#textile company

Text

Master the Art of Analyzing Textile Companies | Quest

Unlock the potential of the textile industry with the course "How to Analyze Textile Companies?" on Quest. Discover the current scenario, competitive positioning, and opportunities in PLI & textile parks. Join expert CA Divam Sharma to gain invaluable insights and learn the strategies to analyze and understand the nuances of the Indian textile and apparel companies. Start your learning journey now with PDFs, flashcards, assessments, and earn a certificate. Explore the immense employment and growth potential of the second-largest textile industry in the world after China. Don't miss out - enroll today!

0 notes

Text

A Tapestry of Change: Unveiling Dynamics in the Textile Industry

The textile industry, a colossal presence in the global market, is currently undergoing a transformative journey, navigating through a mosaic of challenges and innovative trends. As of 2024, the industry's valuation stands at an estimated USD 748 billion, poised to ascend to USD 889.24 billion by 2029, showcasing a robust and consistent growth rate of 3.52% annually. However, this trajectory has not been without hurdles, especially considering the disruptions brought about by the seismic impact of the COVID-19 pandemic.

COVID-19 Impact: Crafting Resilience Amidst Turbulence

In the tumultuous year of 2020, the textile industry faced unprecedented challenges in the wake of the global pandemic. Asia, a linchpin in the textile market, bore the brunt of prolonged lockdowns and a sudden plummet in international demand. The International Labour Organization (ILO) reported a staggering collapse in global textile trade during the first half of 2020, with exports to major regions such as the European Union, the United States, and Japan plunging by approximately 70%. Further complicating matters, the industry grappled with disruptions in the supply chain, notably facing shortages of critical raw materials, including cotton.

Key Players: Anchors in a Dynamic Landscape

In the intricate tapestry of the textile industry, four major players emerge as key anchors: China, the European Union, the United States, and India.

China: Undoubtedly, China stands as the preeminent global producer and exporter of both raw textiles and garments. Its robust industry infrastructure positions it as an undisputed force in the market.

United States: Holding sway in raw cotton production and export, the United States claims the title of the leading importer of raw textiles and garments.

European Union: Comprising economic powerhouses like Germany, Spain, France, Italy, and Portugal, the EU commands a substantial share, contributing over one-fifth to the global textile industry.

India: Emerging as the third-largest textile manufacturing industry globally, India shoulders over 6% of the total textile production, adding a dynamic touch to the industry's landscape.

Market Trends: Riding the Crest of Transformation

1. Increasing Demand for Natural Fibers

Natural fibers, including cotton, silk, linen, wool, hemp, jute, and cashmere, are currently enjoying a surge in demand. Renowned for their strength and lightness, these fibers find diverse applications in garments, apparel, construction materials, medical dressings, and even automobile interiors.

Global Impact: The abundance of natural fibers, particularly cotton, in countries like China, India, and the United States, acts as a propellant, steering the global textile market toward unprecedented growth.

Versatility: Silk, valued for its finesse, graces upholstery and apparel. Meanwhile, wool and jute, celebrated for their resilience, elasticity, and softness, emerge as quintessential textile materials.

Consumer Preference: The increasing consumption of natural fibers is expected to act as a catalyst, propelling the global textile market forward throughout the forecast period.

2. Shifting Focus Toward Non-woven Fabrics

The textile industry is witnessing a deliberate shift toward non-woven fabrics, driven by evolving demographics and changing consumer preferences.

Demand Drivers: The burgeoning demand for hygiene products, such as baby diapers, sanitary napkins, and adult incontinence products, is fueling the need for non-woven fabrics.

Applications: Nonwovens, extending beyond personal care products, are making significant inroads in road construction as geotextiles, bolstering the durability of roads. In the automobile industry, non-woven fabrics are increasingly employed for both exterior and interior parts due to their inherent durability.

Market Growth: A positive outlook in the automobile and transportation industry, coupled with the cost-effectiveness of nonwovens, is expected to propel substantial growth in this segment.

The Road Ahead: Opportunities and Challenges

The textile industry stands on the precipice of a transformative era, driven by factors such as rapid industrialization and the relentless evolution of technology.

Rapid Industrialization: Both developed and developing nations are experiencing a whirlwind of industrialization, playing a pivotal role in modernizing textile industry installations, fostering higher efficiency, and augmenting revenues.

Technological Evolution: Recent innovations in textile technology assume a pivotal role in shaping the industry's future. The adoption of advanced technologies is anticipated to further elevate the efficiency and capabilities of textile production.

Conclusion: Navigating Change with Innovation

As the textile industry threads its way through challenges, it is the innovative trends that paint a promising tableau for the future. The resilience displayed in the face of the COVID-19 pandemic, coupled with a strategic focus on natural fibers and non-woven fabrics, vividly demonstrates the industry's adaptability.

The collaborative efforts of major players like China, the European Union, the United States, and India form the warp and weft of the global textile landscape. With a keen eye on sustainability, versatility, and technological advancements, the textile industry stands poised not only to overcome present challenges but also to emerge as a dynamic force in the years to come.

#textile industry#textile sector#textile industry analysis#textile stocks#textile stocks in india#textile industry in india Textile#textile company#cotton industry in india#indian textiles#top textile companies in india

0 notes

Text

Textile Company in India - Tridentindia

Tridentindia is one of the leading textile company in India. Our objective is to provide superior quality fabrics to the clients and give the highest level of comfort and durability. To know more details, visit the website.

0 notes

Text

[T]he Dutch Republic, like its successor the Kingdom of the Netherlands, [...] throughout the early modern period had an advanced maritime [trading, exports] and (financial) service [banking, insurance] sector. Moreover, Dutch involvement in Atlantic slavery stretched over two and a half centuries. [...] Carefully estimating the scope of all the activities involved in moving, processing and retailing the goods derived from the forced labour performed by the enslaved in the Atlantic world [...] [shows] more clearly in what ways the gains from slavery percolated through the Dutch economy. [...] [This web] connected them [...] to the enslaved in Suriname and other Dutch colonies, as well as in non-Dutch colonies such as Saint Domingue [Haiti], which was one of the main suppliers of slave-produced goods to the Dutch economy until the enslaved revolted in 1791 and brought an end to the trade. [...] A significant part of the eighteenth-century Dutch elite was actively engaged in financing, insuring, organising and enabling the slave system, and drew much wealth from it. [...] [A] staggering 19% (expressed in value) of the Dutch Republic's trade in 1770 consisted of Atlantic slave-produced goods such as sugar, coffee, or indigo [...].

---

One point that deserves considerable emphasis is that [this slave-based Dutch wealth] [...] did not just depend on the increasing output of the Dutch Atlantic slave colonies. By 1770, the Dutch imported over fl.8 million worth of sugar and coffee from French ports. [...] [T]hese [...] routes successfully linked the Dutch trade sector to the massive expansion of slavery in Saint Domingue [the French colony of Haiti], which continued until the early 1790s when the revolution of the enslaved on the French part of that island ended slavery.

Before that time, Dutch sugar mills processed tens of millions of pounds of sugar from the French Caribbean, which were then exported over the Rhine and through the Sound to the German and Eastern European ‘slavery hinterlands’.

---

Coffee and indigo flowed through the Dutch Republic via the same trans-imperial routes, while the Dutch also imported tobacco produced by slaves in the British colonies, [and] gold and tobacco produced [by slaves] in Brazil [...]. The value of all the different components of slave-based trade combined amounted to a sum of fl.57.3 million, more than 23% of all the Dutch trade in 1770. [...] However, trade statistics alone cannot answer the question about the weight of this sector within the economy. [...] 1770 was a peak year for the issuing of new plantation loans [...] [T]he main processing industry that was fully based on slave-produced goods was the Holland-based sugar industry [...]. It has been estimated that in 1770 Amsterdam alone housed 110 refineries, out of a total of 150 refineries in the province of Holland. These processed approximately 50 million pounds of raw sugar per year, employing over 4,000 workers. [...] [I]n the four decades from 1738 to 1779, the slave-based contribution to GDP alone grew by fl.20.5 million, thus contributing almost 40% of all growth generated in the economy of Holland in this period. [...]

---

These [slave-based Dutch commodity] chains ran from [the plantation itself, through maritime trade, through commodity processing sites like sugar refineries, through export of these goods] [...] and from there to European metropoles and hinterlands that in the eighteenth century became mass consumers of slave-produced goods such as sugar and coffee. These chains tied the Dutch economy to slave-based production in Suriname and other Dutch colonies, but also to the plantation complexes of other European powers, most crucially the French in Saint Domingue [Haiti], as the Dutch became major importers and processers of French coffee and sugar that they then redistributed to Northern and Central Europe. [...]

The explosive growth of production on slave plantations in the Dutch Guianas, combined with the international boom in coffee and sugar consumption, ensured that consistently high proportions (19% in 1770) of commodities entering and exiting Dutch harbors were produced on Atlantic slave plantations. [...] The Dutch economy profited from this Atlantic boom both as direct supplier of slave-produced goods [from slave plantations in the Dutch Guianas, from Dutch processing of sugar from slave plantations in French Haiti] and as intermediary [physically exporting sugar and coffee] between the Atlantic slave complexes of other European powers and the Northern and Central European hinterland.

---

Text above by: Pepijn Brandon and Ulbe Bosma. "Slavery and the Dutch economy, 1750-1800". Slavery & Abolition Volume 42, Issue 1. 2021. [Text within brackets added by me for clarity. Bold emphasis and some paragraph breaks/contractions added by me. Presented here for commentary, teaching, criticism purposes.]

#abolition#these authors lead by pointing out there is general lack of discussion on which metrics or data to use to demonstrate#extent of slaverys contribution to dutch metropolitan wealth when compared to extensive research#on how british slavery profits established infrastructure textiles banking and industrialisation at home domestically in england#so that rather than only considering direct blatant dutch slavery in guiana caribbean etc must also look at metropolitan business in europe#in this same issue another similar article looks at specifically dutch exporting of slave based coffee#and the previously unheralded importance of the dutch export businesses to establishing coffee mass consumption in europe#via shipment to germany#which ties the expansion of french haiti slavery to dutch businesses acting as intermediary by popularizing coffee in europe#which invokes the concept mentioned here as slavery hinterlands#and this just atlantic lets not forget dutch wealth from east india company and cinnamon and srilanka etc#and then in following decades the immense dutch wealth and power in java

24 notes

·

View notes

Text

Periods are probably more likely to be irregular in the wasteland due to radiation and the various levels of food insecurity and S T R E S S.

But I wonder if everyone's just free bleeding or if they've reinvented pads.

Cause like depending on where you are you don't wanna waste clean water on cleaning reusable pads. But at the same time I can not IMAGINE the sort of wasteland fuck off diseases and mutations that'd result from pads cleaned with dirty AND irradiated water with who fucking knows trace amounts of FEV floating in it with the microplastics

#blogging#fallout#This is how you get WVD.#Wasteland Vagina Dentata.#Like you could make reuseable pads from whatever the sheep mutated into and maybe there's plenty of plants to be made into fabric.#But that then goes into post-post-apocolypse textile development which is a whole nother story.#You know pre-war companies weren't spending too much on new period product developments.#At least ones that weren't profitable.#PRe-War was somewhat more egalitarian than our current time so idk they probably started using something thicker than water to test pads.

8 notes

·

View notes

Text

i was talking on discord about kiibo wearing sweaters and joked about him learning to knit or crochet to make his own bc i think that would be silly and he'd enjoy it AND I WAS REMINDED by a friend of the fact that crochet can't be replicated by machines and now i'm sooooo soft about this hc oh my god

kiibo taking up a hobby postgame that gives him something to do during those long quiet nights when everyone else is sleeping... he is all about learning and doing stuff and crochet is so methodical.... he hangs out with kaito or himiko to crochet together, makes a blanket for kaede and shuichi and they're like "hey um this is your blanket too.... <3"

a hobby that only human hands can do but here he is... and sure it's because he's a robot with human-shaped hands but it's still something he's doing because he wants to

#q#meows#top 10 fics i would write#me when kiibo postgame is more than tdr's tool and gets to explore his own humanity waaaaaaaaa#he's important to me..................#thank u james btw...... your mind#i was gonna mention maybe he listens to kiyo talk abt textile arts but#my postgame hcs for kiyo are different every time jfhdjf and complicated#i think.... would he still enjoy anthropology now that the interest has been beamed into his head. yes#and would kiibo enjoy his company...... i think so. even if it's contentious around some of the others#would kiyo wanna hang out with anyone and would they accept him as one of the group. probably yes but my thoughts are complex#so idk. too insecure about my lack of good headcanons to put it in the body of the post LMFAO#but i think kiibo and kiyo could be funny friends i just feel like they would vibe. i can see them postgame hanging out

5 notes

·

View notes

Text

(okay the crotch sashiko post is making me a little insane bc like. huge love and respect for visible mending but i gotta say i would Not personally wear a pair of pants out in public ft. a swathe of bright yellow Xs drawing onlookers' attention to my groin unless i really and truly had no other option????)

#like maybe some ppl DO feel totally unfazed by that prospect‚ and more power to you if that's you#but it just seems like there's a wide range of possible approaches btwn 'do a bright yellow crotch repair' and 'buy brand new pants'?#and suggesting that ppl‚ say‚ thrift a replacement pair instead of buying brand new ones#or alternatively buy from companies who are working to reduce how much water it takes to produce their denim#(and hang onto the old denim to use for patching future rips in less sensitive areas)#seems like it might be a more plausible approach#for ppl who are trying to mitigate their environmental impact but also‚ you know‚ exist in the ordinary social world#(i mean clearly the BEST approach = 'be tumblr user fourpatch & deploy yr astonishing textile wizardry to produce genuinely subtle mends')#(but like. we cannot all be 4p‚ alas)#anyway. hashtag normieposting i realize#but it just seems 2 me like. probably there are ppl out there who would like to be less wasteful but aren't ready to become full-on hippies#and like probably it would be more useful to present those people with paths that feel possible for them#than to be like 'actually you can totally become a full-on hippie‚ it's great and i recommend it!!'#like. true! but. ¯\_ (ツ)_/¯

8 notes

·

View notes

Text

For a really long time now, I’ve wanted historical silk stockings, because they’re just *so fucking cool*.

Most people probably think of either drab brown and grey wool stockings or plain white silk stockings when they think of Olde Tyme Sokks™️. In reality, they used to be made in all kinds of colors, materials, lengths, so on and so forth.

Those cherry print stockings are from the 1870s!

The elaborate embroidery at the ankles was were known as clocks or clocking, and originally was functional. It helped reinforce the seams of the ankle gussets back when stockings were seamed and not knit in the round. Later on the embroidery took on a purely decorative purpose, sometimes even being replaced by lace inserts:

The really fun thing is that for a long time, beautifully decorated stockings were totally gender neutral. Men embraced floral embroidery and lace and bright colors and wore heels to show off their (appropriately stockinged) ankles and calves. And since shorter breeches were in style for quite a long time before giving way to trousers as we know them today, men had way more real estate for showing off their socks.

What’s even more amazing is that the knitting machine was invented in 1589. No, that’s not a typo. You read that right. In the 16th fucking century, William Lee invented the first knitting machine for the express purpose of knitting stockings. The knitting machine was literally invented two and a half centuries before the first commercial sewing machine.

Really puts in perspective what human hands are capable of, huh?

#pancake talks textiles#yes this is a lead up to *another* project announcement#blame the adhd#machines still have not fully replace hand sewing by the way#like in an industrial context#there are some things machines still simply cannot do#it is my honest opinion that it will never be feasible to fully replace human handsewing in certain industries#much as some companies may try#the problem of course is that the engineers aren’t doing the sewing so they don’t Understand

24 notes

·

View notes

Text

Navigating the Threads of Change: Sustainable Textile Practices Transforming the Fashion Industry

In an era of heightened environmental awareness, the textile industry is undergoing a profound transformation, driven by a growing commitment to sustainability. These practices might get started right from the design process. In this article, you’ll learn about some of the practices that are changing the textile industry trends and can bring a revolutionary change.

||Re-thinking Raw Materials: A Shift towards Eco-Friendly Choices||

At the heart of sustainable textile practices lies a re-evaluation of materials used in the production process. Traditional textiles often rely on resource-intensive materials such as conventional cotton, which is notorious for its heavy use of pesticides and water.

Sustainable alternatives, for example, organic cotton, bamboo, and hemp, have emerged as eco-friendly options that minimize the environmental impact. Organic cotton, for instance, is grown without the use of synthetic pesticides or fertilizers, promoting soil health and reducing harm to nearby ecosystems.

||Recycled Materials: Closing the Loop and Reducing Waste||

One noteworthy development in sustainable practices is the rise of recycled materials. Post-consumer waste, including discarded plasticized objects and other textile scraps, is being repurposed to create new products. This not only diverts waste from landfills but also mitigates the demand for new materials, contributing to a more circular and sustainable system.

||Slow Fashion: A Counterbalance to Fast Fashion's Disposable Culture||

Furthermore, these sustainable initiatives are closely tied to the concept of slow fashion. This movement advocates for a shift away from the fast-paced, disposable nature of the industry, encouraging consumers to invest in high-quality, timeless pieces that endure through seasons.

||Revolutionizing Manufacturing: Waterless Dyeing and Plant-Based Alternatives||

Beyond the choice of raw materials, these practices extend to the manufacturing processes employed by many best textile industries. The conventional dyeing and finishing of textiles involve the use of numerous harmful chemicals that not only pose risks to the environment but also to the workers involved in the production process. Therefore, the use of natural alternatives can change the whole scenario of attaining sustainability.

||Current scenario towards sustainability||

Major fashion brands are recognizing the importance of sustainability and are following these principles into their business models. From creating sustainable materials into their collections to adopting transparent and ethical supply chain practices, these top textile companies are driving positive change within the industry.

Yet, the shift towards sustainable textile practices is not without its challenges. The initial costs associated with sustainable materials and processes can be higher, posing financial obstacles for some manufacturers. However, as consumer demand for eco-friendly products continues to rise, economies of scale and increased innovation are expected to drive costs down, making sustainability practices more accessible for all.

||Conclusion||

In conclusion, sustainable textile practices are setting a new narrative for the industry, one that prioritizes environmental stewardship, ethical practices, and long-term viability. The threads of change are being woven into the fabric of fashion, stitching together a more sustainable and conscious future for all.

#textile industry#textile shop near me#textile#textile company in panipat#textile industry in panipat#textile mills in panipat

2 notes

·

View notes

Text

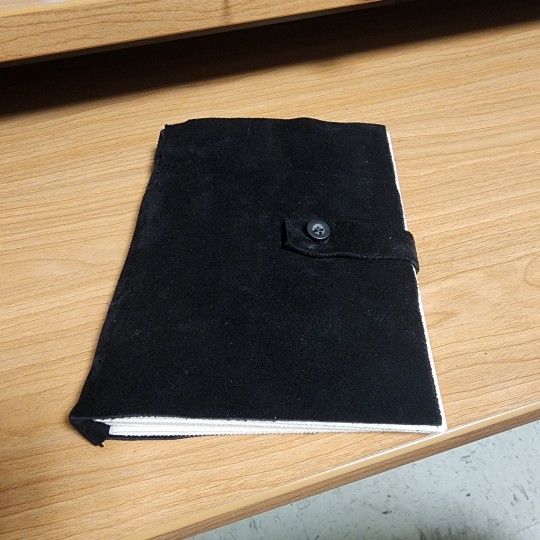

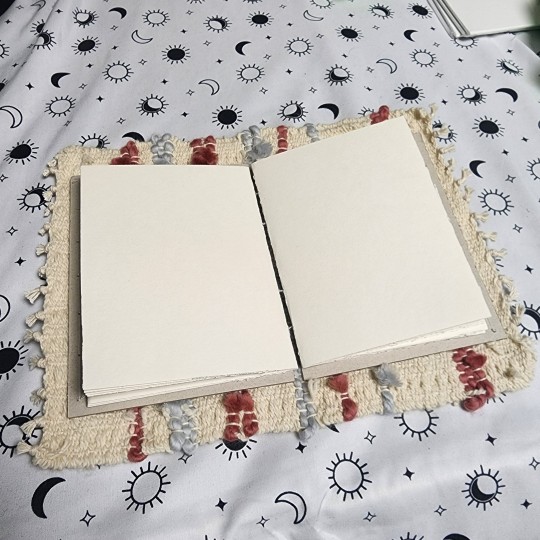

some janky little sketchbooks i made this week

#bookbinding#textiles#weaving#cover of the first is suede second is alpaca and cotton#i want to say the first is deer suede but i cant be sure the company its from has like jackshit info on their site#if i work with leather more in the future im definitely gonna buy from a local -_- i just grabbed this piece on impulse from a craft store#oh also the suede one is softback the woven one is hardback. i stitched that weaving into the cardstock covers#i really ought to start using a stitch other than coptic.. im limiting myself too much

21 notes

·

View notes

Photo

(via Back to the Earth: Schacht Spindle Company Celebrates 50 Years in the Fiber Industry - Craft Industry Alliance)

This is an interesting read.

58 notes

·

View notes

Text

Indian Textile Industry

0 notes

Link

Trident India, the group's flagship textile company , is one of the top five global terry towel heavyweights, owing to an expanding product variety. To know more details, read this blog.

0 notes

Text

Here's a plush I made a while back, and here's the pattern I made for it.

I hope, if you make this sad little friend, having them with you when you are sad will make it a little less lonely.

This sad little friend is so you don't have to be sad all alone :]

Please note that the bottom is made by gathering the open edge at the bottom after stuffing (like a drawstring bag) and then the feet and circle are sewn on over to hide the edges

#handmade plush#stuffies#sewing#sewing patterns#self care#textile art#a sad little friend to keep you company when it seems we need it most

14 notes

·

View notes

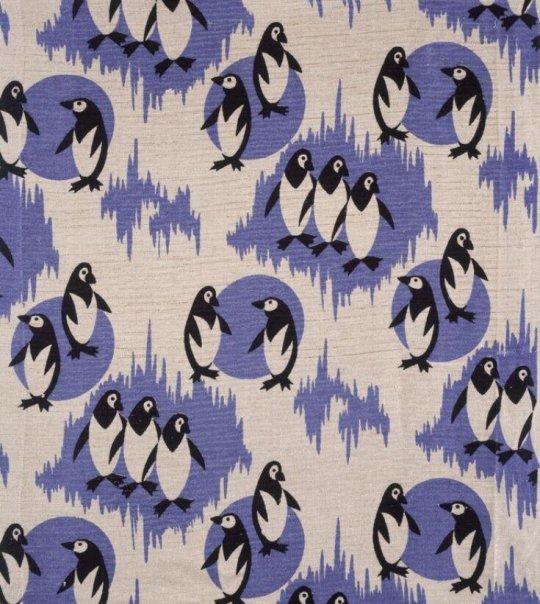

Photo

Penguin furnishing fabric, manufactured by Old Bleach Linen Company Limited, 1936-1937

#screen printing#linen#textiles#fabric#furnishing fabric#so cute!#old bleach linen company limited#Ireland#interwar period#depression era#europe#penguins#prints#20th century#1930s

12 notes

·

View notes