#raw materials

Photo

https://www.therawmaterials.com/

#Raw Materials#design#studio#company#colors#portfolio#typographic#typography#type#typeface#font#Stabil Grotesk#2023#Week 24#website#web design#inspire#inspiration#happywebdesign

17 notes

·

View notes

Text

#building materials#building construction#building#construction#business#raw materials#construction materials

2 notes

·

View notes

Photo

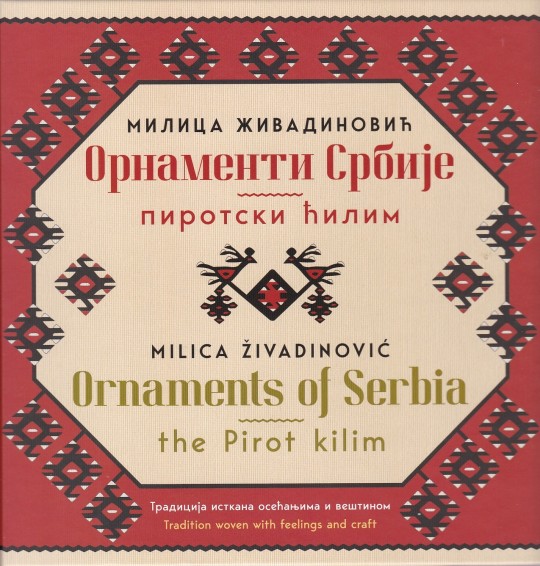

Ormanents of Serbia The Pirot Kilim

Tradition woven with feelings and craft

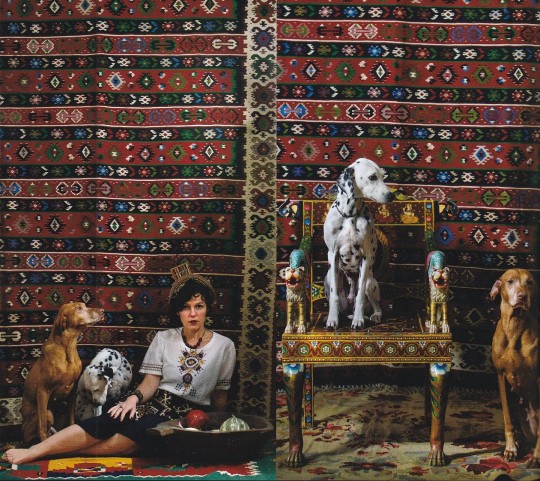

Milica Živadinović

Laguna, Belgrade 2022, 272 pages, 22 x 23 cm, Hardcover, ISBN 978-86-521-4625-3

euro 60,00

email if you want to buy :[email protected]

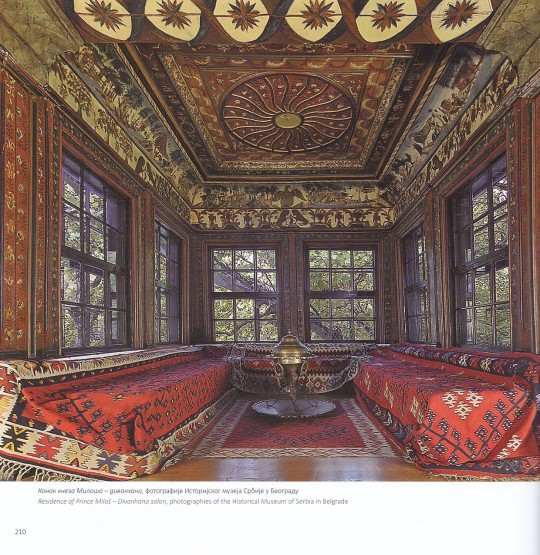

Searching for the origin and possible meanings of the Pirot kilim ornaments, this book offers a particular overview into the tradition of this female craft. This particular collection of rare and carefully curated photographs has been presented for the first time, especially for this luxury edition. The beauty, harmony and craftsmanship of the kilims inspire and amaze, and their aesthetics enrich contemporary interiors. The Serbian tradition is rich in colorful symbols, and some of the most famous ones are found on Pirot kilim-rug.The Pirot carpet is known in the world for its beauty and quality, the weaving technique, the raw material from which it is made and loomed, the stylized ornamentation, the richness of patterns and colors, durability. The peculiarity of the Pirot rug is that it has no reverse, is smooth and identical on both sides, which is achieved by firm weaving of the weft. They are woven in the technique of kneeling by making multicolored weft threads with patterns that are narrower than the entire width of the weave.

30/12/22

orders to: [email protected]

ordini a: [email protected]

twitter: @fashionbooksmi

instagram: fashionbooksmilano, designbooksmilano tumblr: fashionbooksmilano, designbooksmilano

#Ornaments Serbia#Pirot Kilim#female craft#weaving technique#raw materials#stykized ornamentation#richness patterns#richness colors#no reverse#tradition woven#textiles books#fashion books#fashionbooksmilano

20 notes

·

View notes

Text

Norway’s parliament authorised deep-sea mining

Norwegian lawmakers gave the green light for deep-sea exploration around the Arctic Archipelago of Svalbard on January 9, sparking concern among environmental groups.

Members of the national parliament authorised deep-sea exploration in the 281,200 square kilometre area on Tuesday to pave the way for commercial exploitation of the minerals abundant in the North Atlantic shelf.

The region is wealthy in copper, manganese, cobalt and lithium, raw materials identified by the EU as of strategic importance as they are considered a prerequisite for the transition to a green and digital economy. Such minerals are currently mined in several countries, including the Democratic Republic of Congo, China and Russia.

In the Critical Raw Materials Act passed by the EU last December, these minerals were three of 16 listed among the highest-priority strategic raw materials.

Read more HERE

#world news#world politics#news#europe#european news#norway#deep sea#deep sea mining#mining#raw materials#copper#manganese#cobalt#lithium

2 notes

·

View notes

Text

Imagine a home that enhances the beauty of its surrounding landscape instead of isolating you from it.

Or look at how @cheshirearchitects and designer Terry Hunziker approached this angle by creating the ideal mix between a living space and cozy observatory.

This team teaches us how mixing the raw natural elements that connect the interior design with the architecture, helps to embed a home in the core of its environment.

#modernfurniture#moderndesign#designers#miami#modernhomes#contemporarydesign#furniturestores#sofas#interior design miami#interiordecoration#raw materials#natural furniture#organic design#cozy interior#views

4 notes

·

View notes

Text

Calcium Carbonate

LimeStone Granules ( Feed )

LimeStone Lumps ( Calcite )

Silica Sand ( Glass )

Foundry Sand

Frac Sand ( Proppant Sand )

Silica Flour ( Quartz Powder )

Cullet ( Broken Glass )

Glass Powder ( Cullet Flour )

Rock Gypsum

Agriculture Gypsum

Gypsum Plaster ( POP - Plaster of Paris )

Poultry Meal

Rock Phosphate

Quick Lime

Hydrated Lime

Bentonite

Barite

#calcium carbonate#raw materials#foundry sand#silica sand#limestone#Cullet#Poultry_Meal#$Silica_Sand

2 notes

·

View notes

Text

7 notes

·

View notes

Text

LILLIT BOLLINGER STUDIO - Wohnatelier Altes Weinlager

Another gorgeous project I'm currently researching is this studio designed in 2019 by Lillit Bollinger Studio.

The new structure is based on the idea of the old building with a massive volume under a large cantilevered roof. Underneath, the reduction creates a huge covered outdoor space. The new building was constructed as a wooden structure on top of the existing structure of the basement.

A studio/residential building will be constructed, consisting of six adjacent units, which will be acquired as condominium property. These have a very simple, inexpensive basic structure and can be further developed by the residents individually, e.g. by adding a further upper floor, partially or over the entire area or dividing the area into rooms.

6 notes

·

View notes

Link

Although the war has driven much of that production offline — Volt Resources Ltd.'s Zavalievsky mine in Ukraine has suspended operations, for instance — the world's appetite for the mineral is only growing as electric vehicle sales boom, and demand for graphite, the largest component of EV batteries by weight, is set to expand.

3 notes

·

View notes

Text

0 notes

Text

Ceramic India, Ceramic Directory for Tiles, Sanitarywares and Raw Materials

#glazed#vitrified#tiles#manufacturers#porcelain#nano#doublecharge#fullbody#gvt#pgvt#floor#exporters#supplier#design#ceramic#india#morbi#gujarat#raw materials#wall#sanitarywares#decorative#step and riser#parking

0 notes

Text

#market research#market report#construction#raw materials#recycling#building materials#factory#manufacturing#industry

0 notes

Text

Use Calcium Carbonate in GRC Pipes

0 notes

Text

The first stop of PCE International Personal Care Expo 2024 has ended perfectly in Guangzhou. 🥇

🤝 Every handshake and conversation is drawing a new blueprint for the future of the industry. 🕊️

Thank you to every participant for your enthusiasm and dedication, making this exhibition not just an event, but a beginning and a brand new starting point. ✨🎈 We have reason to believe that through continuous exploration and innovation, we will jointly embark on a more brilliant chapter. 🏅🎖️🏆🌹

🌟 Goodbye, not farewell, but looking forward to the next more exciting encounter. Let's gather again at the Shanghai station on August 7-9 to welcome a brighter tomorrow together! ✈️🎉

#personal care#trade shows#china#guangzhou#public exhibition#pce#china expo#personal care expo#expochina2024#nanfung#oralcare#hygieneproducts#cleaningproducts#raw materials#beauty devices#skincare ingredients#personalcareexhibition#personal hygiene#internationaltrade

1 note

·

View note

Text

Exploring Rubber Sheeting Facilities: Everything You Need to Know

Rubber sheeting facilities are essential hubs in the manufacturing industry, responsible for producing a wide range of rubber sheets used in various applications. From conveyor belts to roofing materials, rubber sheets serve diverse purposes across industries. In this comprehensive guide, we'll delve into the world of rubber sheeting facilities, exploring their processes, products, and significance in modern manufacturing.

What are Rubber Sheeting Facilities?

Rubber sheeting facilities are specialized manufacturing plants equipped with machinery and equipment for the production of rubber sheets. These facilities typically handle raw rubber materials, additives, and fillers, processing them through various stages to create finished rubber sheets with specific properties and dimensions. Rubber sheets produced in these facilities serve as essential components in numerous industries, including automotive, construction, aerospace, and healthcare.

Processes Involved in Rubber Sheeting

Rubber sheeting involves several key processes, each contributing to the production of high-quality rubber sheets:

Mixing: The process begins with the mixing of raw rubber materials, additives, and fillers. This step is crucial for achieving uniform dispersion of additives and fillers throughout the rubber compound, ensuring consistent properties in the final product.

Calendering: Calendering is a process used to flatten and shape rubber compounds into thin sheets of uniform thickness. The rubber compound is passed through a series of rollers in a calender machine, where it undergoes compression and elongation to achieve the desired thickness.

Curing: Curing is the process of applying heat and pressure to the rubber sheets to promote cross-linking of the polymer chains, resulting in improved strength, elasticity, and durability. Curing can be done using various methods, including hot air curing, steam curing, and vulcanization.

Cutting and Finishing: Once cured, the rubber sheets are cut to the desired dimensions and undergo finishing processes such as trimming, punching, and surface treatment to meet specific customer requirements.

Products of Rubber Sheeting Facilities

Rubber sheeting facilities produce a wide range of rubber sheets tailored to meet the diverse needs of industries and applications. Some common types of rubber sheets include:

Natural Rubber Sheets: Made from natural rubber latex obtained from the sap of rubber trees, natural rubber sheets offer excellent elasticity and resistance to abrasion, making them ideal for applications such as conveyor belts, gaskets, and seals.

Synthetic Rubber Sheets: Synthetic rubber sheets, such as styrene-butadiene rubber (SBR) and nitrile rubber (NBR), are manufactured from petroleum-derived chemicals. These sheets exhibit specific properties such as oil resistance, weather resistance, and high tensile strength, making them suitable for applications in automotive, construction, and marine industries.

Silicone Rubber Sheets: Silicone rubber sheets are known for their exceptional temperature resistance, flexibility, and non-reactivity. They are commonly used in medical devices, food processing equipment, and electrical insulation applications.

Neoprene Rubber Sheets: Neoprene rubber sheets offer excellent resistance to oil, ozone, and weathering, making them suitable for outdoor and marine applications, such as boat seals, gaskets, and weather stripping.

Significance of Rubber Sheeting Facilities

Rubber sheeting facilities play a significant role in modern manufacturing for several reasons:

Versatility: Rubber sheets produced in these facilities are highly versatile and can be customized to meet specific requirements in terms of thickness, hardness, elasticity, and chemical resistance.

Reliability: Rubber sheets are essential components in critical applications such as conveyor systems, sealing applications, and industrial machinery. High-quality rubber sheets produced in specialized facilities ensure reliable performance and durability in demanding environments.

Innovation: Rubber sheeting facilities drive innovation in materials science and engineering, developing new formulations and manufacturing techniques to meet evolving industry standards and customer needs.

Economic Impact: Rubber sheeting facilities contribute to the economy by providing employment opportunities, supporting downstream industries, and fostering technological advancements in manufacturing.

Conclusion

Rubber sheeting facilities are integral to the manufacturing industry, producing essential components used in a wide range of applications across diverse industries. By understanding the processes involved, the products produced, and the significance of these facilities, we gain insight into the essential role they play in modern manufacturing and the global economy. As technology advances and market demands evolve, rubber sheeting facilities continue to innovate and adapt, ensuring they remain at the forefront of materials manufacturing now and in the future.

#manufacturing#industry#rubber sheets#rubber sheet facilities#manufacturing industry#technology#rubber sheeting facilities#materials#raw materials#rubber sheet processing#rubber products#rubber sheet mixing#rubber sheeting techniques#rubber sheeting procedures

0 notes