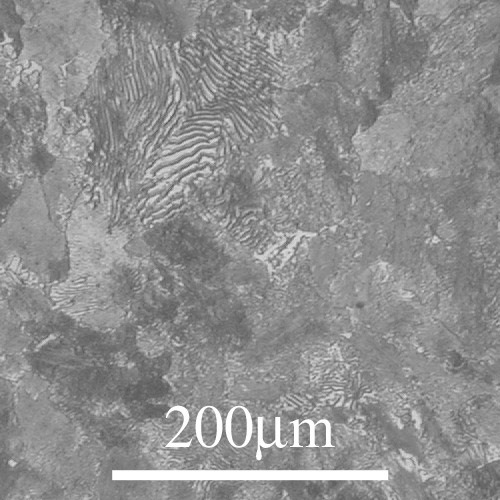

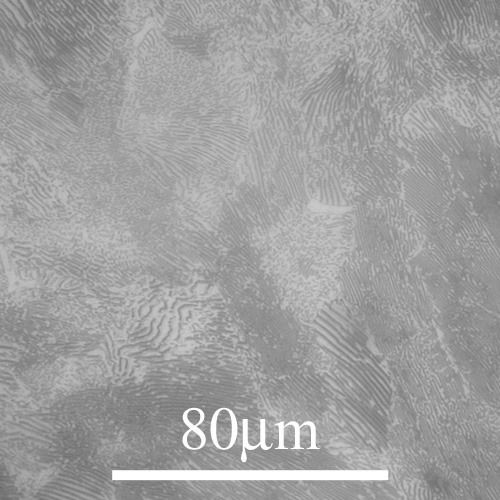

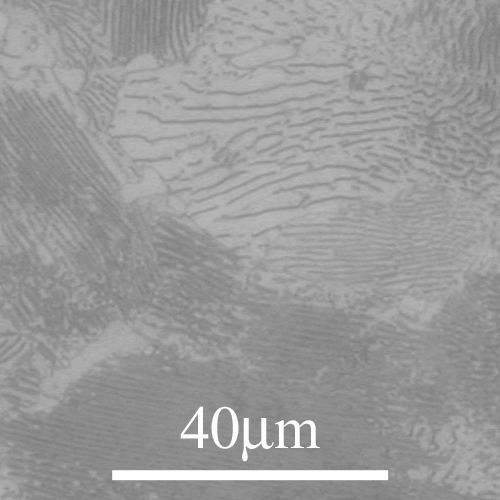

Fe, C 0.8 (wt%), eutectoid transformation - pearlite (coarse)

Processing

Slow cooled

[...]

Technique

Reflected light microscopy

Length bar

200 μm / 80 µm / 40 µm

Further information

This steel is of the eutectoid composition. Once the temperature is lowered below the eutectoid temperature the steel becomes simultaneously supersaturated with both ferrite and cementite. A eutectoid transformation results (g to a + Fe3C). The resultant microstructure, known as pearlite, comprises lamellae of cementite (dark) embedded in ferrite (white). The platelets are parallel to each other and do not follow a specific crystallographic direction.

Each pearlite colony is made up of a number of subgrains. Thus each pearlite colony consists of two interpenetrating single crystals having an orientation relationship with respect to each other and with respect to the austenite grain they grow from, but not with respect to the austenite grain they have grown into. Changes in the apparent interlamellar spacing from colony to colony in the photograph are due to differences in the lamellae spacing with respect to the polished surface.

The coarseness of the pearlite is determined by the interlamellar spacing. This spacing is inversely proportional to the undercooling. This is primarily because of the increased rate of carbide nucleation with increased undercooling.

The pearlite in this sample is coarse due to it being slowly cooled. The undercooling is low so the lamellae spacing is relatively large resulting in a coarse microstructure.

[...]

Organisation

Department of Materials Science and Metallurgy, University of Cambridge

Sources: ( 1 ) ( 2 ) ( 3 )

#Materials Science#Science#Pearlite#Microstructures#Steel#Alloys#Magnified view#Optical microscopy#DoITPoMS#University of Cambridge

18 notes

·

View notes

Link

Recent advancements in building technology have allowed for the creation of concretes that are almost without these constraints and close to optimal circumstances. Modifying the microstructure of cement paste, adding more air to make it lighter, allowing flexibility in lowering or increasing setting pace, etc. are some approaches that improve its qualities.

Special Concrete

The word Special already has value, and in this context, it refers to the distinctive qualities of the concrete. The term special implies that the concrete is even stronger, more resilient, and more difficult to break. According to the specifications, special components are mixed through a unique technique to create the special concrete.

Technology is used to enhance the particular properties of a material, which is beneficial for certain kinds of works, for example, lightweight concrete roofs are preferred for buildings in order to save money while still maintaining the aesthetic aspect while taking into account the surroundings.

Types of special concrete

Lightweight type special concrete

Conventional concrete is usually made of coarse aggregate, and it has a high density, as well as a high thermal conductivity. However, lightweight concrete does not have these characteristics. As compared to normal concrete, lightweight concrete has an effective density reduction when compared to traditional concrete, which is due to its reduced density.

In order to achieve the reduction in weight, large amounts of air are introduced, as well as concrete that does not contain fines and lightweight aggregates that are used. Concrete voids as well as lightweight aggregates help to reduce the overall weight of the concrete, along with the aggregates themselves.

Read more

1 note

·

View note

Text

MTS-Microstructure Analysis

MTS allows you to examine the material at its microscopic level and also guide you if they will perform to its expectation.

We have many experience in Microstructure Analysis across the globe.

Our Team is well trained and has the ability to conduct testing and analysis in diverse sectors.

For more details contact us - https://mts-india.in/

1 note

·

View note

Text

The constant ebb and flow of hormones that guide the menstrual cycle don't just affect reproductive anatomy. They also reshape the brain, and a new study has given us insight into how this happens.

Led by neuroscientists Elizabeth Rizor and Viktoriya Babenko of the University of California Santa Barbara, a team of researchers tracked 30 women who menstruate over their cycles, documenting in detail the structural changes that take place in the brain as hormonal profiles fluctuate.

The results, which are yet to be peer-reviewed but can be found on preprint server bioRxiv, suggest that structural changes in the brain during menstruation may not be limited to those regions associated with the menstrual cycle.

"These results are the first to report simultaneous brain-wide changes in human white matter microstructure and cortical thickness coinciding with menstrual cycle-driven hormone rhythms," the researchers write.

Continue Reading.

694 notes

·

View notes

Text

Effect of Sintering Temperature and Two-Stage Alloying on the Microstructure and Hardness of Tungsten Heavy Alloys W-Ni-Co_Crimson Publishers

Effect of Sintering Temperature and Two-Stage Alloying on the Microstructure and Hardness of Tungsten Heavy Alloys W-Ni-Co by Mohammad Reza Samadi* in Crimson Publishers: Peer Reviewed Material Science Journals

The main problem in production of Tungsten Heavy Alloys (THA) is the high specific weight and melting point of the tungsten element. Nowadays, powder metallurgy plays a great role in production of these alloys. In this study, W-8Ni-2Co alloys was produced by powder metallurgy method at different condition and their microstructure and properties were investigated. For this purpose, one sample with the one-stage alloying condition was produced at 1450 ̊C sintering temperature and other samples having the same composition, were produced at 1350, 1400 and 1450 ˚C sintering temperatures in two-stage alloying condition. Scanning Electron Microscope (SEM) images showed that at two-stage alloying condition, the microstructure is more uniform and the W-W bonding reduces. In addition, it was shown that increasing the sintering temperature increases the diffusion of the bond phase (Nickel-Cobalt) and as a result, increases microstructure uniformity. The results of densitometry and micro hardness tests at the same chemical composition and sintering temperature showed that density and hardness of sample produced by two-stage alloying technique inceases16% and 31.6% respectively in comparison to the sample produced by one-stage alloying technique. Also, as the sintering temperature enhances the density and hardness increase from 15.4 to 16.832gr/cm3 and 525.2 to 541.4 Hv, respectively.

For more Open access journals in Crimson Publishers please click on below link https://crimsonpublishersresearch.com/

For more article in Peer Reviewed Material Science Journals please click on below link https://crimsonpublishers.com/rdms/

#Crimson Publishers#Crimson Publishers LLC#Tungsten Heavy Alloys#One stage and two-stage alloying#Sintering#Temperature#Microstructure

0 notes

Text

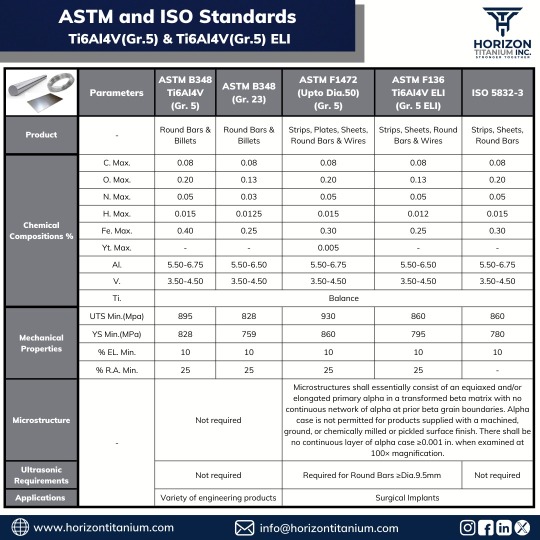

Looking for best Titanium for Surgical Implants?

Dive into the world of Titanium standards, comparing ASTM B348, ASTM F1472, ASTM F136, and ISO 5832-3 for Ti6Al4V (Gr.5), Titanium Gr.23 & Ti6Al4V (Gr.5) ELI.

Learn about product types, chemical compositions, mechanical properties, microstructure, and ultrasonic testing requirements for top-tier medical implants.

Stay tuned for our upcoming post, exploring important mechanical properties like fracture toughness and fatigue strength—the foundation of medical implants.

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#TitaniumSheets#TitaniumWires#TitaniumStrips#TitaniumPlates#TitaniumStandards#ASTMB348#ASTMF136#ASTMF1472#ISO5832_3#ChemicalComposition#MechanicalProperties#Microstructure#UltrasonicRequirements#Ti6Al4V#Ti6Al4VELI#Grade5#Grade5ELI#MedicalImplants#SurgicalImplants#OrthopeadicImplants#OrthopeadicApplication#Orthopeadic#TitaniumSupplier#MedicalGrade#HorizonTitanium#StrongerTogether

0 notes

Text

Challenges and Advances in Microstructure Analysis Techniques: Discovering a Tiny World! 👀

Hey there, little curious minds! 🌟 Have you ever wondered about the tiny, invisible things that make up our world? Well, today, we're going to embark on an exciting journey to explore the incredible world of microstructure analysis! 🚀

Metnmat Research and Innovation

Table of Contents-

What's Microstructure? 🧐

Why Do We Need to Analyze It? 🤔

The Microscope Magic: How It Helps! 🔬

The Puzzle of Crystallography: Cracking the Code! 🧩

The Magnificent Electron Microscope: Zooming In! 🚀

Adventures in Spectroscopy: Colors of Microstructure! 🌈

The AI Wizardry: Solving Microstructure Mysteries! 🧙♂️

Challenges Galore: What Makes Microstructure Analysis Hard? 😓

Advancing: Innovations in Microstructure Analysis Techniques! 🚀

The Future: What Lies Ahead for Microstructure Analysis? 🔮

Summary: Unlocking the Hidden World! 🗝️

Call to Action: Embrace the Marvels of Microstructure! 🤗

Introduction: What's the Fuss About Microstructure?

The microstructure is like a secret code that nature uses to create everything around us. It's like having a bunch of magical Legos that fit together to build the amazing world we live in! 🏰 But here's the twist - these magical building blocks are so teeny-tiny that you can't even see them with your own eyes! That's where super cool tools, like microscopes and other high-tech gadgets, come to the rescue! 🔬

Think of it this way: Imagine you have a super-duper microscope that can see things a million times smaller than a grain of sand. 🕵️♀️ When we look closely at materials like metals, rocks, or even candies (yum!), we see that they are made up of these tiny building blocks, just like Legos! These little blocks arrange themselves in unique patterns, like little puzzle pieces forming something big and amazing! And that, my friends, is what we call "microstructure." Now, you might be wondering why we need to analyze these itty-bitty building blocks. Well, hold onto your hats because microstructure analysis is like becoming a super detective who can solve mysteries! 🔍 You see, by studying microstructure.

What's Microstructure? 🧐

Imagine you have a super-duper microscope that can see things a million times smaller than a grain of sand. 🕵️♀️ When we look closely at materials like metals, rocks, or even candies (yum!), we see that they are made up of teeny-tiny building blocks, just like Legos! These building blocks arrange themselves in unique patterns, like little puzzle pieces forming something big and amazing! 🏰 These patterns are what we call "microstructure." So, it's like discovering a secret code that nature uses to create everything around us!

Why Do We Need to Analyze It? 🤔

Analyzing microstructure is like becoming a super detective who can solve mysteries! 🔍 We can learn so much about how things work and why they behave in certain ways. For example, by studying microstructure, we can figure out why some materials are super strong (like superheroes!), while others are squishy like marshmallows! We can also create new and better materials to build cool stuff like spaceships, fast cars, or even magical wands! 🚀✨

The Microscope Magic: How It Helps! 🔬

Alright, let's talk about the magic tool that helps us see the invisible! It's called a microscope, and it's like having superhero eyes! 👀 With the microscope's help, scientists can zoom in and see the tiniest details of anything they want! It's like looking at a whole new world that nobody else can see!

There are different types of microscopes. Some work with beams of light, and others use super tiny particles called electrons to see things even better! They are like little explorers that can go into the tiniest nooks and crannies!

The Puzzle of Crystallography: Cracking the Code! 🧩

Now, let's talk about crystals! No, not the sparkling ones you see in fairy tales, but the ones that make up many things around us! Crystals are like nature's building blocks, just like the bricks you use to build castles with Lego! 💎 When we study crystals, we can understand how they fit together and create beautiful patterns.

Scientists use something special called X-rays to see inside crystals. It's like having X-ray vision, just like superheroes! These X-rays help them take pictures of the crystals' secret patterns, and then they can decode the crystal puzzle!

🌈 From crystals to superheroes, join us in an epic quest to understand the fascinating realm of microstructures and their impact on industries! 🏭💎

The Magnificent Electron Microscope: Zooming In! 🚀

Time to meet our superhero friend, the electron! 👋 Electrons are like tiny wizards that have magical powers to show us the tiniest details of things! They zoom around super fast and help us see what's happening at the atomic level!

With the help of electron microscopes, scientists can see how atoms (the tiniest particles of stuff) arrange themselves. It's like discovering the secrets of the building blocks that make everything in the universe!

Adventures in Spectroscopy: Colors of Microstructure! 🌈

Do you know how rainbows have different colors? 🌈 Well, scientists have a way to use colors to learn about microstructure too! It's called spectroscopy, and it's like a rainbow magic show! When light shines on different materials, it bends and makes colorful patterns. Each material has its special rainbow fingerprint, like a secret ID! By looking at these patterns, scientists can figure out what a material is made of and how its tiny building blocks are arranged!

The AI Wizardry: Solving Microstructure Mysteries! 🧙♂️

Now, let's talk about some super cool technology called AI (Artificial Intelligence)! It's like having a robot friend who can think and learn just like we do! 🤖

With the help of AI, scientists can do microstructure analysis faster and better! It's like having a super helper who can spot tiny details and find patterns that even the smartest human might miss! AI and scientists make an incredible team, just like superheroes and their sidekicks!

Challenges Galore: What Makes Microstructure Analysis Hard? 😓

As amazing as microstructure analysis is, it comes with some challenges too! Dealing with tiny things is no easy task, and it's like trying to find a needle in a haystack! 🐜 Sometimes, things don't turn out perfect, and materials might have flaws or defects. It's like trying to build a sandcastle, but one tiny grain of sand gets in the way!

Sometimes, nature likes to play games and create super complex microstructures. It's like a tricky puzzle that even the best scientists need to solve with their thinking caps on! 🌳 But hey, challenges make life exciting, right?

Advancing: Innovations in Microstructure Analysis Techniques! 🚀

Guess what? Science is always moving forward and discovering new and better ways to analyze microstructure! Let's check out some of the exciting innovations!

3D Microscopy: Imagine seeing things in 3D, like watching a 3D movie! Scientists can do that with microscopes now! 🌌

Advanced Spectroscopy Techniques: Scientists keep improving the rainbow magic show to see even more details! 🌟

Combining AI with Microscopy: When AI and microscopes work together, they make an unstoppable team! 🤝

Nanotechnology: Scientists are building super tiny tools to see even tinier things! It's like shrinking everything!

The Future: What Lies Ahead for Microstructure Analysis? 🔮

Hold onto your hats, little explorers, because the future is full of surprises! 🧙♀️ Scientists believe that with better tools and smarter AI, we'll unlock even more of nature's secrets! We might discover new materials that we never knew existed, and they could be used to build incredible things!

Microstructure analysis might change how we create stuff in the future. Imagine having materials that can heal themselves like magic or make our gadgets even faster and cooler! The possibilities are endless, and it's like a never-ending treasure hunt!

🔍 Ever wondered how scientists see what's invisible to the naked eye? Delve into the enchanting world of microstructure with our ELI5-style blog! 🧙♀️🔬

Summary: Unlocking the Hidden World! 🗝️

Wow, we've come a long way on this tiny adventure! We learned all about microstructure analysis and how scientists use super tools like microscopes, X-rays, and AI to discover the hidden world of tiny building blocks! 🌌

We found out how crystals are like puzzles waiting to be solved, and how colors can reveal secrets like magic! We met electrons, the super wizards, and saw how they help us zoom into the tiniest details! 🚀

Though it's not always easy, scientists love exploring the microstructure and finding new ways to make our world even better! 🌟

Call to Action: Embrace the Marvels of Microstructure! 🤗

future scientists and curious minds! 🧠✨ If you want to be a part of the magical world of microstructure analysis, keep asking questions and exploring the wonders around you! Who knows, one day, you might discover something amazing that changes the world! 🌍 So, keep your eyes curious, and your mind open, and remember, the tiniest things can hold the biggest secrets! Happy exploring! 🌟🔍

#Microstructure Analysis#Microscopic World#Crystals#Electron Microscope Spectroscopy#AI in Science#Materials Science#Advanced Technology

0 notes

Text

Round Three: Ambopteryx vs Caihong

Ambopteryx longibrachium

Artwork by Gabriel Ugueto, written by @i-draws-dinosaurs

Name meaning: Both wings with long arms

Time: 163 million years ago (Callovian stage of the Middle Jurassic)

Location: Haifanggou Formation, China

Look, evolution has done a lot of weird stuff to dinosaurs. It put penguins underwater, and did whatever the hall mamenchisaurid necks are, and game lambeosaurs a built-in face trumpet. But I would argue there is one group that represents dinosaur evolution at its most unhinged, and that is scansoropterygidae.

Scansoriopterygids were generally considered “weird little tree dinosaurs” in the 2000s, with long fingers to pick grubs out of bark or something. Then Yi qi swept along in 2015 and revealed that those long fingers were actually supporting membranous bat wings. With an extra bony rod (the “styliform element”) sticking out of the wrist to help support it, because well if you’re a dinosaur evolving bat wings why bother being normal about it after that? Although really, the dinosaurs did it first so bats actually have dinosaur wings.

Yi was sensational, but it was also extremely weird and completely unique. Even other scansoriopterygids didn’t have wing membranes, so the whole bat thing was a bit up in the air. Or not up in the air, as the case may be. But then along comes Ambopteryx, published in 2019, packing another set of skin wings, and the vindication of Yi is complete!

Ambopteryx preserves a styliform element and wing membrane, as well as a thick coat of feathers, and honestly out of a whole selection of dinosaurs I think these might be some of the most huggable in the lot. Obviously this whole wing membrane thing didn’t end up working out for them long term, but Ambopteryx is part of an incredible lineage that challenged what we thought was possible for dinosaurs!

Caihong juji

Artwork by @i-draws-dinosaurs, written by @i-draws-dinosaurs

Name meaning: Rainbow with big crest

Time: 161 million years old (Oxfordian stage of the Late Jurassic)

Location: Tiaojishan Formation, China

It’s always a special treat to hear the announcement of a dinosaur with known colours, because it gives the most direct impression of how truly stunning these animals would have been to witness in real life. And Caihong might just be the most spectacular of them all so far, described in 2018 from an immaculate full-body fossil that preserves detailed feathers! Caihong’s feathers are longer than some other floofy dinosaurs, and would have had the appearance of a luxurious mane along its neck. Not only that, the fossil preserves feather microstructures that in life would have made this dinosaur gloriously iridescent!

Now iridescent dinosaurs aren’t new, Microraptor has been decked out in fabulous starling-esque plumage for a while now, but Caihong absolutely takes it to the next level. Its whole body was covered in iridescent black, including the enormous tail, but the real star of the show are the platelet-like melanosomes found on the head, neck, and the base of the tail. Different from the usual iridescent melanosomes, the structure of these tiny organelles reflects brilliantly iridescent colours, like those on the heads of hummingbirds and particularly the bright purple feathers on the necks of the trumpeter family. Caihong would have put on an absolutely dazzling jewel-toned display in the treetops or on the forest floor of prehistoric China!

#dmm#dmm rising stars#dinosaur march madness#dinosaurs#birds#palaeoblr#birblr#bracket#march madness#polls#paleontology#ambopteryx#caihong#round three

472 notes

·

View notes