#safety hazard mitigation

Text

Expert Refinery Engineering Solutions by Little P.Eng.

In the dynamic and complex world of refinery operations, the demand for cutting-edge, reliable engineering solutions is more critical than ever. Little P.Eng. Engineering Services emerges as a beacon of excellence, offering bespoke engineering solutions tailored to the unique needs of refineries. With a deep understanding of the challenges and intricacies of refinery engineering, Little P.Eng. stands out as a premier choice for operators aiming to enhance efficiency, safety, and profitability.

Unmatched Expertise in Refinery Engineering

At the core of Little P.Eng.'s services lies a team of highly skilled and experienced engineers specializing in refinery operations. Our professionals are adept at navigating the latest industry standards, ensuring that all projects not only meet but exceed expectations. From process engineering to safety management systems, Little P.Eng. offers a comprehensive suite of services designed to address every aspect of refinery engineering.

Process Optimization for Enhanced Efficiency

Understanding the critical importance of process efficiency, Little P.Eng. employs state-of-the-art techniques and technologies to optimize refinery operations. Our approach focuses on minimizing energy consumption, reducing waste, and maximizing product yield, thereby significantly enhancing overall operational efficiency. Through detailed analysis and innovative solutions, we help our clients achieve their goals of cost reduction and improved productivity.

Safety and Compliance: A Top Priority

In the refinery industry, safety cannot be overstated. Little P.Eng. places paramount importance on ensuring that all engineering projects adhere to the strictest safety standards and regulatory compliance. Our safety management systems are designed to identify potential hazards, mitigate risks, and create a safe working environment for all employees. By staying ahead of regulatory changes, we ensure that our clients' operations are not only safe but also future-proofed against evolving industry requirements.

Customized Solutions for Every Challenge

Expert Refinery Engineering Solutions by Little P.Eng.

Partnering with Little P.Eng. for Your Refinery Needs

Choosing Little P.Eng. for your refinery engineering services means partnering with a leader in the field. Our commitment to excellence, combined with a client-centric approach, sets us apart in the industry. We invite you to discover how our expertise can transform your refinery operations, driving them towards unparalleled efficiency, safety, and success.

With Little P.Eng., your refinery is in expert hands. Contact us today to explore how we can support your engineering needs and propel your operations to new heights.

Tags:

Little P.Eng.

operational efficiency

engineering consulting

industry standards

regulatory compliance

process optimization

engineering solutions

refinery project management

process engineering

refinery engineering services

productivity improvement

energy consumption reduction

refinery optimization

engineering analysis

project efficiency

safety management systems

refinery technology

safety hazard mitigation

innovative engineering

efficiency enhancement

waste reduction

refinery design

refinery management solutions

refinery safety standards

bespoke engineering

tailored engineering services

safety and compliance

custom engineering solutions

engineering expertise

refinery operations

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng.#operational efficiency#engineering consulting#industry standards#regulatory compliance#process optimization#engineering solutions#refinery project management#process engineering#refinery engineering services#productivity improvement#energy consumption reduction#refinery optimization#engineering analysis#project efficiency#safety management systems#refinery technology#safety hazard mitigation#innovative engineering#efficiency enhancement#waste reduction#refinery design#refinery management solutions#refinery safety standards#bespoke engineering#tailored engineering services#safety and compliance#custom engineering solutions#engineering expertise

0 notes

Text

The Crucial Role of Stop Time Distance Meters in Ensuring Machine Safety and Efficiency

Stop time distance meters play a pivotal role in determining a machine’s stop time, thereby contributing significantly to the safety and efficiency of industrial operations. These meters offer accurate and reliable results, making them indispensable tools in various industrial settings.

Value and Importance

Investing in stop time distance meters is of paramount importance for businesses…

View On WordPress

#data collection#machine compliance#Machine efficiency#Mitigating hazards#safety risk assessment#Stop Time Distance Meter

0 notes

Text

The Legacy of Colonel T.E. Lawrence: Why Helmet Use Became Essential

Discover the story behind the authorization of helmet use after Colonel T.E. Lawrence’s tragic motorcycle accident. Explore the tradeoffs, challenges, and impact of this pivotal decision in road safety history. #HelmetSafety #RoadSafety #ColonelLawrenceLegacy

In 1935, tragedy struck the world with the untimely death of Colonel T.E. Lawrence, better known as Lawrence of Arabia. His demise wasn’t…

View On WordPress

#book-reviews#books#Colonel T.E. Lawrence#Freedom vs safety#Good Old Bandit#Government intervention#Gud Ol Bandit#Head injury prevention#helmet#Helmet Safety#Helmet use authorization#Historical impact#history#Lawrence of Arabia#motorcycle accident#Motorcyclist safety#News#Personal liberty#Proactive safety measures#Protective gear#Public health#Risk mitigation#road hazards#Road safety history#Safety advocacy#Safety measures#Sanjay K Mohindroo#Sanjay Kumar Mohindroo#Sanjay Mohindroo#Tragic legacy

0 notes

Text

Examples of border initiatives.

Singapore: Dengue control programme

Australia: Skin cancer prevention programme

"Climate change and safety and health at work." World Day for Safety and Health at Work 2024, April 28th.

#singapore#workers#safeday#australia#workplace health and safety#uv radiation#UV safety training#exposure risks#knowledge of hazards and risks#osh hazards#occupational hazards#identifying hazards#international labour organization#occupational health#28 april#worker's safety#worker's health#climate health nexus#changing climate#climate change#climate change mitigation

0 notes

Text

Strengthening Earthquake and Tsunami Monitoring in the Philippines: Phivolcs Calls for Urgent Action

In a recent Senate hearing, the Philippine Institute of Volcanology and Seismology (Phivolcs) emphasized the critical need for expanding earthquake monitoring and tsunami early warning systems across the country. The call comes as part of a broader initiative to enhance hazard mapping and mitigate the potential impact of seismic activities.

During the hearing, Phivolcs Director Teresito Bacolcol…

View On WordPress

#Disaster mitigation#Disaster Resilience#Earthquake Monitoring#Earthquake Precursors#Emergency Preparedness#Hazard Mapping#Infrastructure Projects#Philippine disaster preparedness#Philippines Safety#Philippines Senate#Phivolcs#Tsunami Early Warning#west valley fault

0 notes

Text

Evacuation Plans for Construction Sites

Evacuation plans for construction sites are not just a regulatory requirement; they are a crucial aspect of ensuring the safety and well-being of workers and visitors. This article delves into why having a detailed evacuation plan is essential for construction sites and provides guidance on creating effective strategies to prepare for emergencies. Understanding and implementing these plans can…

View On WordPress

#accessibility considerations#communication channels#Construction Safety#drill practices#emergency preparedness#evacuation plans#feedback integration#hazard mitigation#incident debriefing#safety protocols#site-specific strategies#worker training

0 notes

Text

Meet Summer and her charming canine companion, Coia, a spirited soul with an undeniable passion for water-based activities, particularly those involving ducks and swans. Recognizing the importance of ensuring Coia's safety, Summer opted for the cutting-edge Halo Collar 3.

Summer's insightful review sheds light on the exceptional features of the Halo Collar 3, a device that effortlessly monitors Coia's aquatic adventures and mitigates potential water hazards. With its user-friendly GPS fence technology, the collar allows the programming of up to 20 virtual fences, making it a versatile choice for various environments and activities. The portable collar can be easily programmed using the Halo Collar app on a smartphone, which is perfect for the avid traveler.

Summer emphasizes the game-changing technology embedded in the Halo Collar, describing it as an invisible dog fence that is a reliable protector for Coia. This comprehensive review underscores the ease of use and the peace of mind, ensuring that both Summer's family and Coia can sleep soundly at night. The Halo Collar emerges not just as a dog collar but as a crucial investment in dog safety, seamlessly combining innovative GPS dog fence features with a user-friendly design. Join Summer on her journey of prioritizing canine companions' well-being with the trusted and versatile Halo Collar.

228 notes

·

View notes

Text

If you see litter/trash on the ground, and you're positive that you can pick it up without it being a health/safety hazard to you, pick it up and dispose of it properly.

Ideally, people shouldn't litter. Littering is rude for a whole list of reasons not limited to the health and safety hazards it can pose to both humans and wildlife, the negative effects it has in the environment, and it's just ugly.

However, unfortunately littering isn't going to go away overnight. Not only are there still quite enough rude and selfish people who don't care about the harms of littering, but also accidents can happen. Wind can blow away trash that someone attempted to or was indenting on disposing of properly, mishaps can happen with children or animals getting a hold of garbage then scattering it where it shouldn't be, ect.

So to help mitigate the harm that can be caused by littered trash: pick up and properly dispose of what you can. Although obviously be safe and smart about it. Avoid picking up things that could potentially be sharp or otherwise hazardous, and try to wash or sanitize your hands afterwards.

113 notes

·

View notes

Text

Tool Safety Series: Table Saws

Whether you're a professional woodworker or just a tool enthusiast, its never a bad idea to brush up on proper tool use and safety practices.

Pictured above are a contractor table saw (Left) and a cabinet maker table saw (Right). Despite their differences, the same standards and safety practices apply to both when hand feeding material.

Guard Requirements:

Blade guards

"Each circular hand-fed rip saw shall be provided with a hood-type guard that will cover the blade at all times when not in use. This may be accomplished by the use of a guard which will automatically adjust to the thickness of the material being cut, or by a fixed or manually adjusted guard"

"Each circular hand-fed rip saw shall be provided with a hood-type guard that will cover the blade at all times when not in use. This may be accomplished by the use of a guard which will automatically adjust to the thickness of the material being cut, or by a fixed or manually adjusted guard"

Above is an automatically adjusting hood-type guard which doubles as a dust extraction hood. These protect operators from small debris that may be thrown back during a rip cut such as dust, splinters, loose knots, and foreign materials such as nails. A guard like this required to be in place at all times if the cut being made allows it. The hood may be removed for special cuts that would otherwise be impossible with the hood in place.

Spreaders

"Each hand-fed circular saw shall be equipped with a spreader to minimize the possibility of material squeezing the saw"

Even the slightest horizontal force on a board in the middle of a cut can cause it to kickback at incredible speed. The spreader helps mitigate this hazard by providing a static surface for cut material to slide against.

These standards are established by ANSI O1.1-1961: Safety Code for Woodworking Machinery - Section 6.1 and are incorporated by reference by 29 CFR 1926.304(f).

General Operating Procedures:

Never start the saw if material is touching the blade. The blade needs time to accelerate to operational speed and will kickback anything touching it when it starts up.

Avoid standing behind the space between the blade and the fence. It is much easier for material in this area to kickback into an operator. When possible, it is safest to stand on the left-hand side of the saw blade. Keep a wide stable stance when hand feeding material and avoid bending or leaning as this may lead to falls.

Related to the previous point, always keep a hand/push-stick on the material between the blade and the fence. This where kickback is most likely to occur. Push-sticks should be used if making narrow cuts that could bring an operators hands close to the blade.

Never apply lateral or vertical force to material being cut. Material must only receive force from behind and above to keep it flat on the table top and moving smoothly forward. Be especially aware of this when cutting large sheets of material with a partner.

Use a roller stand or ask for assistance when cutting material that hangs off the edge of the table top. Hanging material may cantilever the rest of the material, causing it to lift off the table top and kickback.

In the picture above, the person in pink in assists the operator in blue. As the operator in blue pushes the sheet through the blade, the assistant keeps their hands on the material, slowly walking along side it. If they were to apply force in any direction (other than to counter gravity) it would almost certainly cause the saw blade to bite into the material and potentially kick it back in to the operator.

Due to the versatility of table saws, these guidelines are not exhaustive. Be sure to read the operators manual before operating machinery for the first time.

355 notes

·

View notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

How To Support a Labor Strike with 3 Simple Steps

There are lots of reasons for a labor strike. Here are just a few:

Not enough compensation. No one should have to go on strike to get a raise. But it happens all the time.

Hazardous working conditions. Lots of people take dangerous jobs. But they have the reasonable expectation that their employer will provide them with protective gear, or put measures in place to mitigate the danger. A company’s cavalier attitude to worker safety can be a great reason for a strike.

Inconsistent cost of living raises. If the workforce hasn’t had a cost of living raise in a decade, and their employer refuses to negotiate a COL raise, that can be grounds for a strike.

Inhumane treatment. Infamously, Amazon employees pee in bottles because they aren’t allowed proper breaks to relieve themselves. In my humble opinion, this means they should strike, like, yesterday.

Insufficient training. If employees are repeatedly asked to do something for which they aren’t trained, or is beyond the scope of their job description, that’s strike-worthy.

Unfair hiring and labor practices. If you’re hired at $8 an hour, and a year later a coworker is hired at $10 an hour, and you’re denied a $2 raise… you’d probably want to go on strike.

Keep reading.

If you found this helpful, consider joining our Patreon.

12 notes

·

View notes

Text

Safety Laser Scanners: Ensuring Machine Safety with Advanced Technology

In the realm of industrial safety, safety laser scanners stand out as sophisticated devices designed to enhance machine safety in hazardous areas, blind spots, and danger zones. These cutting-edge scanners are pivotal in preventing accidents and ensuring workplace safety by detecting foot traffic and providing visual safeguards in real-time, eliminating the need for operating access during…

View On WordPress

#E-Safety Devices#hazard Mitigating#precense sensing safety#Robotic Automation#safety laser scanners

0 notes

Text

"The privilege to deny has drastic consequences to the lives of immunocompromised people like myself. I do not have the luxury of denial, I am still focused on my survival.

"I definitely feel more at risk without mask mandates. I feel this way because I am more at risk without mask mandates.

"It is not a perceived threat, it is a real and active hazard that disproportionately affects certain groups. The NSW government has an opportunity to reduce a hazard and mitigate a public health and safety risk, and are opting not to."

198 notes

·

View notes

Text

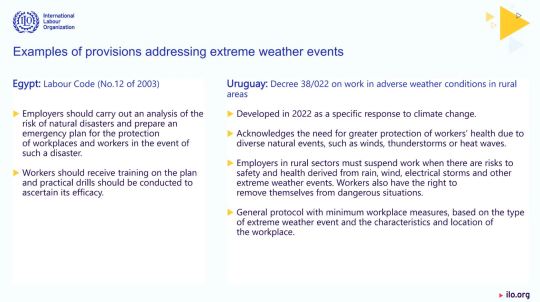

Exemples of provisions addressing extreme heat.

Egypt: Labour Code n°12 of 2003.

Uruguay: Decree 38/202

#advocacy#workers#worker's health#worker's safety#climate health nexus#climate change#climate change mitigation#changing climate#osh hazards#extreme heat#safeday#international labour organization#egypt#uruguay

0 notes

Text

The watermelons are at it again

So-called "environmentalists" at the Sierra Club are celebrating the fact that they won't have nuclear power.

Most "environmentalists" are like this, but in my experience the big ones like Greenpeace and WWF simply boo nukes and then go into what they want you to do to help stop nuclear power. This release from the Sierra Club goes into why, which I found moderately interesting to see what they're lying about.

Illinois -- Today, Governor JB Pritzker vetoed SB76—a bill that would have lifted Illinois’ decades-old moratorium on new nuclear power plants.

Responding to growing concerns about safety, waste and cost associated with nuclear power generation,

"Responding to fear, uncertainty and doubt that we ourselves have been stirring up," more like.

Everyone involved in writing this should be made to live in France for a year, in a house where every electrical device reminds the reader that France gets the majority of its electricity from nuclear power. The "concerns" are mostly ignorant hypotheticals. France has been getting the majority of its electricity from nuclear power for thirty years. France is an ongoing demonstration of the safety of nuclear power at scale. The waste goes in storage. The cost is an absolute non-issue, electricity in France is both cheaper and cleaner than in Germany.

In the absence of the 25-year moratorium, Illinois would be exposed to risk from long-lapsed rules, regulations and oversight.

So when are you planning to do something about the rules, regulations and oversight? Because I smell a rat here: each half of this will be used as a circular argument for not fixing the other one.

(Also, Illinois has active nuclear power plants, which receive regular oversight. What exactly is lapsed about them? Liars.)

Additionally, Illinoisans would bear the burden of exorbitant construction costs and growing stockpiles of hazardous waste with no safe, permanent disposal method.

Again: electricity in France is both cheaper and cleaner than in Germany.

The exorbitant construction costs in America are largely the result of the environmentalist movement choking the nuclear construction industry, demanding infinite mitigation and infinite paperwork review, with rules such as the ALARA standard.

Meanwhile the coal plants continue to operate because of status quo bias.

new nuclear’s exorbitant cost threatens to distract investment from Illinois’ plan for a clean energy future.

For those unaware of the context, Illinois recently passed a bill promising (in the completely unenforceable way of politician promises) to switch to 100% CO2-free electricity generation by 2050.

New nuclear power is the only way this is achievable. Nuclear is not a distraction. Everything else is a distraction from nuclear.

Illinois has a head start on this goal because it already has a good deal of nuclear power. Braidwood nuclear plant originally built in 1988 can generate 2400 MW, day or night. The biggest wind farm in Illinois is Radford's Run, opened 2018, generating... up to 308MW, if the wind blows right.

With billions of dollars poured into shiny new wind turbines, while new nuclear power plants have had a 25-year moratorium, wind power in Illinois is still providing less power than natgas or coal, each of which in turn is providing less than nuclear, which is both clean and independent of weather.

Who's the fucking distraction here?

“SB76 would have opened the door to increased risk, negative environmental impacts, and higher costs for consumers while jeopardizing our progress toward Illinois’ clean energy future. We applaud Governor Pritzker for vetoing the bill and ensuring that Illinois follows the roadmap laid out in the Climate and Equitable Jobs Act toward that vision for our future,” said Sierra Club Illinois Director Jack Darin.

A case study in deceptive phrasing. Building new nuclear power plants would have increased risk - by a minuscule amount, which would still be preferable to the alternatives, for example: the even higher risk of coal plants, the wishful thinking of wind power, and the other risk of people freezing to death for lack of electricity.

10 notes

·

View notes

Text

Risk Management Best Practices

In the dynamic field of construction, embracing risk management best practices is not just beneficial; it’s essential. This article dives into the core of risk management best practices in construction safety, exploring how these strategies can significantly reduce hazards and enhance overall project efficiency. Understanding these principles is crucial for every construction safety…

View On WordPress

#construction industry#Construction Project Management#Construction Risk Control#Construction Safety#construction site safety#hazard identification#Health and Safety Standards#Ongoing Monitoring#project management#Risk Analysis#risk assessment#Risk Management#Risk Mitigation#Safety Best Practices#Safety Compliance#safety equipment#safety protocols#Safety Review Process#Safety Training#Workplace Safety

0 notes