#Industrial Gas Generator

Text

Sustainable Power Generation: Renewable Energy Solutions

Total Power Solutions

Kaltimex Energy is a well-known company in Bangladesh that specializes in providing engineering, procurement, and construction (EPC) services, particularly in the energy sector.

Kaltimex Energy Bangladesh is involved in various projects related to power generation, including the installation and maintenance of power plants, electrical and mechanical works, and other energy-related services. They have been involved in the development of both conventional and renewable energy projects in Bangladesh.

Kaltimex Energy has been working in the field of power plant business for over 2 decades. They deal with natural Gas Engine, Industrial Gas Generator, Diesel Generator, Exhaust Gas Boiler, Gas Fired Boiler, Vapor Absorption Machine (Chiller), Thermal Fluid Heater, Transformer, Radial Gas Turbine and Steam Turbine for power plants on turnkey basis projects from concept to commissioning within stipulated time period & budget.

MWM, HTT, VIESSMANN, VOLTAS, ENMAX & MAXWATT, and others are marketed brands.

#Gas Engine#Power Generation#Power Plants#Natural Gas Engine#Industrial Gas Generator#Diesel Generator#Exhaust Gas Boiler#Gas Fired Boiler#Vapor Absorption Machine#Industrial Boiler#Thermal Fluid Heater#Transformer#Radial Gas Turbine#Steam Turbine

4 notes

·

View notes

Text

#i’ve heard this and seaweed/kelp? i think#but also we need to have beef alternatives and just eat less meat in general#but every bit helps#good news#animals#science#meat eating#climate change#meat industry#environmentalism#environment#methane#greenhouse gases#greenhouse gas reduction

58 notes

·

View notes

Note

genuine question, what do you have against induction stovetops? is it just that you have non-magnetic pans?

it's fake heat. it's not fire it's not real it doesn't cook your food. yes i have used them before several times. they are fake

#they like. activate the caveman part of my brain that goes fire. heat. cook food. no fire no cook.#there's a reason the restaurant industry generally uses gas#ask

12 notes

·

View notes

Text

Shoutout to the tobacco corporations for winning at gaslighting

#me#everyone must smoke cigarettes#its good for mens health#its good for womens health#its healthy for children!#its especially good for taking the edge off during a stressful pregnancy#you'll be so fucking cool if you smoked guys!#for like a century they knew it was harmful and they just stuck to their guns and kept blasting us with bullshit#they even dodged perjury by claiming they had no idea#best gaslighters by far#i cant think of many examples that come close#like sure lead gasoline was unthinkabley bad and has impacts on humans still today#but that didnt last for anywhere near as long#side note though a lot of smaller planes still use lead fuel for some reason probably historical accuracy or some excuse#the same guy that invented leaded gasoline also invented freon gas or CFCs#you know the shit they would put in aerosols and royally fucked up the ozone layer for all of humanity for generations#unthinkable the amount of damage to humanity on a global scale this man caused#and all because he wanted to make money#same with the tobacco industry just causing death and decay at every chance they get#it makes me so so sad to think about#sad time

1 note

·

View note

Link

A leading company in the copper wire industry.

#Oil Impregnated Paper#Insulated Instrument Transformers#Outdoor Resin Cast Instrument Transformers#Indoor Resin Cast Instrument#Outdoor oip instrument transformer#Ring Type Current Transformers#Power Transformers#Wind Energy Generator Components#High voltage Transformer#Transformer manufacturers company in India#Switchgear Manufacturers company in India#Electrical Power Industry#Gas Insulated Switchgear#Insulated Condenser Bushings

3 notes

·

View notes

Quote

Amid high temperatures this summer, the increased use of air-conditioning in cities has led to a surge in power demand. With a demand-supply gap for electricity widening through the heat waves, many states are giving preference to residential consumers, imposing longer power cuts in industrial hubs. Many businesses are struggling as piped natural gas is not available while diesel generators are widely banned in order to cut air pollution - leaving factories powerless during outages. "If our machines are idle, our workers are idle and everyone loses," said Anil Bhardwaj, general secretary of the Federation of Indian Micro and Small & Medium Enterprises (FISME). Small firms are finding it especially tough as they lack the power back-up arrangements of bigger manufacturers, he added. While industry groups such as FISME are lobbying for green energy subsidies, they say switching to renewables faces issues from funding and battery capacity to maintaining solar panels. It is not just a matter of energy sources, but also design.

Anuradha Nagaraj, ‘Indian workers suffer as heat waves turn factories into 'furnaces'’, Thomson Reuters Foundation

#Thomson Reuters Foundation#Anuradha Nagaraj#India#heat waves#global warming#climate change#power demand#air-conditioning#demand-supply gap#residential consumers#power cuts#industrial hubs#piped natural gas#diesel generators#Anil Bhardwaj#FISME#Small firms#power back-up#green energy subsidies#renewables#funding#battery capacity#solar panel maintenance#energy sources#design

2 notes

·

View notes

Text

No paywall version here.

"Two and a half years ago, when I was asked to help write the most authoritative report on climate change in the United States, I hesitated...

In the end, I said yes, but reluctantly. Frankly, I was sick of admonishing people about how bad things could get. Scientists have raised the alarm over and over again, and still the temperature rises. Extreme events like heat waves, floods and droughts are becoming more severe and frequent, exactly as we predicted they would. We were proved right. It didn’t seem to matter.

Our report, which was released on Tuesday, contains more dire warnings. There are plenty of new reasons for despair. Thanks to recent scientific advances, we can now link climate change to specific extreme weather disasters, and we have a better understanding of how the feedback loops in the climate system can make warming even worse. We can also now more confidently forecast catastrophic outcomes if global emissions continue on their current trajectory.

But to me, the most surprising new finding in the Fifth National Climate Assessment is this: There has been genuine progress, too.

I’m used to mind-boggling numbers, and there are many of them in this report. Human beings have put about 1.6 trillion tons of carbon in the atmosphere since the Industrial Revolution — more than the weight of every living thing on Earth combined. But as we wrote the report, I learned other, even more mind-boggling numbers. In the last decade, the cost of wind energy has declined by 70 percent and solar has declined 90 percent. Renewables now make up 80 percent of new electricity generation capacity. Our country’s greenhouse gas emissions are falling, even as our G.D.P. and population grow.

In the report, we were tasked with projecting future climate change. We showed what the United States would look like if the world warms by 2 degrees Celsius. It wasn’t a pretty picture: more heat waves, more uncomfortably hot nights, more downpours, more droughts. If greenhouse emissions continue to rise, we could reach that point in the next couple of decades. If they fall a little, maybe we can stave it off until the middle of the century. But our findings also offered a glimmer of hope: If emissions fall dramatically, as the report suggested they could, we may never reach 2 degrees Celsius at all.

For the first time in my career, I felt something strange: optimism.

And that simple realization was enough to convince me that releasing yet another climate report was worthwhile.

Something has changed in the United States, and not just the climate. State, local and tribal governments all around the country have begun to take action. Some politicians now actually campaign on climate change, instead of ignoring or lying about it. Congress passed federal climate legislation — something I’d long regarded as impossible — in 2022 as we turned in the first draft.

[Note: She's talking about the Inflation Reduction Act and the Infrastructure Act, which despite the names were the two biggest climate packages passed in US history. And their passage in mid 2022 was a big turning point: that's when, for the first time in decades, a lot of scientists started looking at the numbers - esp the ones that would come from the IRA's funding - and said "Wait, holy shit, we have an actual chance."]

And while the report stresses the urgency of limiting warming to prevent terrible risks, it has a new message, too: We can do this. We now know how to make the dramatic emissions cuts we’d need to limit warming, and it’s very possible to do this in a way that’s sustainable, healthy and fair.

The conversation has moved on, and the role of scientists has changed. We’re not just warning of danger anymore. We’re showing the way to safety.

I was wrong about those previous reports: They did matter, after all. While climate scientists were warning the world of disaster, a small army of scientists, engineers, policymakers and others were getting to work. These first responders have helped move us toward our climate goals. Our warnings did their job.

To limit global warming, we need many more people to get on board... We need to reach those who haven’t yet been moved by our warnings. I’m not talking about the fossil fuel industry here; nor do I particularly care about winning over the small but noisy group of committed climate deniers. But I believe we can reach the many people whose eyes glaze over when they hear yet another dire warning or see another report like the one we just published.

The reason is that now, we have a better story to tell. The evidence is clear: Responding to climate change will not only create a better world for our children and grandchildren, but it will also make the world better for us right now.

Eliminating the sources of greenhouse gas emissions will make our air and water cleaner, our economy stronger and our quality of life better. It could save hundreds of thousands or even millions of lives across the country through air quality benefits alone. Using land more wisely can both limit climate change and protect biodiversity. Climate change most strongly affects communities that get a raw deal in our society: people with low incomes, people of color, children and the elderly. And climate action can be an opportunity to redress legacies of racism, neglect and injustice.

I could still tell you scary stories about a future ravaged by climate change, and they’d be true, at least on the trajectory we’re currently on. But it’s also true that we have a once-in-human-history chance not only to prevent the worst effects but also to make the world better right now. It would be a shame to squander this opportunity. So I don’t just want to talk about the problems anymore. I want to talk about the solutions. Consider this your last warning from me."

-via New York Times. Opinion essay by leading climate scientist Kate Marvel. November 18, 2023.

#WE CAN DO THIS#I SO TRULY BELIEVE THAT WE CAN DO THIS#WE CAN SAVE OURSELVES AND THE WORLD ALONG WITH US#climate crisis#united states#climate change#conservation#hope posting#sustainability#climate news#climate action#climate emergency#fossil fuels#global warming#environmentalism#climate hope#solarpunk#climate optimism#climate policy#earth#science#climate science#meteorology#extreme weather#renewable energy#solar power#wind power#renewables#carbon emissions#climate justice

33K notes

·

View notes

Text

Anduril Industries soars into the future of warfare, selected for USAF's CCA project

Anduril Industries USAF’s CCA Programme: The US Air Force (USAF) has taken a bold step towards the future of aerial combat with the selection of Anduril, a non-traditional defense company, to participate in the Collaborative Combat Aircraft (CCA) program. Announced on April 24, 2024, this selection marks a significant shift in the defense industry landscape and opens doors for innovative…

View On WordPress

0 notes

Text

Common properties that are must haves in the turbine oil

Oxidation Stability: Oxidation stability is a chemical reaction that occurs with a combination of the lubricant and oxygen. The rate of oxidation is accelerated by high temperatures, water, acids, and catalysts such as copper. The service life of a lubricant reduces with an increase in temperature.

Viscosity Index: The viscosity index (VI) is an arbitrary, unit-less measure of a fluids change in viscosity relative to temperature change. It is mostly used to characterise the viscosity-temperature behaviour of lubricating oils. The higher the VI, the more stable the viscosity remains over temperature fluctuations.

Filterability: Capable of being filtered or separated by filtering.

Low Sludging Formation Tendency: Having low sludge formation tendency.

To know more about sludging, read: https://www.linkedin.com/pulse/what-varnish-its-effects-anshuman-agrawal

We at Minimac study your maintenance needs and provide the best solution. We believe in Discern, Design & Deliver.

Call +91 7030901266 for Mechanical Maintenance & Oil Check.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#chemical cleaning#frf condition systems#oil condition monitoring#electrostatics lube cleaner#oil dehyration#coalescer separator#transformation oil purification#diesel oil purification#oil analysis#oil filters#oil and gas#oil industry#oil#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#power generation#metal#heavy metal#black metal#mining

0 notes

Text

Data Bridge Market Research analyses that the laboratory gas generators market will exhibit a CAGR of around 14.2% for the forecast period of 2021-2028. Growing scope of application of laboratory gas generators, increased focus by the manufacturers on the development of technologies involved in manufacturing of medical devices and rising expenditure on the healthcare infrastructure development especially in the developing economies are the major factors attributable to the growth of laboratory gas generators market. .

The laboratory gas generators are responsible for providing a consistent and regular supply of gases in a laboratory or similar facility. The laboratory gas generators are nothing but a better alternative to gas cylinders. This is because the laboratory gas generators are safe, better in terms of design and infrastructure, require no labour for the transportation of bulky cylinders and take up minimum space.

0 notes

Text

Reading an extremely fascinating paper about the industrialization of the home that talks about the extremely rapid changes to middle-class homes in the pre- and post-WWI era, specifically through the lens of ads in women's magazines

#please feel free to ignore this#Jake meets world#Gas lamps were almost completely replaced by electric lights within like 10 years#It also dismantles this romanticized idea of like the extended family self-sufficient cottage industry#where multiple generations or whatever live in one home and do all the work to keep the household going#and only rarely visit a market or whatever#which I thought was interesting because I feel like that's an extremely common fallacy across political ideologies#There's also just a lot of really cool historical info in this paper#The modern American idea of a bathroom emerged and was completely standardized between WWI and WWII

0 notes

Text

/PRNewswire/ -- Industrial Filtration Market is expected to reach USD 47.1 billion by 2029 from USD 37.1 billion in 2024 at a CAGR of 4.9% during the forecast period according to a new report by MarketsandMarkets™.

#industrial filtration#industrialization#industrial#energy#energia#power generation#utilities#utility#power plant#power plants#industrial wastewater treatment#industrial waste#wastewatertreatment#wastewater treatment#zero waste#waste management#filter press#bag filter#filtration#water filtration#oil and gas industry#enviromental

1 note

·

View note

Text

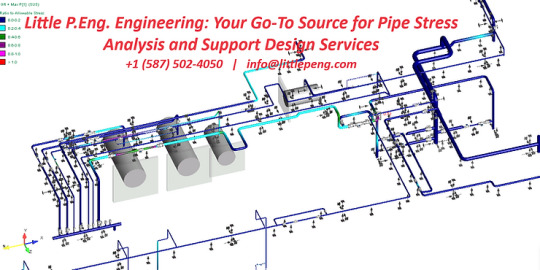

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

In the vast and complex world of engineering, precision and accuracy are paramount. Nowhere is this truer than in the field of piping systems, where even the smallest miscalculation or oversight can lead to catastrophic consequences. To ensure the safe and efficient operation of piping systems, the expertise of specialized engineers is required. This is where Little P.Eng. Engineering comes into play. With a reputation for excellence and a commitment to providing top-notch pipe stress analysis and support design services, Little P.Eng. Engineering stands as a trusted partner for industries that rely on flawless piping systems.

In this comprehensive guide, we will delve into the world of pipe stress analysis and support design services offered by Little P.Eng. Engineering. We will explore the importance of these services, their role in various industries, and how Little P.Eng. Engineering excels in delivering tailored solutions. Additionally, we will discuss the key factors that set Little P.Eng. Engineering apart from the competition and provide valuable insights into their commitment to safety, quality, and customer satisfaction.

Chapter 1: Understanding Pipe Stress Analysis

1.1 What is Pipe Stress Analysis?

Pipe stress analysis is a critical component of engineering that involves evaluating the forces and stresses acting on a piping system to ensure its structural integrity and safety. It plays a pivotal role in various industries, including petrochemical, oil and gas, power generation, and more. Pipe stress analysis helps engineers identify potential issues such as excessive strain, deformation, or failure that could compromise the functionality and safety of the system.

1.2 The Importance of Pipe Stress Analysis

The significance of pipe stress analysis cannot be overstated. Failing to perform adequate stress analysis can lead to a range of problems, including:

1.2.1 Safety Risks: Inadequate pipe stress analysis can result in ruptures, leaks, and catastrophic failures, endangering human lives and the environment.

1.2.2 Cost Overruns: Repairs and maintenance due to unforeseen issues can lead to substantial cost overruns in construction and operation projects.

1.2.3 Downtime: Unscheduled downtime can disrupt operations, leading to production losses and revenue reduction.

1.2.4 Legal and Regulatory Issues: Non-compliance with safety standards and regulations can result in legal and financial repercussions.

1.2.5 Reputation Damage: Incidents related to piping system failures can tarnish a company's reputation.

Chapter 2: The Role of Pipe Stress Analysis in Different Industries

2.1 Oil and Gas Industry

The oil and gas industry relies heavily on complex piping systems to transport hydrocarbons from extraction sites to refineries and end-users. Pipe stress analysis is crucial in this industry to prevent leaks, ruptures, and environmental disasters. Little P.Eng. Engineering provides specialized services tailored to the unique challenges of the oil and gas sector.

2.2 Petrochemical Industry

Petrochemical plants process raw materials into valuable chemical products. The precise and safe transport of chemicals through piping systems is essential. Pipe stress analysis ensures the structural integrity of these systems, mitigating the risk of chemical leaks and ensuring worker safety.

2.3 Power Generation

Power plants, whether they run on fossil fuels, nuclear energy, or renewable sources, require intricate piping networks to deliver steam, water, and gases to turbines and generators. Pipe stress analysis is vital to prevent system failures and maintain uninterrupted power generation.

2.4 Pharmaceutical and Food Industries

In industries where product purity and safety are paramount, such as pharmaceuticals and food production, pipe stress analysis ensures the integrity of sanitary piping systems. Little P.Eng. Engineering's expertise extends to designing hygienic piping solutions that meet the strictest standards.

2.5 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial and industrial buildings rely on complex piping networks. Proper stress analysis ensures the efficient functioning of HVAC systems, contributing to comfort and energy efficiency.

Chapter 3: Little P.Eng. Engineering's Pipe Stress Analysis Services

3.1 Expertise and Experience

Little P.Eng. Engineering boasts a team of highly skilled and experienced engineers with a deep understanding of the complexities involved in pipe stress analysis. Their expertise spans various industries, ensuring that clients receive tailored solutions that align with their specific needs and challenges.

3.2 Advanced Technology and Software

Staying at the forefront of technological advancements is crucial in the engineering field. Little P.Eng. Engineering utilizes state-of-the-art software and tools for pipe stress analysis, enabling precise simulations and evaluations. This ensures the accuracy and reliability of their services.

3.3 Customized Solutions

One of the key strengths of Little P.Eng. Engineering is their ability to provide customized solutions. They understand that each project is unique and may have distinct requirements. By tailoring their services to individual client needs, they ensure optimal results and client satisfaction.

3.4 Compliance with Industry Standards

Compliance with industry standards and regulations is non-negotiable in the world of engineering. Little P.Eng. Engineering ensures that all their pipe stress analysis services meet or exceed relevant industry standards, codes, and safety guidelines.

Chapter 4: Pipe Support Design Services

4.1 What is Pipe Support Design?

Pipe support design is an integral part of piping system engineering. It involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibration, and stress. Proper support design ensures the longevity and stability of piping systems.

4.2 Importance of Pipe Support Design

Inadequate or improperly designed supports can lead to several problems, including:

4.2.1 Excessive Stress: Unsupported piping can experience undue stress, leading to damage and failure.

4.2.2 Vibrations: Vibrations can affect the performance of piping systems and nearby equipment.

4.2.3 Misalignment: Improper alignment can cause leaks and inefficiencies.

4.2.4 Premature Wear: Unsupported piping can wear out faster, leading to maintenance and replacement costs.

4.3 Little P.Eng. Engineering's Pipe Support Design Services

Little P.Eng. Engineering offers comprehensive pipe support design services to ensure that piping systems are adequately supported and stable. Their services include:

4.3.1 Structural Analysis: Evaluating the structural integrity of supports and ensuring they meet safety and code requirements.

4.3.2 Custom Designs: Tailoring support solutions to the unique needs of each project.

4.3.3 Material Selection: Recommending suitable materials for support components, considering factors like corrosion resistance and load-bearing capacity.

4.3.4 Installation Guidance: Providing guidance and recommendations for the proper installation of supports.

Chapter 5: What Sets Little P.Eng. Engineering Apart

5.1 Commitment to Safety

Safety is Little P.Eng. Engineering's top priority. Their pipe stress analysis and support design services are driven by a commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

5.2 Quality Assurance

Quality is woven into the fabric of Little P.Eng. Engineering's services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

5.3 Timely and Efficient Service

Time is often of the essence in engineering projects. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality.

5.4 Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process.

5.5 Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members.

Chapter 6: Case Studies and Success Stories

6.1 Case Study 1: Oil Refinery Piping

A major oil refinery faced ongoing issues with leaks and failures in its piping system, resulting in costly downtime and environmental concerns. Little P.Eng. Engineering conducted a comprehensive pipe stress analysis and identified critical stress points. They then designed and implemented reinforced supports and provided guidance on material selection. The result was a significant reduction in incidents, ensuring safe and uninterrupted operations.

6.2 Case Study 2: Pharmaceutical Facility

A pharmaceutical company needed to upgrade its piping system to comply with stringent FDA regulations. Little P.Eng. Engineering provided customized pipe stress analysis and support design services to ensure compliance with hygienic standards. The project was completed successfully, allowing the company to maintain product integrity and regulatory compliance.

6.3 Case Study 3: Power Plant Efficiency

A power plant was experiencing inefficiencies in its piping system, resulting in reduced energy output. Little P.Eng. Engineering conducted a detailed pipe stress analysis and identified areas of improvement. They designed and implemented optimized supports, resulting in increased energy efficiency and cost savings.

Chapter 7: Conclusion

In conclusion, Little P.Eng. Engineering stands as a premier provider of pipe stress analysis and support design services, catering to various industries where the integrity and safety of piping systems are of utmost importance. Their commitment to safety, quality, client satisfaction, and continuous improvement sets them apart as a trusted partner in the world of engineering.

Whether you operate in the oil and gas, petrochemical, power generation, pharmaceutical, or HVAC sector, Little P.Eng. Engineering has the expertise and experience to deliver customized solutions that meet your unique needs. By prioritizing safety, adhering to industry standards, and consistently providing timely and efficient services, Little P.Eng. Engineering has earned its reputation as a leader in the field of pipe stress analysis and support design.

Little P.Eng. Engineering: Your Go-To Source for Pipe Stress Analysis and Support Design Services

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Pipe Stress Analysis

Little P.Eng. Engineering

Finite Element Analysis

Structural Integrity

Engineering Expertise

Thermal Expansion

Support Design Services

Oil and Gas

ASME Codes

Industry Standards

Power Generation

Stress Evaluation

Piping Systems

Safety and Compliance

Engineering Solutions

Precision Analysis

Industrial Processes

Petrochemical

Seismic Analysis

Customized Solutions

Pressure Analysis

Pipe Support Design

Safety Regulations

Reliability Assurance

Complex Piping Systems

Chemical Industry

Pharmaceutical Industry

Vibrations Analysis

Stress Distribution

Pipe Failure Prevention

Pipe Stress Analysis Services

Engineering Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Pipe Stress Analysis#Little P.Eng. Engineering#Finite Element Analysis#Structural Integrity#Engineering Expertise#Thermal Expansion#Support Design Services#Oil and Gas#ASME Codes#Industry Standards#Power Generation#Stress Evaluation#Piping Systems#Safety and Compliance#Engineering Solutions#Precision Analysis#Industrial Processes#Petrochemical#Seismic Analysis#Customized Solutions#Pressure Analysis#Pipe Support Design#Safety Regulations#Reliability Assurance#Complex Piping Systems#Chemical Industry#Pharmaceutical Industry#Vibrations Analysis#Stress Distribution

0 notes

Text

Innovations in Compressed Air Nitrogen Gas Generator Technology: What's New?

In the ever-evolving landscape of industrial innovation, compressed air nitrogen gas generator technology stands out as a pivotal player, revolutionizing various sectors with efficiency and sustainability. With Trident Pneumatics leading the charge, let’s delve into the latest advancements shaping the future of nitrogen gas generator systems.

Nitrogen gas, an essential component in numerous industrial processes, was traditionally sourced through cumbersome methods like nitrogen cylinders or liquid nitrogen tanks. However, the advent of compressed air nitrogen gas generators has transformed this landscape, offering a more convenient, cost-effective, and environmentally friendly solution.

Trident Pneumatics has been at the forefront of enhancing the efficiency of nitrogen gas generation systems. Their innovative designs leverage compressed air to produce high-purity nitrogen on demand, eliminating the need for bulk storage and frequent cylinder replacements. This streamlines operations and minimizes downtime, ensuring uninterrupted workflow continuity.

One of the key areas of innovation lies in precision engineering, where Trident Pneumatics has continuously pushed boundaries. Advanced filtration systems coupled with state-of-the-art membrane technology ensure nitrogen gas delivery at precise purity levels tailored to meet the specific requirements of diverse industries, from food packaging to electronics manufacturing.

Incorporating Internet of Things (IoT) capabilities, Trident’s nitrogen gas generator systems now offer remote monitoring and control functionalities. Operators can seamlessly monitor nitrogen production, adjust settings, and receive real-time alerts, empowering them with greater operational visibility and control, even remotely. This enhances operational efficiency and enables proactive maintenance, preventing potential downtimes.

Recognizing the diverse needs of different industries, Trident offers customizable nitrogen gas generator solutions tailored to specific applications. Whether meeting stringent purity requirements in pharmaceutical manufacturing or providing an inert atmosphere in chemical processes, their versatile systems can be fine-tuned to deliver optimal performance across a wide spectrum of use cases.

As technology advances, the future of compressed air nitrogen gas generators looks promising. Trident Pneumatics remains committed to driving innovation in this space, exploring avenues such as artificial intelligence for predictive maintenance, enhanced energy efficiency through regenerative systems, and integration with renewable energy sources for a greener footprint.

Safety is paramount in industrial environments, and Trident Pneumatics understands this well. Their nitrogen gas generator systems have enhanced safety features, including automatic shutdown mechanisms in case of pressure fluctuations or system malfunctions. Moreover, built-in sensors continuously monitor gas levels, ensuring compliance with safety standards and minimizing risks of accidents or leaks.

Innovation isn’t just about technology; it’s also about improving the overall user experience. Trident’s nitrogen gas generator systems are designed for streamlined installation and maintenance, reducing downtime associated with setup and servicing. Modular designs and user-friendly interfaces simplify installation procedures, while predictive maintenance algorithms help anticipate potential issues before they escalate, further enhancing reliability and uptime.

In the era of Industry 4.0, connectivity and data-driven insights are indispensable. Trident Pneumatics integrates its nitrogen gas generator systems seamlessly into Industry 4.0 frameworks, enabling data exchange with other smart devices and systems. This facilitates holistic process optimization, where nitrogen generation parameters can be dynamically adjusted based on real-time production demands or quality control requirements, maximizing efficiency and resource utilization.

Trident Pneumatics fosters a collaborative innovation ecosystem, engaging with industry partners, research institutions, and customers to drive continuous improvement and address evolving market needs. By leveraging collective expertise and insights, they remain agile in responding to emerging challenges and opportunities, ensuring that their nitrogen gas generator technology remains at the forefront of industry standards and best practices.

In conclusion, the evolution of compressed air nitrogen gas generator technology represents a significant leap forward in industrial gas generation. With Trident Pneumatics leading the charge, the landscape has witnessed remarkable efficiency, precision, sustainability, safety, and connectivity advancements. As we look towards the future, the continued innovation in this field promises to redefine industrial processes, driving towards greater efficiency, sustainability, safety, and operational excellence.

#nitrogen generator manufacturers#industrial nitrogen generator#compressed air nitrogen gas generator

0 notes

Text

Europe Gas Generator Market Growth, Trends, Demand, Industry Share, Challenges, Future Opportunities and Competitive Analysis 2033: SPER Market Research

The Europe Gas Generator Market encompasses the production, distribution, and utilization of gas-powered generators across European countries. With increasing concerns about energy security, environmental sustainability, and power reliability, the demand for gas generators is rising. Key drivers include the transition to cleaner energy sources, infrastructure development, and backup power requirements. Additionally, advancements in gas generator technology, such as improved efficiency and reduced emissions, contribute to market growth. Key players focus on innovation, product differentiation, and service quality to meet the diverse needs of customers and capitalize on market opportunities in Europe.

#Europe Gas Generator Market#Europe Gas Generator Market Challenges#Europe Gas Generator Market Competition#Europe Gas Generator Market Demand#Europe Gas Generator Market Future Outlook#Europe Gas Generator Market Growth#Europe Gas Generator Market Report#Europe Gas Generator Market Revenue#Europe Gas Generator Market Segmentation#Europe Gas Generator Market Share#Europe Gas Generator Market Size#Europe Gas Generator Market Trends#Europe Hydrogen Gas Generator Market#Europe Industrial Gas Generator Market#Europe Laboratory Gas Generators Market#Europe Large Generator Market#Europe Natural Gas Generator Market#Europe Natural Gas Generator Market Forecast#Europe Natural Gas Generator Market Opportunities#Europe Power Generator Market#Europe Residential Gas Generator Market#Gas Generator Market

0 notes

Text

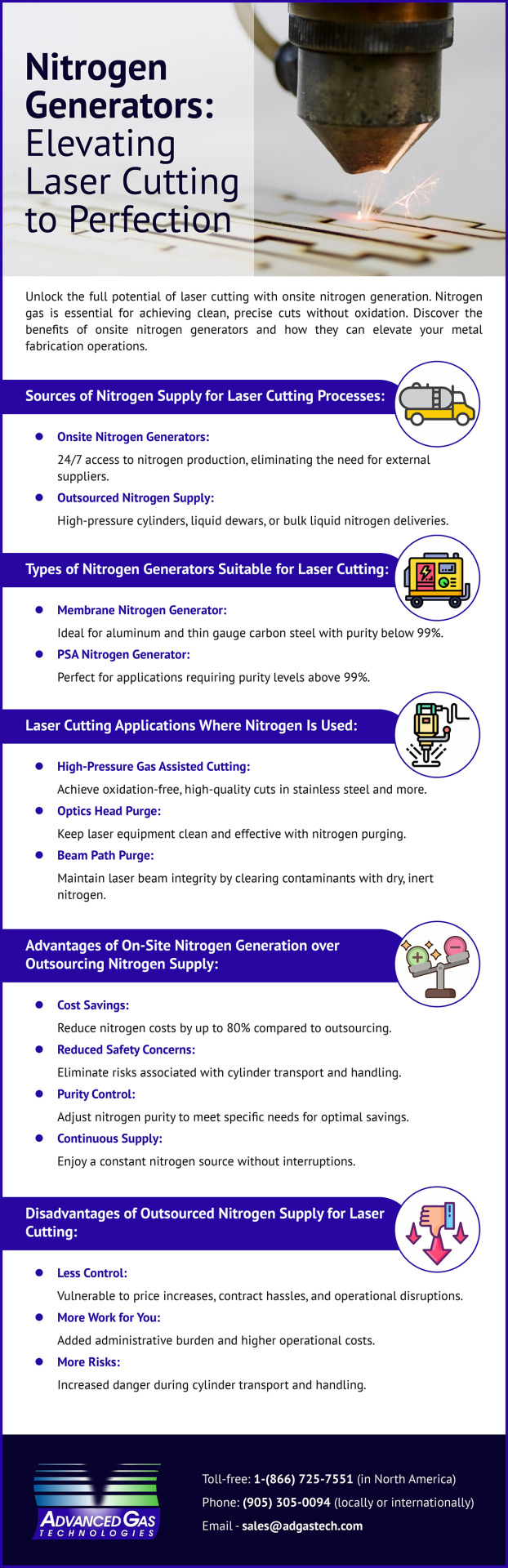

Unlock the full potential of laser cutting with onsite nitrogen generation. Nitrogen gas is essential for achieving clean, precise cuts without oxidation. Discover the benefits of onsite nitrogen generators and how they can elevate your metal fabrication operations. Learn more at https://adgastech.com/

#Nitrogen gas#nitrogen gas for mining industry#nitrogen gas generator#Nitrogen generators#nitrogen generating systems#onsite nitrogen generation

0 notes