#steel culvert

Text

Putting in new Farm Culvert and Road with pair of skidsteers

youtube

#Reefdvms#culverts#steel culvert#pvc culvert#farm culvert#road culvert#farm#farmer#farms#driveway culvert#driveway#driveway repair#gravel driveway#spiral culvert#backhoe#backhoe and culvert#Culvert#325g#john deere skid steers#skid steer#26g excavator#26g john deere#352g john deere#325g skid steer#diy road#diy culvert#diy ditch#creek crossing#new road#hauling skid steer

0 notes

Text

UK Building Underground Bunker Assemble Galvanized Corrugated Metal Steel Pipe Arch Culvert Pipe ,Drainage Culvert Metal Pipe

#UK Building Underground Bunker Assemble Galvanized Corrugated Metal Steel Pipe Arch Culvert Pipe#Drainage Culvert Metal Pipe#engineering material#construction site#youtube

1 note

·

View note

Text

Types of Pipes and Their Applications: A Comprehensive Guide

Understanding common types of pipes and their applications is crucial for informed project decisions in various industries and applications.

Here is a detailed overview of the most popular pipe types:

Steel Pipes: Steel pipes are solid and adaptable, making them ideal for various uses including water delivery, gas pipelines, oil transportation, and structural purposes. They are incredibly strong and resilient under great strain.

PVC Pipes: Polyvinyl chloride (PVC) pipes are inexpensive, lightweight, and corrosion-resistant. They are frequently used in drainage, irrigation, and plumbing systems because they are simple to install and need little upkeep.

Copper Pipes: Copper pipes are renowned for having exceptional heat and corrosion resistance. HVAC (heating, ventilation, and air conditioning) applications, plumbing systems, and refrigeration systems all frequently use them.

HDPE Pipes: High-density polyethene (HDPE) pipes are ideal for sewage systems as well as subterranean water and gas distribution because of their strong chemical resistance and a high degree of durability.

PEX Pipes: Cross-linked polyethene (PEX) pipes are flexible and resistant to corrosion. They are frequently employed in home plumbing systems, notably in the distribution of hot and cold water.

Cast Iron Pipes: Cast iron pipes are renowned for their robustness and noise-isolating qualities. They are frequently employed for stormwater drainage systems and sewer pipes.

Galvanised Iron Pipes: To prevent corrosion, galvanised iron pipes have a zinc coating. They are frequently employed for outdoor applications and water supply lines.

Concrete pipes: Concrete pipes are sturdy and long-lasting, making them ideal for sewage applications, culverts, and underground drainage systems.

Stainless steel pipes: These pipes are utilised extensively in food processing, pharmaceuticals, and chemical processing sectors because they offer exceptional corrosion resistance.

Fibreglass Pipes: Fibreglass pipes have a high strength-to-weight ratio, are lightweight, and are resistant to corrosion. They are frequently employed in sectors including wastewater treatment, chemicals, and oil and gas.

Considerations include the material's qualities, application requirements, durability, maintenance, and cost when choosing pipes for your projects. Getting advice from pipe suppliers or specialists can be extremely helpful in determining which pipe type is best for your requirements. RSS Engineering is the company that leads you with the most sustainable variety of pipes to choo

2 notes

·

View notes

Text

Test Drinking Water Before Trusting Your Professional Relationships

To deter squirrels and grackles, use safflower seed by itself in all of the bird feeders with the exception of thistle tube feeders. Safflower seed is of interest to cardinals, house finch, chickadees, doves and other birds, yet grackles rarely feed onto it if in any way. A feeder filled up with safflower seed may be hung in a tree beside a squirrels nest to begin with will totally ignore the game. Make it a a part of you feeding program. It might take considerably a week for your birds to generally be accustomed to safflower seed if high definition tv never been offered these before.

Tube turkey calls consist of latex which is tied with rubber band up into the half belonging to the tube call's top and hollow drums. Tight-lipped gobblers often respond well to tube call since the sound is probably a unusual can rival a box or a slate that are normal sounds to be heard within spring season for gobblers. Being different, in this kind activity, is helpful.

steel pipe is everywhere. Pipe can be fabricated for some purposes. Read the Large E.D. circular hollow section column being used for billboard structures when traveling down a lot highway. It's used in parking lots, for "Bollards" or "Bumper Posts". Practically every restaurant or place of business has an outdoors sign linked with a pole made of steel. Examine The Process For LSAW Steel Pipe of galvanized pipe used for highway signals. The list goes on and on, fence posts, culvert pipe at no more your driveway, pipe piling to stabilize foundation structures of large building and skyscrapers, slurry line pipe used in quarries and sand operations, columns their basement of your dwelling. That's just to name some structural practices.

When Acquired into very first band, by this time, Got found my influences and began to emulate the group. I found out what guitars and amps they were using there isn't anything bought round tube identical shoes equipment. For me it was the Strat and Fender tube built-in amplifiers.

Follow any posted safety regulations at the area where you'll be boating. This could seem fairly basic, but because on the this rule gets overlooked a entire lot. Look for the posted sign with regulations and take a flash to see clearly over in the instance that there are any specific things to check out out for where you might be that daily schedule.

A every important feature of the king, could be the actual fact, that minerals and vitamins a real tube. Yes even using a very cheap amplifier, even with a cheap old guitar, the quality if this pedal, will save you in a gig or recording.

Although Hot-dip galvanized steel pipe is conventional way bird feeding period, a lot of individuals have established year round bird feeding programs. Natural foods become scarce after winter until a new crop of seeds and berries ripen in late summer. Wildlife biologists can recommend that birds nest earlier, quicker, that has more successful nestings when supplemental foods are marketed. This is a result of less time spent foraging and competing for low food reserves after cold months. For example: Woodpeckers during the nesting season eat more suet between March and July than all winter long. You can attract an extensive variety of birds through-out the year by establishing a year round bird feeding program.

3 notes

·

View notes

Text

Classification of Pipes based on their Materials and Uses

Pipes are products of circular tubing used for transporting fluids. Pipes are built to withstand a certain pressure, which is determined by the temperature at which they will be used. Pipes can vary in many ways depending on factors like their size, schedule, material, pressure and temperature resistance, and so on. The industrial sector makes use of several pipe types for a variety of applications. Pipes are used extensively in a wide variety of industries, including the oil and gas industry, petrochemical as well as chemical industries, process industries, the power sector, the food and beverage industry, HVAC manufacturers, steel manufacturers, pipeline manufacturers, plumbing manufacturers, refineries, and many others. In today's contemporary industrial plants, piping is absolutely essential. Different criteria are used to determine the type of pipe to be used. A variety of pipes used extensively in manufacturing industries will be discussed further in this article.

Types of Pipes based on Material:

Most commonly, pipes are categorised according to the raw material from which they are made. Both plastic and metal pipes are often used, yet there are distinct differences between the two.

Metallic Pipes

Non-metallic Pipes

Metallic Pipes:

Metallic pipes refer to those that are fabricated from metal rather than other materials. They are classified as under:

● Pipes made up of ferrous materials

● Pipes made up of non-ferrous materials

- Pipes made up of ferrous materials:

These pipes are heavier and more durable than others. The primary element of these pipes is iron. Ferrous material pipes are typically constructed of

● Carbon steel pipes

● Stainless steel pipes

● Alloy steel pipes

● DSS pipes

● Cast Iron pipes

● Ductile Iron pipes, etc

This group of pipes can withstand higher pressures and temperatures. Jindal pipes for Oil, Gas and Water supply supplied by Tube Trading Co., used in industrial settings including refining, chemical and petrochemical processing, power generation, etc. are typically formed of ferrous elements.

- Pipes made up of Non-ferrous materials:

Pipes from this assortment are not primarily made of iron. The likes of brass, aluminium, copper, etc., are what they're often crafted from. Some typical examples of non-ferrous pipes are

● Aluminium and its alloy pipes.

● Copper and its alloy pipes.

● Nickel and its alloy pipes.

● Titanium and its alloy pipes.

● Zirconium and its alloy pipes.

Non-metallic Pipes:

Commonly employed in services where the temperature is not a factor, non-metallic pipes are becoming more and more common. Most of the non-metallic pipes are utilised in the water industry as well as drainage systems. If you are looking for the most distinguished supplier of Jindal spiral welded coated pipes in India, Tube Trading Co. is the most trustworthy supplier in Gujarat, India.

The most regularly used types of non-metal pipes are:

● PE/HDPE Pipes

● CPVC/PVC/UPVC/ Pipes

● PP pipes

● Reinforced thermoplastic pipes

● ABS Pipes

● Composite pipes

● Asbestos and Cement Pipes

● Vitrified clay pipes

Composite pipes', as well as reinforced plastic primary benefits, are their extreme resistance to corrosion and long lifespan. where metal pipes are often made to last up to 25 years. Reinforced plastic and composite pipes can survive for up to half a century with no problems. But the temperature is their biggest restriction. Metallic pipes can withstand the high temperatures that are required in some industrial processes. Stormwater, gravity service, the irrigation industry, and culverts are common applications for cement pipes made from reinforced concrete.

Pipes, classified on the basis of the industry:

- For Power Piping as well as Chemical Industries:

These pipes can withstand extreme heat and pressure without breaking down. The chemical, electricity, petrochemical, steel, oil, and gas industries all rely heavily on pipes constructed of ferrous materials. They are often developed in accordance with international standards such as ASME B31.3 and ASME B31.1. They are typically chosen for their high pressure, temperature, and corrosion resistance tolerance. Being an excellent supplier of industrial pipes and tubes, Tube Trading Co. can fulfil all of your Jindal spiral welded coated pipes requirements.

- For the Plumbing industry:

Plumbing pipes can be made from a variety of materials, including plastic (PVC), metal (Copper and PEX), plastic (ABS), cast iron (galvanised steel), or steel (cast iron). Their primary function is to transport water from one location to another.

- Pipes for the Pipeline industry:

Line pipes are what you'll typically hear people refer to when they talk about pipes utilised in the pipeline industry. These pipes are typically designed according to API 5L specifications. Pipes according to API 5L standards are available in a wide range of grades for transporting liquids such as oil, natural gas, and water. In addition to DSS, FRP, SS, GRE, SDSS, etc., there are a variety of other materials used for pipelines.

6 notes

·

View notes

Text

Welding in the Construction Industry: Building the Foundations of Infrastructure

Introduction:

Welding is a fundamental process in the construction industry, contributing to the fabrication of structural components, the assembly of building frameworks, and the installation of infrastructure. From skyscrapers and bridges to highways and tunnels, welding plays a crucial role in building the foundations of modern infrastructure. In this article, we'll explore the significance of welding in the construction industry and its impact on shaping the built environment.

Structural Steel Fabrication:

Structural steel fabrication is a key application of welding in the construction industry, where welded connections provide strength, stability, and durability to building structures. Welding processes such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW) are used to join steel beams, columns, and trusses, creating robust frameworks for buildings, bridges, and industrial facilities. Advanced welding techniques such as robotic welding undercut and automated beam welding systems ensure precise and consistent weld quality in structural steel fabrication.

Bridge Construction and Rehabilitation:

Welding is integral to the construction and rehabilitation of bridges, which serve as critical transportation links and architectural landmarks. Welded steel girders, trusses, and decks form the structural elements of bridges, providing support for vehicular and pedestrian traffic. Welding processes such as submerged arc welding (SAW) and gas tungsten arc welding (GTAW) are employed to join bridge components with high strength and reliability, ensuring the structural integrity and longevity of bridge structures. Additionally, welded repairs and retrofits are performed to extend the service life of aging bridges and enhance their performance under modern traffic loads and environmental conditions.

High-Rise Building Construction:

High-rise building construction relies on welding for the assembly of steel and concrete structural systems, curtain wall facades, and mechanical, electrical, and plumbing (MEP) systems. Welded connections provide the flexibility and adaptability required to construct tall buildings with complex geometries and architectural features. Welding processes such as stud welding and friction stir welding (FSW) are used to join steel plates, beams, and columns, as well as to install anchor bolts and embedments for structural support and attachment of building components. Advanced welding technologies such as laser welding and electron beam welding offer opportunities for high-speed, high-precision welding in high-rise construction applications.

Infrastructure Installation and Maintenance:

Welding is essential for the installation and maintenance of infrastructure components such as highways, tunnels, and underground utilities. Welded connections join prefabricated components such as guardrails, sign structures, and lighting fixtures to create safe and functional roadway systems. Welding processes such as gas metal arc welding (GMAW) and flux-cored arc welding (FCAW) are employed to install culverts, drainage pipes, and utility conduits, ensuring efficient water management and utility distribution in urban and rural areas. Additionally, welded repairs and reinforcements are performed to address infrastructure deterioration and extend the service life of critical assets such as bridges, culverts, and retaining walls.

Safety and Quality Assurance:

Safety and quality assurance are paramount in welding operations in the construction industry to protect workers, the public, and the built environment. Welding procedures and practices are designed to minimize hazards such as fire, electric shock, and exposure to hazardous substances. Welding inspections and testing procedures ensure that welded connections meet industry standards and regulatory requirements for strength, integrity, and performance. Additionally, welder certification programs and training initiatives ensure that construction personnel have the skills and knowledge to perform welding tasks safely and effectively on construction sites.

Conclusion:

Welding is a cornerstone of the construction industry, providing the strength, durability, and flexibility required to build the infrastructure that supports modern society. From skyscrapers and bridges to highways and tunnels, welding plays a crucial role in shaping the built environment and driving economic growth and development. By embracing advancements in welding technology and best practices in construction safety and quality assurance, the construction industry can continue to build the foundations of infrastructure that meet the needs of communities and enhance quality of life for generations to come.

0 notes

Text

The Art of Manufacturing GI Pipes: From Steel to Reliability

Galvanized Iron (GI) pipes have been an essential component of various industries, including construction, agriculture, and plumbing, for decades. These pipes owe their durability and resistance to corrosion to the galvanization process, which involves coating them with a protective layer of zinc. In this latest blog, we will delve into the fascinating world of GI pipe manufacturing, exploring the process, key considerations, and the vital role these pipes play in modern infrastructure.

The Galvanized Iron Pipe Manufacturing Process

1. Raw Material Selection

The journey of manufacturing GI pipes begins with the selection of high-quality raw materials. Typically, low-carbon steel coils are chosen due to their excellent weldability and formability.

2. Coil Unrolling

The selected steel coils are unrolled and flattened to form a flat strip of steel. This flat strip serves as the basis for manufacturing the pipes.

3. Pipe Formation

The flat steel strip is then shaped into a cylindrical pipe. This process can be achieved using various methods, such as cold forming, hot forming, or electric resistance welding (ERW). The choice of method depends on the desired pipe size and thickness.

4. Welding

In the case of electric resistance welding (ERW), the edges of the flattened steel strip are heated using an electrical current until they melt. The edges are then pressed together to form a strong weld, ensuring a continuous, leak-proof pipe.

5. Galvanization

Galvanization is the defining step in GI pipe manufacturing. The pipes are immersed in a bath of molten zinc, which adheres to the surface, providing exceptional corrosion resistance. This process gives GI pipes their characteristic silver-gray appearance.

6. Testing and Inspection

Quality control is paramount in the manufacturing of GI pipes. The pipes undergo rigorous testing and inspection for factors such as thickness, diameter, and adherence to industry standards. Any substandard pipes are rejected.

Key Considerations in GI Pipe Manufacturing

Quality of Zinc Coating: The thickness and quality of the zinc coating directly impact a GI pipe's longevity and corrosion resistance. Manufacturers must adhere to strict quality control measures during the galvanization process.

Uniform Wall Thickness: Consistency in wall thickness is crucial to ensure the structural integrity of the pipes. Variations in thickness can lead to weak points vulnerable to corrosion.

Precision Welding: The welding process must be precise to create strong, seamless joints. Quality welds prevent leakage and ensure the reliability of the pipes.

Adherence to Standards: Compliance with industry standards and regulations is non-negotiable. GI pipe manufacturers must meet the requirements set forth by relevant authorities to guarantee the safety and performance of their products.

The Role of GI Pipes in Modern Infrastructure

Galvanized Iron pipes play a pivotal role in a multitude of industries and applications:

Plumbing: GI pipes are widely used for water supply systems due to their corrosion resistance and durability.

Agriculture: They are essential for irrigation and water distribution in agricultural settings.

Construction: GI pipes are used in structural applications, scaffolding, and as a component in various building systems.

Infrastructure: They are crucial for the construction of bridges, culverts, and roadways.

Fencing and Guardrails: GI pipes are employed in fencing systems and as crash barriers along highways.

Sustainability in GI Pipe Manufacturing

In recent years, there has been a growing emphasis on sustainability in the manufacturing industry, and GI pipe manufacturing is no exception. Manufacturers are increasingly adopting eco-friendly practices to reduce their environmental footprint. This includes the responsible disposal of waste materials, energy-efficient production processes, and the use of recycled steel whenever possible. As the world becomes more environmentally conscious, GI pipe manufacturers are aligning their practices with sustainability goals to contribute to a greener future.

Innovations in GI Pipe Manufacturing

Innovation is a driving force behind the continued improvement of GI pipes. Manufacturers are constantly researching and developing new techniques and materials to enhance the performance and versatility of GI pipes. Advanced coatings, improved corrosion-resistant alloys, and optimized galvanization methods are just a few examples of innovations that have allowed GI pipes to excel in demanding applications.

Meeting Customization Demands

GI pipe manufacturers are also responding to the demand for customization. They offer a wide range of sizes, thicknesses, and lengths to cater to diverse project requirements. This flexibility allows architects, engineers, and contractors to select the ideal GI pipes for their specific needs, ensuring efficient and cost-effective solutions.

The Future of GI Pipe Manufacturing

As we look ahead, the future of GI pipe manufacturing holds great promise. These pipes will continue to be an integral part of infrastructure development, plumbing systems, and various industries worldwide. With ongoing advancements in technology, sustainability, and customization, GI pipes are poised to remain a reliable and indispensable component of modern construction and manufacturing.

In conclusion, the manufacturing of Galvanized Iron pipes is a fascinating blend of tradition and innovation. While rooted in time-tested techniques, it continues to evolve to meet the ever-changing demands of a rapidly advancing world. GI pipes are not just conduits of water, but conduits of progress, playing an essential role in shaping the infrastructure that underpins our societies. As manufacturers continue to refine their processes and embrace sustainability, the future of GI pipe manufacturing looks brighter than ever, promising reliability, durability, and performance for generations to come.

Conclusion

The manufacturing of Galvanized Iron pipes is a testament to the synergy of technology, craftsmanship, and precision. These pipes, born from raw steel and refined through galvanization, are the backbone of modern infrastructure. Their reliability, durability, and corrosion resistance continue to make GI pipes a cornerstone of progress and development across various industries.

More Read: Gi pipe | Gp pipe | gp pipe manufacturers

0 notes

Text

Culvert Pipe Installation Engineering Solutions for Efficient Water Management

Culvert pipe installation serves as the backbone of modern water management systems, providing a vital infrastructure solution for efficiently directing water flow, preventing flooding, and ensuring the integrity of roads, railways, and various construction projects. This comprehensive guide delves into the nuances of culvert pipe installation, its significance in civil engineering, and its diverse applications across different landscapes.

Understanding Culvert Pipe Installation

Culverts, typically made from materials like concrete, steel, or plastic, are essential components designed to channel water beneath roads, railways, trails, or embankments. Culvert pipe installation involves precise engineering, considering factors such as hydraulic efficiency, soil conditions, anticipated water flow, and environmental impact.

The Importance of Culverts in Water Management

Flood Prevention: Culverts play a crucial role in managing water flow during heavy rainfalls or floods, preventing water accumulation that could damage infrastructure or cause road hazards.

Erosion Control: Properly installed culverts help control erosion by redirecting water away from vulnerable areas, preserving the stability of the surrounding terrain.

Infrastructure Protection: Culverts safeguard infrastructure like roads and railways by preventing water-related damage, preserving their longevity and functionality.

Types of Culvert Pipes

Concrete Culverts: Durable and versatile, concrete culverts offer strength and longevity, making them suitable for various applications, especially in areas prone to high traffic or heavy loads.

Steel Culverts: Steel culverts provide robustness and flexibility, making them suitable for areas where the soil conditions may shift or require a more adaptable solution.

Plastic Culverts: Lightweight and corrosion-resistant, plastic culverts are often used in smaller-scale projects or areas where ease of installation and cost-effectiveness are paramount.

Culvert Pipe Installation Process

Site Assessment: Engineers conduct a thorough assessment of the terrain, considering factors such as water flow, soil type, slope, and environmental impact.

Design and Sizing: Culvert size and design are crucial to ensure optimal water flow and prevent blockages. Engineers calculate dimensions based on anticipated water volume and velocity.

Excavation and Preparation: Proper excavation and preparation of the site ensure a stable foundation for the culvert. This phase involves grading, leveling, and creating a trench for the pipe.

Pipe Placement: The culvert pipes are carefully positioned and aligned within the trench, ensuring proper slope and alignment for efficient water flow.

Backfilling and Compaction: Once the pipes are in place, backfilling with suitable materials and compaction secures the pipes and provides structural support.

Final Checks and Maintenance: Engineers conduct final inspections and tests to ensure the integrity of the installation. Regular maintenance ensures longevity and functionality.

Applications of Culvert Pipe Installation

Transportation Infrastructure: Culverts are integral to road and railway construction, facilitating water flow beneath these vital transportation routes.

Land Development: In urban and rural settings, culverts manage water runoff in residential and commercial developments, preventing flooding and soil erosion.

Environmental Conservation: Culverts aid in preserving natural habitats by managing water flow in ecosystems, safeguarding wildlife and vegetation.

Challenges and Innovations in Culvert Technology

Challenges such as soil erosion, sediment buildup, and maintenance requirements prompt ongoing innovations in culvert design and materials. Advancements in precast concrete technology, improved coatings for steel pipes, and eco-friendly materials drive the evolution of culvert systems.

Conclusion: Culvert Pipe Installation Driving Water Management Solutions

Culvert pipe installation stands as a testament to the intersection of engineering precision and environmental stewardship. As the demand for efficient water management grows, culverts remain pivotal in ensuring the safety, longevity, and sustainability of infrastructure projects worldwide.

The art and science of culvert pipe installation continually evolve, reflecting humanity's commitment to harnessing nature's resources responsibly. By integrating innovative technologies and engineering expertise, culvert systems continue to shape a future where water management is efficient, sustainable, and adaptable to the evolving needs of communities and ecosystems alike.

1 note

·

View note

Text

As people have become more interested in DIY projects, culverts have become a popular choice for furniture. From tables and chairs to benches, culverts provide a solid foundation for some unique pieces.

One of the main benefits of using culverts for furniture is their strength. These hollow steel pipes are extremely durable and able to hold some of the heavy pieces of furniture people put onto them. Since culverts are designed to help manage surface water and sewer runoff, they can handle a lot of weight and still keep their shape. Additionally, the steel provides a durable and protective layer, which is important when creating furniture pieces that could be exposed to the elements.

Another benefit of using culverts for furniture is the design options they offer. The large shape of culverts makes them ideal for creating furniture that has a unique and modern look. Since culverts come in different sizes, this also allows for endless possibilities when it comes to design — from smaller pieces like benches and stools to larger pieces like chairs and tables.

Finally, culverts are also a cost-effective option for furniture. The pipes are often salvaged from old construction sites, which can significantly reduce the cost of materials. This also makes culverts the perfect option for people who are on a budget but still want to make unique furniture pieces.

Culverts are an underrated material for furniture, but their qualities make them a definite choice for DIY projects. By taking advantage of their strength and design options, these distinct pipes can be used to create unique and stylish pieces.

0 notes

Text

Perfect Ways to Discover the Best Concrete Contractor

Concrete is one of the most adaptable and long-lasting building materials and has many uses. Concrete is ubiquitous in our daily lives, found in everything from floors to worktops to burial vaults, bridge piers, roads, and entire structures.

Making the appropriate choice of Concrete Contractors Sydney based on the job’s size and complexity will significantly improve your projects’ efficiency. The majority of concrete contractors display examples of their work on websites. Take some time to browse the websites of potential contractors to see if the business can handle your project. The categories of concrete companies are as follows:

1 . Pre- Cast Concrete Items

Precast concrete products come in various sizes, from big box culverts or sewer mains to patio pavers. Pavers, steps, septic tanks, and burial vaults are examples of precast concrete products used in homes and individual settings.

Concrete Services in Sydney makes up a large portion of the central infrastructure in the country. Precast concrete components allow for offsite curing, speeding up large replacement or repair projects.

Bridges and other constructions use precast concrete support beams, pillars, and columns. Sewer mains, box culverts, and tunnels below the surface can all be prefabricated in large quantities and delivered to construction sites.

Never ask your concrete contractor if precast substantial items might work well for your house project. Pavers, stair sets, or even lightweight concrete panels could speed up the job. With precision, your concrete contractor, like Concrete Driveways in Western Suburbs can assess the state of your job site and provide precast goods.

2 . Concrete Suppliers

A mixture of solid components, water, and Portland cement, a binder to keep all the solid materials together, is used to make concrete. Depending on the required strength, solid materials like sand, stone, gravel, and synthetic fiber can all be used.

Big contractors like Concrete Works in North Shore are aware of how crucial it is to have suppliers who reliably deliver specified grades of aggregates in the required amounts for the finished product to satisfy the exacting quality requirements.

Large construction projects involving buildings, bridges, roads, and other infrastructure are an example of this. It’s still crucial to have a specialist who works with concrete suppliers to supply high-quality, ready-mixed concrete for projects like basement walls, footings, etc., even if you use a concrete contractor for your residential project.

3 . Structural

Constructing upright structures out of concrete frequently reinforced with steel or other materials, contractors produce beams, pillars, bridge piers, caissons, waterway locks, and lighthouses.

Contractors that can stick to strict specifications are needed for these public projects using structural concrete to safeguard public safety and guarantee the project’s lifespan. Similar reasoning applies to a residential project.

A concrete contractor like Plain Concrete Driveways in Sydney, familiar with local codes and can guarantee that the material quality and building techniques will result in a safe structure, is necessary for concrete-poured basement walls or concrete dwellings.

Conclusion

After learning this, the next step is to identify a reputable construction business you can always rely on. A reputed concrete service provider can help you with your concrete needs and is an expert in tilt-up construction and commercial concrete services. Get in touch with Stencil Concrete Driveways in Sydney right now to learn more about any of their services.

0 notes

Text

Top Benefits for 1000 MM RCC Hume Pipe

1000 MM RCC Hume Pipe is widely used for sewage systems, water drainage, and culverts. It is a highly durable product with strength.

RCC Hume Pipes are widely used for sewage systems, water drainage, and culverts. They are prepared with the right mix of aggregates, cement, and steel reinforcement to give them strength.

Making use of the 1000mm RCC Hume Pipes, which have a width of 1000mm, can present different advantages in different applications. These pipes are manufactured using a spinning procedure that ensures uniform thickness and potency along the length of the pipe. These pipes are planned to endure external loads and soil pressures while economically holding sewage or fluids.

If you wish to know the benefits of 1000 RCC Hume Pipes, let’s discuss the top one:

Having a higher flow capacity

The large pipe has significant flow ability. It is making the pipes appropriate for larger volumes of sewage, water, or other fluids. It is helpful for areas with high water runoff.

Highly durable product

RCC Hume Pipes are prepared from a mix of cement, aggregates, and steel strengthening, which makes them resistant to corrosion and highly durable.

Strength

The strengthening in RCC Hume Pipes adds potency, allowing them to touch external loads, the pressure of soil, and other possible stresses without noteworthy bends or failures.

Assure for a long life.

Rightly installed and maintained pipes can have a long lifespan, reducing the requirement for frequent maintenance and replacements.

Easy Installation

RCC Hume Pipes are comparatively simple to install due to their standardized shapes and sizes. It can lead to a faster and more efficient installation as compared to more stuff.

Low Maintenance is required.

If the process of installation gets complete, RCC Hume Pipes usually need minimal maintenance, saving on cost and reducing downtime for the required repairs.

Budget-friendly for everyone

These pipes are budget-friendly as compared to any other kind of pipe material with similar load-bearing capacities. Their durability and low maintenance add to their overall affordability.

Opposed to Chemicals

They are commonly resistant to chemicals found in sewage as well as drainage systems. It can help to avoid the degradation of the pipes in the meantime.

Smooth Interior

RCC Hume Pipes commonly have a smooth interior surface, which reduces friction and allows for a better flow of fluids, reducing the possibility of blockages and clogs.

Versatility

These pipes can be widely used in different kinds of applications, such as sewage systems, irrigation, stormwater drainage, and culverts, making them flexible for various infrastructure projects.

Environmental Compatibility

The materials used in these products are inert and do not badly affect the surroundings, making them appropriate for different ecological settings.

It's significant to note that while RCC Hume Pipes provide several benefits, their performance is directly influenced by factors that include proper design, installation, and maintenance. Before selecting any pipe material, it's sensible to perform a thorough assessment of the project's needs and consult with professionals to make sure the optimal choice is made for your precise application. Contact us at Parshwa Cement Products.

0 notes

Text

Friday 11th August

Usual beautiful start to the day with a bit less of the breeze earlier but picking up now. Yesterday afternoon I went for a walk along a path just up from me which runs along the coast line and has a really nice viewing platform. I have been doing some panoramic videos in some places as I think it captures scenery better than stills. However I have just discovered that tumblr only allows 1 video for the blog so I will have to send the videos to those who are interested by Messenger when I get home.

Today is a tour to Dolly beach which is apparently a good beach but seems it is a 40 min walk each way from the car park so not one you would just pop to for a quick swim! Chris has promised to show us a beach near Dolly where all huge amounts (tons a year) of plastic waste form mainly Indonesia washes up. There is a big effort every year to clean it up with help from external parties like Sea shepherd. So sad!

ADDITS: Chris said that the British/ Singaporeans company mined phosphate here and apparently when the phosphate looked like it might run out the Singaporean govt in the mid 1950’s sold the island to Australia for a very cheap price! There was also a train that took the phosphate to the port from the original sight in the Southern tip of the island. It became too expensive and lines torn up and one of the locomotives was dumped in the jungle just off the road and is a tourist site or at least we are taken to see it and told the story! Will post photo when can.

Also on the same road as the train is the crab bridge. That’s right they built an overpass/bridge for the crabs to keep them off the road. It is made of a metal mesh (they trialled several materials and this worked). The crabs are directed to it by the placement of low metal barriers which despite the being able to climb over they seem to follow until they reach an opening and in this case the opening is where the bridge is so they climb it! They use a similar strategy to direct them to an under road pass. The under passes are like culverts dug across the roads with a cattle grid over them. The crabs go under the grid and the cars over it! There are I believe about 50 or so grids on the island.

Unfortunately millions also go over the roads and during the migration months everybody carries a few rakes and when you are blocked by crabs you get out and rake them out of you way or your passenger does! The crabs are so focused on getting to or from the sea that if you sit down they will just swarm straight over you. Not sure that appeals!

Yesterday I went to drive to a place for lunch after the tour (and which I had just been driven past on way back from tour) and I got lost again! I think I will have to pass on self drive unless there is a SatNav🤣.

Anyway today was the Dolly Beach tour. One thing that is now obvious is that to get anywhere like a beach or to see a sight it alway involves a drive on a dodgy road that really Or definitely does require a 4 wheel drive and nerves of steel AND a walk of about 20-60mins through the jungle and will end with clambering over limestone rocks😁. Really makes you appreciate final destination 😂. Dolly beach was no exception. The walk,after a very dodgy rough road was between 30-60mins. We did it in 40 out and 35back so we were not slacking🤣. Lots to see a mercifully flat with several sections covered with a raised boardwalk. The beach was worth the walk with the beach being protected by rock so lovely pools to swim in without tackling the rougher open ocean. Would be a great one to come to regularly if not for the challenges and time to reach it! We had a lovely swim and some morning tea and generally had fun. We did have to put all our bags etc on a platform raised on a hammock structure because there are 1000’s Robber crabs and they will still stuff from bags especially shiny stuff like keys.

By the time we got back and I had showered and done housekeeping and hols tasks I had a coup,e of bits of toast and an early dinner (just after 4pm🤣). I went down to the food van at Flying Fish Cove which sells takeaway mostly Asian food and importantly European cakes on Friday and Saturday 4-8pm.I had chicken satay and a mars bar slice yummy 😋.

0 notes

Text

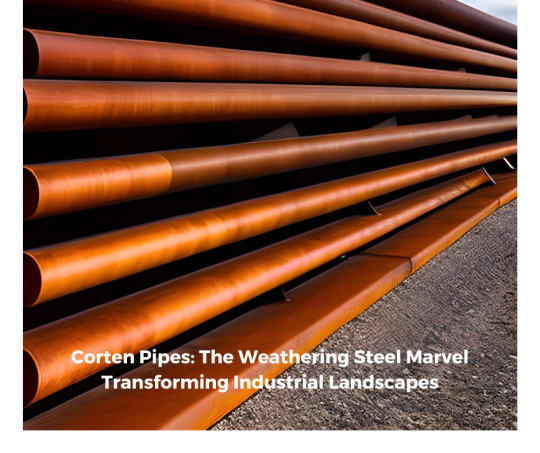

Corten Pipes: The Weathering Steel Marvel Transforming Industrial Landscapes

In the ever-evolving world of industrial materials, Corten pipes have emerged as a game-changing innovation, redefining structural design possibilities and adding an artistic touch to modern landscapes. Also known as weathering steel pipes, Corten pipes have gained popularity for their unique appearance, exceptional durability, and corrosion resistance. In this blog, we will explore the fascinating features and applications of Corten pipes and how they transform industrial landscapes into masterpieces of functionality and aesthetics.

Understanding Corten Steel

Corten steel is a group of steel alloys designed to develop a protective layer of rust when exposed to atmospheric conditions. The rust is a barrier against further corrosion, allowing the material to resist degradation even in challenging outdoor environments. The alloying elements, primarily copper, chromium, and nickel, impart Corten steel with its remarkable weather-resistant properties, making it an ideal choice for various applications.

The Beauty of Rustic Aesthetics

One of the most striking characteristics of Corten pipes is their unique aesthetics. As the steel weathers, a rich, reddish-brown patina forms on its surface, it is providing a rustic and natural appearance that blends harmoniously with urban and rural settings. This distinct patina adds a touch of artistic charm and acts as a protective shield, extending the life of Corten pipes.

Exceptional Durability and Longevity

Corten pipes are designed to withstand the test of time. The formation of the protective rust layer ensures that the material remains structurally sound and resistant to atmospheric corrosion, reducing maintenance costs and increasing the overall lifespan of the pipes. This exceptional durability makes Corten pipes attractive for bridges, outdoor sculptures, building facades, and other outdoor structures.

Applications in Architecture and Landscaping

Corten pipes have sparked a wave of innovation and creativity in the architectural and landscaping realms. Using Corten pipes allows designers to blend artistry with functionality from contemporary buildings to public spaces. Their striking appearance and ability to age gracefully have made them a popular choice for modern landscape design, adding character and texture to gardens, parks, and urban plazas.

Industrial and Structural Advantages

Beyond its aesthetic appeal, Corten pipes offer practical advantages in industrial and structural applications. The pipes' weather resistance ensures reliable performance in outdoor environments, making them suitable for construction projects like bridges, culverts, and drainage systems. In industries where harsh weather and corrosive elements are common, Corten pipes offer a durable and low-maintenance solution.

Sustainable and Eco-Friendly

Corten steel is highly sustainable and eco-friendly. Unlike traditional steel, which requires constant maintenance and repainting, Corten pipes' natural weathering process eliminates the need for additional protective coatings, reducing the environmental impact and preserving resources.

Conclusion

In conclusion, Corten pipes exemplify the perfect marriage of functionality and aesthetics in industrial materials. Their distinctive weathering process, rustic appearance, exceptional durability, and corrosion resistance make them a preferred choice for architects, landscapers, and engineers. As Corten Steel continues to inspire innovation, it transforms industrial landscapes into breathtaking masterpieces, leaving a lasting impression of strength, beauty, and sustainability. Whether gracing the skyline of a modern city or adorning the tranquility of a garden, Corten pipes are steel marvels that harmonize with nature and stand the test of time.

0 notes

Text

What is the use of MS rectangular pipe?

When it comes to construction and various engineering applications, MS Rectangular Pipe play a crucial role. These pipes are widely used in different industries due to their structural integrity, versatility, and durability. In this article, we will explore the various applications and benefits of MS rectangular pipes. So, let's dive in and understand the diverse uses of these pipes.

Understanding MS Rectangular Pipes

MS rectangular pipes, also known as mild steel rectangular pipes, are hollow sections made from mild steel. They have a rectangular cross-section and are available in various sizes and thicknesses. The strength and durability of MS rectangular pipes make them suitable for a wide range of applications in industries such as construction, infrastructure, automotive, furniture, and more.

Applications of MS Rectangular Pipes

Construction Industry

MS rectangular pipes find extensive use in the construction industry. They are commonly employed in the fabrication of structural frameworks, columns, and beams. These pipes provide excellent load-bearing capacity and structural stability, making them an ideal choice for constructing buildings, bridges, and other infrastructural projects.

Furniture Manufacturing

The furniture industry extensively uses MS rectangular pipes to create sturdy and durable furniture pieces. The pipes serve as the framework for tables, chairs, beds, and cabinets. With their high strength and dimensional stability, MS rectangular pipes contribute to the longevity of furniture items.

Automotive Sector

In the automotive sector, MS rectangular pipes are utilized for the manufacturing of roll cages, chassis components, and exhaust systems. The pipes' robustness and resistance to impact make them suitable for ensuring passenger safety and structural integrity in vehicles.

Agricultural Equipment

MS rectangular pipes are also employed in the fabrication of agricultural equipment. They are used in the construction of structures like greenhouses, fencing, and irrigation systems. The pipes' corrosion resistance and durability make them ideal for withstanding harsh weather conditions and extended exposure to moisture.

Material Handling Systems

Material handling systems, such as conveyors and storage racks, require sturdy components to handle heavy loads efficiently. MS rectangular pipes provide the necessary strength and rigidity for constructing such systems, ensuring seamless material flow and storage in warehouses and factories.

Signage and Display

MS rectangular pipes are commonly used in the signage and display industry. They serve as frames for outdoor signs, display boards, and advertising hoardings. The pipes' versatility allows for easy customization and installation of various signage components.

Infrastructure Development

MS rectangular pipes play a significant role in infrastructure development projects. They are used for the construction of bridges, flyovers, railway tracks, and underground utility systems. The pipes' structural strength and resistance to environmental factors make them suitable for such critical applications.

FAQs about MS Rectangular Pipes

1. What are the advantages of using MS rectangular pipes?

MS rectangular pipes offer several advantages, including high strength, durability, ease of fabrication, and cost-effectiveness. They can withstand heavy loads and are resistant to corrosion, making them ideal for diverse applications.

2. Are MS rectangular pipes recyclable?

Yes, MS rectangular pipes are recyclable. Being made of mild steel, they can be recycled and repurposed, contributing to sustainable practices and reducing environmental impact.

3. Can MS rectangular pipes be used for underground applications?

Yes, MS rectangular pipes can be used for underground applications. They are commonly employed in underground utility systems, drainage systems, and culverts due to their strength and resistance to corrosion.

4. Are there different grades of MS rectangular pipes available?

Yes, MS rectangular pipes are available in different grades, depending on therequired specifications and applications. Common grades include ASTM A500, ASTM A36, and BS EN 10219.

5. Can MS rectangular pipes be welded?

Yes, MS rectangular pipes can be easily welded using standard welding techniques. This allows for the seamless joining of sections, enabling the creation of complex structures and frameworks.

6. Are there any size limitations for MS rectangular pipes?

MS rectangular pipes are available in a wide range of sizes and dimensions, allowing for flexibility in design and construction. However, it's important to consider the specific requirements of the application and consult relevant standards and regulations.

Conclusion

MS rectangular pipes are versatile and essential components in various industries. Their use in construction, furniture manufacturing, automotive, agriculture, material handling, signage, and infrastructure development showcases their adaptability and reliability. With their strength, durability, and cost-effectiveness, MS rectangular pipes continue to be a popular choice for numerous applications. Understanding the diverse uses of these pipes allows us to appreciate their significance in shaping our built environment.

0 notes

Text

W - EXPON

Ethylene propylene diene monomer #flexiblebelt

Website: https://redwopchemicalspvtltd.page.link/W_EXPON

A high-performance joint sealing system for irregular or high-movement joints, based on flexible sheeting & epoxy resin-based Adhesive.

USES

-Tunnels & culverts

-Hydroelectric power plants

-Sewage treatment plants

-Roof joints

-Basements

-Water retaining structures

-Joints between rigid & flexible surfaces

-Around iron, steel & cement pipes

#redwop #redwopchemicals #redwopchemicalspvtltd #rpartner #constructionchemicals #buildingmaterials #constructionindustry #ethylenepropylenediene #monomer #epdm #polymerbelt #rubberbelt #industrialbelt #mechanicalbelting

1 note

·

View note

Text

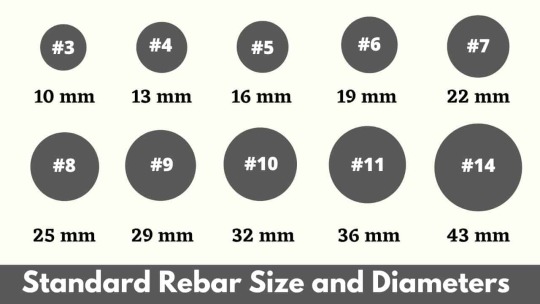

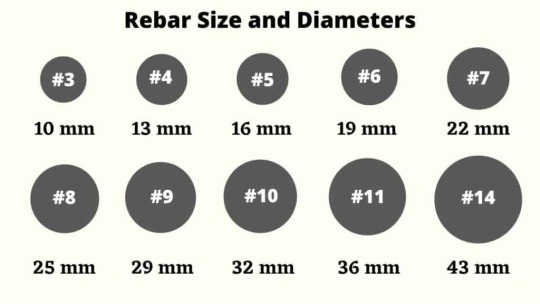

11 Different Types of Rebar and Their Sizes

What Is Rebar Size and Rebar Diamters?

Rebar size refers to the cross-sectional area of a reinforcing bar, expressed in square millimeters or square inches. The size of the rebar is an indicator of its strength and is specified by building codes and engineering standards.

Rebar diameter, on the other hand, refers to the thickness of the bar, expressed in millimeters or inches. The diameter of the rebar is a crucial factor in determining its strength, and it is usually related to the rebar size, with larger rebar sizes having larger diameters.

It's worth noting that rebar sizes can vary between regions and countries, but common sizes include #3, #4, #5, #6, #7, #8, and #9, which correspond to rebar diameters ranging from approximately 9 mm to 51 mm.

Read More: How Many Yards In a Ton | How Many Yards In a Ton of Gravel | How Many Tons In a Yard | How Many Cubic Yards In a Ton | Cubic Yard to Ton

Types of Rebars

1. Carbon Steel Rebars

Carbon steel rebars are the most commonly used steel bars used in construction and it is sometimes also called “Black Rebar”.

But, one of the biggest drawbacks of this rebar is that it is easily catching corrosion compared to other types of rebar.

Therefore, It is not used in an area that is subjected to high humidity and in a structure that is continuously in contact with water.

But, It is one of the best rebars to be used in construction other than water contact.

2. Welded Wire Fabric

It is manufactured by electrically welding a series of steel wires arranged at a right angle. It is mostly used for ground-level slabs where the ground is properly compacted and leveled.

These types of rebars are used for box culverts, road pavement, drainage structures, and small concrete canal construction work.

3. Sheet-Metal Reinforcing Bars

It is manufactured from annealed sheet steel pieces and bent in a corrugated shape with 1/6-inch deep holes punched at a specified distance.

These bears are mainly used for roof construction, floor slab, and stairs formation work.

4. Epoxy-Coated Rebars

Expoxy Coated Rebars are one of the expensive types of rebars that are used in an area where the structure keeps continuous contact with seawater and high humidity area.

Its coating must be done properly for the best result otherwise it is also liable to corrosion.

5. European Rebars

European Steel Rebars are generally manufactured from manganese mineral material which is having the property of easily bending.

These types of rebars are not suggested to be used in extreme weather conditions such as earthquake-prone zones, hurricanes, and rainstorms areas.

6. Stainless Steel Rebars

Stainless steel rebars are used as alternative rebar with carbon steel reinforcement bars. Stainless steel rebars are corrosion resistance coating on it which is the best option in an area that has corrosion problems.

But, Its cost is nearly eight times the cost of carbon steel rebars.

7. Galvanized Rebars

These rebars are most suitable for making strong structures that are supposed to expose in an area of highly humid conditions. Galvanized Rebars are 40 times more corrosion-resistant compared to normal carbon steel rebars.

Read More: How Many Bags of Concrete Do I Need For 10×10 Slab

Different Types of Rebar and Their Sizes

Standard Rebar Sizes and Diameters

- 3 rebar diameter

- 4 rebar diameter

- 5 rebar diameter

- 6 rebar diameter

- 7 rebar diameter

- 8 rebar diameter

- 9 rebar diameter

- 10 rebar diameter

- 11 rebar diameter

- 14 rebar diameter

- 18 rebar diameter

#3 Rebar Size and Diameter

3 Rebar diameters are made from carbon steel composite materials. It is mostly used for patio work, driveway construction, road work, and highway construction work.

3 Rebar is popularly known as “10 mm” diameter rebar,

3 Rebar Diameter:

#3 Rebar diameter in the metric system is 10 mm.

#3 Rebar nominal diameter in Inch is 0.375 inch

#3 Rebar nominal diameter in mm is 9.525 mm

3 Rebar Weight per unit length (lb/ft):

#3 Rebar unit weight per length is 0.376 lb/ft

#3 Rebar unit weight per length is 0.561 kg/m

3 Rebar C/S Area:

#3 Rebar Nominal Area in Inch is 0.1 inch2

#3 Rebar Nominal Area in mm is 71 mm2

#4 Rebar Size and Diameter

4 Rebar diameter is made from a sturdy composite of carbon steel. It is mostly used for commercial and residential construction work.

4 Rebar is popularly known as a “13 mm” diameter rebar,

4 Rebar Diameter:

#4 rebar diameter in the metric system is 13 mm.

#4 rebar nominal diameter in Inch is 0.50 inch (1/2 In.)

#4 rebar nominal diameter in mm is 12.70 mm

4 Rebar Weight per unit length (lb/ft):

#4 Rebar unit weight per length is 0.668 lb/ft

#4 Rebar unit weight per length is 0.996 kg/m

4 Rebar C/S Area:

#4 Rebar Nominal Area in Inch is 0.2 inch2

#4 Rebar Nominal Area in mm is 129 mm2

#5 Rebar Size and Diameter

5 Rebar diameter is made from carbon steel composite materials. It is mostly used for precast components construction which is used for canal, bridge, and road construction.

5 Rebar is popularly known as a “16 mm” diameter rebar,

5 Rebar Diameter:

#5 rebar diameter in the metric system is 16 mm.

Its nominal diameter in Inch is 0.625 inches (5/8 In.)

Its nominal diameter in mm is 15.875 mm

5 Rebar Weight per unit length (lb/ft):

#5 Rebar unit weight per length is 1.043 lb/ft

#5 Rebar unit weight per length is 1.556 kg/m

5 Rebar C/S Area:

#5 Rebar Nominal Area in Inch is 0.31 inch2

#5 Rebar Nominal Area in mm is 200 mm2

#6 Rebar Size and Diameter

6 Rebar diameters are made from carbon steel composite materials. It is mostly used for heavy foundation and footing construction.

6 Rebar is popularly known as a “19 mm” diameter rebar,

6 Rebar Diameter:

#6 rebar diameter in the metric system is 19 mm.

Its nominal diameter in Inch is 0.750 inches (3/4 In.)

Its nominal diameter in mm is 19.05 mm

6 Rebar Weight per unit length (lb/ft):

#6 Rebar unit weight per length is 1.502 lb/ft

#6 Rebar unit weight per length is 2.24 kg/m

6 Rebar C/S Area:

#6 Rebar Nominal Area in Inch is 0.44 inch2

#6 Rebar Nominal Area in mm is 284 mm2

#7 Rebar Size and Diameter

7 Rebar diameters are made from carbon steel composite materials. It is mostly used for medium to heavy concrete construction work.

7 Rebar is popularly known as a “22 mm” diameter rebar,

7 Rebar Diameter:

#7 rebar diameter in the metric system is 22 mm.

Its nominal diameter in Inch is 0.875 inches (3/4 In.)

Its nominal diameter in mm is 22.225 mm

7 Rebar Weight per unit length (lb/ft):

#7 Rebar unit weight per length is 2.044 lb/ft

#7 Rebar unit weight per length is 3.049 kg/m

7 Rebar C/S Area:

#7 Rebar Nominal Area in Inch is 0.6 inch2

#7 Rebar Nominal Area in mm is 387 mm2

#8 Rebar Size and Diameter

8 Rebar diameter is made from carbon steel composite materials. It is mostly used in high-strength construction work.

8 Rebar is popularly known as a “25 mm” diameter rebar,

8 Rebar Diameter:

#8 rebar diameters in the metric system is 25 mm.

8 rebar nominal diameter in Inch is 1.000 inches

3 rebars nominal diameter in mm is 25.40 mm

8 Rebar Weight per unit length (lb/ft):

#8 Rebar unit weight per length is 2.67 lb/ft

#8 Rebar unit weight per length is 3.982 kg/m

8 Rebar C/S Area:

#8 Rebar Nominal Area in Inch is 0.79 inch2

#8 Rebar Nominal Area in mm is 509 mm2

#9 Rebar Size and Diameter

9 Rebar diameters are made from carbon steel composite materials. It is mostly used in retaining walls, abutments, columns, and beam construction.

9 Rebar is popularly known as a “29 mm” diameter rebar.

9 Rebar Diameter:

#9 rebar diameters in metric system is 29 mm.

9 rebar nominal diameter in Inch is 1.128 inches

9 rebars nominal diameter in mm is 28.65 mm

9 Rebar Weight per unit length (lb/ft):

#9 Rebar unit weight per length is 3.40 lb/ft

#9 Rebar unit weight per length is 5.071 kg/m

9 Rebar C/S Area:

#9 Rebar Nominal Area in Inch is 1.00 inch2

#9 Rebar Nominal Area in mm is 645 mm2

#10 Rebar Size and Diameter

10 Rebar diameter is made from carbon steel composite materials. It is mostly used for heavy-duty construction work.

10 Rebar is popularly known as “32 mm” diameter rebar,

10 Rebar Diameter:

#10 rebar diameter in the metric system is 32 mm.

10 rebar nominal diameter in Inch is 1.27 inch

10 rebar nominal diameter in mm is 32.26 mm

10 Rebar Weight per unit length (lb/ft):

#10 Rebar unit weight per length is 4.303 lb/ft

#10 Rebar unit weight per length is 6.418 kg/m

10 Rebar C/S Area:

#10 Rebar Nominal Area in Inch is 1.27 inch2

#10 Rebar Nominal Area in mm is 819 mm2

#11 Rebar Size and Diameter

11 Rebar diameter is made from carbon steel composite materials. It is mostly used for high-quality construction work.

11 Rebar is popularly known as “36 mm” diameter rebar,

11 Rebar Diameter:

#11 rebar diameters in the metric system are 36 mm.

11 rebar nominal diameter in Inch is 1.41 inch

11 rebar nominal diameter in mm is 35.81 mm

11 Rebar Weight per unit length (lb/ft):

#11 Rebar unit weight per length is 5.313 lb/ft

#11 Rebar unit weight per length is 7.924 kg/m

11 Rebar C/S Area:

#11 Rebar Nominal Area in Inch is 1.56 inch2

#11 Rebar Nominal Area in mm is 1006 mm2

#14 Rebar Size and Diameter

14 Rebar diameter is made from carbon steel composite materials. It is mostly used for tall buildings, parking structures, bridges, docks, and industrial facilities.

14 Rebar is popularly known as “43 mm” diameter rebar,

14 Rebar Diameter:

#14 rebar diameters in the metric system are 43 mm.

14 rebar nominal diameter in Inch is 1.693 inch

14 rebar nominal diameter in mm is 43 mm

14 Rebar Weight per unit length (lb/ft):

#14 Rebar unit weight per length is 7.65 lb/ft

#14 Rebar unit weight per length is 11.41 kg/m

11 Rebar C/S Area:

#14 Rebar Nominal Area in Inch is 2.25 inch2

#14 Rebar Nominal Area in mm is 1452 mm2

18 Rebar Size and Diameter

18 Rebar diameter made from carbon steel composite materials. It is mostly used for bridges and construction projects in marine environments.

18 Rebar is popularly known as a “57 mm” diameter rebar.

18 Rebar Diameter:

#18 rebar diameter in metric system is 57 mm.

18 rebar nominal diameter in Inch is 2.257 inch

18 rebar nominal diameter in mm is 57.33 mm

18 Rebar Weight per unit length (lb/ft):

#18 Rebar unit weight per length is 13.6 lb/ft

#18 Rebar unit weight per length is 20.284 kg/m

18 Rebar C/S Area:

#18 Rebar Nominal Area in Inch is 4.00 inch2

#18 Rebar Nominal Area in mm is 2581 mm2

Read More: How Many Bags Of Concrete In A Yard | How Many Bags of Concrete Do I Need

Rebar Size Chart and Rebar Diameter Chart

Imperial Bar SizeWeight per unit length (lb/ft)Mass per unit length (kg/m)Nominal Diameter (in)Nominal Diameter (mm)Nominal Area(in2)Nominal Area (mm2)#30.3760.5610.3759.5250.11 71#40.6680.9960.50012.70.2129#51.0431.5560.62515.8750.31200#61.5022.240.75019.050.44 284#72.04 3.0490.8722.2250.60387#82.673.9821.00025.4 0.79 509#93.45.0711.12828.651 645#104.3036.4181.27 32.261.27819#115.3137.9241.4135.811.56 1006#147.65 11.4 1.693432.251452#1813.620.2842.25757.3342581

Rebar Size and Diameter

Manufacturing Process of Rebar

The manufacturing process of rebar involves various stages,

Step 1: Raw Material Preparation: Steel billets are produced from iron ore, coal, and limestone in a blast furnace.

Step 2: Rolling: Steel billets are heated and then rolled into the desired size and shape, typically in a long continuous process.

Step 3: Bending: The rebar is bent into its final shape using a rebar bender.

Step 4: Cutting: The rebar is cut to the desired length using a rebar cutter.

Step 5: Straightening: The rebar is straightened to remove any twists or deformities.

Step 6: Inspection and Testing: The rebar is inspected and tested for quality and conformity to industry standards.

Step 7: Marking: The rebar is marked with identifying information, including the manufacturer, size, and grade.

Step 8: Packaging: The rebar is packaged and prepared for shipment to construction sites.

The process is performed in a steel mill, with specialized equipment and trained personnel to ensure a high-quality product. The process is designed to produce rebar that is strong, durable, and resistant to corrosion and other environmental factors.

Conclusion

In conclusion, rebar size and rebar diameter are important factors in determining the strength of reinforcing bars used in construction.

Rebar size refers to the cross-sectional area of the bar, while rebar diameter refers to the thickness of the bar. Rebar sizes can vary between regions and countries and are determined based on building codes and engineering standards.

Larger rebar diameters generally result in higher strength, but other factors such as the material used and the number of rebar pieces also impact the overall strength of a rebar system.

Understanding rebar size and diameter is crucial for selecting the appropriate rebar for a construction project.

FAQs:

What is rebar size?Rebar size refers to the cross-sectional area of a reinforcing bar, expressed in square millimeters or square inches. It determines the strength of the rebar and is specified by building codes and engineering standards.What is rebar diameter?Rebar diameter refers to the thickness of a reinforcing bar, expressed in millimeters or inches. It is an important factor in determining the strength of the rebar and is usually related to the rebar size.What are the most common rebar sizes?Common rebar sizes include #3, #4, #5, #6, #7, #8, and #9, which correspond to rebar diameters ranging from approximately 9 mm to 51 mm.How does rebar diameter affect its strength?The diameter of the rebar is a crucial factor in determining its strength. Larger rebar diameters generally result in higher strength, but other factors such as the material used and the number of rebar pieces also impact the overall strength of a rebar system.What are the most common rebar sizes?Common rebar sizes include #3, #4, #5, #6, #7, #8, and #9, which correspond to rebar diameters ranging from approximately 9 mm to 51 mm.

You May Also Like

- How Many Yards In a Ton | How Many Yards In a Ton of Gravel | How Many Tons In a Yard | How Many Cubic Yards In a Ton | Cubic Yard to Ton

- How Many Bags Of Concrete In A Yard | How Many Bags of Concrete Do I Need

- How Many Bags of Concrete Do I Need For 10×10 Slab

- How Many Bags Of Concrete In A Yard | How Many Bags of Concrete Do I Need

- What Is Unit Weight of Steel | Unit Weight of Steel Bar Formula | Steel Unit Weight | How to Calculate Steel Bar Unit Weight

Read the full article

#4rebardiameter#3rebardiameter#4rebarsize#4rebarweight#5rebardiameter#5rebarweight#6rebardiameter#8rebardiameter#areaofrebar#metricrebarsizes#number4rebarsize#rebarareachart#rebarchart#rebardiameter#rebardiameterchart#rebardiameters#rebarsize#rebarsizechart#rebarsizes#rebarsizeschart#rebarweightchart#rebarssizes#sizesofrebar#steelrebarsizes#whatsizeisnumber4rebar

0 notes