#puf panels

Text

ENGKO: Revolutionizing Manufacturing with High-Quality PUF Panels in India

In the dynamic landscape of construction, innovation and efficiency are paramount. ENGKO, a pioneering name in the industry, stands out as a leading manufacturer of Polyurethane Foam (PUF) panels in India. With a commitment to quality, sustainability, and cutting-edge technology, ENGKO has emerged as a game-changer in prefab construction.

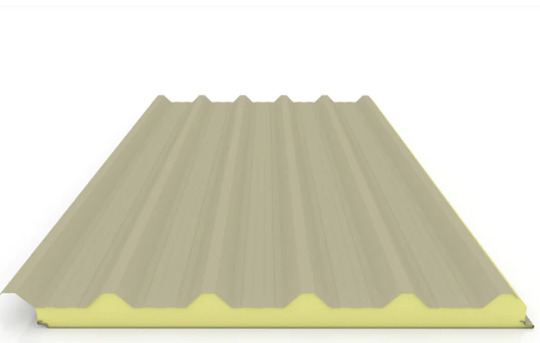

The Power of PUF Panels

Polyurethane Foam (PUF) panels are at the core of ENGKO Engineering Company offerings, and for good reason. These panels are renowned for their outstanding thermal insulation properties, durability, and versatility. As a leading manufacturer, ENGKO ensures that its PUF panels adhere to the highest industry standards, providing an optimal solution for diverse construction needs.

Energy Efficiency and Sustainability

One of the key advantages of ENGKO PUF panels is their exceptional energy efficiency. These panels act as a formidable barrier against heat transfer, significantly reducing the need for artificial heating or cooling within a structure. This not only contributes to lower energy consumption but also aligns with global sustainability goals. ENGKO is committed to eco-friendly practices, and their PUF panels play a crucial role in creating energy-efficient and environmentally conscious buildings.

Customization for Varied Applications

ENGKO understands that each construction project is unique, with distinct requirements and challenges. The company offers a range of PUF panels that can be customized to suit specific applications. Whether it's for industrial buildings, cold storage, clean rooms, or residential structures, ENGKO PUF panels are designed to meet the diverse needs of the construction industry.

Rapid and Cost-effective Construction

Prefabricated construction, powered by PUF panels, is synonymous with speed and cost-effectiveness. EPACK Engineering Company's panels are manufactured precisely and efficiently, allowing for faster construction timelines. This not only reduces overall project costs but also minimizes the environmental impact associated with traditional construction methods.

Quality Assurance and Certifications

ENGKO places a premium on quality assurance. The company adheres to stringent quality control measures at every stage of production, ensuring that each PUF panel meets the highest durability and performance standards. Additionally, the panels are backed by relevant certifications, providing clients with the assurance that they are investing in a reliable and compliant construction solution.

Contact Detail

ENGKO Engineering Company

Add- DB Plaza, RDC, Near Yes Bank, Ghaziabad INDIA

Phone no- 9319777949

Email: [email protected]

Website- https://www.engko.co.in

3 notes

·

View notes

Text

Top Quality PUF Panel For Cold Storage - TSSC

Do you need to buy the best PUF panels for cold storage? If yes, TSSC is the best place to get top-quality PUF panels that ensure optimal insulation and temperature control. We offer PUF panels designed specifically for cold storage applications. Our panels are built to withstand extreme temperatures and provide excellent thermal insulation, ensuring the freshness and quality of stored goods. Get more details about us by visiting our website. For any further queries, email us at [email protected].

0 notes

Text

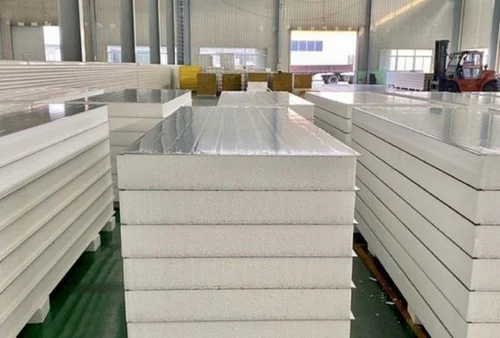

Blue Ice India manufacture, trade, and supplies a wide range of PUF Panels. Our designed structure is crafted and fabricated by our qualified professionals using the best quality raw material.PUF Panels are used to build roofs and walls, and their preference in the market is quite high. This structure is highly demanded in the market owing to its stability and good strength.

0 notes

Text

Puf Insulated Cold Room Panels

Puf Insulated Cold Room Panels are capable of rapid erection without lifting equipment, easier installation, and in hostile climates. Our panels are noise-resistance, fire-resistant, contribute to energy conservation, are easily relocatable, and are easy to install. Our panels are free of CFCs and HCFCs, reducing global warming.

0 notes

Text

sherlouis commission for @hergan416! ty for the comm and letting me draw sleepy cute louis hehe 🥰

#he’s so tsun tsun and I pat pat his head#I don’t draw louis enough but I want to lovingly draws his hair#I’m always boolying sherly in my art and this time around ligjtly boolying louis? lol#sherlouis#louis james moriarty#ynm sherlock Holmes#yuukoku no moriarty#moriarty the patriot#comm#hergan416#the puffed up cheeks louis and his hair being tucked back are my favorite panels#ty for providing such a cute comic idea this was fun!!!!

104 notes

·

View notes

Text

so on top of the new gemstore stuff and Black Lion copter, some really neat dieselpunk skins came out for Halloween this year. I'm kinda digging them, and since I haven't seen anybody else spotlight them yet, here's a handful of the designs!

for anyone wanting to check out the rest via the in-game wardrobe, they're called the Grim Machine weapon set.

#gw2#Guild Wars 2#my posts#I'm betting people probably haven't seen them yet since you can't preview them via the achievement panel for some reason#so here you go here's a few of them. they're neat i dig it#i'm fond of steampunk and dieselpunk stuff in general tho#most also have moving gears and pumps and stuff too + the smoke puffing out of the chimneys

13 notes

·

View notes

Text

Robin Jason really is a magical boy. I don’t care he doesn’t actually use magic he’s still a magical boy. That’s just the best way to describe him.

#insert the ‘Robin is magic’ panel and that comic where Bruce and Alfred gave him cake & he puffed his cheeks out stuffed full ❤️#jason todd#robin jason todd#robin ii#batfam#batman#dc#dc comics#heroesriseandfall

19 notes

·

View notes

Text

Maruthi engineering solutions Offers No.1 best quality Nitrile Rubber, XLP Foam,Glasswool & Rockwool, HVLS Fan, Puf Panel Dealers & Suppliers in chennai

2 notes

·

View notes

Text

#naruto#uchiha izuna#chapter 609#asdf naruto just told him he looked like shit and we got a immediate zoomed in panel on kakashi on the ground huffing and puffing

2 notes

·

View notes

Text

Exploring the Versatility of Porta Cabins | Abuildtech

Abuildtech offers high-quality Porta Cabins that are perfect for temporary office spaces, construction sites, events, and more. Our cabins are durable, weather-resistant, and can be easily customized to fit your specific needs. Trust Abuildtech for reliable, portable solutions for your workspace requirements.

Click here - https://www.abuildtech.com/

#Wooden work#Guard Cabin in Delhi#Security Guard Cabin manufacturer#PUF Panel Residence#Prefabricated site office#Prefab cabin manufacturer#Prefab site offices#Porta Cabin site Office#Interior Turnkey Projects#Industrial Sheds#Glass Work

0 notes

Text

PUF Panel Manufacturer & Supplier in India

PBPL is a leading PUF Panel Manufacturer & Supplier in India. Being a PUF Panel manufacturer We put a lot of effort into offering PUF Panels, PUF Sheets, and Sandwich panels of the highest quality. With the aid of the latest machinery and technology and in accordance with established industry standards, this panel is made from the best raw materials.

1 note

·

View note

Text

Energy Efficiency and Clean Room Doors: Saving Costs Without Compromising Quality

In today's competitive marketplace, businesses are constantly searching for ways to reduce operational costs while maintaining high standards of quality and efficiency. One critical area where companies can achieve significant savings is in their energy consumption. Investing in high-quality clean room doors is a smart move for industries that rely on controlled environments, such as pharmaceuticals, biotechnology, food processing, and electronics manufacturing. Isoflex, a reputable Clean Room Doors Manufacturers, offers solutions that enhance energy efficiency and uphold the stringent standards required in these environments.

The Importance of Clean Room Doors in Controlled Environments

Clean rooms are specialized environments that minimize contamination from airborne particles, microorganisms, and other pollutants. They are essential in various industries where even the smallest contamination can lead to significant product defects, health risks, or regulatory non-compliance. Clean room doors play a vital role in maintaining these controlled conditions by providing a barrier that prevents the ingress of contaminants and helps regulate internal environments.

Energy Efficiency: A Key Consideration

Energy consumption is one of the most pressing concerns for businesses operating clean rooms. Clean rooms typically require extensive HVAC systems to maintain specific temperature, humidity, and particulate levels. These systems can be energy-intensive, leading to high operational costs. However, by investing in high-quality clean room doors from reputable manufacturers like Isoflex, businesses can significantly enhance their energy efficiency and reduce costs.

How Isoflex Clean Room Doors Enhance Energy Efficiency

Isoflex clean room doors are engineered with energy efficiency in mind. Here are several ways in which our doors contribute to energy savings:

Superior Insulation

Isoflex clean room doors are constructed using advanced materials that provide superior insulation. This insulation minimizes heat transfer between the clean room and adjacent areas, reducing the load on HVAC systems. As a result, less energy is required to maintain the desired environmental conditions within the clean room.

Airtight Seals

Our clean room doors are designed with high-performance seals that ensure airtight closure. These seals prevent the leakage of conditioned air, maintaining consistent temperature and humidity levels inside the clean room. Isoflex doors reduce the energy required to compensate for temperature fluctuations by preventing air exchange with the outside environment.

Durable and Reliable Construction

Isoflex doors are built to withstand the demanding conditions of clean room environments. Their durability ensures long-term performance with minimal maintenance. Reliable doors that maintain their integrity over time reduce the need for frequent replacements or repairs, further contributing to cost savings and energy efficiency.

Cost Savings Without Compromising Quality

While the primary focus is often on energy savings, these savings mustn't come at the expense of quality. Isoflex clean room doors offer the perfect balance between cost-effectiveness and uncompromised quality.

Compliance with Standards

Isoflex clean room doors are designed to meet or exceed industry cleanliness and environmental control standards. They comply with regulations such as ISO 14644, which specifies the requirements for clean rooms and associated controlled environments. Investing in doors that meet these standards ensures that your cleanroom operations remain compliant and efficient.

Enhanced Operational Efficiency

High-quality clean room doors from Isoflex enhance overall operational efficiency. With features such as smooth and reliable opening mechanisms, our doors facilitate easy access while maintaining the integrity of the controlled environment. This ease of use reduces downtime and increases productivity, leading to cost savings over time.

Customization for Specific Needs

Every clean room has unique requirements, and Isoflex understands the importance of providing customized solutions. Our clean room doors can be tailored to fit specific dimensions, configurations, and operational needs. This customization ensures you get a product that perfectly suits your application, maximizing efficiency and cost-effectiveness.

Why Choose Isoflex?

When it comes to clean room doors manufacturers, Isoflex stands out for several reasons:

Expertise and Experience

With years of experience in the industry, Isoflex has developed a deep understanding of the needs and challenges faced by cleanroom operators. Our expertise allows us to design and manufacture doors that meet the highest performance and reliability standards.

Commitment to Quality

Quality is at the core of everything we do at Isoflex. From the selection of materials to the manufacturing process and final inspection, we maintain stringent quality control measures to ensure that our products exceed customer expectations.

Comprehensive Support

Isoflex offers comprehensive support to our customers, from initial consultation and design to installation and maintenance. Our team of experts is always available to provide guidance and assistance, ensuring you get the most out of your investment.

Conclusion

Investing in high-quality, clean room doors is a strategic decision that can lead to significant energy savings and cost reductions without compromising the quality of your controlled environment. Isoflex, a reputable manufacturer of clean room doors, offers solutions that provide superior insulation, airtight seals, and durable construction. Our doors are designed to enhance operational efficiency, comply with industry standards, and can be customized to meet your specific needs.

By choosing Isoflex clean room doors, you are making a smart investment in your business's future. Our commitment to quality, expertise, and comprehensive support ensures you receive a product that meets and exceeds your expectations. Make the switch to Isoflex clean room doors today and start saving on energy costs while maintaining the highest standards of quality and efficiency.

For more information about our products and how they can benefit your operations, please visit our website or contact our sales team. Isoflex is here to help you achieve your energy efficiency goals and ensure the success of your cleanroom operations.

0 notes

Text

Cost-Effectiveness of PUF Sandwich Panels in Construction Projects

The construction industry continually evolves, with new materials and techniques being developed to improve efficiency, sustainability, and cost-effectiveness. One such innovation that has gained significant traction is using PUF (Polyurethane Foam) sandwich panels. These panels, produced byIsoflex, a reputable PUF Sandwich Panels Manufacturer, offer many benefits that make them a preferred choice for modern construction projects. This blog will delve into the cost-effectiveness of PUF sandwich panels and explore why they are becoming an integral part of contemporary construction practices.

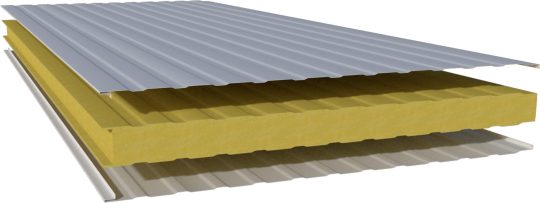

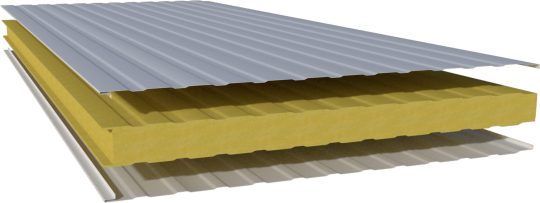

Understanding PUF Sandwich Panels

PUF sandwich panels are composite materials of a lightweight core material, typically polyurethane foam, sandwiched between two layers of durable facing materials such as galvanized steel, aluminium, or other metal sheets. This configuration provides an excellent combination of strength, thermal insulation, and lightweight properties, making them ideal for various applications in the construction industry.

Key Benefits of PUF Sandwich Panels

Before diving into their cost-effectiveness, it's essential to understand the key benefits that PUF sandwich panels offer:

Thermal Insulation: PUF sandwich panels have superior thermal insulation properties, which can significantly reduce heating and cooling costs in buildings.

Lightweight: Despite their strength, these panels are lightweight, reducing the structural load on buildings and simplifying transportation and installation.

Durability: The materials used in PUF sandwich panels are highly durable and resistant to weathering, corrosion, and other environmental factors.

Quick Installation: These panels' modular nature allows for rapid installation,

reducing Labour costs and construction timelines.

Fire Resistance: Many PUF sandwich panels are designed with fire-resistant properties, enhancing the safety of buildings.

Cost-Effectiveness of PUF Sandwich Panels

When evaluating the cost-effectiveness of any construction material, it's crucial to consider both the initial investment and the long-term savings. PUF Sandwich panels excel in both areas, making them a financially savvy choice for construction projects.

Initial Investment

While the upfront cost of PUF sandwich panels might be higher than some traditional materials, their overall value becomes evident when considering the following factors:

Reduced Structural Costs: The lightweight nature of PUF sandwich panels means that buildings require less structural support, leading to savings on foundational materials and labour.

Lower Transportation Costs: Due to their lightweight, transportation costs are significantly lower compared to traditional building materials.

Simplified Installation: The ease of installation reduces labour costs and shortens the construction timeline, leading to faster project completion and earlier occupancy.

Long-Term Savings

The long-term savings associated with PUF sandwich panels are substantial and contribute to their overall cost-effectiveness:

Energy Efficiency: The superior thermal insulation properties of PUF sandwich panels result in significant energy savings.

Maintenance Costs: The durability and resistance to environmental factors mean that buildings constructed with PUF sandwich panels require less maintenance and have a longer lifespan.

Sustainability: Many PUF sandwich panels are made with eco-friendly materials and processes, which can contribute to green building certifications and potential tax incentives.

Applications of PUF Sandwich Panels

The versatility of PUF sandwich panels allows them to be used in various construction projects. Some common applications include:

Commercial Buildings: Office complexes, shopping centers, and warehouses benefit from the energy efficiency and quick installation of PUF sandwich panels.

Residential Buildings: Homes and apartment complexes can achieve better insulation and reduced energy costs with these panels.

Cold Storage: The excellent thermal properties make PUF sandwich panels ideal for cold storage facilities and refrigeration units.

Industrial Buildings: Factories and industrial units require durable and low-maintenance materials, making PUF sandwich panels a suitable choice.

Conclusion

PUF Sandwich panels represent a cost-effective, efficient, and sustainable solution for modern construction projects. Their superior thermal insulation, durability, and lightweight properties make them a valuable addition to any building, offering both initial cost savings and long-term financial benefits. By partnering with Isoflex, a reputable PUF Sandwich Panels Manufacturer, construction companies can use high-quality materials that enhance their projects' overall performance and cost-effectiveness.

The adoption of PUF sandwich panels is not just a trend but a smart investment towards building a more sustainable and economically viable future. Whether for commercial, residential, or industrial applications, these panels offer unmatched benefits that make them a cornerstone of modern construction practices. As the industry continues to evolve, the role of innovative materials like PUF sandwich panels will only become more prominent, driving the construction sector towards greater efficiency and sustainability.

0 notes

Text

Cost-Effectiveness of PUF Sandwich Panels in Construction Projects

The construction industry continually evolves, with new materials and techniques being developed to improve efficiency, sustainability, and cost-effectiveness. One such innovation that has gained significant traction is using PUF (Polyurethane Foam) sandwich panels. These panels, produced by Isoflex, a reputable PUF Sandwich Panels Manufacturer, offer many benefits that make them a preferred choice for modern construction projects. This blog will delve into the cost-effectiveness of PUF sandwich panels and explore why they are becoming an integral part of contemporary construction practices.

Understanding PUF Sandwich Panels

PUF sandwich panels are composite materials of a lightweight core material, typically polyurethane foam, sandwiched between two layers of durable facing materials such as galvanized steel, aluminium, or other metal sheets. This configuration provides an excellent combination of strength, thermal insulation, and lightweight properties, making them ideal for various applications in the construction industry.

Key Benefits of PUF Sandwich Panels

Before diving into their cost-effectiveness, it's essential to understand the key benefits that PUF sandwich panels offer:

Thermal Insulation: PUF sandwich panels have superior thermal insulation properties, which can significantly reduce heating and cooling costs in buildings.

Lightweight: Despite their strength, these panels are lightweight, reducing the structural load on buildings and simplifying transportation and installation.

Durability: The materials used in PUF sandwich panels are highly durable and resistant to weathering, corrosion, and other environmental factors.

Quick Installation: These panels' modular nature allows for rapid installation,

reducing Labour costs and construction timelines.

Fire Resistance: Many PUF sandwich panels are designed with fire-resistant properties, enhancing the safety of buildings.

Cost-Effectiveness of PUF Sandwich Panels

When evaluating the cost-effectiveness of any construction material, it's crucial to consider both the initial investment and the long-term savings. PUF Sandwich panels excel in both areas, making them a financially savvy choice for construction projects.

Initial Investment

While the upfront cost of PUF sandwich panels might be higher than some traditional materials, their overall value becomes evident when considering the following factors:

Reduced Structural Costs: The lightweight nature of PUF sandwich panels means that buildings require less structural support, leading to savings on foundational materials and labour.

Lower Transportation Costs: Due to their lightweight, transportation costs are significantly lower compared to traditional building materials.

Simplified Installation: The ease of installation reduces labour costs and shortens the construction timeline, leading to faster project completion and earlier occupancy.

Long-Term Savings

The long-term savings associated with PUF sandwich panels are substantial and contribute to their overall cost-effectiveness:

Energy Efficiency: The superior thermal insulation properties of PUF sandwich panels result in significant energy savings.

Maintenance Costs: The durability and resistance to environmental factors mean that buildings constructed with PUF sandwich panels require less maintenance and have a longer lifespan.

Sustainability: Many PUF sandwich panels are made with eco-friendly materials and processes, which can contribute to green building certifications and potential tax incentives.

Applications of PUF Sandwich Panels

The versatility of PUF sandwich panels allows them to be used in various construction projects. Some common applications include:

Commercial Buildings: Office complexes, shopping centers, and warehouses benefit from the energy efficiency and quick installation of PUF sandwich panels.

Residential Buildings: Homes and apartment complexes can achieve better insulation and reduced energy costs with these panels.

Cold Storage: The excellent thermal properties make PUF sandwich panels ideal for cold storage facilities and refrigeration units.

Industrial Buildings: Factories and industrial units require durable and low-maintenance materials, making PUF sandwich panels a suitable choice.

Conclusion

PUF Sandwich panels represent a cost-effective, efficient, and sustainable solution for modern construction projects. Their superior thermal insulation, durability, and lightweight properties make them a valuable addition to any building, offering both initial cost savings and long-term financial benefits. By partnering with Isoflex, a reputable PUF Sandwich Panels Manufacturer, construction companies can use high-quality materials that enhance their projects' overall performance and cost-effectiveness.

The adoption of PUF sandwich panels is not just a trend but a smart investment towards building a more sustainable and economically viable future. Whether for commercial, residential, or industrial applications, these panels offer unmatched benefits that make them a cornerstone of modern construction practices. As the industry continues to evolve, the role of innovative materials like PUF sandwich panels will only become more prominent, driving the construction sector towards greater efficiency and sustainability.

0 notes

Text

Puf Panels

One of the key advantages of Engko Puf panels is is their lightweight nature coupled with high strength. This makes them easy to handle and install, saving time and labor during construction. Despite their light weight, PUF panels are incredibly durable and can withstand various environmental conditions, including extreme temperatures, moisture, and corrosion. As a result, buildings constructed using PUF panels are resilient and long-lasting.

0 notes