#gas analysis system

Text

HCL Gas Analyzer - Enviro Gas Solutions

The HCL Gas Analyzer by Enviro Gas Solutions utilizes cutting-edge technologies such as Tunable Diode Laser Absorption Spectroscopy (TDLAS) and Fourier Transform Infrared (FTIR) spectroscopy. TDLAS employs tunable lasers to precisely measure the absorption of light at specific wavelengths, enabling accurate detection and quantification of hydrogen chloride (HCl) gas. Meanwhile, FTIR spectroscopy broadens the scope, allowing for the measurement of a wide range of compounds, including HCl gas, through the absorption of infrared light. This advanced HCl gas analyzer provides comprehensive and reliable monitoring solutions for HCl gas in various industrial and environmental settings.

0 notes

Text

remember when annie literally talked to annie!abed and came to the definite conclusion that she does not love jeff, never really has, and really only needed the feeling of being loved, creating the seeming end to a three-season arc, then immediately backtracked in the next season about fifteen episodes later by getting giddy like a child when a hotel thought she was jeff's wife.

I Remember.

#did she ever get like a good arc actually#like one time could have been a relapse or something#but then it just kept happening till the last episode#gas leak year ...... it did things to all of us.#annie edison#jeff winger#virtual systems analysis#conventions of space and time#community#nbc community#jeffannie

500 notes

·

View notes

Text

Functions of hydraulic oil and the reasons of its contamination

There are four basic functions of hydraulic oil:

To act as an energy transmission medium

To Lubricate internal moving parts of components

To act as a heat transfer medium

To seal clearances between moving parts

Proper hydraulic fluid maintenance helps to prevent or reduce breakdown maintenance. This is accomplished through continuous improvement program that minimizes and removes contaminants. Hydraulic fluid is expected to create a lubricating film to keep precision parts separated. Ideally, the film is thick enough to completely fill the clearance between moving parts. This condition results in low wear rates. When the wear rate is kept low enough, a component is likely to reach its intended life expectancy.

The actual thickness of a lubricating film depends on:

fluid viscosity

applied load

relative speed of the two surfaces

So, if after multiple cycles the oil loses its viscosity or is contaminated. It will lead to addition friction and wear and tear.

What harm will the contaminants make?

If not properly flushed, contaminants from manufacturing and assembly will be left in the system. These contaminants include dust, welding slag, rubber particles from hoses and seals, sand from castings, and metal debris from machined components. Also, when fluid is initially added to the system, contamination is introduced. During system operation, contamination enters through breather caps, worn seals, and other system openings. System operation also generates internal contamination. This occurs as component wear debris and chemical by-products react with component surfaces to generate more contamination.

What are the types & sources of Contamination?

There are basically 4 sources of contamination:

Built-in Contamination

Natural Contamination

Ingressed Contamination

Generated Contamination

While the first three types of contamination is self-explanatory, there is the further classification of generation contamination on the basis of how it is generated:

Abrasive Wear: Hard particles bridging two moving surfaces, scraping one or both.

Cavitation Wear: Restricted inlet flow to pump causes fluid voids that implode causing shocks that break away critical surface material.

Fatigue Wear: Particles bridging a clearance cause a surface stress riser that expands into a spall due to repeated stressing of the damaged area.

Erosive Wear: Fine particles in a high-speed stream of fluid eat away a metering edge or surface.

Adhesive Wear: Loss of oil film allows metal to metal contact between moving surfaces.

Corrosive Wear: Water or chemical contamination in the fluid causes rust or a chemical reaction that degrades a surface.

Are contaminants visible with naked eye?

Particle sizes are generally measured on the micrometer scale. One micrometer (or micron) is one-millionth of one meter, or 39 millionths of an inch. The limit of human visibility is approx.. 32μm micrometers. Keep in mind that most damage-causing particles in hydraulic or lubrication systems are smaller than 14μm micrometers. Therefore, they are microscopic and cannot be seen by the unaided eye. To put the sizes in perspective, below are the sizes of some known objects.

Hence filtration of hydraulic oil is of prime importance. Minimac System provides an array of the solution in this regard. What we also do is filter check via our experts for any of your rig/equipment.

At Minimac Systems we offer Flushing Services and Filter Check Services which ensure a clean system including oil tanks and lines. Book an appointment with our technical expert by clicking on https://www.linkedin.com/company/minimacsystemsprivatetlimited or call +91 8975150700

Like, Comment, Share this article to spread awareness and sensitize the reader for Zero Mechanical Breakdown.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#lube oil flushing#electrostatics lube cleaner#oil dehydration systems#frf condition systems#transformer oil#diesel oil purification#coalser separator#oil analysis#oil filter systems

0 notes

Text

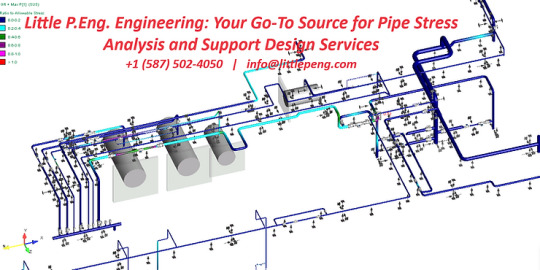

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

In the vast and complex world of engineering, precision and accuracy are paramount. Nowhere is this truer than in the field of piping systems, where even the smallest miscalculation or oversight can lead to catastrophic consequences. To ensure the safe and efficient operation of piping systems, the expertise of specialized engineers is required. This is where Little P.Eng. Engineering comes into play. With a reputation for excellence and a commitment to providing top-notch pipe stress analysis and support design services, Little P.Eng. Engineering stands as a trusted partner for industries that rely on flawless piping systems.

In this comprehensive guide, we will delve into the world of pipe stress analysis and support design services offered by Little P.Eng. Engineering. We will explore the importance of these services, their role in various industries, and how Little P.Eng. Engineering excels in delivering tailored solutions. Additionally, we will discuss the key factors that set Little P.Eng. Engineering apart from the competition and provide valuable insights into their commitment to safety, quality, and customer satisfaction.

Chapter 1: Understanding Pipe Stress Analysis

1.1 What is Pipe Stress Analysis?

Pipe stress analysis is a critical component of engineering that involves evaluating the forces and stresses acting on a piping system to ensure its structural integrity and safety. It plays a pivotal role in various industries, including petrochemical, oil and gas, power generation, and more. Pipe stress analysis helps engineers identify potential issues such as excessive strain, deformation, or failure that could compromise the functionality and safety of the system.

1.2 The Importance of Pipe Stress Analysis

The significance of pipe stress analysis cannot be overstated. Failing to perform adequate stress analysis can lead to a range of problems, including:

1.2.1 Safety Risks: Inadequate pipe stress analysis can result in ruptures, leaks, and catastrophic failures, endangering human lives and the environment.

1.2.2 Cost Overruns: Repairs and maintenance due to unforeseen issues can lead to substantial cost overruns in construction and operation projects.

1.2.3 Downtime: Unscheduled downtime can disrupt operations, leading to production losses and revenue reduction.

1.2.4 Legal and Regulatory Issues: Non-compliance with safety standards and regulations can result in legal and financial repercussions.

1.2.5 Reputation Damage: Incidents related to piping system failures can tarnish a company's reputation.

Chapter 2: The Role of Pipe Stress Analysis in Different Industries

2.1 Oil and Gas Industry

The oil and gas industry relies heavily on complex piping systems to transport hydrocarbons from extraction sites to refineries and end-users. Pipe stress analysis is crucial in this industry to prevent leaks, ruptures, and environmental disasters. Little P.Eng. Engineering provides specialized services tailored to the unique challenges of the oil and gas sector.

2.2 Petrochemical Industry

Petrochemical plants process raw materials into valuable chemical products. The precise and safe transport of chemicals through piping systems is essential. Pipe stress analysis ensures the structural integrity of these systems, mitigating the risk of chemical leaks and ensuring worker safety.

2.3 Power Generation

Power plants, whether they run on fossil fuels, nuclear energy, or renewable sources, require intricate piping networks to deliver steam, water, and gases to turbines and generators. Pipe stress analysis is vital to prevent system failures and maintain uninterrupted power generation.

2.4 Pharmaceutical and Food Industries

In industries where product purity and safety are paramount, such as pharmaceuticals and food production, pipe stress analysis ensures the integrity of sanitary piping systems. Little P.Eng. Engineering's expertise extends to designing hygienic piping solutions that meet the strictest standards.

2.5 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial and industrial buildings rely on complex piping networks. Proper stress analysis ensures the efficient functioning of HVAC systems, contributing to comfort and energy efficiency.

Chapter 3: Little P.Eng. Engineering's Pipe Stress Analysis Services

3.1 Expertise and Experience

Little P.Eng. Engineering boasts a team of highly skilled and experienced engineers with a deep understanding of the complexities involved in pipe stress analysis. Their expertise spans various industries, ensuring that clients receive tailored solutions that align with their specific needs and challenges.

3.2 Advanced Technology and Software

Staying at the forefront of technological advancements is crucial in the engineering field. Little P.Eng. Engineering utilizes state-of-the-art software and tools for pipe stress analysis, enabling precise simulations and evaluations. This ensures the accuracy and reliability of their services.

3.3 Customized Solutions

One of the key strengths of Little P.Eng. Engineering is their ability to provide customized solutions. They understand that each project is unique and may have distinct requirements. By tailoring their services to individual client needs, they ensure optimal results and client satisfaction.

3.4 Compliance with Industry Standards

Compliance with industry standards and regulations is non-negotiable in the world of engineering. Little P.Eng. Engineering ensures that all their pipe stress analysis services meet or exceed relevant industry standards, codes, and safety guidelines.

Chapter 4: Pipe Support Design Services

4.1 What is Pipe Support Design?

Pipe support design is an integral part of piping system engineering. It involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibration, and stress. Proper support design ensures the longevity and stability of piping systems.

4.2 Importance of Pipe Support Design

Inadequate or improperly designed supports can lead to several problems, including:

4.2.1 Excessive Stress: Unsupported piping can experience undue stress, leading to damage and failure.

4.2.2 Vibrations: Vibrations can affect the performance of piping systems and nearby equipment.

4.2.3 Misalignment: Improper alignment can cause leaks and inefficiencies.

4.2.4 Premature Wear: Unsupported piping can wear out faster, leading to maintenance and replacement costs.

4.3 Little P.Eng. Engineering's Pipe Support Design Services

Little P.Eng. Engineering offers comprehensive pipe support design services to ensure that piping systems are adequately supported and stable. Their services include:

4.3.1 Structural Analysis: Evaluating the structural integrity of supports and ensuring they meet safety and code requirements.

4.3.2 Custom Designs: Tailoring support solutions to the unique needs of each project.

4.3.3 Material Selection: Recommending suitable materials for support components, considering factors like corrosion resistance and load-bearing capacity.

4.3.4 Installation Guidance: Providing guidance and recommendations for the proper installation of supports.

Chapter 5: What Sets Little P.Eng. Engineering Apart

5.1 Commitment to Safety

Safety is Little P.Eng. Engineering's top priority. Their pipe stress analysis and support design services are driven by a commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

5.2 Quality Assurance

Quality is woven into the fabric of Little P.Eng. Engineering's services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

5.3 Timely and Efficient Service

Time is often of the essence in engineering projects. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality.

5.4 Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process.

5.5 Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members.

Chapter 6: Case Studies and Success Stories

6.1 Case Study 1: Oil Refinery Piping

A major oil refinery faced ongoing issues with leaks and failures in its piping system, resulting in costly downtime and environmental concerns. Little P.Eng. Engineering conducted a comprehensive pipe stress analysis and identified critical stress points. They then designed and implemented reinforced supports and provided guidance on material selection. The result was a significant reduction in incidents, ensuring safe and uninterrupted operations.

6.2 Case Study 2: Pharmaceutical Facility

A pharmaceutical company needed to upgrade its piping system to comply with stringent FDA regulations. Little P.Eng. Engineering provided customized pipe stress analysis and support design services to ensure compliance with hygienic standards. The project was completed successfully, allowing the company to maintain product integrity and regulatory compliance.

6.3 Case Study 3: Power Plant Efficiency

A power plant was experiencing inefficiencies in its piping system, resulting in reduced energy output. Little P.Eng. Engineering conducted a detailed pipe stress analysis and identified areas of improvement. They designed and implemented optimized supports, resulting in increased energy efficiency and cost savings.

Chapter 7: Conclusion

In conclusion, Little P.Eng. Engineering stands as a premier provider of pipe stress analysis and support design services, catering to various industries where the integrity and safety of piping systems are of utmost importance. Their commitment to safety, quality, client satisfaction, and continuous improvement sets them apart as a trusted partner in the world of engineering.

Whether you operate in the oil and gas, petrochemical, power generation, pharmaceutical, or HVAC sector, Little P.Eng. Engineering has the expertise and experience to deliver customized solutions that meet your unique needs. By prioritizing safety, adhering to industry standards, and consistently providing timely and efficient services, Little P.Eng. Engineering has earned its reputation as a leader in the field of pipe stress analysis and support design.

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Pipe Stress Analysis

Little P.Eng. Engineering

Finite Element Analysis

Structural Integrity

Engineering Expertise

Thermal Expansion

Support Design Services

Oil and Gas

ASME Codes

Industry Standards

Power Generation

Stress Evaluation

Piping Systems

Safety and Compliance

Engineering Solutions

Precision Analysis

Industrial Processes

Petrochemical

Seismic Analysis

Customized Solutions

Pressure Analysis

Pipe Support Design

Safety Regulations

Reliability Assurance

Complex Piping Systems

Chemical Industry

Pharmaceutical Industry

Vibrations Analysis

Stress Distribution

Pipe Failure Prevention

Pipe Stress Analysis Services

Engineering Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Pipe Stress Analysis#Little P.Eng. Engineering#Finite Element Analysis#Structural Integrity#Engineering Expertise#Thermal Expansion#Support Design Services#Oil and Gas#ASME Codes#Industry Standards#Power Generation#Stress Evaluation#Piping Systems#Safety and Compliance#Engineering Solutions#Precision Analysis#Industrial Processes#Petrochemical#Seismic Analysis#Customized Solutions#Pressure Analysis#Pipe Support Design#Safety Regulations#Reliability Assurance#Complex Piping Systems#Chemical Industry#Pharmaceutical Industry#Vibrations Analysis#Stress Distribution

0 notes

Text

#Flare Gas Recovery System Market – Ireland Industry Analysis#Size#Share#Trends and Forecast 2023 – 2030

0 notes

Text

#Gas Booster Systems Market#Gas Booster Systems Market Size#Gas Booster Systems Market Share#Gas Booster Systems Market Forecast#Gas Booster Systems Market Analysis#Gas Booster Systems Market Trends

0 notes

Text

#Global PA & GA Systems Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Text

Global Anesthesia Gas Scavenging System Market Is Estimated To Witness High Growth Owing To Increasing Focus on Patient Safety

The global Anesthesia Gas Scavenging System Market is estimated to be valued at US$ 5.5 billion in 2022 and is expected to exhibit a CAGR of 5.5% over the forecast period, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

Anesthesia gas scavenging systems are used to remove waste anesthetic gases, ensuring the safety of healthcare providers and patients during anesthesia procedures. These systems prevent the accumulation of anesthetic gases in the operating room, maintaining a safe working environment. The advantages of anesthesia gas scavenging systems include reduced exposure to anesthetic gases, decreased risk of adverse health effects, and compliance with safety regulations.

B) Market Key Trends:

One key trend in the anesthesia gas scavenging system market is the increasing focus on patient safety. Healthcare providers are becoming more aware of the potential risks associated with exposure to waste anesthetic gases. This has led to the implementation of strict safety guidelines and regulations, driving the demand for anesthesia gas scavenging systems. For example, the Occupational Safety and Health Administration (OSHA) in the United States recommends the use of scavenging systems to minimize exposure to waste anesthetic gases.

C) PEST Analysis:

- Political: Governments across the globe are implementing regulations and guidelines to ensure the safety of healthcare providers and patients. These regulations drive the adoption of anesthesia gas scavenging systems.

- Economic: The growing healthcare industry and increasing number of surgical procedures contribute to the growth of the anesthesia gas scavenging system market.

- Social: Awareness about the potential health risks associated with waste anesthetic gases is increasing among healthcare providers, leading to higher demand for scavenging systems.

- Technological: Advancements in technology have led to the development of more efficient and user-friendly anesthesia gas scavenging systems.

D) Key Takeaways:

- The Global Anesthesia Gas Scavenging System Market Size is expected to witness high growth, exhibiting a CAGR of 5.5% over the forecast period, due to increasing focus on patient safety. Healthcare providers are increasingly adopting anesthesia gas scavenging systems to comply with safety regulations and minimize the risks associated with waste anesthetic gases.

- North America is expected to be the fastest growing and dominating region in the anesthesia gas scavenging system market. The region has well-established healthcare infrastructure and stringent safety regulations, driving the demand for scavenging systems.

- Key players operating in the global anesthesia gas scavenging system market include Beacon Medaes, CGA 30 MEDEVICE system by DeviceInformed, MEC medical Ltd., MidMark, Pneumatech Medical Gas Solutions (PMGS), Coltronics system Ltd., Becker pumps, and G.Samaras S.A.

In conclusion, the global anesthesia gas scavenging system market is expected to witness substantial growth in the coming years. The increasing focus on patient safety and the implementation of strict safety regulations drive the demand for anesthesia gas scavenging systems. North America is expected to be the fastest growing region, driven by its well-established healthcare infrastructure and stringent safety regulations. Key players in the market are continuously developing new and innovative products to cater to the growing demand for anesthesia gas scavenging systems.

#Anesthesia Gas Scavenging System Market#Anesthesia Gas Scavenging System Market Trends#Anesthesia Gas Scavenging System Market Outlook#Anesthesia Gas Scavenging System Market Analysis#Anesthesia Gas Scavenging System Market Forecast#Anesthesia Gas Scavenging System#Anesthesia gas#Closed scavenging systems#healthcare facilities

0 notes

Text

space launch services market trends, flue gas treatment systems market size, flue gas treatment systems market share, space launch services market analysis, space launch services market outlook, space launch services market overview, space launch services market growth, space launch services market segments, space launch services market insights, space launch services market, space launch services market forecast, space launch services market report

#space launch services market trends#flue gas treatment systems market size#flue gas treatment systems market share#space launch services market analysis#space launch services market outlook#space launch services market overview#space launch services market growth#space launch services market segments#space launch services market insights#space launch services market#space launch services market forecast#space launch services market report

0 notes

Text

NOx Gas Analyzer - Enviro Solutions Technology

Enviro Solutions Technology presents a cutting-edge NOx Gas Analyzer employing Differential Optical Absorption Spectroscopy (DOAS) and Partial Least Squares (PLS) technologies. This innovative analyzer accurately measures the concentrations of various gases such as SO2, NO2, NO, NH3, Cl2, O3, H2S, and more. Boasting high measurement precision, exceptional reliability, rapid response times, and versatile applicability, it stands as a robust solution for comprehensive gas analysis across diverse environmental and industrial settings.

0 notes

Text

Flue Gas Desulfurization Systems Market will witness the world's highest growth between 2022-2028

The global “Flue Gas Desulfurization Systems Market” report 2022 highlights all of the dynamic elements affecting key growth factors, as well as the most recent trends and developments in the global industry. It gives a complete understanding of key manufacturers’ business development plans, current industry condition, growth areas, and future scope. The Flue Gas Desulfurization Systems market research seeks to give regional development, market driving factors, and sales revenue. With numerous research approaches such as SWOT and PESTLE analysis, it provides extensive research and analysis of key elements and emphasizes current market circumstances. In addition, the study contains valuable information on global players’ future plans and possibilities.

Enquire before purchasing this report

In accordance with the Flue Gas Desulfurization Systems market is set to grow at a CAGR of 5.6% over a forecast period (2022-2028).

#Flue Gas Desulfurization Systems Market Analysis#Flue Gas Desulfurization Systems Market Research#Flue Gas Desulfurization Systems Market Size#Flue Gas Desulfurization Systems Market share

0 notes

Text

Standards of turbine oil

A) BSI (British Standards) – BSI BS 489:1999: Specification For Turbine Lubricants.

B) DIN (German Institute for Standardization DIN 51515-1, 51515-2: This document specifies minimum requirements for oils for high thermal stress (high-temperature service) in turbines.

C) ABB (ABB Group) ABB G12106: Ultra-clean turbine oil, Long-life, Rust & Oxidation-inhibited circulating oil.

D) ASTM International – ASTM D4304: Define the properties of the mineral and synthetic oil-based turbine lubricating oils that are functionally interchangeable with existing oils of this type, are compatible with most existing machinery components, and with appropriate field maintenance, will maintain their functionality.

E) GE (General Electric) GE: GEK-32568: Lubricating Oil Recommendations for Gas Turbines With Bearing Ambients above 500°F (260°C)

Also Read: https://www.linkedin.com/pulse/mandatory-properties-steam-gas-turbine-oil-anshuman-agrawal-mlt-1-/

We at Minimac study your maintenance needs and provide the best solution. We believe in Discern, Design & Deliver.

Call +91 7030901266 for Mechanical Maintenance & Oil Check.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil analysis#oil filters#oil industry#oil and gas#oil#oil purification system#oil purification system#oil purification#oil contamination#mlc lvdh#lvdh full form#lvdh#mlc#transformer oil filtration#oil filtration machine#oil filtration systems#oil dehyration#electrostatics lube cleaner#transformer oil#transformers

0 notes

Text

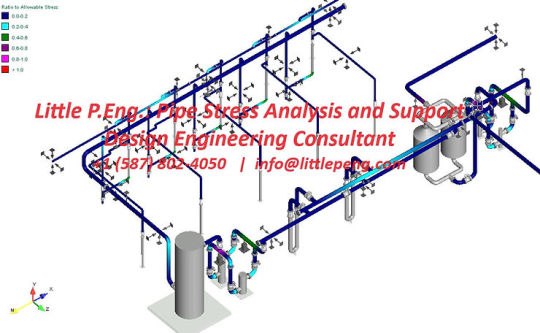

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

In the world of engineering, precision and safety are paramount, especially when it comes to piping systems. Any miscalculation or oversight can have severe consequences, ranging from safety hazards to costly downtime. This is where Little P.Eng. Engineering steps in as a trusted partner, providing expert pipe stress analysis and support design services to ensure the structural integrity and efficiency of piping systems across various industries.

With a reputation for excellence and a commitment to delivering tailored solutions, Little P.Eng. Engineering has established itself as a go-to engineering consultant for those seeking to optimize their piping systems.

Expertise in Pipe Stress Analysis

At the core of Little P.Eng.'s services is their expertise in pipe stress analysis. This crucial engineering discipline involves assessing the forces, stresses, and displacements acting on piping systems to ensure they operate safely and efficiently. Whether it's static stress analysis, dynamic stress analysis, thermal analysis, or seismic analysis, Little P.Eng. Engineering has a team of highly skilled engineers who are well-versed in these complex assessments.

Static stress analysis, for example, is employed to evaluate the stresses in stationary piping systems, ensuring they can withstand the pressures and loads they are subjected to during normal operation. Dynamic stress analysis, on the other hand, deals with transient conditions such as startup, shutdown, and water hammer, which can place additional stress on the system.

Ensuring Compliance with Standards

One of the hallmarks of Little P.Eng.'s services is their unwavering commitment to compliance with industry standards and codes. Piping systems must adhere to strict safety and regulatory guidelines, and Little P.Eng. Engineering ensures that all their analyses and designs meet or exceed these standards. Whether it's ASME, ANSI, API, ASTM, or local building codes, clients can trust that their projects are in full compliance.

Customized Solutions for Unique Needs

No two piping systems are identical, and Little P.Eng. Engineering understands this well. They excel in providing customized solutions that align with the specific needs and challenges of each project. Whether it's an oil refinery, a pharmaceutical facility, or a power plant, Little P.Eng.'s team tailors their services to ensure optimal results.

Support Design Expertise

In addition to pipe stress analysis, Little P.Eng. Engineering offers support design services that play a critical role in the stability and longevity of piping systems. Proper support design involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibrations, and stress.

Little P.Eng. Engineering's support design services encompass a range of aspects, including pipe support design, structural analysis, material selection, and installation guidance. These services are crucial in preventing issues like excessive stress, vibrations, misalignment, and premature wear in piping systems.

Commitment to Safety and Quality

Safety is Little P.Eng.'s top priority. Their pipe stress analysis and support design services are driven by a deep commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

Quality assurance is woven into the fabric of Little P.Eng.'s services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process. This approach fosters trust and transparency, key elements in successful engineering projects.

Timely and Efficient Service

In the world of engineering, time is often of the essence. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality. This ensures that clients can rely on them to meet their project deadlines and objectives.

Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members. This dedication to staying at the forefront of technological advancements allows them to provide cutting-edge solutions to their clients.

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

A Pipe Stress Analysis and Support Design engineering consultant offers a range of services to ensure the structural integrity, safety, and efficiency of piping systems in various industries. These services may include:

1. Pipe Stress Analysis:

Static Stress Analysis: Evaluating stresses, forces, and displacements in stationary piping systems.

Dynamic Stress Analysis: Assessing the effects of transient conditions, such as startup, shutdown, and water hammer.

Thermal Stress Analysis: Analyzing the impact of temperature variations on piping materials and components.

Seismic Analysis: Evaluating the response of piping systems to seismic forces and designing for earthquake resistance.

Fatigue Analysis: Predicting the fatigue life of components subjected to cyclic loading.

2. Support Design Services:

Pipe Support Design: Designing supports, hangers, and restraints to prevent excessive movement and stress in piping systems.

Structural Analysis: Evaluating the structural integrity of support structures and ensuring compliance with safety codes.

Material Selection: Recommending suitable materials for support components based on factors like load-bearing capacity and corrosion resistance.

Installation Guidance: Providing recommendations and specifications for the proper installation of supports.

3. Compliance with Standards and Codes:

Ensuring that all designs and analyses meet relevant industry standards, codes, and regulations, such as ASME, ANSI, API, ASTM, and local building codes.

Assisting clients in obtaining necessary permits and approvals for piping system installations or modifications.

4. Customized Solutions:

Tailoring pipe stress analysis and support design services to the specific needs and requirements of each project.

Developing unique solutions for complex or challenging piping system configurations.

5. Failure Analysis and Troubleshooting:

Investigating and diagnosing issues related to piping system failures, leaks, or performance problems.

Recommending corrective actions and retrofits to address identified problems.

6. Hygienic Piping Design (in industries like pharmaceuticals and food production):

Designing piping systems that comply with stringent sanitary and hygiene standards to prevent contamination.

Implementing design solutions that minimize dead legs, reduce the risk of bacterial growth, and facilitate cleaning and sterilization.

7. Stress Testing and Simulation:

Conducting computer simulations and modeling to predict stress and strain behavior under different operating conditions.

Performing load testing to validate the performance of pipe supports and restraints.

8. Energy Efficiency Optimization:

Identifying opportunities to improve energy efficiency by optimizing piping system configurations and insulation.

Recommending modifications to reduce heat loss or improve heat transfer.

9. Retrofit and Upgrade Design:

Developing plans and designs for the retrofit or upgrade of existing piping systems to meet current safety and performance standards.

Incorporating advanced technologies and materials for improved reliability and efficiency.

10. Documentation and Reporting:

Generating comprehensive reports, including stress analysis reports, design drawings, specifications, and installation instructions.

Maintaining accurate records of all analyses, designs, and project documentation.

11. Consulting and Expert Witness Services:

Providing expert consulting services for legal matters, including expert witness testimony in cases involving piping system failures or disputes.

12. Project Management and Coordination:

Overseeing and coordinating the implementation of recommended design changes or support installations to ensure proper execution.

Pipe Stress Analysis and Support Design engineering consultants play a crucial role in ensuring the safe and efficient operation of piping systems across various industries, and their services are vital for preventing failures, reducing downtime, and maintaining regulatory compliance.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Little P.Eng.

ASME standards

Engineering expertise

Thermal expansion

Structural integrity

Regulatory compliance

Pipe stress analysis

Documentation

Industrial processes

Engineering consultant

Advanced software

Pressure changes

API standards

Maintenance costs

Optimization

ISO standards

Seismic events

Oil and gas industry

Custom support systems

Inspection readiness

Load-bearing capacities

Compliance standards

Piping systems

Power generation

Fluid dynamics

Petrochemical industry

Support design engineering

Troubleshooting

Temperature fluctuations

Safety analysis

Pipe Stress Analysis Services

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng.#ASME standards#Engineering expertise#Thermal expansion#Structural integrity#Regulatory compliance#Pipe stress analysis#Documentation#Industrial processes#Engineering consultant#Advanced software#Pressure changes#API standards#Maintenance costs#Optimization#ISO standards#Seismic events#Oil and gas industry#Custom support systems#Inspection readiness#Load-bearing capacities#Compliance standards#Piping systems#Power generation#Fluid dynamics#Petrochemical industry#Support design engineering#Troubleshooting#Temperature fluctuations

0 notes

Text

Flue Gas Desulfurization Systems Market 2022 Industry Outlook and Sales Analysis 2027

The report titled Flue Gas Desulfurization Systems Market offers detailed insights on the Flue Gas Desulfurization Systems industry entailing key information on its different market segments. The report gives an industry overview from around the world and covers the latest trends, market restraints, and investment opportunities, and conducts exclusive interviews of the Flue Gas Desulfurization Systems industry leaders to contribute to the report’s findings. The report discusses the buyers’ requirements and suggests strategic actions & business changes accordingly to the market players. Moreover, the natural, internal, and external barriers to progress are given in the report. The wider business environment of the Flue Gas Desulfurization Systems market and the industry challenges are included in the report.

Read Full Report at:

Growth prospects, leading trends, progress projections, key industries, and business innovations are the primary focus of the Flue Gas Desulfurization Systems study. A comprehensive Flue Gas Desulfurization Systems study is available for a number of key areas involved in the report. Furthermore, the Flue Gas Desulfurization Systems study examines present and potential consumer positions in terms of sales based on market goods around the globe.

Key Players in the Flue Gas Desulfurization Systems Market:

FLSmidth & Co. A/S (CPH: FLS), Hamon Corp, Clyde Bergemann Power Group, Marsulex Environmental Tech, Babcock & Wilcox Enterprises Inc. (NYSE: BW), Burns & Mcdonnell, Alstom SA (EPA: ALO), Mitsubishi Electric Corp., Siemens AG (ETR: SIE), Thermax Ltd (NSE: THERMAX), Andritz AG, China Boqi Environmental (Holding) Co. Ltd., Chiyoda Corporation, Doosan Lentjes GmbH, Ducon Technologies Inc., General Electric Company, Kawasaki Heavy Industries Ltd., LAB S.A., Rafako S.A, Shandong Baolan Environmental Protection Engineering Co. Ltd., Steinmuller Engineering GmbH and others.

Flue Gas Desulfurization Systems Market Types:

Wet FGD

Dry & Semi-Dry FGD

Flue Gas Desulfurization Systems Market Applications:

Power Generation

Chemical

Iron & Steel

Cement Manufacturing

Others

Highlights of the Report:

The report gives information on all the active tenders in the Flue Gas Desulfurization Systems industry across the globe based on different categories. The important government notifications and change in regulations according to the latest updates is provided in the report.

The market size and forecast estimates of the Flue Gas Desulfurization Systems market is given in the report considering the economic, financial, and general business conditions prevailing in the Flue Gas Desulfurization Systems market from 2022 to 2027.

The report demonstrates the contribution of each segment and sector in the improvement of Flue Gas Desulfurization Systems market share, market size, and CAGR.

Request a sample report:

Regional Flue Gas Desulfurization Systems Market (Regional Output, Demand & Forecast by Countries):

North America (United States, Canada, Mexico)

South America (Brazil, Argentina, Ecuador, Chile)

Asia Pacific (China, Japan, India, Korea)

Europe (Germany, UK, France, Italy)

Middle East Africa (Egypt, Turkey, Saudi Arabia, Iran) And more.

Why Purchase This Market Research Report?

Critical issues and challenges the Flue Gas Desulfurization Systems market will be facing in the forecasted years are identified in the report to help market players align their business decisions and strategies accordingly.

The report identifies key trends facing the Flue Gas Desulfurization Systems market.

Trends responsible for global and regional economic growth of the Flue Gas Desulfurization Systems market are highlighted in the report to help market players in a critical understanding of the future of the Flue Gas Desulfurization Systems market.

The report conducts an assessment of the production and operational practices taking place in the marketplace.

The report presents the challenges faced by the leading geographies and nations from the pandemic and their reorientation of policies to survive the market.

The Report Attempts to Answer the Following Questions:

What will be the financial performance of North America, APAC, Europe, and Africa in the Flue Gas Desulfurization Systems market in 2022 and beyond?

Which companies are likely to succeed in the Flue Gas Desulfurization Systems market with the help of foreign companies, mergers and acquisitions and new product launches?

What are the strategy recommendation and business models for emerging market players?

Which are the Flue Gas Desulfurization Systems market’s largest manufacturing firms and most competitive firms?

Thanks for showing interest in the Flue Gas Desulfurization Systems Market research publication; you can also get individual chapter-wise sections or region / Country report versions like Germany, France, China, LATAM, GCC, North America, Europe, or Asia.

ABOUT US:

IndustryDataAnalytics is your single point market research source for all industries including pharmaceutical, chemicals and materials, energy resources, automobile, IT, technology and media, food and beverages, and consumer goods, among others.

CONTACT US:

Irfan Tamboli (Head of Sales) – Industry Data Analytics

+1 (704) 266-3234 | [email protected]

#Flue Gas Desulfurization Systems Market#Flue Gas Desulfurization Systems Market Analysis#Flue Gas Desulfurization Systems Market Top Companies#Flue Gas Desulfurization Systems Market Research

0 notes

Text

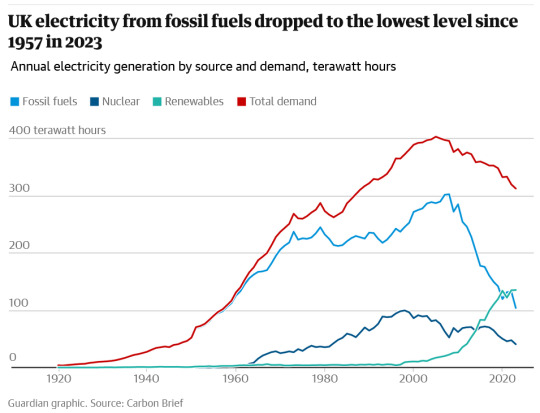

"The amount of electricity generated by the UK’s gas and coal power plants fell by 20% last year, with consumption of fossil fuels at its lowest level since 1957.

Not since Harold Macmillan was the UK prime minister and the Beatles’ John Lennon and Paul McCartney met for the first time has the UK used less coal and gas.

The UK’s gas power plants last year generated 31% of the UK’s electricity, or 98 terawatt hours (TWh), according to a report by the industry journal Carbon Brief, while the UK’s last remaining coal plant produced enough electricity to meet just 1% of the UK’s power demand or 4TWh.

Fossil fuels were squeezed out of the electricity system by a surge in renewable energy generation combined with higher electricity imports from France and Norway and a long-term trend of falling demand.

Higher power imports last year were driven by an increase in nuclear power from France and hydropower from Norway in 2023. This marked a reversal from 2022 when a string of nuclear outages in France helped make the UK a net exporter of electricity for the first time.

Carbon Brief found that gas and coal power plants made up just over a third of the UK’s electricity supplies in 2023, while renewable energy provided the single largest source of power to the grid at a record 42%.

It was the third year this decade that renewable energy sources, including wind, solar, hydro and biomass power, outperformed fossil fuels [in the UK], according to the analysis. Renewables and Britain’s nuclear reactors, which generated 13% of electricity supplies last year, helped low-carbon electricity make up 55% of the UK’s electricity in 2023.

[Note: "Third year this decade" refers to the UK specifically, not global; there are several countries that already run on 100% renewable energy, and more above 90% renewable. Also, though, there have only been four years this decade so far! So three out of four is pretty good!]

Dan McGrail, the chief executive of RenewableUK, said the data shows “the central role that wind, solar and other clean power sources are consistently playing in Britain’s energy transition”.

“We’re working closely with the government to accelerate the pace at which we build new projects and new supply chains in the face of intense global competition, as everyone is trying to replicate our success,” McGrail said.

Electricity from fossil fuels was two-thirds lower in 2023 compared with its peak in 2008, according to Carbon Brief. It found that coal has dropped by 97% and gas by 43% in the last 15 years.

Coal power is expected to fall further in 2024 after the planned shutdown of Britain’s last remaining coal plant in September. The Ratcliffe on Soar coal plant, owned by the German utility Uniper, is scheduled to shut before next winter after generating power for over 55 years.

Renewable energy has increased sixfold since 2008 as the UK has constructed more wind and solar farms, and the large Drax coal plant has converted some of its generating units to burn biomass pellets.

Electricity demand has tumbled by 22% since its peak in 2005, according to the data, as part of a long-term trend driven by more energy efficient homes and appliances as well as a decline in the UK’s manufacturing sector.

Demand for electricity is expected to double as the UK aims to cut emissions to net zero by 2050 because the plan relies heavily on replacing fossil fuel transport and heating with electric alternatives.

In recent weeks [aka at the end of 2023], offshore wind developers have given the green light to another four large windfarms in UK waters, including the world’s largest offshore windfarm at Hornsea 3, which will be built off the North Yorkshire coast by Denmark’s Ørsted."

-via The Guardian, January 2, 2024

#uk#united kingdom#england#scotland#wales#northern ireland#electricity#renewables#renewable energy#climate change#sustainability#hope posting#green energy#fossil fuels#oil#coal#solar power#wind power#environment#climate action#global warming#air pollution#climate crisis#good news#hope

386 notes

·

View notes

Text

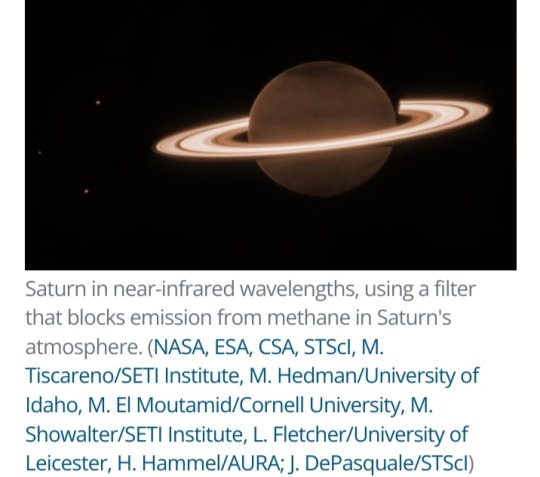

With the addition of Saturn, the James Webb Space Telescope has finally captured all four of our Solar System's giant worlds.

JWST's observations of the ringed planet, taken on 25 June 2023, have been cleaned up and processed, giving us a spectacular view of Saturn's glorious rings, shining golden in the darkness.

By contrast, the disk of Saturn is quite dark in the new image, lacking its characteristic bands of cloud, appearing a relatively featureless dim brown.

This is because of the wavelengths in which JWST sees the Universe – near- and mid-infrared.

These wavelengths of light are usually invisible to the naked human eye, but they can reveal a lot.

For example, thermal emission – associated with heat – is dominated by infrared wavelengths.

When you're trying to learn about what's going on inside a planet wrapped in thick, opaque clouds, studying its temperature is a valuable way to go about it.

Some elements and chemical processes emit infrared light, too. Seeing the planets of the Solar System in wavelengths outside the narrow range admitted by our vision can tell us a lot more about what they have going on.

Saturn

As we saw last week, when we clapped eyes on the raw JWST Saturn images, the observations involved filters that dimmed the light of the planet, while allowing light from the rings and moons to shine brightly.

This is so a team led by planetary scientist Leigh Fletcher of the University of Leicester in the UK can study the rings and moons of Saturn in more detail.

They hope to identify new ring structures and, potentially, even new moons orbiting the gas giant.

The image above shows three of Saturn's moons, Dione, Enceladus and Tethys, to the left of the planet.

Although dim, the disk of the planet also reveals information about Saturn's seasonal changes.

The northern hemisphere is reaching the end of its 7-year summer, but the polar region is dark. An unknown aerosol process could be responsible.

Meanwhile, the atmosphere around the edges of the disk appears bright, which could be the result of methane fluorescence, or the glow of trihydrogen, or both. Further analysis could tell us which.

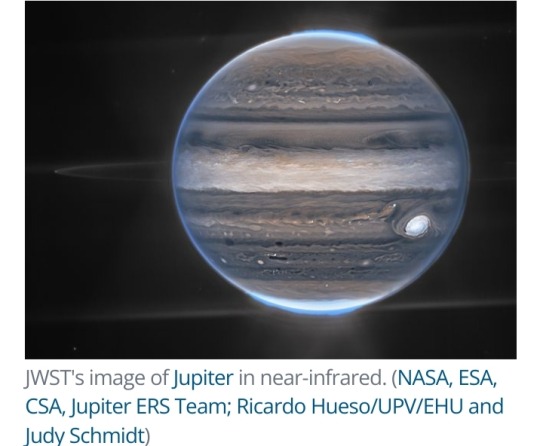

Jupiter

Jupiter was the first of the giant planets to get the JWST treatment, with images dropping in August of last year – and boy howdy were they stunning.

The spectacular detail seen in the planet's turbulent clouds and storms was perhaps not entirely surprising.

However, we also got treated to some rarely seen features: the permanent aurorae that shimmer at Jupiter's poles, invisible in optical wavelengths, and Jupiter's tenuous rings.

We also saw two of the planet's smaller, lesser-known moons, Amalthea and Adrastea, with fuzzy blobs of distant galaxies in the background.

"This one image sums up the science of our Jupiter system program, which studies the dynamics and chemistry of Jupiter itself, its rings, and its satellite system," said astronomer Thierry Fouchet of Paris Observatory in France, who co-led the observations.

Neptune

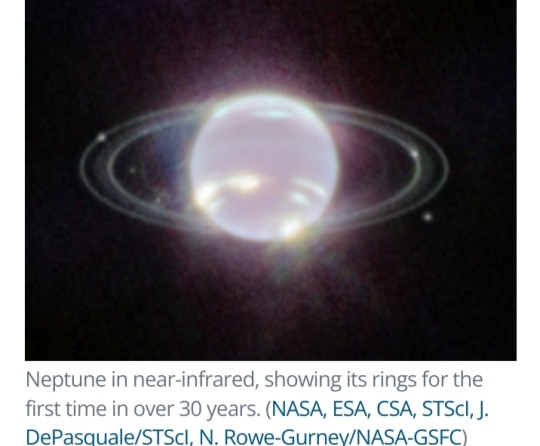

Observations of Neptune arrived in the latter half of September 2022.

Because Neptune is so very far away, it tends to get a little neglected; you're probably used to seeing, if anything, the images taken by Voyager 2 when it flew past in 1989.

JWST's observations gave us, for the first time in more than 30 years, a new look at the ice giant's dainty rings – and the first ever in infrared.

It also revealed seven of Neptune's 14 known moons, and bright spots in its atmosphere.

Most of those are storm activity, but if you look closely, you'll see a bright band circling the planet's equator.

This had never been seen before and could be, scientists say, a signature of Neptune's global atmospheric circulation.

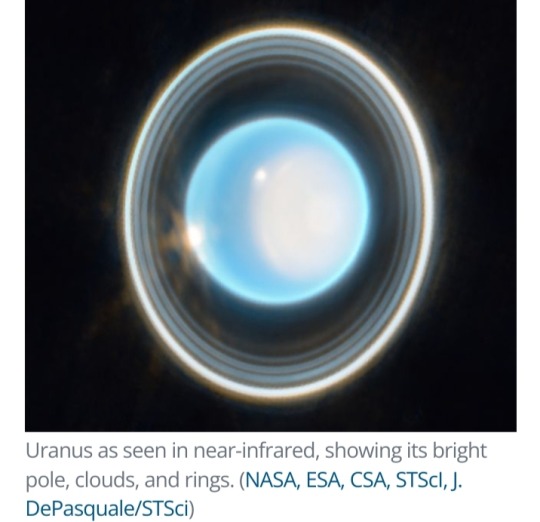

Uranus

Uranus is also pretty far away, but it's also a huge weirdo. Although very similar to Neptune, the two planets are slightly different hues, which is something of a mystery.

Uranus is also tipped sideways, which is challenging to explain too.

JWST's observations, released in April 2023, aren't solving these conundrums.

However, they have revealed 11 of the 13 structures of the incredible Uranian ring system and an unexplained atmospheric brightening over the planet's polar cap.

JWST has a lot to say about the early Universe; but it's opening up space science close to home, too.

As its first year of operations comes to an end, we can't help but speculate what new wonders will be to come in the years ahead.

Top: Jupiter - Neptune / Bottom: Uranus - Saturn

Credit: NASA

#James Webb Space Telescope#Solar System#Saturn#Jupiter#Uranus#Neptune#planets#space#universe#infrared wavelengths#wavelengths#JWST#Leigh Fletcher#planetary science#Thierry Fouchet#moons#Voyager 2#giant planets#astronomy

1K notes

·

View notes