#Piping systems

Text

Ensuring Integrity in Process Plant Piping Through Leak Testing

In process plants, piping systems are essential for the seamless transport of fluids and gases. Ensuring these systems are leak-free is crucial, and this is where internal tank and pipeline inspection services come into play. These services are vital for conducting comprehensive leak testing and verification to maintain system integrity.

Leak Testing Essentials

Leak testing is a fundamental process for identifying leaks in piping systems. Undetected leaks can lead to severe consequences, including environmental harm, safety risks, and financial losses. Therefore, regular leak testing is indispensable for maintaining operational integrity.

Common Leak Testing Methods

Hydrostatic Testing: This method involves filling the pipeline with water and pressurizing it to check for leaks. It's highly effective but requires proper handling to prevent contamination and manage water disposal.

Pneumatic Testing: Air or another inert gas is used to pressurize the pipeline. While it is cleaner than hydrostatic testing, it poses higher risks due to the compressibility of gases.

Helium Leak Testing: Helium's small atomic size makes it ideal for detecting minute leaks. This method is renowned for its sensitivity and accuracy.

Verification Techniques

Verification ensures that the piping system adheres to industry standards and specifications. This process includes a series of inspections and tests performed by certified inspectors from a tank inspection company. They check for correct installation, material quality, and compliance with safety regulations.

0 notes

Text

Leak Testing and Verification in Process Plant Piping

Piping systems in process plants are critical for transporting fluids, gases, and other materials necessary for operations. Ensuring these systems are leak-free is paramount for safety and efficiency. One crucial aspect of maintaining piping integrity is leak testing and verification, often conducted by specialized internal tank and pipeline inspection services.

Importance of Leak Testing

Leak testing is essential for detecting and addressing potential leaks before they become significant issues. Leaks can lead to costly downtime, environmental damage, and safety hazards. Hence, regular and thorough testing is necessary to maintain operational integrity.

Methods of Leak Testing

Several methods are employed to test for leaks in piping systems:

Hydrostatic Testing: This involves filling the pipeline with water and pressurizing it to check for leaks. It's a common and effective method but requires careful handling to avoid water contamination and disposal issues.

Pneumatic Testing: Using air or another inert gas, this method is used when hydrostatic testing is impractical. It is less messy but can be more dangerous due to the compressibility of gases.

Helium Leak Testing: Helium is used due to its small atomic size, which makes it ideal for detecting small leaks. This method is highly sensitive and precise.

Verification Process

Verification ensures that the piping system meets the required standards and specifications. This involves a series of inspections and tests conducted by a tank inspection company or other certified inspectors. These professionals check for proper installation, material integrity, and compliance with safety standards.

0 notes

Text

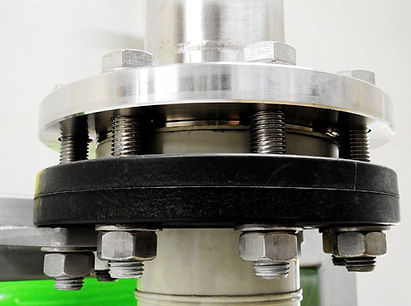

Little P.Eng.: Delivering Expert Flange Design Services as per ASME Sec. VIII Div. 1, Appendix 2

Flange design plays a critical role in ensuring the safety and integrity of pressure vessels and piping systems. When it comes to designing flanges as per ASME (American Society of Mechanical Engineers) Sec. VIII Div. 1, Appendix 2 for ABSA (Alberta Boilers Safety Association) submission, it is crucial to rely on the expertise of a trusted engineering firm. Little P.Eng. is a renowned engineering consultancy that specializes in providing comprehensive flange design services. With their deep understanding of ASME codes and regulations, they are well-equipped to assist clients in meeting ABSA requirements with precision and efficiency.

Expertise in ASME Sec. VIII Div. 1, Appendix 2:

Little P.Eng. prides itself on its extensive knowledge and experience in working with ASME codes, specifically Section VIII Division 1. Appendix 2 of this section provides detailed guidelines for flange design, including bolt loads, gasket constants, and allowable flange stresses. Compliance with these specifications is crucial for ensuring the safety and reliability of pressure vessels. The team at Little P.Eng. possesses a deep understanding of this appendix and keeps up-to-date with the latest revisions, ensuring their designs meet the most current standards.

Accurate and Reliable Flange Design:

When it comes to flange design, precision is paramount. Little P.Eng. employs highly skilled engineers who utilize advanced design software and tools to accurately calculate critical parameters such as bolt loads, gasket constants, and flange stresses. By leveraging their expertise and cutting-edge technology, they deliver robust and reliable designs that are tailored to each client's specific requirements. The team ensures that the design complies with the ASME code, meeting the stringent ABSA submission criteria.

Compliance with ABSA Requirements:

ABSA, as the regulatory authority in Alberta, Canada, mandates strict adherence to safety standards for pressure vessels and piping systems. Little P.Eng. understands the ABSA submission process and the specific requirements that need to be met. Their flange design services are customized to comply with ABSA regulations, enabling clients to obtain necessary approvals for their projects. By engaging Little P.Eng., clients can rest assured that their flange designs will undergo a thorough review process, meeting all ABSA requirements.

Collaborative Approach and Client Satisfaction:

Conclusion:

When it comes to flange design services as per ASME Sec. VIII Div. 1, Appendix 2 for ABSA submission, Little P.Eng. stands out as a reliable and experienced engineering firm. Their deep understanding of ASME codes, expertise in flange design, and commitment to compliance with ABSA requirements make them the go-to choice for clients seeking precision and reliability. By partnering with Little P.Eng., clients can ensure the safety and integrity of their pressure vessels and piping systems, while also meeting the necessary regulatory standards.

Keywords:

Flange design, ASME Sec. VIII Div. 1, Appendix 2, ABSA submission, Little P.Eng., pressure vessels, piping systems, compliance, design calculation, bolt loads, gasket constants, flange stresses, safety, engineering firm, precision, reliability, regulatory standards, ABSA requirements, client satisfaction.

Tags:

Meena Rezkallah

Little P.Eng.

safety

piping systems

engineering firm

reliability

client satisfaction

pressure vessels

Flange design

ASME Sec. VIII Div. 1

Appendix 2

ABSA submission

compliance

design calculation

bolt loads

gasket constants

flange stresses

precision

regulatory standards

ABSA requirements

Engineering Services

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng.#safety#piping systems#engineering firm#reliability#client satisfaction#pressure vessels#Flange design#ASME Sec. VIII Div. 1#Appendix 2#ABSA submission#compliance#design calculation#bolt loads#gasket constants#flange stresses#precision#regulatory standards#ABSA requirements

0 notes

Text

Why Opt for Automatic Safety Valves Over Bursting Diaphragms: Expert Insights

When it comes to ensuring the safety and reliability of industrial processes, choosing the right safety valve is crucial. Safety relief valves are essential components in various industries, including oil and gas, chemical manufacturing, and power generation. In this article, we will explore the advantages of opting for automatic safety valves over bursting diaphragms, based on insights from experts at Safety Relief valve suppliers in China.

The Role of Safety Relief Valve Suppliers in China

Safety relief valve suppliers in China play a vital role in providing high-quality safety valves to industries worldwide. These valves are designed to protect equipment and personnel by relieving excess pressure in a controlled manner, preventing catastrophic failures. In recent years, there has been a shift towards automatic safety valves, and for good reason.

Advantages of Automatic Safety Valves

Precise Pressure Control: Automatic safety valves offer precise control over pressure relief. They can open and close in response to changing pressure conditions, ensuring that your system operates within safe limits at all times.

Reduced Maintenance: Bursting diaphragms, a traditional alternative to safety valves, can rupture and require frequent replacements. Automatic safety valves are more durable and require less maintenance, reducing downtime and costs.

Reliability: High-pressure magnetic drive pumpsare commonly used in industrial processes. Automatic safety valves are better suited to work with these pumps, offering enhanced reliability and compatibility.

Instant Response: In critical situations, every second counts. Automatic safety valves can respond instantly to pressure spikes, providing immediate protection against overpressure events.

Customization: Safety relief valve suppliers in China offer a range of automatic safety valves that can be customized to meet specific industry requirements. This flexibility ensures that you get the right valve for your application.

In conclusion

The experts at Safety Valve Suppliers in China recommend opting for automatic safety valves over bursting diaphragms for enhanced safety and efficiency in industrial processes. These valves provide precise pressure control, reduce maintenance requirements, offer greater reliability, respond instantly to pressure changes, and can be customized to meet your unique needs. As industries continue to prioritize safety and efficiency, automatic safety valves have become the preferred choice for many applications, ensuring the protection of equipment & personnel.

Resource: Why Opt for Automatic Safety Valves Over Bursting Diaphragms: Expert Insights

0 notes

Text

DEE - The Biggest Bend Pipe Suppliers In India & Overseas

We are a bulk Seller and Exporter of stainless steel bend pipes, seamless pipes, welded pipes, fittings, and flanges from our factory, and able to give you the best price and quality just in time.

0 notes

Text

hi this is your obligatory reminder from a Mi'kmaq-Saulteaux pal that:

1.) the ribbon skirt is a traditional ceremonial garment worn by many First Nations women to celebrate their connection to Mother Earth and reclaim their Indigenous identity from and in spite of colonization;

2.) the RCMP was literally founded as a colonial police force meant to drive Indigenous / First Nations peoples out of their territory to make way for settlers (see: the "starlight tours")

3.) racism towards indigenous people in Canada is still alive and well (the last residential school didn't close until 1996) and so the RCMP adopting ribbon skirts is not only incredibly tone deaf towards their own history and the role they played in wiping out Indigenous culture, but insulting to the practice of ribbon skirts and what they mean to many Indigenous people across the country

4.) when a government entity limits who can comment on their posts, that should tell you exactly where their priorities and intentions lie.

#P.S. canada is just as bad as the US when it comes to institutionalized racism#we even have the red vs. blue two party system and all the problems that come with it#canada has just done a better job at depicting itself as some kind of wonderland#even our “free healthcare” is a joke#many of us do not have family doctors and have no way of seeking treatment or basic aid#how about we stop running oil pipes thru indigenous land before adopting the ribbon skirt into the RCMP uniform as a form of “reparation"

254 notes

·

View notes

Text

Can we please just take a moment to mourn all the batshit insane fanart we would've had if Etho had stuck with his Mario skin. Thank you and goodnight

#imagine with me for a second. hermitcraft mail system? ethario jumping in and out of pipes with letters.#decked out? mario scampering through the burning through the burning dark.#IMAGINE ETHOSLAB FANART WITHOUT A FACE COVERING. FULL BARE FACE AND WITH A MOUSTACHE TOO#etho#ethoslab#imp and skizz podcast#elfy talks#breaking news: man who invented the hopper clock is italian

66 notes

·

View notes

Text

day 9 - filtration system

the final stretch. shoutout to @0hmanit for inspiring the :fish out of this piece (go follow them ) more insight below the cut

#rwartmonth#rwartmonth 2024#rain world art month#rain world#rain world art#rain world fanart#filtration system#black lizard#slugcat#pipes#industrial#wild draws#wild draws rain world

80 notes

·

View notes

Text

together in every universe. or something

#bojan cvjetićanin#kris guštin#joker out#im neglecting schoolwork to draw this but that seems like the norm at this point#hoping if i get it all out of my system now i'll be normal during exam szn (in like. a week 😨)#<<sorry if i keep talking about school btw (semi age reveal ahead) gcses are fucking killing me uuaghhgshhahhhaj#i actually quite like this since i started drawing on a whim this afternoon and its only ten now#i dont even mind the lineart (DONT LOOK AT BOJANS HAND OR ILL JUMP OUT A WINDOW)#only a one storey one tho 💗💗💗 can't die without seeing bokris irl <<pipe dream as im too embarrassed to go to a concert#NO because bumping into jo in london would be my worst fucking nightmare 😭😭😭#what do i even fucking say 'hey are you jan from jo--' NO id combust on the spot#and what if im bothering them uknow 😭😭 idk but i used to live in an asian city where none of my idols from the west would ever visit#(except safiya love you safiya) so keeping the real life person and fictiinalized versions apart in my brain and/or at arms length was easy#but now that i live in the uk and the chances of seeing them irl are non-zero? and presented with the chance to#actively seek them out and you know go to a concert#im just too scared and awkward to do it#maybe i'll bully my friend into going with me#i feel safer revealing age more in the fucking depths of these tags but another thing that makes me feel awkward about going is age#like ik lots of jo fans are younger than me and there's no shame at all in bringing your parents i just feel so embarrassed?? to???#like i'd rather go with my friends#but that would require at least us riding the train alone and i am a small east asian girl who never looks up from the floor ever#sooooo#not happening any time soon#maybe next yr?? but probably not#unless i suddenly get a lot more independant and cool#i doubt anyone's read this much of my tags but if you have 😭😭 hope you like the art i guess#at the time of me writing i want to draw more but i'll see#(you will know since it will have been posted)#a tag previously used to say 'queueing to post at school' this is false as i am now in fact nauseous at home#my art

90 notes

·

View notes

Text

⠀goodreambased⠀⠀⠀⠀⠀⠀⠀ dreambased ⠀⠀⠀⠀⠀⠀⠀nightmarebased

goodreambased ;; a -based term where good/comforting dreams affect the innerworld/headspace, headmate roles or even headmates themselves. however this isnt an origin.

dreambased ;; a -based term where dreams(in general) affect the innerworld/headspace, headmate roles or even headmates themselves. however this isnt an origin.

nightmarebased ;; a -based term where nightmares affect the innerworld/headspace, headmate roles or even headmates themselves. however this isnt an origin.

⠀⠀⠀⠀tagging ;; @radiomogai @plurplex-archive-dot-net

⠀⠀⠀⠀⠀⠀⠀⠀⠀⠀⠀⠀⠀⠀⠀⠀⠀@plurchive

id in alt text

#goodreambased#nightmarebased#dreambased#✧ vermins gift ~ coining#✧ cockroach we keep in the pipes ~ (🌻)#mogai#liom#mogai coining#mogai safe#plural coining#system coining#system terms#plural terms#-based#nightmare#dream#good dream#>> ik dreambased is already a thing but that was about accessing headspace through them and not dreams affecting the system

29 notes

·

View notes

Text

why the fuck does hope's peak academy have the swimming pool on the SECOND floor of the building.........

#danganronpa thh#danganronpa#jin kirigiri youre gonna be pyaing out the nose for mold services#is this why hpa went out of business. they couldnt hire an ultimate architect to build them a functioning school#that's a flooding hazard you dumb sons of bitches!!! think of the plumbing system! the pipes!!!!!

26 notes

·

View notes

Text

The Stench is REAL: Rotten Eggs + Reeking Weed Factory+ Bad Pipes = "It smells. Bad. VERY bad. VERY VERY bad."

The irony of bridezlla Rachel MEgain Markle kicking up a fuss over a one (1) hour "spectacle" inside the Queen’s "musty" chapel, only to acquire a 1st homebuyer loan for an odorous property.

"It smells like offal that has been rotting in the sun. It makes my stomach churn," a local from the Montecito area reportedly told The Mirror. "I’ve seen lots of homeowners closing their windows when it wafts over."

"According to the New York Post, the smell is wafting over from a nearby bird refuge (which is situated on a 42-acre stretch of saltwater marsh). Specifically, the refuge is the Andrée Clark Bird Refuge, which happens to be one of the largest wildlife refuges in the U.S. Cameron Benson, the City of Santa Barbara's clean water manager, told the Mirror that stagnant water can contribute to the smell, and that the “odor issues are sporadic and sometimes they are worse in some conditions."

"Last year, it was reported the Duke and Duchess of Sussex live just minutes from a legal weed factory base in Santa Barbara, California.

The couple's mansion is just up the road from the 20 large greenhouses full of the plants - leaving the luxury suburb reeking.

Neighbours made a string of complaints, sparking the company to install new “odour control systems”.

The Meghans, Dorito & Markus can get high just by standing outdoors as "...one resident complained that the stench was so bad that they had to pull over while driving along the road."

Imagine taking out a $14.65 million dollar loan on your VERY first home: a 9 bedroom, 16 bathroom mansion and you are CanNOT use your property for business purposes. No Spotify podcasts, NO staged Megflix/Netflix zoom calls, NO staged juggling acts outside the windows, NO book interviews, NO staged instant messages from Beyonce, NO Easter egg hunts, NO cooking shows, NO Variety photo shoots---- only 1 chicken coop interview with NOprah.

The 14,500sq ft, or 1,350sq m, main house sits on 7.4ac of grounds that include a pool, tennis court, tea house and children's cottage.

Money Pit : "The pair have paid a lot less for the property than a previous owner: in May 2009 it sold for more than $25 million. It was put on the market in 2015 for $34.5 million but failed to sell. It was relisted at the start of this year for $16.975 million, selling to the Sussexes for $2.325 million less than the asking price at $14.65 million."

From asks @the-cat-with-the-emerald-tiara-1 Royal Organic Weed "Harry's Choice"

Poll Error: The 4th answer "Money Pit of Montecito"

#The Stench#Environmentally Conscious#save the planet#NIMBY#megxit#Montecito Weed Factory#Montecito Rotten Eggs#Plumbling Issues#Bad Pipes#the invisibles#odor control systems#jam scam#scam jam#money pit#Royal Organic Weed#my polls

15 notes

·

View notes

Text

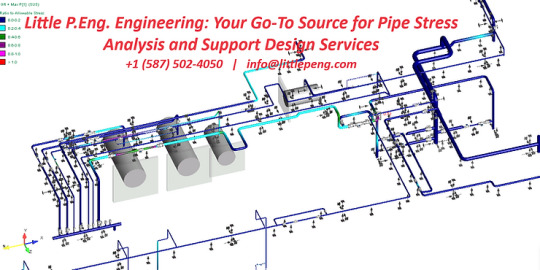

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

In the vast and complex world of engineering, precision and accuracy are paramount. Nowhere is this truer than in the field of piping systems, where even the smallest miscalculation or oversight can lead to catastrophic consequences. To ensure the safe and efficient operation of piping systems, the expertise of specialized engineers is required. This is where Little P.Eng. Engineering comes into play. With a reputation for excellence and a commitment to providing top-notch pipe stress analysis and support design services, Little P.Eng. Engineering stands as a trusted partner for industries that rely on flawless piping systems.

In this comprehensive guide, we will delve into the world of pipe stress analysis and support design services offered by Little P.Eng. Engineering. We will explore the importance of these services, their role in various industries, and how Little P.Eng. Engineering excels in delivering tailored solutions. Additionally, we will discuss the key factors that set Little P.Eng. Engineering apart from the competition and provide valuable insights into their commitment to safety, quality, and customer satisfaction.

Chapter 1: Understanding Pipe Stress Analysis

1.1 What is Pipe Stress Analysis?

Pipe stress analysis is a critical component of engineering that involves evaluating the forces and stresses acting on a piping system to ensure its structural integrity and safety. It plays a pivotal role in various industries, including petrochemical, oil and gas, power generation, and more. Pipe stress analysis helps engineers identify potential issues such as excessive strain, deformation, or failure that could compromise the functionality and safety of the system.

1.2 The Importance of Pipe Stress Analysis

The significance of pipe stress analysis cannot be overstated. Failing to perform adequate stress analysis can lead to a range of problems, including:

1.2.1 Safety Risks: Inadequate pipe stress analysis can result in ruptures, leaks, and catastrophic failures, endangering human lives and the environment.

1.2.2 Cost Overruns: Repairs and maintenance due to unforeseen issues can lead to substantial cost overruns in construction and operation projects.

1.2.3 Downtime: Unscheduled downtime can disrupt operations, leading to production losses and revenue reduction.

1.2.4 Legal and Regulatory Issues: Non-compliance with safety standards and regulations can result in legal and financial repercussions.

1.2.5 Reputation Damage: Incidents related to piping system failures can tarnish a company's reputation.

Chapter 2: The Role of Pipe Stress Analysis in Different Industries

2.1 Oil and Gas Industry

The oil and gas industry relies heavily on complex piping systems to transport hydrocarbons from extraction sites to refineries and end-users. Pipe stress analysis is crucial in this industry to prevent leaks, ruptures, and environmental disasters. Little P.Eng. Engineering provides specialized services tailored to the unique challenges of the oil and gas sector.

2.2 Petrochemical Industry

Petrochemical plants process raw materials into valuable chemical products. The precise and safe transport of chemicals through piping systems is essential. Pipe stress analysis ensures the structural integrity of these systems, mitigating the risk of chemical leaks and ensuring worker safety.

2.3 Power Generation

Power plants, whether they run on fossil fuels, nuclear energy, or renewable sources, require intricate piping networks to deliver steam, water, and gases to turbines and generators. Pipe stress analysis is vital to prevent system failures and maintain uninterrupted power generation.

2.4 Pharmaceutical and Food Industries

In industries where product purity and safety are paramount, such as pharmaceuticals and food production, pipe stress analysis ensures the integrity of sanitary piping systems. Little P.Eng. Engineering's expertise extends to designing hygienic piping solutions that meet the strictest standards.

2.5 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial and industrial buildings rely on complex piping networks. Proper stress analysis ensures the efficient functioning of HVAC systems, contributing to comfort and energy efficiency.

Chapter 3: Little P.Eng. Engineering's Pipe Stress Analysis Services

3.1 Expertise and Experience

Little P.Eng. Engineering boasts a team of highly skilled and experienced engineers with a deep understanding of the complexities involved in pipe stress analysis. Their expertise spans various industries, ensuring that clients receive tailored solutions that align with their specific needs and challenges.

3.2 Advanced Technology and Software

Staying at the forefront of technological advancements is crucial in the engineering field. Little P.Eng. Engineering utilizes state-of-the-art software and tools for pipe stress analysis, enabling precise simulations and evaluations. This ensures the accuracy and reliability of their services.

3.3 Customized Solutions

One of the key strengths of Little P.Eng. Engineering is their ability to provide customized solutions. They understand that each project is unique and may have distinct requirements. By tailoring their services to individual client needs, they ensure optimal results and client satisfaction.

3.4 Compliance with Industry Standards

Compliance with industry standards and regulations is non-negotiable in the world of engineering. Little P.Eng. Engineering ensures that all their pipe stress analysis services meet or exceed relevant industry standards, codes, and safety guidelines.

Chapter 4: Pipe Support Design Services

4.1 What is Pipe Support Design?

Pipe support design is an integral part of piping system engineering. It involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibration, and stress. Proper support design ensures the longevity and stability of piping systems.

4.2 Importance of Pipe Support Design

Inadequate or improperly designed supports can lead to several problems, including:

4.2.1 Excessive Stress: Unsupported piping can experience undue stress, leading to damage and failure.

4.2.2 Vibrations: Vibrations can affect the performance of piping systems and nearby equipment.

4.2.3 Misalignment: Improper alignment can cause leaks and inefficiencies.

4.2.4 Premature Wear: Unsupported piping can wear out faster, leading to maintenance and replacement costs.

4.3 Little P.Eng. Engineering's Pipe Support Design Services

Little P.Eng. Engineering offers comprehensive pipe support design services to ensure that piping systems are adequately supported and stable. Their services include:

4.3.1 Structural Analysis: Evaluating the structural integrity of supports and ensuring they meet safety and code requirements.

4.3.2 Custom Designs: Tailoring support solutions to the unique needs of each project.

4.3.3 Material Selection: Recommending suitable materials for support components, considering factors like corrosion resistance and load-bearing capacity.

4.3.4 Installation Guidance: Providing guidance and recommendations for the proper installation of supports.

Chapter 5: What Sets Little P.Eng. Engineering Apart

5.1 Commitment to Safety

Safety is Little P.Eng. Engineering's top priority. Their pipe stress analysis and support design services are driven by a commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

5.2 Quality Assurance

Quality is woven into the fabric of Little P.Eng. Engineering's services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

5.3 Timely and Efficient Service

Time is often of the essence in engineering projects. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality.

5.4 Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process.

5.5 Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members.

Chapter 6: Case Studies and Success Stories

6.1 Case Study 1: Oil Refinery Piping

A major oil refinery faced ongoing issues with leaks and failures in its piping system, resulting in costly downtime and environmental concerns. Little P.Eng. Engineering conducted a comprehensive pipe stress analysis and identified critical stress points. They then designed and implemented reinforced supports and provided guidance on material selection. The result was a significant reduction in incidents, ensuring safe and uninterrupted operations.

6.2 Case Study 2: Pharmaceutical Facility

A pharmaceutical company needed to upgrade its piping system to comply with stringent FDA regulations. Little P.Eng. Engineering provided customized pipe stress analysis and support design services to ensure compliance with hygienic standards. The project was completed successfully, allowing the company to maintain product integrity and regulatory compliance.

6.3 Case Study 3: Power Plant Efficiency

A power plant was experiencing inefficiencies in its piping system, resulting in reduced energy output. Little P.Eng. Engineering conducted a detailed pipe stress analysis and identified areas of improvement. They designed and implemented optimized supports, resulting in increased energy efficiency and cost savings.

Chapter 7: Conclusion

In conclusion, Little P.Eng. Engineering stands as a premier provider of pipe stress analysis and support design services, catering to various industries where the integrity and safety of piping systems are of utmost importance. Their commitment to safety, quality, client satisfaction, and continuous improvement sets them apart as a trusted partner in the world of engineering.

Whether you operate in the oil and gas, petrochemical, power generation, pharmaceutical, or HVAC sector, Little P.Eng. Engineering has the expertise and experience to deliver customized solutions that meet your unique needs. By prioritizing safety, adhering to industry standards, and consistently providing timely and efficient services, Little P.Eng. Engineering has earned its reputation as a leader in the field of pipe stress analysis and support design.

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Pipe Stress Analysis

Little P.Eng. Engineering

Finite Element Analysis

Structural Integrity

Engineering Expertise

Thermal Expansion

Support Design Services

Oil and Gas

ASME Codes

Industry Standards

Power Generation

Stress Evaluation

Piping Systems

Safety and Compliance

Engineering Solutions

Precision Analysis

Industrial Processes

Petrochemical

Seismic Analysis

Customized Solutions

Pressure Analysis

Pipe Support Design

Safety Regulations

Reliability Assurance

Complex Piping Systems

Chemical Industry

Pharmaceutical Industry

Vibrations Analysis

Stress Distribution

Pipe Failure Prevention

Pipe Stress Analysis Services

Engineering Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Pipe Stress Analysis#Little P.Eng. Engineering#Finite Element Analysis#Structural Integrity#Engineering Expertise#Thermal Expansion#Support Design Services#Oil and Gas#ASME Codes#Industry Standards#Power Generation#Stress Evaluation#Piping Systems#Safety and Compliance#Engineering Solutions#Precision Analysis#Industrial Processes#Petrochemical#Seismic Analysis#Customized Solutions#Pressure Analysis#Pipe Support Design#Safety Regulations#Reliability Assurance#Complex Piping Systems#Chemical Industry#Pharmaceutical Industry#Vibrations Analysis#Stress Distribution

0 notes

Text

Magnetic Drive Pumps in Clean Energy: Supporting Sustainable Power Generation

In the quest for sustainable power generation, technological advancements are continuously reshaping the landscape of clean energy solutions. Among these innovations, magnetic drive pumps have emerged as a pivotal component, showcasing their efficiency and reliability in supporting various clean energy processes. These pumps, including high-temperature magnetic drive pumps & Magnetic Drive Centrifugal Pumps, play a crucial role in enhancing the efficiency and sustainability of power generation systems.

One of the leading contributors to the magnetic drive pump industry is China, with several prominent magnetic drive pump manufacturers in the region. These manufacturers have been instrumental in producing cutting-edge technology that addresses the challenges of clean energy production. With a focus on reducing carbon footprints and enhancing operational safety, Chinese manufacturers have become key players in advancing magnetic drive pump technology.

Read Also: Why Settle for Less? The Benefits of Choosing a Top Safety Relief Valve Manufacturer

High-temperature magnetic drive pumps, a remarkable achievement in this sector, have overcome the limitations of traditional pumps that might falter under extreme conditions. These pumps can efficiently handle high-temperature fluids without the risk of leakage that is often associated with traditional pump seals. This advancement is particularly beneficial in processes involving geothermal power generation and concentrated solar power, where High-Temperature Magnetic Drive Pumps are the norm. By mitigating leakage risks & ensuring the integrity of the system, high-temperature magnetic drive pumps contribute to the efficiency and longevity of clean energy processes.

Furthermore, the magnetic drive centrifugal pump technology has garnered attention for its exceptional reliability and low maintenance requirements. These pumps utilize a magnetic coupling that eliminates the need for direct physical contact between the motor and the impeller, thus reducing wear and tear. This innovative design minimizes the risk of system failures, enhancing the overall stability of power generation facilities.

In conclusion, magnetic drive pumps are playing a vital role in advancing clean energy technologies. The efforts of Magnetic Drive Pump Manufacturers in China and beyond have propelled the industry forward, contributing to the sustainability of power generation. With high-temperature magnetic drive pumps and magnetic drive centrifugal pumps leading the charge, these advancements are enabling clean energy processes to operate more efficiently, reliably, and safely. As the world strives for a greener future, magnetic drive pumps stand out as a cornerstone of progress in the realm of sustainable power generation.

0 notes

Text

DEE Piping's Vast Portfolio

At Dee, we offer a wide range of steel piping systems designed to meet the specific needs of our customers. With our vast portfolio of products and services, we are the ideal partner for all your piping needs.

#dee pipings#dee systems#piping solution#piping systems#induction bending#pipe fitting#fabricated piping#modular piping#dee piping systems

0 notes

Text

parabased

parabased refers to a system based in one or more paraphilias, but is not inherently an origin. this paraphilia would affect system functions, the headspace, headmates, roles, and any other aspects of the system. how it would affect the system depends on what paraphilias the system has and how they work for that system.

- from pluralpedia

#🔥 —– “ packing the pipe … ”#plural community#plural coining#actually plural#plural system#plurality#pluralpedia#paraphile#paraphilia#paraphile community#para#paraphile safe

20 notes

·

View notes