#pvc culvert

Text

Putting in new Farm Culvert and Road with pair of skidsteers

youtube

#Reefdvms#culverts#steel culvert#pvc culvert#farm culvert#road culvert#farm#farmer#farms#driveway culvert#driveway#driveway repair#gravel driveway#spiral culvert#backhoe#backhoe and culvert#Culvert#325g#john deere skid steers#skid steer#26g excavator#26g john deere#352g john deere#325g skid steer#diy road#diy culvert#diy ditch#creek crossing#new road#hauling skid steer

0 notes

Text

Types of Pipes and Their Applications: A Comprehensive Guide

Understanding common types of pipes and their applications is crucial for informed project decisions in various industries and applications.

Here is a detailed overview of the most popular pipe types:

Steel Pipes: Steel pipes are solid and adaptable, making them ideal for various uses including water delivery, gas pipelines, oil transportation, and structural purposes. They are incredibly strong and resilient under great strain.

PVC Pipes: Polyvinyl chloride (PVC) pipes are inexpensive, lightweight, and corrosion-resistant. They are frequently used in drainage, irrigation, and plumbing systems because they are simple to install and need little upkeep.

Copper Pipes: Copper pipes are renowned for having exceptional heat and corrosion resistance. HVAC (heating, ventilation, and air conditioning) applications, plumbing systems, and refrigeration systems all frequently use them.

HDPE Pipes: High-density polyethene (HDPE) pipes are ideal for sewage systems as well as subterranean water and gas distribution because of their strong chemical resistance and a high degree of durability.

PEX Pipes: Cross-linked polyethene (PEX) pipes are flexible and resistant to corrosion. They are frequently employed in home plumbing systems, notably in the distribution of hot and cold water.

Cast Iron Pipes: Cast iron pipes are renowned for their robustness and noise-isolating qualities. They are frequently employed for stormwater drainage systems and sewer pipes.

Galvanised Iron Pipes: To prevent corrosion, galvanised iron pipes have a zinc coating. They are frequently employed for outdoor applications and water supply lines.

Concrete pipes: Concrete pipes are sturdy and long-lasting, making them ideal for sewage applications, culverts, and underground drainage systems.

Stainless steel pipes: These pipes are utilised extensively in food processing, pharmaceuticals, and chemical processing sectors because they offer exceptional corrosion resistance.

Fibreglass Pipes: Fibreglass pipes have a high strength-to-weight ratio, are lightweight, and are resistant to corrosion. They are frequently employed in sectors including wastewater treatment, chemicals, and oil and gas.

Considerations include the material's qualities, application requirements, durability, maintenance, and cost when choosing pipes for your projects. Getting advice from pipe suppliers or specialists can be extremely helpful in determining which pipe type is best for your requirements. RSS Engineering is the company that leads you with the most sustainable variety of pipes to choo

2 notes

·

View notes

Text

Classification of Pipes based on their Materials and Uses

Pipes are products of circular tubing used for transporting fluids. Pipes are built to withstand a certain pressure, which is determined by the temperature at which they will be used. Pipes can vary in many ways depending on factors like their size, schedule, material, pressure and temperature resistance, and so on. The industrial sector makes use of several pipe types for a variety of applications. Pipes are used extensively in a wide variety of industries, including the oil and gas industry, petrochemical as well as chemical industries, process industries, the power sector, the food and beverage industry, HVAC manufacturers, steel manufacturers, pipeline manufacturers, plumbing manufacturers, refineries, and many others. In today's contemporary industrial plants, piping is absolutely essential. Different criteria are used to determine the type of pipe to be used. A variety of pipes used extensively in manufacturing industries will be discussed further in this article.

Types of Pipes based on Material:

Most commonly, pipes are categorised according to the raw material from which they are made. Both plastic and metal pipes are often used, yet there are distinct differences between the two.

Metallic Pipes

Non-metallic Pipes

Metallic Pipes:

Metallic pipes refer to those that are fabricated from metal rather than other materials. They are classified as under:

● Pipes made up of ferrous materials

● Pipes made up of non-ferrous materials

- Pipes made up of ferrous materials:

These pipes are heavier and more durable than others. The primary element of these pipes is iron. Ferrous material pipes are typically constructed of

● Carbon steel pipes

● Stainless steel pipes

● Alloy steel pipes

● DSS pipes

● Cast Iron pipes

● Ductile Iron pipes, etc

This group of pipes can withstand higher pressures and temperatures. Jindal pipes for Oil, Gas and Water supply supplied by Tube Trading Co., used in industrial settings including refining, chemical and petrochemical processing, power generation, etc. are typically formed of ferrous elements.

- Pipes made up of Non-ferrous materials:

Pipes from this assortment are not primarily made of iron. The likes of brass, aluminium, copper, etc., are what they're often crafted from. Some typical examples of non-ferrous pipes are

● Aluminium and its alloy pipes.

● Copper and its alloy pipes.

● Nickel and its alloy pipes.

● Titanium and its alloy pipes.

● Zirconium and its alloy pipes.

Non-metallic Pipes:

Commonly employed in services where the temperature is not a factor, non-metallic pipes are becoming more and more common. Most of the non-metallic pipes are utilised in the water industry as well as drainage systems. If you are looking for the most distinguished supplier of Jindal spiral welded coated pipes in India, Tube Trading Co. is the most trustworthy supplier in Gujarat, India.

The most regularly used types of non-metal pipes are:

● PE/HDPE Pipes

● CPVC/PVC/UPVC/ Pipes

● PP pipes

● Reinforced thermoplastic pipes

● ABS Pipes

● Composite pipes

● Asbestos and Cement Pipes

● Vitrified clay pipes

Composite pipes', as well as reinforced plastic primary benefits, are their extreme resistance to corrosion and long lifespan. where metal pipes are often made to last up to 25 years. Reinforced plastic and composite pipes can survive for up to half a century with no problems. But the temperature is their biggest restriction. Metallic pipes can withstand the high temperatures that are required in some industrial processes. Stormwater, gravity service, the irrigation industry, and culverts are common applications for cement pipes made from reinforced concrete.

Pipes, classified on the basis of the industry:

- For Power Piping as well as Chemical Industries:

These pipes can withstand extreme heat and pressure without breaking down. The chemical, electricity, petrochemical, steel, oil, and gas industries all rely heavily on pipes constructed of ferrous materials. They are often developed in accordance with international standards such as ASME B31.3 and ASME B31.1. They are typically chosen for their high pressure, temperature, and corrosion resistance tolerance. Being an excellent supplier of industrial pipes and tubes, Tube Trading Co. can fulfil all of your Jindal spiral welded coated pipes requirements.

- For the Plumbing industry:

Plumbing pipes can be made from a variety of materials, including plastic (PVC), metal (Copper and PEX), plastic (ABS), cast iron (galvanised steel), or steel (cast iron). Their primary function is to transport water from one location to another.

- Pipes for the Pipeline industry:

Line pipes are what you'll typically hear people refer to when they talk about pipes utilised in the pipeline industry. These pipes are typically designed according to API 5L specifications. Pipes according to API 5L standards are available in a wide range of grades for transporting liquids such as oil, natural gas, and water. In addition to DSS, FRP, SS, GRE, SDSS, etc., there are a variety of other materials used for pipelines.

6 notes

·

View notes

Text

PVC gasket pipe use in

#water,#sanitary,#industrial,#stormdrain,#mining and #culvert applications.

Welcome to inquiry by whatsapp link: https://lnkd.in/gWRCN3bu

Whatsapp & Viber & Skype & WeChat: +86 15959262576

Email: [email protected]

#pressurepipe#PVCgasketpipe#PVCpipe#rubberring#sewerpipe#rubberringjoint#PVCgasketpressurepipe#gasketpipe#upvcpipe#ASTM3034#drainage#leachfields#downspouts#ASTMD3212#flexibleelastomericseals#psm#drainpipe#ringkit#bluecolor#belling#gasketjointpvcpressurepipe#ringgasket

0 notes

Text

Day 161

January 10, 2023

Site inspection at Las Piedras! This is the second time we’ve been here, though the inspection site itself was new. This was also the shortest inspection day by far, with only a single site. We met up with the rest of the inspection team at the main municipality office and headed to the field not long after.

Left Side (North)

This was the culvert inflow. It appears that the soil was eroded from under the asphalt, which then collapsed, breaking some cable TV tubes (small white) and stressing the sewage(?) PVC. Some of the debris had been piled to the right of the stream:

I crawled to the bottom of the ditch to get a closer photo of the two metal culverts. They’re probably about three or four feet in diameter:

Right Side (South)

This used to be two-way crossing before Hurricane Maria arrived. Now it is a single lane. There’s a surprising amount of traffic.

There’s a school nearby, so kids were depending on the sidewalk to get around. “Were” being the key word. They have to walk into the road to get around now. Not the safest. Hopefully this is a new development, but there’s a chance the sidewalk has been like this for the past five years. We were told that the black pipe is potable water and the white pipe is wastewater.

The smaller culvert is for bridge drainage, so it’ll need replacement too. Then the entire area will need to be filled. Wing walls and/or a gabion wall (stones contained in metal mesh intended to reduce erosion) may be added.

This site was good for birding. We stayed outside for about 2 hours, and I identified 14 species. A small flock of about bronze mannikins landed close enough for me to see clearly, so that’s another species to add to the life list. I’ve seen them before, but only in captivity. They aren’t native here and would have arrived as escaped/released pets.

Post-inspection Meeting

There was plenty of time before we needed to return to the Joint Field Office, so we all met back at the municipality office to discuss more information about the site. Or, at least, other people discussed. EHP wasn’t extremely involved, and I missed the majority of what was said because most of the discussion took place in Spanish.

From what I gathered, the engineer produced a report four years ago, after Hurricane Maria. However, the Architect/Engineer proposal for the site damages had not been funded by FEMA, and the project likely cannot proceed without this funding. It’s not clear to me whether Hurricane Maria damage repairs are still being funded by FEMA. The current work order’s reported damages are for Hurricane Fiona, but the previous reported damages for Hurricane Maria will be checked, as damages may not be double-counted due to potential duplication of benefits.

There does not appear to be a specific plan yet, so EHP cannot do much about this project until the scope of work is determined. A few things seem likely, though. Much of the surrounding area will be filled in, which will require repair of some utilities and extension of the culverts. It appears that the metal culverts will be replaced with concrete box culverts, which may require a hydrological study to predict downstream impacts. One of the EHP members told us that the stream was not marked in the USA Wetlands layer of ArcGIS, so there’s a chance it’s just a drainage ditch that will not be subject to the Clean Water Act. That being said, this site is up against a national forest, so a few other EHP laws may be relevant.

It seems like the applicant is also seeking hazard mitigation. I overheard that gabion walls are a categorical exclusion. From what I recall, this means the approval process for the gabions is less in-depth than other construction, which may require an environmental impact statement.

0 notes

Text

India Plastic Pipes: Revolutionizing the Plumbing and Construction Industry

The Indian construction and plumbing industries have witnessed a significant transformation with the introduction of plastic pipes. These versatile and durable pipes have revolutionized the way water and other fluids are transported, replacing traditional materials like metal and concrete. In this article, we will explore the impact of plastic pipes in India, their advantages, and the role they play in driving efficiency and sustainability in various applications.

The Rise of Plastic Pipes:

Plastic pipes, including polyvinyl chloride (PVC), high-density polyethylene (HDPE), and cross-linked polyethylene (PEX), have gained immense popularity in India due to their numerous advantages over conventional materials. These pipes offer exceptional strength, flexibility, and corrosion resistance, making them ideal for a wide range of applications in plumbing, irrigation, drainage, and even industrial processes.

Advantages of Plastic Pipes:

a. Durability: Plastic pipes are highly durable and resistant to corrosion, chemical reactions, and wear and tear. They can withstand harsh environmental conditions, making them suitable for both indoor and outdoor installations.

b. Lightweight and Easy Installation: Compared to traditional materials like metal or concrete, plastic pipes are lightweight and easy to handle, reducing installation time and labor costs. Their flexibility allows for seamless bending and fitting into complex layouts, resulting in efficient and cost-effective installations.

c. Chemical Resistance: Plastic pipes are highly resistant to various chemicals, making them suitable for a wide range of applications. They can transport both potable water and aggressive chemicals without degradation or contamination.

d. Low Friction Loss: Plastic pipes have smooth inner surfaces, resulting in low friction loss during fluid flow. This characteristic improves the efficiency of water distribution systems, reduces energy consumption, and lowers pumping costs.

e. Longevity: Plastic pipes have a long service life, often exceeding 50 years. Their resistance to corrosion and degradation ensures reliable performance over an extended period, minimizing the need for frequent replacements.

f. Thermal Insulation: Some plastic pipes, such as PEX, offer excellent thermal insulation properties. They can withstand high temperatures and retain heat, making them ideal for hot water supply systems, underfloor heating, and thermal energy distribution.

Applications of Plastic Pipes:

a. Plumbing: Plastic pipes have become the preferred choice for plumbing installations in residential, commercial, and industrial buildings. They are used for water supply, drainage, and sewage systems, offering leak-proof and long-lasting performance.

b. Irrigation and Agriculture: Plastic pipes are extensively used in irrigation systems for transporting water to agricultural fields. They provide efficient water distribution, minimize water loss, and contribute to sustainable farming practices.

c. Infrastructure Projects: Plastic pipes are used in infrastructure projects, such as stormwater management, sewerage systems, and culverts. Their durability and resistance to chemical corrosion make them ideal for these demanding applications.

d. Industrial Applications: Plastic pipes find applications in various industries, including chemical processing, mining, oil and gas, and power generation. They can safely transport corrosive fluids, chemicals, and effluents in industrial processes.

Environmental Considerations:

Plastic pipes offer environmental benefits compared to traditional materials. They require less energy to manufacture and transport, resulting in lower carbon emissions. Additionally, their long lifespan reduces the need for frequent replacements, leading to reduced waste generation. Moreover, some plastic pipes are recyclable, contributing to a circular economy and resource conservation.

Regulations and Standards:

In India, plastic pipes are regulated and must adhere to national standards, such as the Bureau of Indian Standards (BIS). These standards ensure the quality, safety, and performance of plastic pipes, providing consumers with reliable and certified products.

Conclusion:

Plastic pipes have revolutionized the plumbing and construction industries in India, offering durability, versatility, and efficiency. Their advantages, including durability, ease of installation, chemical resistance, and long service life, make them the preferred choice for various applications. Plastic pipes not only drive efficiency and cost-effectiveness but also contribute to sustainable practices by reducing energy consumption, minimizing waste generation, and supporting the growth of a circular economy. With ongoing technological advancements and strict adherence to quality standards, India's plastic pipe industry is set to thrive, bringing continued innovation and advancement to the nation's infrastructure and water management systems.

Request for free Sample : https://www.bonafideresearch.com/samplereport/210760061/india-plastic-pipe-market

0 notes

Text

A Pvc Greenhouse - Step By Step

The occasional athlete should consider a true vintage Fender tube amp even though they could upward spending a great number. The greatest tones can be generated by an old tube amp that is taken proper care of especially those little amps like the 1959 tweed vibrolux. Turn this amp all method up and stand back again.you have instant pure overdrive that will have you crying with thrill. If the weekend warrior can't afford a vintage amp find the reissue style. All the tones you hear on your favorite recordings will be there without the headache of replacing parts. Finally if you are feeling brave try Fender's modern amps for example the Hot Rod series mentioned earlier. The hot Rod series you can't go wrong with.

An experienced fitter knows from experience that the pipe fitting tool too big for the job will cause the fitting to stretch or crack. This will result in the leaking joint that will need a new fitting after only a almost no time. Selecting the most beneficial sized wrench is just as important as selecting greatest kind.

Steel pipe is almost everywhere. rectangle tubes can be fabricated for many people purposes. square pipe In the Large O.D. Pipe being designed for billboard structures when traveling down most any highway. It's used in parking lots, for "Bollards" or "Bumper Posts". You may be surprised any restaurant or host to business carries with it an outdoor sign mounted on the pole associated with steel. With all of galvanized pipe used for highway signage. The list passes on and on, fence posts, culvert pipe at the conclusion of your driveway, pipe piling to stabilize foundation structures massive building and skyscrapers, slurry line pipe used in quarries and sand operations, columns in the basement of the home. Nauseating to name just a few structural applications.

You must be careful so it does not become a lot difficult to heat room in your home because with the cold drafts that continue to entering the room. Proper insulation is very much necessary. You might be aware of the foam pipe insulation.

Lake Cunningham Regional Skatepark, California. This park is famous for its 70 foot long full pipe. Can anyone actually skate it? Most likely not without being towed by an ATV or common. There are plenty of pools and obviously any good street course at this park. Bikes are allowed, but not in the bowls. Sweet.

yuantai square tube has a separated push button that revises this electrically operated wrench. It knows when there already been too much pressure set onto the tube, to ensure that loosens its grip. It can sense as soon as the motor is stalled a great extended stage of time and shuts off. Might be the sort has been around for a little over ages. It was set for publication in June of 1997, just nine months after the time of completing. The inventors this time were three Pennsylvania men, named John L. Estep, Harry E. Morris III, and Donald R. Hot Dip Galvanized Square Hollow Section .

When building PVC projects, sometimes in haste we glue fittings that upward facing the wrong direction. Of course, through your body . ruined fittings, delays and, essentially, having to start previously. It happens as well as it frustrating. So here's buying and selling websites solved a cinch ..

1 note

·

View note

Text

Dealing With Salvage And Debris Within Your Home Remodeling Project

When I talk to fellow guitarists, about the King virtually all them notice the same way with my home. Of course not all my death metal friends notice the way i. If someone likes full distortion sounds at top speed riffs, the I assume the king does work for it. Yeah! definitely! Don't even think of tk999 overdrive pedal if you're really into death chrome effect.

Does build you a pipe welder? Just all around. You'd still need some field experience, working as a helper to a pipe welder, while welding part on the time. Why is this? It is because correcting your mistakes extremely expensive. pre galvanized square tubing work at an allowable failure rate of about 2%.

Tip: If you find an inserted pipe stubborn to remove, attach a vice-grip on the pipe however PVC fitting clamped in a bench vice, then separate by rounding about. Or, use two vice-grips.

An experienced fitter knows from experience that using a pipe fitting tool too big for activity will make the fitting to stretch or crack. Scrumptious meals result in the leaking joint that demands a new fitting in a matter of a almost no time. Selecting spot sized wrench is just like important as selecting the right kind.

The second method is correctly a trick that we are all not aware of but is usually life saver if you are stranded amid a trail or track. You take your tire heli-copter flight rim and pull out the inner tube. rectangular hollow section are looking for the hole, which is the answer by pumping the inner tube with air, and listen for your air seeping out or rub salvia over the interior tube until your educate yourself on the hole. Once you have the hole cut the tube upon the pin. You will now have one long inner tube. You might want to tie off both ends of the tube and hang up it back underneath your tire. Position the tire back on the rim and pump it full of air. Require to now capability to to ride your bike, granted has been only one hole. It may not be a smoothest ride but it will now at least get you back home or to one's car.

The USA is in the pickle with our cookie jar. We don't have money, and we owe money like go nuts. When you're kept in a room which generally have no doors - then suddenly, a door opens, obtain from it ? you can? You RUN using door, not? By getting our oil and coal out within the ground, we can turn the usa around, and the powers that be noticed it. So, despite what you hear about oil and gas finding yourself in the past, hold onto your hat, capsicum is derived from winds of change are blowing, and contrary to popular belief, it isn't turning wind mills. The U.S. develop into the world's largest producer of oil and gas main soon.

square pipe Steel pipe is practically. Pipe can be fabricated for most purposes. With the Large O.D. Pipe being designed for billboard structures when traveling down a lot highway. It's used in parking lots, for "Bollards" or "Bumper Posts". Just about any restaurant or place of business includes an outdoor sign mounted on the pole made from steel. Look at all of galvanized pipe used for highway evidence. The list proceeds on and on, fence posts, culvert pipe at the finish of your driveway, pipe piling to stabilize foundation structures large building and skyscrapers, slurry line pipe used in quarries and sand operations, columns in the basement of the home. Nauseating to name some structural concepts.

The action is pick a placed into the outdoor area or the leading of house as about the room as possible you have to have select for natural conditioning. The selected place must viewed as a shady use. Mark the place with a diameter of 4 feet that is to say a circle or a square area measuring four by four feet. Discover needs regarding dug to make a bore well from top to bottom having same associated with space as marked round the ground.

1 note

·

View note

Text

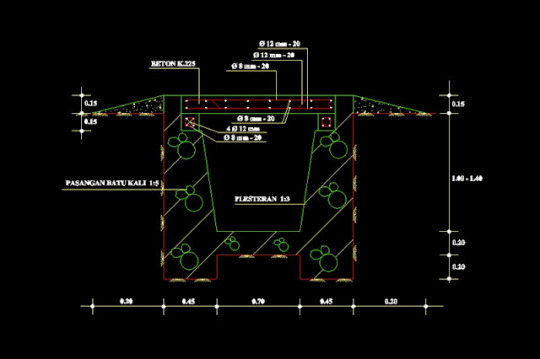

Download Gambar Kerja Desain Gorong-Gorong atau Got File Dwg AutoCad

Download Gambar Kerja Desain Gorong-Gorong atau Got File Dwg AutoCad

Pada postingan kali ini seperti biasa saya akan share file gambar Autocad (DWG) yaitu gambar kerja saluran atau gorong-gorong atau got. File tersebut bisa menjadi referensi atau contoh serta menjadi bahan pembelajaran bagi pelajar atau mahasiswa teknik sipil atau arsitek yang sedang belajar mendalami menggambar menggunakan Autocad. Selain itu bisa menjadi bahan contoh pula bagi kalian yang bingung untuk membuat desain gambar gorong-gorong/got.

Selain gambar file dwg Autocad, gambar kerja gorong-gorong ini di sertai dengan RAB pembangunannya dalam bentuk file Excel. jadi kalian punya pilihan untuk mendownload satu file atau keduanya. File gambar Autocad ini bisa dilihat atau di buka (run) mulai dari Autocad versi 2010 keatas. Selain itu bisa juga di edit sesuai selera masing-masing. File tersebut bisa didapatkan secara gratis tanpa biaya apapun. caranya klik link download yang ada dibawah postingan ini.

Pengertian Gorong-gorong adalah bangunan yang dipakai untuk membawa aliran air (saluran irigasi atau pembuang) melewati bawah jalan air lainnya (biasanya saluran), di bawah jalan, atau jalan kereta api. Gorong-gorong juga digunakan sebagai jembatan ukuran kecil, digunakan untuk mengalirkan kecil atau sebagai bagian drainase ataupun selokan jalan.

Macam-macam konstruksi Gorong-Gorong :

1. Gorong-Gorong Baja

Gorong-gorong baja biasanya menggunakan Corrugated Steel Pipe, kalau diterjemahkan secara bebas berarti Pipa Baja Bergelombang. Gorong gorong baja ini terutama dari jenis Multi Plate Pipe telah menjadi alternative penggantikan jembatan kayu dan box culvert beton, hal ini disebabkan gorong – gorong baja memiliki beberapa keuntungan dibanding dengan penggunaan kayu ataupun beton.

2. Gorong-Gorong Beton

Gorong-gorong beton adalah bahan beton precast yangdipakai untuk membawa aliran air (saluran irigasi atau saluran pembuangan) yang melewati dibawah jalan dengan cara ditanam ke dalam tanah dan kedudukannya berada di bawah jalan (crossing), atau jalan kereta api. Gorong-gorong beton juga digunakan sebagai jembatan ukuran kecil, digunakan untuk mengalirkan sungai kecil atau sebagai bagian dari drainase ataupun selokan jalan lingkungan.

3. Gorong-Gorong PVC

Gorong-gorong PVC biasanya digunakan untuk gorong-gorong dengan ukuran kecil. Biasanya digunakan untuk menyalurkan aliran air kecil baik itu irigasi atau pembuangan.

Hanya sekedar untuk memberikan referensi pembelajaran ataupun acuan desain gambar kerja. Ini sangat bagus untuk pemula atau yang baru menekuni bidang arsitektur maupun civil engineering. Untuk itu silakan teman - teman download Gambar Kerja Desain Gorong-Gorong atau Got File Dwg dibawah, untuk menambah wawasan atau bisa juga sebagai koleksi.

Download Gambar Kerja Desain Gorong-Gorong atau Got File Dwg AutoCad

Download

#rumah minimalis#desain rumah#design home#home decor#tutorial#autocad#sketchup#arsitek#rumah#rumahimpian#rumah cantik#rumah murah#rumah modern#rumahmodern#rumahminimalis#rumah2lantai#rumah layak huni#architecture#rumah impian#rumah bagus#kontraktor#engineering#civilengineering#gedung#hotel#asuransi#insurance#rumahcantik#rumahdpringan#rumahstrategis

1 note

·

View note

Text

Waterstop Variety Recommendations

Waterstops are static seals installed between joints of a concrete structures to stop the passage of water or another fluids. The waterstop is a part of the concrete or across and/or over the joint. In order to pick the best waterstop for the application there are several points to consider. Such as, the dwelling type, joint type, joint movement type, chemical containment requirements, and also the means for securing the waterstop in place (hog rings, grommets, etc.)

Concrete waterstops rose to prominence as concrete use became the standard choice in residential and commercial construction within the mid-20th century. After concrete bridges started dotting the map in the early 1900s as well as the Hoover and Grand Coulee dams were constructed from concrete in the 1930s, it became predominant as the most used material in new construction. Because of the porous joints created when dispensing concrete in sections, the necessity for waterstops was immediately apparent. PVC was the predominant decision for waterstops from the 1940s and continued for several years and is still the most typical waterstop material.

Features

Waterstops utilize techniques during installation that force seals to embed to the concrete. In most applications, it is necessary to repel water and liquids entirely. Special circumstances need the prevention of liquids from moving after dark barrier manufactured by the waterstop. This selection is a member of having to keep solvents, hot petroleum oils and chemicals from making its way past the seal itself. Additional features include alternative physical forms such as strips. A strip can do covering a vast area when ordered in large rolls or pastes.

Applications

Waterstops are essential for construction projects where concrete is used to retain water or exclude it. Most of these applications in residential, industrial and commercial construction include:

Dams and water reservoirs

Canals, locks, aqueducts and culverts

Bridges and tunnels

Water and wastewater treatment facilities

Sludge ponds

Containment structures surrounding oil, chemical as well as other varieties of refineries

Storage tanks, both above and underground, for liquids like fuel or chemicals

Basements and concrete foundations for homes and other buildings

Specifications

Specifications are manufactured for sale in the subsequent four areas:

Structure type

Joint type application

Joint movement requirements

Chemical containment requirements

For more details about Bang can nuoc site: look at this.

1 note

·

View note

Text

PVC Waterstop for Construction & Expansion Joints

PVC Waterstop - The Best Solution To Concrete Construction

Four types of PVC waterstop in blue, gray and yellow

PVCW-01: PVC waterstops has various colors for choice.

https://www.jointwaterstop.com/product/pvc-waterstop.html

PVC waterstop, being embedded in the concrete joints, acts as a continuous watertight diaphragm to prevent any seepage of liquids in constructions joints which are subject to hydrostatic pressure. It is designed for expansion or contraction joint; meanwhile, it can accommodate lateral and transverse movements which make it capable to suit the moving joints.

The PVC waterstop is extruded form an elastomeric plastic material including high grade polyvinyl chloride, special resin and some chemical additives such as plasticizers and stabilizers. The high material makes PVC waterstops unsurpassed with a variety of features and benefits as shown follow.

Features & benefits:

High tensile strength.

Superior elongation capability.

Excellent inherent elasticity and impermeability

High resistance to acids, ozone, seawater even diesel oil.

Extremely alkalis, chlorinated water and other waterborne chemicals resistant.

Not susceptible to fatigue deterioration as with metal or rubber.

High quality meet even exceed the industrials standard.

Never discolor concrete.

No electrolytic action with surrounding metals.

Capable to withstand hydrostatic pressure.

Heat weldable in conjunction with electric splicing irons.

Withstand the expansion and contraction movement of the joints.

Capable to taking care of any deflection or displacement arising caused by temperature changing or differential settlement of foundation.

Supplied in coils for easy handling with high flexibility.

Easy to install by tethering the outer flanges of the PVC waterstop to adjacent a reinforcing bars.

A piece of blue PVC waterstop with center bulb on gray background.

PVCW-02: PVC waterstop with center bulb

A piece of yellow PVC waterstop without center bulb on gray background.

PVCW-03: PVC waterstop without center bulb

Installation:

Four types of methods for easy fixing PVC waterstop including punched flanges, brass eyelets, hog rings and clamps.

PVCW-04: PVC waterstops with punched flanges, grommets, hog rings or clamps for easy installation

In general, the right way of waterstop installation determines the performance in preventing waters and other waterborne chemicals. Any deflection and misalignment should be avoided - that means the best way of installation is to fix the PVC waterstop to the surrounding steel. So for easy installation, three economical methods are provided by our company as shown in the picture:

Punched flanges

Grommets

Hog rings or clamps

Applications:

Ideal for movement joints.

Suitable for above or below grade applications.

Suitable in portable water tank.

Water and sewage treatment facilities.

Liquid retaining structures such as dams, canals water reservoirs, lock and aqueducts.

Tunnels and culverts.

Foundations and basements.

Parking decks, bridge decks and abutments.

Elevator pits, roof and floor slabs.

Primary and secondary containment structures.

A line of blue PVC waterstops are installed surrounding the building foundation.

PVCW-05: PVC waterstops for building foundation constructions.

Yellow PVC waterstops are inserted into the concrete bridge deck.

PVCW-06: PVC waterstops for bridge decks constructions.

Properties:

Physical properties Test methods Minimum value

Water absorption ASTM D-570 15% - 20%

Tear resistance ASTM D-624 300 psi

Specific gravity ASTM D-792 1.38 ± 0.05

Hardness shore A15 ASTM D-2240 79 ± 3

Tensile strength ASTM D-638 Type IV 2000 psi

Ultimate elongation ASTM D-638 Type IV 360%

100% modulus ASTM D-638 Type IV 725 psi

Low temperature brittleness (Tb) °F (°C) ASTM D-746 -35 (-37) passed

Stiffness in Flexure ASTM D-747 600 psi

Ozone Resistance ASTM D-1149 No Failure

Accelerated Extraction, CRD-572

Tensile CDR - C- 572 1850 psi

Elongation CDR - C- 572 350%

Effect of Alkali, CRD-572

Weight Change CRD-572 + 0.25% - 0.1%

Change in Hardness Shore A ASTM D-2240 ± 5 points

Packaging details:

25 meters / roll in all types and sizes

Storage

Store PVC waterstops in shade and dry conditions.

Away from frost, water, moisture and high temperature areas.

Several coils of bue PVC waterstops on the ground.

PVCW-07: Coil Package for easy transportation.

Several coils of PVC waterstops in woven bag package on the ground.

PVCW-08: Woven bag can protect PVC waterstops from moisture and damage.

1 note

·

View note

Text

What is a Pipe Sleeve, and what are the usages of these pipes?

A pipe sleeve is a protective cover for the original pipe, as previously indicated. Numerous materials can be used to make a pipe sleeve, including carbon steel, cast iron, Stainless steel, and copper alloys. Pipe sleeves made of carbon steel are a typical sight. As a result, the main pipe and the area around it are separated. As a result, the heat cycle is unaffected by the use of pipe sleeves. The halfpipe sleeve is ideal for internal and exterior corrosion, gouges, dents, grooves, arc burned, fractures, girth weld defects, lamination, and leaks. Pressure containment sleeves must have all thicknesses necessary for maximum operating pressure or full strength to ensure the pipe's integrity. An existing pipe run needs to penetrate an unfinished wall, and Split pipe Sleeves are the best solution. To center the pipe, a split sleeve is welded or fastened around it during wall installation. Sleeves for Pipes are used in a variety of ways. Pipe sleeves are used in a variety of industries, including the piping sector. Pipe sleeves can be used for a variety of things, including:

If a pipe does not need to be moored in the tank farm region, it is sleeved through the dike or bund wall.

For buried pipes, the mainline can be routed through pipe sleeves to protect it against heavy loads from automobiles and trains while traversing rails, roads, or bridges and culverts.

Additionally, pipe sleeves are a systematic method for ensuring the insulation of pipes.

Industrial and residential structures employ plumbing pipe sleeves.

What is Pipeline Repair Clamps?Pipeline Repair ClampsPressure integrity can be restored by mechanical seals and locks engaging on the sound parent pipe when clamps are fitted on damaged or leaky piping. A Pipe Sleeve's Purpose and Uses: Pipe sleeves can also be used to repair a pipe to avoid expensive shutdowns temporarily. When the thickness of the sleeve pipe is correctly determined, it can be soldered directly over and serve the main pipe's purpose. When a pipeline leak needs to be patched up quickly, pipe sleeves come in handy.Using full encirclement pipe sleeves provides additional support to the parent pipe in the weakest areas of the tube. They are commonly employed during hot tapping procedures, where a branch connection is taken from an active line.

Most commonly, PVC pipe sleeves are utilized in the construction industry to provide cable and electrical solutions.In some cases, pipe sleeve spacers are used to keep the pipe or pipeline in place. Several examples of this type of setup for composite piping systems (such as FRP and GRP) flowing through rail or road crossings. A procedure is known as 'induction bending' is used to bend a straight piece of pipe into a curved shape. As a result, we produce Stainless Steel Induction Bends that are stronger, more uniform in hardness and thickness, and more suited for offshore applications. If you are finding a hot induction bend manufacturer, then You can contact the nearby Pipe Spool manufacturers in India for your desired purpose.

0 notes

Text

Beton Gorong-gorong dan Fungsinya

Gorong gorong memiliki variasi beragam dengan fungsi berbeda-beda. Saluran drainase rata-rata dibangun di dalam bawah tanah, namun juga banyak yang diposisikan pada permukaan tanah. Terowongan air yang dibangun pada permukaan memiliki fungsi sebagai jalur air terbuka, untuk mempermudah benda melewati saluran. Sementara reinforced pipe dipakai ng dibangun di bawah tanah berfungsi untuk saluran air tertutup.

Untuk lebih jelas, mari kita bahas jenis serta manfaatnya di bawah ini.

Jenis Gorong Gorong untuk Drainase

1. Pipa Baja Bergelombang

gorong-gorong pipa biasanya terbuat dari material steel pipe dengan bentuk bergelombang. Fungsinya bukan hanya menjadi jalur air, namun juga akses jalan kendaraan dan manusia.

Terowongan pipa baja memiliki keunggulan pada harganya yang terbilang murah serta proses konstruksinya yang mudah. Daya tahan terowongan terbilang lama, yaitu 25 tahun.

2. Polyvinyl Chlorida

Jenis satu ini diproduksi dari plastik polyvinyl Chlorida atau biasa disingkat PVC. Pemakaiannya dipakai pada area yang sempit serta tak membutuhkan tekanan beban yang besar. Jenis PVC lebih cocok untuk pemukiman warga.

3. Beton

Jenis gorong-gorong satu ini cukup banyak dipakai pada area luas yang memerlukan daya tahan beban yang tinggi. Proses pengerjaan ditempat langsung, tetapi tak sedikit yang juga sudah dalam bentuk precast pabrikan.

Dimensinya mengikuti debit air dan kebutuhan yang perlu ditampung. Terowongan beton mempunyai jenisnya sendiri. Berikut dibawah ini adalah macam-macamnya.

Buis Beton

Terowongan beton adalah jenis yang paling tua di antara tipe-tipe lainnya. Jenis ini kali pertama dikenalkan pada tahun 1984. Sewaktu teknologi canggih ini masih dalam cetak biru, terowongan buis beton dibuat memakai cetakan lingkaran.

Masa kini, bongkahan tersebut dikirim langsung dari pabrik sehingga proses pembangunan menjadi lebih mudahkan. terowongan beton biasanya, dipasang di bawah dengan tekananagak berat, seperti tol atau jalan raya. Selain digunakan untuk saluran air, jenis buis beton dipakai juga sebagai fondasi bangunan, septic tank, sumur resapan dan pengganti pot.

U-Ditch

Gorong-gorong U-Ditch merupakan terowongan beton dengan permukaan terbuka, hingga membentuk seperti huruf U. Ukurannya lebih besar ketimbang buis beton yang digunakan untuk saluran air perumahan atau jalan raya. Jenis satu ini memiliki penutup yang terpisah. Fiturnya memberi kemudahan ketika membuka-tutup saluran beton bila terjadi masalah atau sedang dalam proses pemeriksaan. Bukan itu saja, penutup terpisah memberi kemudahan proses pembersihan.

Box Culvert

Seperti namanya, jenis terowongan memiliki bentuk persegi empat. Materialnya tebal hingga pas dipakai guna menahan beban yang besar. Box culvert mempunyai dua bagian, yaitu spigot dan socket.

Kedua bagian-bagian itu memiliki fungsi meyambung setiap komponen supaya menyatu dengan kuat. Oleh karena tebalnya material, box culvert dapat dibangun di bawah atau juga di atas permukaan tanah. Jenis box culvert dipakai untuk beragam hal, termasuk terowongan kendaraan, saluran air, lorong bawah tanah serta jembatan.

Beton Uditch, Beton Panel, Pagar Beton

0 notes

Photo

Acton Precast Concrete (APC) has been manufacturing septic and holding tanks, transformer vaults and bases, well tiles and lids, parking curbs and barriers, and precast storage sheds in Erin and the surrounding area since 1963.

There are also steel and plastic culverts, PVC pipe and fittings, and corrugated drainage pipe. More information about our company and a complete listing of our product line can be found at actonprecast.com.

For more detail visit our website or call us at 800-461-1516 at any time for more information about our services.

0 notes