#StressStrainCurve

Text

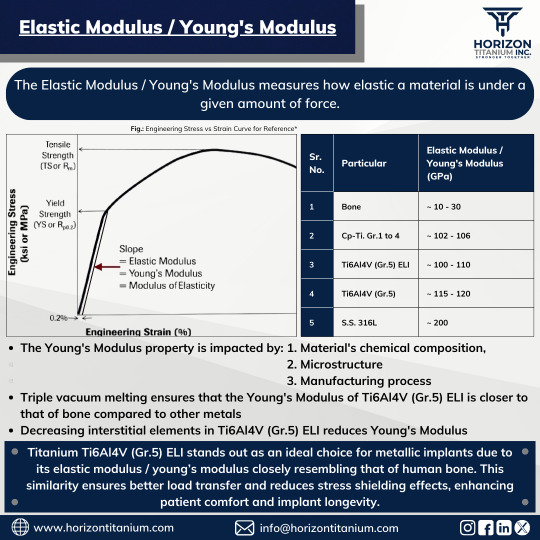

Metal implants play a crucial role in biomedical engineering, offering durability and reliability for bone reconstruction.

With superior mechanical properties compared to ceramics and polymers, metals like Titanium Ti-6Al-4V (Gr.5) ELI are preferred for handling heavy loads. In fact, 80% of implants are made from metal, with Titanium Ti-6Al-4V (Gr.5) ELI being the major choice, especially due to its higher fatigue strength and fracture toughness.

The value of the Elastic Modulus / Young's Modulus, should closely match that of the bone to minimize the stress-shielding effect between the bone and the implant. We will delve into more details about the stress-shielding effect in our next post.

Ti-6Al-4V ELI closely matches bone's Young's modulus as compared to other metallic implantable materials, making it a top choice for bone replacements.

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#ElasticModulus#YoungsModulus#ModulusofElasticity#Elasticity#StressStrainCurve#EngineeringStressStrainCurve#BoneYoungsModulus#TitaniumYoungsModulus#StainlessSteelYoungsModulus#StressShieldingEffects#CPTitanium#Ti6Al4V#Ti6Al4VELI#SS316L#ChemicalComposition#Microstructure#3VAR#ELI#TitaniumImplant#OrthopeadicImplant#PatientComfort#ImplantLongevity#HorizonTitanium#StrongerTogether

1 note

·

View note

Text

Difference between Ductile and Brittle Materials with Stress Strain Curve

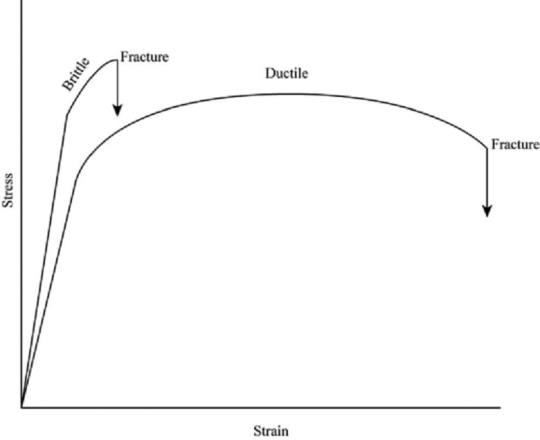

In engineering, each and every material has to bear external loading of various natures like repetitive, continuous and fluctuating nature. Materials are used for different applications depending upon the required properties in final product. So how a material will respond to external loading? To find out the answer of this question, we classify materials into two categories – brittle and ductile.

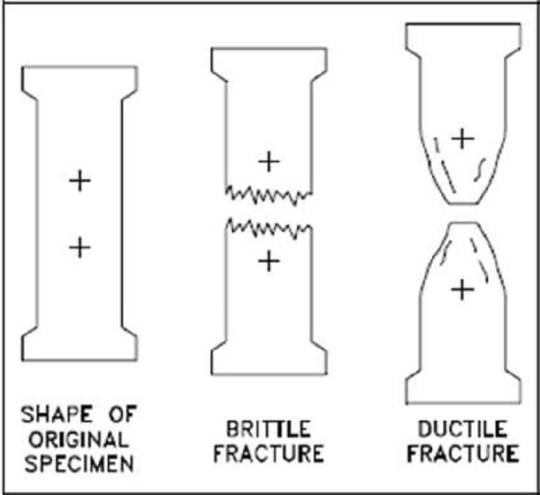

When a material is subjected to external tensile load then there is a limit up to which material can tolerate stress. After that limit, definitely material undergoes deformation or it breaks down. Some materials undergo plastic deformation (material will change its shape permanently even if stress is removed) at this point and other will breakdown instantly. The materials that undergoes plastic deformation before fracture are ductile while the materials which have no plastic deformation are brittle i.e. they break instantly.

Ductility and ductile materials

Ductility is a physical property of a material by which it can be stretched into wires without breakage. In other words, the ability to bend as external stress is applied.

Ductile materials are those which can be easily drawn out into wires. Many of metals are best examples of ductile materials like copper, gold and silver. Other metal like aluminum is not a ductile material. Ductility of a material is dependent on temperature. Usually when metals are heated, their brittleness is reduced. By increasing temperature, dislocations move due to which plastic deformation occurs and hence ductility is improved. On the other hand, some non-metals become ductile on heating.

Brittle materials

The materials that are easily snapped or broken are known as brittle materials. These materials cannot withstand with continuous external loading. They instantly break as stress is applied, without any plastic deformation after producing a sound. Examples of brittle materials include glass and ceramics.

Common features of ductile and brittle materials:

Both are linked with the plastic deformation under tensile stress.

Both properties are temperature dependent i.e. if a material is ductile at room temperature then it can be converted into brittle material when restricted to 0 degree celcius. Similarly at high temperature a brittle material becomes ductile.

Differences between ductile and brittle material

Definition

Ductile: A material that can be easy bent or material can be drawn into wires.

Brittle: A material that instantly snaps by external load application.

Deformation

Ductile: Such material will undergo plastic deformation before fracture.

Brittle: These material show zero plastic deformation after stress and instantly break.

Elongation

Ductile: Under tensile stress, percentage elongation before fracture is higher in these materials.

Brittle: They show very less percentage elongation before fracture.

Energy absorption before fracture

Ductile: Under tensile load, they can absorb more energy before fracture.

Brittle: Very small amount of energy is absorbed by such materials before fracture.

Forming operations

Ductile: Metal forming operations like rolling, drawing or bending can be made on such materials.

Brittle: They cannot withstand with any forming operation.

Stress strain curve

Area under curve in stress strain graph denotes the absorbed energy by material.

Factors that can influence properties of materials

Ductile: Ability to draw wires is affected by temperature.

Brittle: Brittleness is dependent on applied stress.

Appearance after fracture

Examples

Ductile: copper, mild steel, rubber, gold, silver and metals.

Brittle: Glass, ceramics, ice, cast iron, concrete and stone.

Conclusion

As a result, ductile materials are those which can be drawn into wires. On the other hand, brittle materials are hard but they can’t withstand with stress, so break instantly. Moreover, the life of ductile materials after load application is greater as compared to brittle materials. The stress strain curve for ductile material covers more area as brittle material because of the reason that brittle material snaps instantly.

Do not forget leaving your valuable comment on this piece of writing and sharing with your near and dear ones. To keep yourself up-to-date with Information Palace, put your email in the space given below and Subscribe. Furthermore, if you yearn to know about zinc oxide nanoparticles, view our construct, ‘Properties and Applications of Zinc Oxide Nano-Particles.’

Read the full article

#brittlefracture#brittlematerial#brittleness#differencebetweenductileandbrittlematerials#ductilematerial#ductilevsbrittle#ductility#hardnessandbrittleness#stressstraincurve#stressstraindiagram#stressstraindiagramforbrittlematerial#stressstraindiagramforductilematerial#whatisbrittlematerial#whatisductilematerial#whatisductility

0 notes