Text

Tumbler mixer in action

youtube

1 note

·

View note

Text

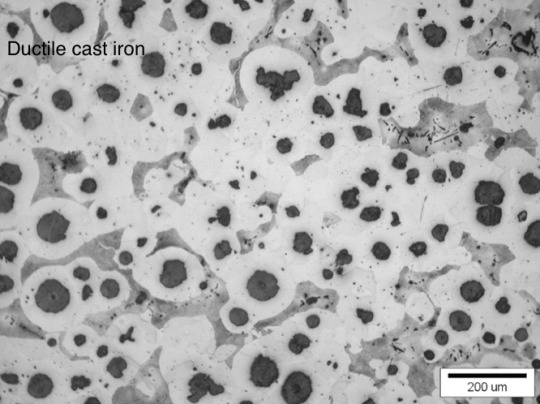

Cast iron is tough, malleable, and ductile and can easily be forged or welded, so it’s known as a very durable material for butterfly valves. The final product will have low ductility, but they are a cheaper option for common non-critical applications that require high amounts of flow along quick, then tight shut off, which is exactly the tumbler mixer!!

1 note

·

View note

Text

How cast iron is processed:

1. Melt iron ores in a blast furnace at very high temperatures.

2. Cast the liquid iron into crude ingots called pigs.

3. Remelt the pigs along with alloying elements, such as 2-4% carbon, and traces of other impurities like sulfur or phosphorus.

4. Recast into molds to produce the butterfly valve.

1 note

·

View note

Text

Did you know that due to the very unique shape of the tumbler mixers, metal injection molding offers the design freedom from the usual constraints of shaping stainless steel? The process involves heating and injecting the liquid metal under pressure into a closed metal mould tool. The molten metal cools and hardens into the shape inside the mould tool, which then opens to allow the mouldings to be removed. So it precisely produces parts without machining while enhancing the strength, ductility, and corrosion resistance of stainless steel!!!

1 note

·

View note

Text

How stainless steel is processed:

1. Melt the raw materials if iron ore, nickel, chromium, silicon, carbon , and others, together to their high temperature melting points in an electric furnace.

2. Refine by removing the excess carbon. Depending on how much carbon is removed, it could result in different variants of the alloy, such as stainless steel 304, which affects the tensile strength and hardness of the final product.

3. Begin the process of hot rolling as the stainless steel beings to cool, while it still above its crystallization temperature. It helps get the steel into the desired shape.

4. Anneal it to relieve internal stresses and alter the stainless steel’s mechanical properties.

5. Put through multiple cutting and shaping processes to create the final object.

1 note

·

View note

Text

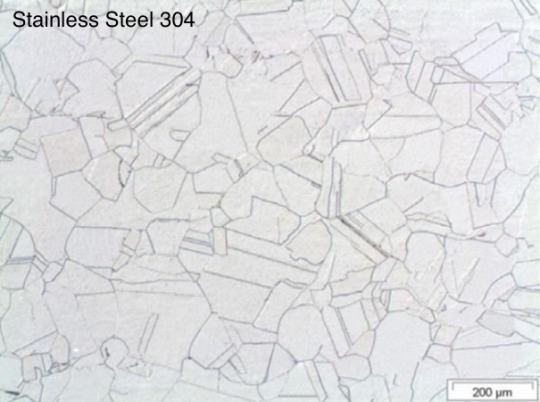

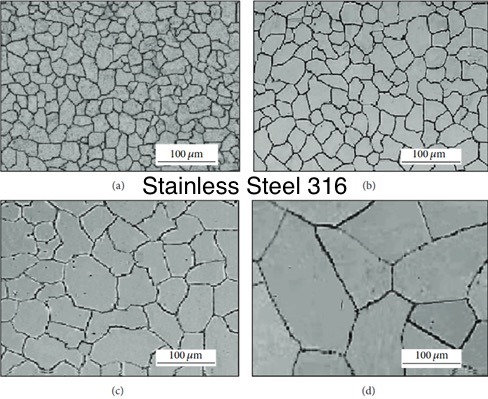

Microstructures

Stainless steel has larger grains compared to cast iron as seen in the figures. The formation of such grains results in a lower tensile strength. Therefore, stainless steel is more ductile than cast iron. As a result, the tank can absorb a certain amount of shock from the repeated colliding of the mixture upon the rotation of the tumbler mixer without fracturing.

1 note

·

View note

Text

Austenitic stainless steels are tougher and more ductile than other ferritic alloys due to their F.C.C. structure. They are challenging to machine since they harden quickly.

1 note

·

View note

Text

Cast iron is another material used to make the valves found in tumbler mixers, particularly in applications that require heavy-duty mixing and blending. Such material is strong and durable as it can withstand the wear and tear of continuous use when handling large volumes of mixtures. Also, it has an excellent heat retention property which can be useful in certain mixing properties.

4 notes

·

View notes

Text

Casted stainless steel mixers can withstand high temperatures with a smooth and non-reactive surface that can be easily cleaned. As a result, pharmaceuticals and food processing industries exploit such hygienic aspect when using stainless steel tumbler mixers resulting in the steel being Food and Drug Administration (FDA) approved. This justifies the design choice of stainless steel even if it is a pricier material given its application.

1 note

·

View note

Text

Stainless steel and cast iron are the main materials used to make a tumbler mixer due to their beneficial properties that accommodate the demands of industrial mixing. For example, Stainless steel mixers are known to be durable as the alloy has relatively high young’s modulus and tensile strength compared to other metals.

1 note

·

View note

Text

Valves are exposed to a wide pressure range without cracking too easily. That is why ductile cast iron is an ideal candidate for valve fabrication since it is tough and its chances of fracturing are reduced compared to gray cast iron. Also, it is not as sensitive to corrosion as gray cast iron. Similarly to stainless steels, these properties bring the price of ductile cast iron higher, but it goes with enhanced durability.

1 note

·

View note

Text

A tumbler mixer should be able to withstand forces exerted on its wall by the contents of the vessel on a regular basis.

Here are some data to consider to design a mixer :

Useful life : 20-25 years

Bulk densities supported : up to 150 lbs/ft3

Working capacity : up to 100 ft3

Angular velocity : 5-25 RPM

Maximum load supported : 15,000 lbs = ~ 6,800 kg = ~ 66,708 N

The following video demonstrates the mechanism behind a tumbler mixer (V-shaped mixer in this video).

youtube

1 note

·

View note

Text

Cast irons are also durable materials and alloy cast irons are resistant to corrosion as well!

1 note

·

View note

Text

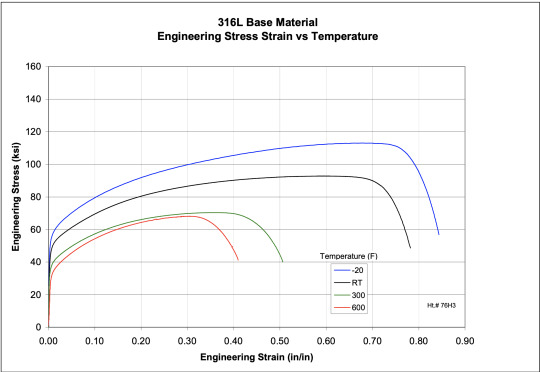

Did you know that stainless steel of type 316 is more corrosion-resistant compared to the other types? However, 304 stainless steel remains the most common and standard design choice when manufacturing tumbler mixtures.

1 note

·

View note

Text

Depending on its intended use, its materials design should also consider the effects of corrosive or abrasive substances on the object. So, stainless steel is preferred due to its corrosion-resistant properties. More broadly, stainless steel has excellent durability upon exposure to a variety of substances.

1 note

·

View note

Text

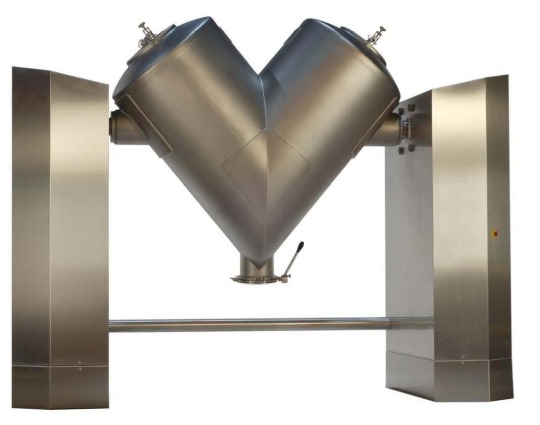

A tumbler mixer is an industrial tumbling machine used to mix both solid-solid mixtures and solid-liquid mixtures, as well as the gentle mixing for delicate particles. It usually consists of a cylindrical container that rotates on its axis to create a tumbling motion which causes the materials inside to mix and blend together due to gravity without the need for an agitator or impeller. That makes them popular in the pharmaceutical industry. They are also useful in the food and beverage, chemical and agricultural industries since they achieve a consistent, thorough, and accurate blending of materials.

1 note

·

View note

Text

Tumbler mixers are usually made of stainless steel austenitic type 304 and type 315, and the manually operated dust-tight butterfly valve is made of ductile cast iron. They also come in different shapes such as V-shaped mixers, double cone mixers and slant mixers.

#HeartShaped

#valentinesDay

#Mixers

#metals

1 note

·

View note