#Pearlite

Text

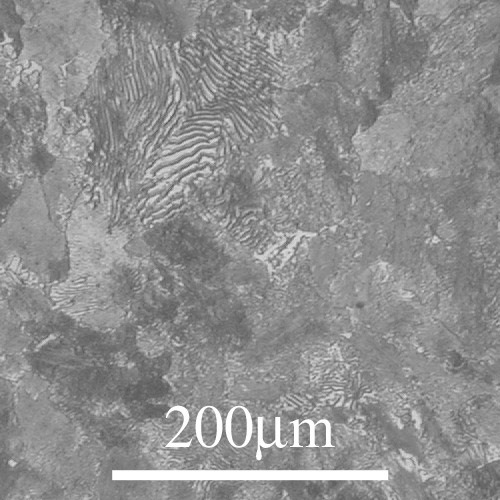

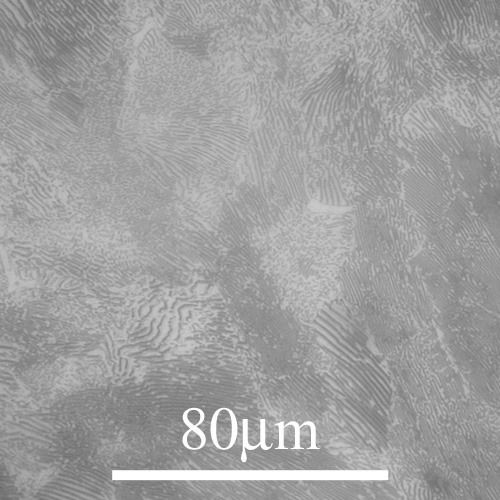

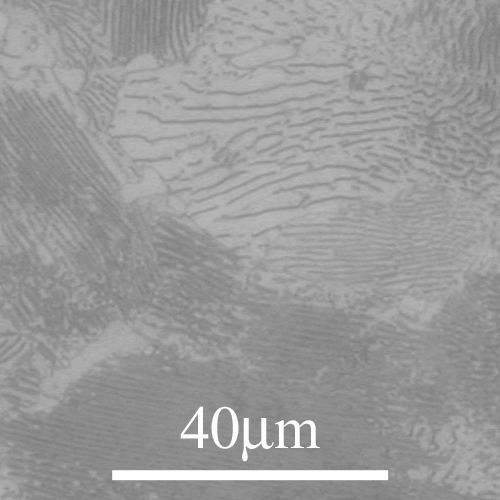

Fe, C 0.8 (wt%), eutectoid transformation - pearlite (coarse)

Processing

Slow cooled

[...]

Technique

Reflected light microscopy

Length bar

200 μm / 80 µm / 40 µm

Further information

This steel is of the eutectoid composition. Once the temperature is lowered below the eutectoid temperature the steel becomes simultaneously supersaturated with both ferrite and cementite. A eutectoid transformation results (g to a + Fe3C). The resultant microstructure, known as pearlite, comprises lamellae of cementite (dark) embedded in ferrite (white). The platelets are parallel to each other and do not follow a specific crystallographic direction.

Each pearlite colony is made up of a number of subgrains. Thus each pearlite colony consists of two interpenetrating single crystals having an orientation relationship with respect to each other and with respect to the austenite grain they grow from, but not with respect to the austenite grain they have grown into. Changes in the apparent interlamellar spacing from colony to colony in the photograph are due to differences in the lamellae spacing with respect to the polished surface.

The coarseness of the pearlite is determined by the interlamellar spacing. This spacing is inversely proportional to the undercooling. This is primarily because of the increased rate of carbide nucleation with increased undercooling.

The pearlite in this sample is coarse due to it being slowly cooled. The undercooling is low so the lamellae spacing is relatively large resulting in a coarse microstructure.

[...]

Organisation

Department of Materials Science and Metallurgy, University of Cambridge

Sources: ( 1 ) ( 2 ) ( 3 )

#Materials Science#Science#Pearlite#Microstructures#Steel#Alloys#Magnified view#Optical microscopy#DoITPoMS#University of Cambridge

18 notes

·

View notes

Text

Normalize this, normalize that. How about you normalize this iron, metallurgy time.

#dumb joke in welding class#metals are so cool though#shit can just be heated up and cooled?#and it'll be different??#anyways#tagging this like an excited geologist#austenite#martensite#ferrite#pearlite#tempering#hardening#annealing#normalizing

0 notes

Text

I just opened up my last survival world after three months of not playing minecraft. In that world I decided to focus on exploration and the joy of simply "finding things", so as soon as I got some leather, paper, and an inc sack, I kept an in-game & in-character diary.

It was nice to be able to read back on what I'd been doing (I was only 8 days in) and I decided to explore a bit and get my bearings again.

So I'm walking back to my temporary settlement from a nearby village, and wanna know what I found? Just chilling out in the open?

A pink sheep.

0.164% chance of spawning.

I've set her up in a little pen & cheated a name tag in so she doesn't despawn. I am beaming.

#minecraft#minecraft survival#pink sheep#ive named her “Pearlite” for now but im open to suggestions#posting this moment so future me never forgets#fav

15 notes

·

View notes

Text

Writers, readers, if you've ever wondered how medieval blacksmiths knew exactly when to quench a blade to make it a certain type of hardness...here you go, the secrets exposed & explained scientifically, replete with color chart, heat ranges, and an explanation of which tempering type is useful for which type of metal you want to create.

I can't remember if it was in the BBC series Secrets of the Castle or in the series Tudor Monastic Farm, but at one point the presenters (same clutch of people in both shows, lol) go to a blacksmithing forge to discuss getting a stonecutting chisel re-shaped and re-hardened. (I honestly think it's in Secrets, since they're constantly having to re-make the chisels as they wear down from the quarrying and masonry work, but can't find the exact moment, sorry. It's totally worth watching both series imho, though!)

Anyway, the blacksmith literally shows a golden sheen reaching the tip of the chisel...and quickly quenches it to freeze the molecules of the metal to the right ratio between toughness (versus being brittle, causing it to spall and break) and hardness (versus being too soft to hold the point for a reasonable length of operational time), in order to be a good stone chisel.

This, by the way, is why scrubbing the iron toward the end of it being forged is so important, because these color-changes are iron oxides. So you genuinely want to remove the traces of all previous oxidation before putting it through one more round of heating, cooling, and quenching it at just the right moment.

This is also why clay would be applied to the non-edge parts of a blade, such as a katana, to help thermally insulate it from the brief high heat needed for creating a tempered edge sharp enough to be a literal razor-edge. The main body of the blade needs to be tough to resent bending and cracking, but the edge needs to be hard to hold its edge and not crumple like tinfoil.

Here's a quote from Wikipedia on the process of creating the "hamon" or "wavy line" on a katana blade: " The hamon outlines the transition between the region of harder martensitic steel at the blade's edge and the softer pearlitic steel at the center and back of the sword. This difference in hardness is the objective of the process; the appearance is purely a side effect. "

The "softness" being referenced in the quote refers to the resistance against cracking and breaking, which is the same as the "toughness" I mentioned above. For a medieval blacksmith (of any ironworking region around the world in a technologically comparable era), being able to gauge just the right moment to quench the iron/steel was absolutely vital to the success of their product. This in turn affected their reputation as a smith.

If John the Smith makes metal sheets that are flexible but not brittle (great for armor), but isn't good at making knife blades that are sharp, you go to him for the flexible metal panels to make you plate armor. If Stephen the Smith makes really sharp knives but can't make big panels without it cracking under stress, you go to him for the knife blades and go find someone else for the other stuff.

And if Claudette the Smith (because there were women blacksmiths!!) can do both types, and do them consistently to order, you go to Claudette the Smith, and you send your children to apprentice with Claudette the Smith if she'll take them on, and you hope & pray she imparts the secrets of her skills to her apprentices if she does take them on.

Anyway...that's how a pre-modern blacksmith would know how to temper their iron & steel to achieve specific types of metal for specific types of uses. So writers, if you want to slip a little bit of information & education into your stories about how it all works, hopefully this gives you a good starting point for doing some fun research!

2 notes

·

View notes

Text

Alright, Locklyle fic for the day written and posted. Now it's time to *check's to-do list* research pearlitic steel wire drawing methods and innovations in automotive plastics?

#the whiplash from going between fandom writing and my actual schoolwork is wild#lockwood and co#materials engineering#the temptation to ignore responsibilities and get a head start on tomorrow's fic is very strong

13 notes

·

View notes

Text

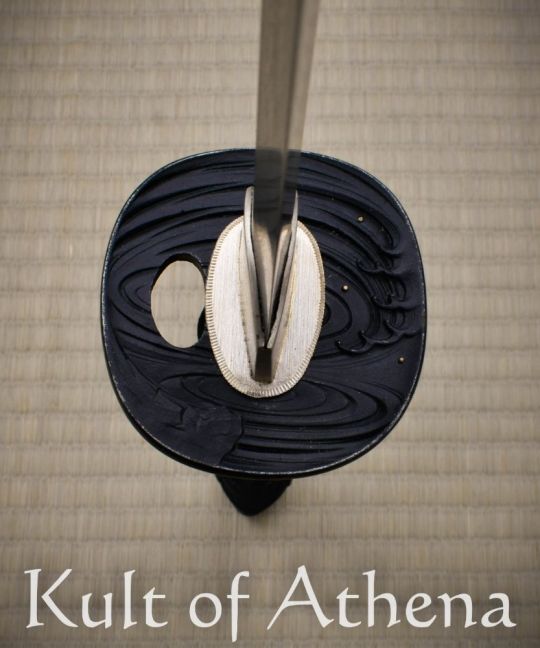

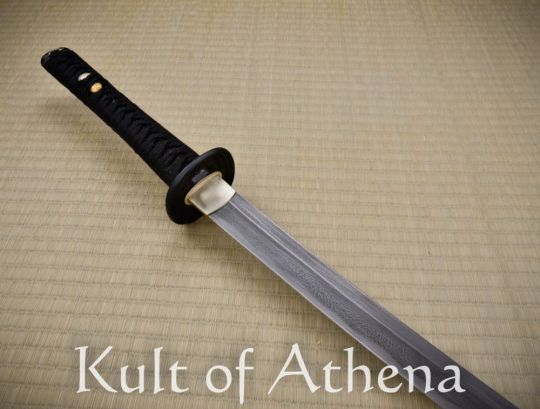

Hanwei Celestial Katana with Wootz Crucible Steel Blade

The celestial bodies pull at the water’s edge and create the tide, the ebb and flow of waves that bring time and balance to our world. As the samurai warrior must give and take with the ever-flowing tides of life, the Celestial Katana reflects all the harmonious aspects of the heavens and the sea.

The kashira and tsuba juxtaposes the hamon with a depiction of turbulent sea with waves crashing against the rocks. The tsuka features black cotton sageo over black same with multi-finish planetary menuki. The saya sparkles with a beautiful silver flake with a gloss polish with a buffalo horn kojiri, kurikata and koiguchi adorned with a navy and white sageo.

This special Celestial Katana is made in the crucible Wootz steel and has been differentially hardened. Swords made from genuine Wootz in the crucible steel process are comparatively rare and stand out from most new swords available. Wootz steel is widely regarded as being the “real” and more historical damascus steel and is different from most of the standard steels listed as damascus. What is called damascus is actually a form of pattern-welded steel and the general purpose of mixing and melding different steels together in modern damascus is to imitate the patterning of Wootz.

What makes Wootz steel different from the outset is that its patterning is not made by the smith while forging a blade billet, but is instead created when an ingot of Wootz is created in a crucible as the raw iron is heated with carbon and other ingredients to produce steel that is not only a high carbon steel, but a high carbon steel infused with crystalline bands of hard martensite and pearlite steel to create a composite steel that in effect functions as an early “alloy” steel with a distinctive appearance – an appearance that was later mimicked in later centuries by the modern damascus method, though this method does not create a blade with the famed properties of wootz. Wootz steel was highly prized for its resilience and ductibility and was a premier steel that was being made as early as the 5th century BC in India. By the later Medieval period the city of Damascus was famed for its swords made from Wootz, with ingots of the precious and premium sword blade Wootz crucible steel being imported from India.

#Kult of Athena#KultOfAthena#Hanwei#New Item Wednesday#Celestial Katana with Wootz Crucible Steel Blade#Celestial Katana#Wootz Crucible Steel#Wootz Steel#katana#katanas#sword#swords#weapon#weapons#blade#blades#Japanese Swords#Japanese Weapons#Asian Swords#Asian Weapons#New Item#New Items

3 notes

·

View notes

Text

The Pacific at Point Reyes - at times pearlescent under the sun, at times banded like pearlite under the microscope :P

10 notes

·

View notes

Text

TMT Bar Manufacturer and Distributor in Kanpur | RHL Profiles limited

Savings & Other Benefits to Construction in Use of High Strength TMT Steel Bars

Steel is an essential element of any civil or construction activity like Houses, Multi Storey, Townships, Malls, Airports, Ports, Dams, Bridges, etc. Steel not only provides strength to any construction but also provides durability and long life.

Each transformation of the steel industry was driven by the growing market need for steel bars with higher strength and elongation. The 21st century has witnessed a rapid increase in the cost of steel products and also brought greater focus on safety and quality norms of construction. This has spurred the demand for the development of TMT bars with properties of high strength and elongation to provide cost savings in the construction by reducing consumption.

Steel researchers across the world have been working hard to develop steel products to meet these specific market needs. This research has led to the development of TMT steel Bars with yield strengths of 500 N/mm 2, 550 N/mm2, and 600 N/mm2. These bars, because of their higher strength than traditional steel bars, are required in lesser quantities, thus, reducing the overall cost of the structure significantly.

The BIS code for IS 1786 (High Strength Deformed Steel Bars And Wires for concrete Reinforcement Specification), IS 13920 (Ductile Detailing of Reinforced concrete structures subjected to Seismic forces - Code of Practice), and IS 456 (Plain And Reinforced Concrete – Code of Practice) incorporated necessary changes to include these latest developments in the field of steel technology.

IS 1786 under its latest revision groups the Steel Bars under the following grades:

Fe 415, Fe 415D, Fe 415S

Fe 500, Fe 500D, Fe 500S

Fe 550, Fe 550D

Fe 600

Reinforcing steel is produced through one or a combination of processes like hot rolling after microalloying, hot rolling followed by cold working, or hot rolling followed by Thermo Mechanical Treatment (TMT process).

TMT Technology

TMT technology involves rapid cooling of hot-rolled bars rolled out of a finishing rolling mill from a temperature of 950-1050°C to 550-600°C using a high-pressure cool water spray system. The bars after quenching are cooled under controlled atmospheric conditions to impart properties based on the size and grade being rolled. The three major steps of the TMT process are as under :

1. QUENCHING: The hot rolled bar coming out of the finishing rolling mill stand is passed through a quenching box where it is rapidly quenched using a high-pressure cool water spray system. The surface of the bar gets hardened to the depth optimized for each section through the formation of a 'Martensitic' rim while the core remains hot and 'Austenitic'.

2. SELF TEMPERING: The bar coming out of the quenching box thus has a hot core compared to the cool outer surface thus allowing the heat to flow from the inner core to the outer surface causing tempering of the outer martensitic rim into "Tempered Martensitic" structure. The core remains "Austenitic" at this stage.

3. ATMOSPHERIC COOLING: The bar is then finished on an Automatic rake type controlled Cooling Bed where uniform atmospheric cooling of each bar takes place under controlled conditions resulting in the transformation of the hot "Austenitic" core of the bar into "Ferrite Pearlite" structure. The resultant final structure of the Bar thus produced consists of a hard and strong outer layer (Tempered Martensitic) with a soft and ductile inner core (Ferrite Pearlite) structure.

Importance of branded steel manufacturer -

Steel Billet of appropriate chemical composition - Right raw material procurement and selection.

Accurate rolling within close tolerances - Robust and Accurate manufacturing equipment.

Quenching under appropriate water pressure, water temperature, and water volume depending on finishing mill speed, chemical parameters, size, and grade of finished steel - Trained manpower.

Uniform atmospheric cooling on Automatic rake type cooling bed - Right technology.

Testing for Mechanical, and Physical properties in the laboratory - Quality Assurance.

Bundling, tagging, and dispatch as per grade and size of finished TMT Steel - Complete customer service and satisfaction.

2 notes

·

View notes

Note

Are you sure you haven’t heard of Pearlite Evans, I mean Oceleian talks about them a lot surely you’ve heard some things right?

I said i heard about em

3 notes

·

View notes

Text

Alloys: Wootz Steel

A high-carbon crucible steel, the history of wootz steel dates back to over 2,000 years ago in the south of India. Though the exact timeline of this alloys invention is unknown, historical records suggest it existed as early as 300-500 BCE. The word wootz is an anglicized version of ukku or urukku, what the steel was known as by the locals in the Dravidian languages.

Wootz steel is characterized by a banded microstructure. Higher carbon varieties contain carbides in a martensitic or pearlitic structure, while lower carbon varieties contain ferrite and pearlite bands (because of its age, there is no set composition for wootz steel). Distinct patterns known as wave, ladder, and rose patterns can be created based on processing. Damascus steel, meanwhile, is merely wootz steel that has been forged into sword blades, and acquired its name from wootz steel that was imported to the city of Damascus before being further processed.

India maintained secrecy around the production of wootz steel for centuries, and thus managed to maintain their status as the primary producer until the 19th century, when Europeans began to produce it as well. The crucible process used to create it involves heating the iron for several days in a clay crucible before slow cooling.

Sources/Further Reading: (Images 1 and 3 - Ancient Origins) (Image 2 - Wikipedia) (ThoughtCo.) (Noblie) (Indian Institute of Science) (Matthew Forde Military Antiques) (Ancient Science) (National Institute of Advanced Studies, Bangalore)

22 notes

·

View notes

Text

Looking for Best UV Master Batch Manufacturers in India?

Perfect Colourants & Plastics is the top UV Masterbatch supplier in India with different transparent, metallic & pearlite special effect shades. We provide UV Master batch with very high color strength compared to competitive concentrates, Good heat stability, excellent processability, etc. For more information in detail visit our website!

#UV Masterbatch manufacturer#UV Masterbatch manufacturers in india#UV Masterbatche manufacturer in india#UV Masterbatche supplier

0 notes

Text

Investigating the Adaptability of MS Squares: Applications, Benefits, and Market Trends

Mild Steel (MS) squares, otherwise called mild steel square bars or square poles, are adaptable metal parts broadly used across different industries for their primary respectability, durability, and simplicity of manufacture. In this article, we dive into the qualities, applications, benefits, and market trends of MS squares.

Qualities of MS Squares

MS squares are produced from low carbon steel, regularly containing under 0.25% carbon, which gives beneficial properties like malleability, weldability, and machinability. They are accessible in different aspects, going from little measured squares utilized in family applications to bigger segments utilized in modern settings.

The microstructure of MS squares principally comprises ferrite and pearlite stages, adding to their mechanical properties. These squares are commonly delivered through hot rolling or cold drawing processes, bringing about uniform aspects and surface completion.

Applications of MS Squares

MS squares track down boundless applications across assorted industries because of their flexibility, primary strength, and simplicity of creation. A few normal applications include:

Construction: MS squares are broadly utilized in construction projects for creating support structures, casings, sections, and reinforcements. Their vigor and burden bearing limit make them ideal for building frameworks, flights of stairs, railings, and design components.

Manufacturing and Designing: In manufacturing and designing sectors, MS squares are utilized in hardware parts, gear outlines, tooling, and dances. Their machinability considers simple cutting, boring, and molding to meet explicit plan prerequisites.

Creation and Welding: MS squares are liked in manufacture and welding applications because of their weldability and formability. They are utilized in the manufacture of doors, walls, grilles, and other metal designs requiring exact welding and gathering.

Furniture and Inside Plan: MS squares are used in the creation of furniture outlines, racking units, table legs, and ornamental components in inside plan. Their perfect lines, uniform aspects, and primary strength make them reasonable for current and modern style furniture plans.

Automotive and Transportation: MS squares track down applications in automotive and transportation industries for creating skeleton parts, edges, sections, and primary reinforcements. Their strength-to-weight proportion and primary respectability add to the durability and wellbeing of vehicles and transportation hardware.

Benefits of MS Squares

MS squares offer a few benefits over other materials, adding to their broad reception across industries:

Cost-Adequacy: MS squares are practical contrasted with other metals, settling on them an economical decision for different applications without settling on quality or performance.

Flexibility: MS squares can be effortlessly manufactured, welded, and machined to meet explicit plan prerequisites, making them reasonable for a large number of applications across industries.

Strength and Durability: MS squares display amazing strength and durability, making them ideal for primary applications where load-bearing limit and flexibility are fundamental.

Simplicity of Support: MS squares require negligible upkeep and can withstand unforgiving natural circumstances, making them reasonable for open air and modern applications.

Recyclability: MS squares are recyclable, adding to manageability drives and diminishing ecological effect through the reuse of materials.

Market Trends in MS Squares

The market for MS squares is affected by different factors, including modern demand, raw material costs, mechanical headways, and regulatory strategies. A few prominent trends molding the MS squares market include:

Modern Demand: The demand for MS squares is driven by modern exercises, infrastructure improvement, and construction projects. Variances in global economic circumstances and government interests in infrastructure influence the demand for MS squares.

Mechanical Progressions: Advances in steel manufacturing advancements add to the development of top notch MS squares with worked on mechanical properties and surface completion. Makers are embracing progressed creation methods to fulfill the developing need for accuracy designed MS squares.

Natural Guidelines: Severe ecological guidelines in regards to emanations decrease and manageability drive the reception of cleaner creation processes in the steel business. Producers of MS squares are progressively zeroing in on earth maintainable practices and materials.

Customization and Worth Added Administrations: Producers of MS squares are offering customized arrangements and worth added administrations like cutting, boring, and surface treatment to meet the particular prerequisites of end-clients across industries.

Market Contest: The MS squares market is portrayed by extreme rivalry among makers, both locally and globally. Organizations are zeroing in on item separation, development, and customer administration to acquire an upper hand on the lookout.

Conclusion

MS squares are fundamental primary parts used across different industries for their adaptability, strength, and cost-adequacy. With their colossal applications in construction, manufacturing, creation, and designing, MS squares assume a pivotal part in current infrastructure and modern turn of events.

As the global economy keeps on developing, the demand for MS squares is supposed to stay powerful, determined by infrastructure ventures, modern extension, and mechanical headways. Makers and partners in the MS squares market should adjust to changing business sector dynamics, mechanical developments, and regulatory necessities to support development and stay cutthroat in the business.

0 notes

Text

SR TMX, a renowned manufacturer of TMT bars based in Ahmedabad, boasts a legacy of excellence dating back to its humble beginnings in 1976. Founded on a modest plot of land in Bhavnagar, Gujarat, with just three employees, SR TMX has evolved into a powerhouse in the steel industry. At the heart of SR TMX's success lies its commitment to quality and innovation. Utilizing the licensed H&K India Thermex (QST) system, SR TMX employs cutting-edge Quenching and self-tempering (QST) technology to produce high-strength deformed bars. These rebar’s are meticulously crafted to meet the specific needs of customers, offering unrivaled durability and performance.

SR TMX's TMT bars find extensive application in a myriad of structural projects, from industrial complexes to transportation infrastructure. With superior strength, enhanced corrosion resistance, and optimal ductility, SR TMX bars excel in demanding environments, ensuring structural integrity and longevity.

A hallmark of SR TMX's TMT bars is their superior mechanical properties, attributed to the Thermo Mechanical treatment process. This treatment enhances the bars' resistance to seismic loads, making them the preferred choice for seismic-prone regions like Ahmedabad.

Furthermore, SR TMX TMT bars feature a unique composition of fine-grained ferrite-pearlite in the core and tempered martensite on the surface, resulting in exceptional toughness and ductility. The formation of a protective layer of ferric oxide on the outer surface further enhances corrosion resistance, ensuring longevity in diverse environmental conditions. Moreover, SR TMX TMT bars offer enhanced weldability, thanks to the use of low-carbon raw materials in the manufacturing process. This not only simplifies construction but also contributes to cost savings, with SR TMX bars boasting a 15% reduction in steel usage compared to competitors.

In essence, SR TMX stands as a beacon of excellence in the TMT bar manufacturing industry, combining decades of expertise with cutting-edge technology to deliver products that exceed expectations. From structural reliability to cost-effectiveness, SR TMX TMT bars epitomize quality and innovation in every aspect. SR TMX, a leading TMT bar manufacturers in Ahmedabad, utilizes state-of-the-art Quenching and self-tempering (QST) technology to produce high-strength deformed bars. With a legacy dating back to 1976, SR TMX has earned a reputation for delivering TMT bars tailored to customer needs, boasting superior mechanical properties and corrosion resistance. Their innovative manufacturing processes ensure optimal weldability and cost savings, making SR TMX the preferred choice for structural projects across various industries.

#Tmt Bars Manufacturers in Ahmedabad#TMT Bar Manufacturers in Ahmedabad#TMX Steel Bar Supplier in Ahmedabad#TMT Bars in Ahmedabad#TMT Manufacturers in Ahmedabad#TMX TMT Steel in Ahmedabad

0 notes

Text

Neon Pothos Climber and Creeper, Foliage Plants (Non-Flowering) Indoor

Money plant (Epipremnum aureum) is a popular houseplant that is grown indoors mostly in water. It is believed that having a money plant at home brings benefits such as good luck, happiness, wealth and prosperity. Money plant is also known by many other names such as golden pothos, silver vine, devil’s vine, devil’s ivy, Solomon Islands ivy, hunter’s robe, ivy arum, taro vine, feng shui money plant.A money plant has large heart-shaped leaves with a leathery and shiny surface.Money plant can grow in both direct and indirect sun light. However, too much direct sun light can turn the leaves yellow and even burn them.Money plant is very easy to propagate. The money plant is easily grown from a cutting. It can be grown in both soil and water.Money plants prefer well-drained soil. You can choose potting soil having high pearlite content, or you can grow your plant well in a mixture of river sand and normal potting soil.If you do not prune your money plant, it will grow very long. To maintain the size of your money plant, carefully prune the plant each year so that it stays low to the trunk with a compact look. You can Propagate money plants easily by the cuttings and that too, with a very high success rate. All you are required to do is to take a stem cutting, which is 3-6 inches long, and plant it in a potting medium or place it in water.

1 note

·

View note

Text

Tall Mug - Pearlitic Axillae, Artsy breezy, wavy and spiral multicolor texture

Abstract designs challenge traditional notions of representation, inviting viewers to appreciate art in a more imaginative and non-literal manner. Abstract designs are artistic compositions that prioritize the use of shapes, lines, colors, and forms divorced from their representational or real-world references. Abstract art is a diverse and innovative artistic movement that prioritizes non-representational and non-figurative forms. Art allows you to explore and express their creativity beyond the constraints of depicting recognizable objects or scenes.

Pearlitic Axillae, Tall Mug.

Order available in @Redbubble

#ecommercestore#fashion#like4like#pattern#Redbubble#ootd#background#onlineshopping#shapes#cool#illustration#random#graphic#gradient#Tall Mug#texture#wall#beautiful#product#purchase

0 notes

Text

What is the benefit of using SAIL TMT Bars for House?

SAIL TMT Bars for House: Elevating Construction Excellence

In the realm of construction, the choice of building materials plays a pivotal role in determining the structural integrity and longevity of a house. Among the myriad options available, SAIL TMT Bars emerge as a stellar choice for those seeking uncompromising quality and durability in their construction projects. These Thermomechanically Treated (TMT) Bars, produced by Steel Authority of India Limited (SAIL), not only meet but exceed industry standards, offering a myriad of benefits that contribute to the robustness and longevity of a building.

Get update on SAIL TMT Bars Price

Unraveling the Chemistry of Strength:

At the heart of SAIL TMT Bars' superiority lies a meticulous manufacturing process that involves the perfect amalgamation of various elements to achieve the desired strength and durability. The primary raw materials include iron ore, coal, limestone, and ferroalloys, which are carefully selected to ensure high purity and quality.

The TMT Bars undergo a sophisticated process known as thermomechanical treatment, where they are subjected to controlled heating and cooling cycles. This process imparts unique metallurgical properties to the bars, enhancing their strength and ductility. The controlled quenching and self-tempering process result in a fine-grained ferrite-pearlite microstructure, ensuring superior mechanical properties.

Strength in Every Strand:

SAIL TMT Bars boast exceptional tensile strength, making them a preferred choice for builders and engineers. The tensile strength of these bars is carefully calibrated during the manufacturing process, ensuring that they can withstand substantial loads and stress without compromising their structural integrity.

Moreover, the yield strength of SAIL TMT Bars is the best to provide the ideal balance between strength and ductility. This ensures that the bars can absorb energy and deform under excessive loads, preventing sudden and catastrophic failure. This property is crucial in enhancing the seismic resistance of structures, a vital consideration in regions prone to earthquakes.

Rigorous Quality Assurance:SAIL TMT FOR CONSTRUCTION OF HOUSE

SAIL's commitment to delivering top-notch products and undergoes a rigorous quality assurance processes. Every batch of TMT Bars undergoes a battery of chemical and physical tests to ensure compliance with national and international standards. These tests include spectroscopic analysis to verify the chemical composition, as well as mechanical tests such as tensile and bend tests.

The bars qualify's to ultrasonic testing to detect any internal defects or irregularities that might compromise their strength. This meticulous quality control not only ensures the reliability of SAIL TMT Bars but also instills confidence in builders and architects regarding the structural soundness of their constructions.

Corrosion Resistance: A Testament to Durability:

Corrosion poses a significant threat to the longevity of steel structures, especially in humid and corrosive environments. SAIL TMT Bars, however, exhibit excellent corrosion resistance due to their high-quality raw materials and the thermomechanical treatment process.

The formation of a protective oxide layer on the surface of the bars impedes the corrosive action of environmental factors. This inherent corrosion resistance significantly extends the lifespan of structures, making SAIL TMT Bars an ideal choice for constructions in coastal areas or regions with high humidity.

Fire Resistance SAIL TMT Bars For House

A Crucial Safety Feature:

In addition to their robustness and corrosion resistance, SAIL TMT Bars excel in terms of fire resistance. The unique microstructure imparted by the thermomechanical treatment process enhances the bars' ability to withstand high temperatures.

During a fire, the TMT Bars maintain their structural integrity for a more extended period compared to conventional steel bars. This characteristic provides occupants with valuable time to evacuate the building safely and allows firefighters to respond effectively. SAIL TMT Bars, therefore, contribute significantly to the overall safety of a structure.

Earthquake Resistance: A Critical Consideration:

In seismic zones, the ability of a building to withstand the lateral forces generated during an earthquake is of paramount importance. SAIL TMT Bars, with their superior ductility and controlled yield strength, it is highly suitable for seismic-resistant constructions.

The bars can undergo controlled deformation without losing their strength, absorbing and dissipating the energy generated during an earthquake. This feature minimizes structural damage and ensures the safety of occupants. Builders and engineers in earthquake-prone regions find SAIL TMT Bars to be a reliable choice for constructing structures that meet or exceed seismic design codes.

Sustainability: House Made by SAIL TMT Bars

A Green Construction Choice:

Beyond their mechanical and chemical attributes, SAIL TMT Bars contribute to sustainable construction practices. The use of recycled steel in their production process minimizes the environmental impact associated with mining and reduces the carbon footprint of construction projects.

Furthermore, the longevity of structures built with SAIL TMT Bars means use of lesser resources for maintenance and repair, making them a sustainable choice in the long run. As the construction industry increasingly embraces eco-friendly practices, the use of SAIL TMT Bars aligns with the global push towards sustainable and responsible building solutions.

Conclusion: SAIL TMT Bars for House is the Best option.

Building the Future with Confidence:

In conclusion, the adoption of SAIL TMT Bars in construction projects brings forth a myriad of benefits that extend beyond mere structural integrity. From the molecular level of their thermomechanical treatment to the macroscopic advantages of corrosion and fire resistance, these bars exemplify excellence in every aspect.

Builders and architects seeking to create enduring structures can place their confidence in the reliability and performance of SAIL TMT Bars. The comprehensive testing, superior metallurgical properties, and sustainability aspects make these bars a cornerstone in the construction industry, ushering in a new era where buildings are not just structures but symbols of strength, durability, and a commitment to a sustainable future.

and Lastly, Get The Latest updates on Benefits of using SAIL TMT Bars for the contruction of House at 9873186252, 9555086252.

Read the full article

0 notes