#cement blocks

Text

Suburban garden. This small garden is one in a row adjoining terraced, single story houses, built so that the wall of one house becomes the garden wall of another. Against this wall, a planting area has been retained with U-shaped pre-cast concrete blocks, and another adjoining row used to form a permanent garden bench, which can be provided with cushions in the summer.

The Garden Book, 1984

#vintage#vintage interior#1980s#80s#interior design#home decor#landscape#design#garden#fountain#plants#cement blocks#cement#flowers#modern#rocks#stones#home#architecture

1K notes

·

View notes

Text

Down on the corner.

25 notes

·

View notes

Text

Spotted pig in field (1925-1936?)

A very stout spotted pig stands near a cement block in a field. There are trees in the background.

Rochester Images digital collection

17 notes

·

View notes

Text

Concrete Blocks - Manufacturing, Classification & Uses

Concrete blocks are nowadays replacing bricks in masonry construction, notably in many multi-storeyed buildings. They are available in three types namely solid, hollow and cellular, widely used for the construction of filler walls and boundary walls in RC framework.

Concrete blocks are usually made in large sizes to make blockwork faster and consume less cement in joints than the brickwork. If the percentage of the voids is more than 25%, then they are hollow blocks and blocks with voids less than 25% are only perforated blocks.

The cellular concrete blocks are generally referred to as lightweight aerated concrete blocks. All these blocks are extensively used for compound walls and non-loadbearing walls.

Hollow blocks are specially made for loadbearing walls, which are useful in reducing a dead load of masonry in buildings. Blocks can also be with cement and sand called cement-sand blocks or with cement and soil called soil-cement blocks which are of low strength and use for low-cost construction.

Manufacturing of Concrete Blocks

BIS recommends a fineness modulus of the combined aggregate between 3.6 to 4 and coarse aggregates used are of size 6 to 12 mm. Lean mixes up to 1:8 are generally used. Concrete mix for concrete blocks should not be richer than one part of the cement to six parts of the volume of combined aggregate.

Concrete blocks can be handmade and also machine-made. The cast block is then cured in a water tank or yard for at least 14 days (water need to be changed at least every 4 days).

After curing, the blocks are dried for 4 weeks before being used in masonry construction. They should be stacked with voids in the horizontal direction to facilitate easy drying, or they should be steam cured and dried.

The whole process allows the complete shrinkage of the block to take place they are laid on the wall, which is very important for strong walls.

Classification of Concrete Blocks

Hollow concrete blocks

Open and Closed cavity-type hollow concrete blocks are classified into three grades:

Grade A - They possess a minimum density of 1500 kg/m³ and are used for load-bearing walls.

Grade B - They have a density below 1500 kg/m¬³ and used for load-bearing walls.

Grade C - These blocks are used for non-load bearing walls and have density more than 1000 kg/m³.

All these blocks are available in decorative facings like fluted facing to provide artistic effects.

Solid concrete blocks

They should be manufactured for specific concrete strength of 4.0 and 5.0 N/mm² in 28 days. These blocks are used as load-bearing walls and have a density of not less than 1800 kg/m³.

Paver blocks

These blocks are solid concrete blocks of different shapes specially made for exterior ground paving on sidewalks, parking lots, driveways, petrol pumps, industrial floors, etc.

AAC Blocks

AAC blocks refer as Autoclaved Aerated Concrete Blocks. These blocks are also termed as light-weight hollow blocks.

They are prepared as solid blocks from cement, water and materials like ground sand, pulverized fly ash together with additives to aerate and stabilize the air bubbles.

The final result is a mixture of thick liquid which is then poured into steel moulds to form large cakes. After some time, the mixture sets and ready to cut into a serious of individual blocks of required size using taut steel wires.

Very light blocks for partition and moderate-weight blocks for light loadbearing walls can be obtained from aac blocks. These blocks do not shrink on drying as the material is obtained by autoclaving.

The autoclaved cement product is crystalline, which is different from the product obtained by normal wet curing or by ordinary steam curing.

Sizes and Tolerances

The nominal dimensions of concrete block as per BIS are as follows:

Length - 600, 500, 450 or 400 mm

Height - 100 or 200 mm

Width - 50, 75, 100, 150, 200, 250 or 300 mm

Actual sizes will be less than 10 mm of mortar thickness. For Concrete and Hollow concrete blocks nominal length 390 mm and height 190 mm. The thickness for loadbearing walls is 190 mm, compound walls 140 mm and for filler walls 90 mm.

These dimensions can easily be achieved in machine-made blocks than handmade blocks. The width of blocks use for load-bearing walls is 200 mm and for parapet or filler walls is 100 mm.

Points to Remember:

The mortar strength should not be more than the strength of the blocks. With high mortar strength, cracks will be less and very large, but with low mortar strength, cracks will be small and distributed.

We should use only blocks that are cured properly for at least 14 days and dried for 4 weeks to avoid shrinkage during construction.

We should not wet the blocks while placing in masonry construction.

Freshly-made and uncured concrete blocks should never be allowed on the work.

Blockwork, particularly ordinary cement sand blocks and soil-cement blocks should not be used as loadbearing walls for concrete slab roof which favours to expand and contract with temperature.

The maximum difference in sizes allowed is ±5 mm in length and ±3 mm in height and width.

They should be protected from rains while being stored as they absorb moisture by wetting and shrinking on drying.

The main disadvantage of concrete blocks is shrinkage due to the movement of moisture content which is not present in bricks. As these blocks are much larger than bricks, any foundation movement will cause blockwork to crack more than the brickwork.

Cement blocks, Concrete blocks, Hollow concrete blocks, solid concrete blocks, Paver blocks, AAC blocks Concrete blocks in Hyderabad

#aac Blocks#aac blocks online#aac block size#Cement blocks#Concrete blocks#Hollow concrete blocks#solid concrete blocks#Paver blocks#AAC blocks

2 notes

·

View notes

Text

5 notes

·

View notes

Text

Cement: From Aesthetic to Sustainable Construction Solutions

Cement plays a pivotal role in the world of construction, serving as the backbone for some of the most magnificent and enduring structures humanity has created. This versatile construction component is essential in binding other building materials together, providing strength, stability, and durability to various structures. From residential homes to colossal skyscrapers, cement blocks is an fundamental element in construction. Its diverse product range, catering to different requirements and applications, further emphasizes its importance in the industry.

Explore Premium Construction Solutions at Birla Pivot

The significance of cement in construction projects cannot be overstated. Allow us to explore the different variants available for use.

1. Cement Used in Construction OPC 43 and 53

Among the different types of cement used, Ordinary Portland Cement (OPC) stands out, particularly the OPC 53 and OPC 43 grades.

2. White Cement for Aesthetic Appeal

White Cement is a variant known for its aesthetic appeal and artistic applications.

3. Ready Mix Concrete for Efficiency

The use of Ready Mix Concrete revolutionises efficiency in construction projects. This form of concrete, pre-mixed in factories under controlled conditions, ensures consistency in quality and performance.

4. Choosing Sustainability: Portland Pozzolana Cement (PPC)

In the quest for sustainable construction materials, Portland Pozzolana Cement (PPC)// stands out.

5. Smooth Finishes with Ready Mix Plaster

Ready to mix plaster brings efficiency and quality to achieving smooth finishes in construction. Its pre-mixed formula ensures consistent texture and quality, resulting in a flawless finish. This plaster is particularly valued for its time-saving qualities and long-lasting durability, making it a preferred choice for both interior and exterior wall applications.

0 notes

Text

2K notes

·

View notes

Text

Sell Cement Online with Cement Exchange App

Sell Cement Online Anywhere, Anytime with Cement Exchange App. Connect with more potential customers in your city and grow your business online hassle-free.

#sell cement online#how to sell cement online#buy cement online#cement exchange#business#news#home & lifestyle#technology#cement blocks#engineered wood flooring#ramco cement#developers & startups#solid wood flooring

0 notes

Text

the sudden cut to jay driving made me laugh

#YOU BROKE HIS LEG WITH A BLOCK OF CEMENT#i love this entry#marble hornets#alex kralie#tim wright#jay merrick#entry 35 btw

464 notes

·

View notes

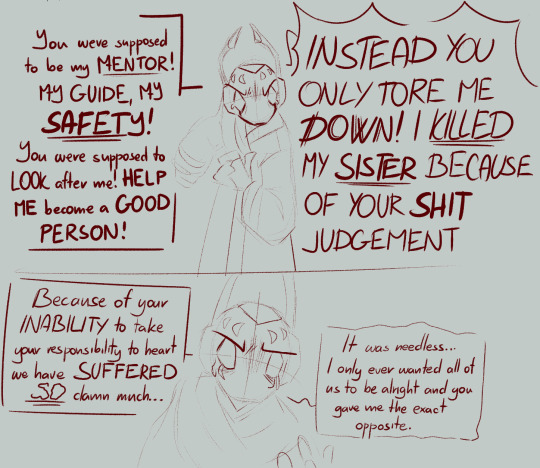

Note

Pebbles hating on Sun? I'm here for it. I love your version of Suns so much because it just encapsulates all their flaws that people often ignore. Is this my Pebbles bias speaking? Yes absolutely. Nobody LETS Pebbles be angry towards Suns when he has every right to. They just let the anger be outweighed or completely ignored in the favor of Pebbles own screwups.

I want to see Pebbles come into his own, decide he has worth as a living person, and there is value in living. Then, as someone who values his OWN worth, realize that Suns was toxic. That their friendship and mentorship was toxic. Let him be angry and let him cut that out of his life so he can focus on righting his own wrongs (which Pebbles does canonically anyways).

Realistically, Sun's and Pebble's friendship would never be the same. Even if Pebbles forgave Suns, I can't see their relationship being anything but strained. Moon and Pebble's situation cannot be compared to this since Moon is A. extremely forgiving/patient and B. her collapse was an accident on Pebble's part. She was angry yes but chose to rekindle her relationship with Pebbles in the end.

Five Pebbles is a completely different person from Moon and has a right to handle his mentorship with Suns in HIS way. So yeah, I cannot see off the string Pebbles doing anything but trying to heal from what Suns did to him (while also dealing with his own guilt).

here's a treat cuz oh i Know you are here for this, every time my version of these two are mentioned you come runnin jgksdlmcklsdm

#spot says stuff#rain world#rw#// body horror //#mr. decay#← for peeps to blacklist Suns' decayed design cuz o boye i kno it nasty. just in case. i aint gon make u look at this shit#anyway i hope this cements in the fact that id absolutely hate drawing these two in a romantic sense. i find the idea absolutely disgusting#not at u asker n i wont namedrop the reason for me sayin this cuz im not mean like that but there Is a reason n it made me really angry#i respect the shippers yall do yall but the moment u try to point the shit at me like that in Whatever small portion even though im very-#-clear about not likin iterator ships i Will be gettin angry. this is a warning. second time n im blocking

194 notes

·

View notes

Photo

Eye-catching arrangement. A clever and humorous use of a number of sculptural pieces. The arrangement is on a roof terrace and disguises surrounding urban ugliness.

The Garden Book, 1984

#vintage#vintage interior#1980s#interior design#home decor#garden#terrace#cement#blocks#flowers#brick#marble#sculpture#rooftop#trellis#city living

3K notes

·

View notes

Text

Back alley yellow.

23 notes

·

View notes

Text

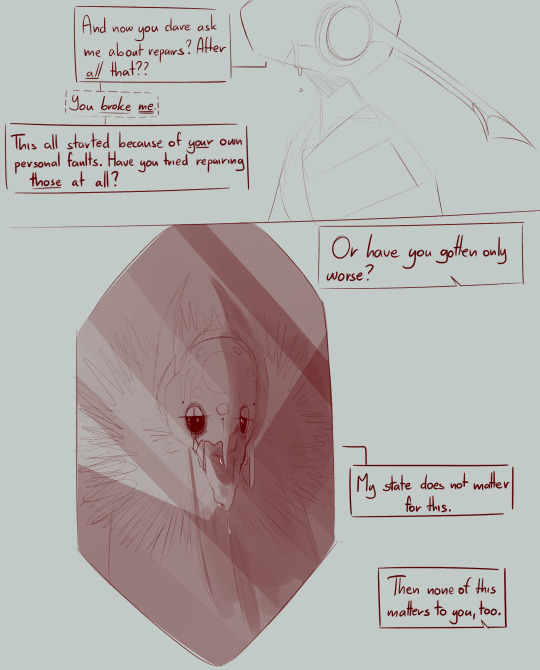

Please... Inagaki... no more...

#dr stone#wmposts#as you can tell by the blocks of text i have many thoughts about the ending#and each new piece of information just cements the late stage capitalist dystopia they made#and this isnt even touching onto my thoughts of senhaku or rurichrome (taiyuzu is fine)#why couldnt we get a bit about matsukaze's life!!!! or anything else!!!!!!!!

83 notes

·

View notes

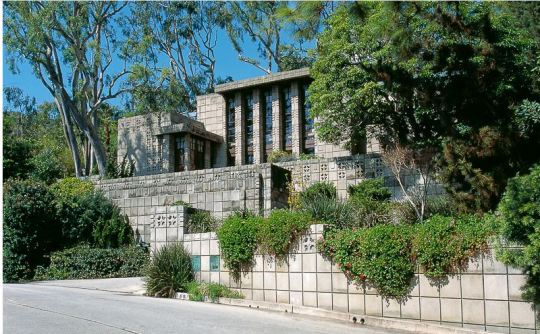

Photo

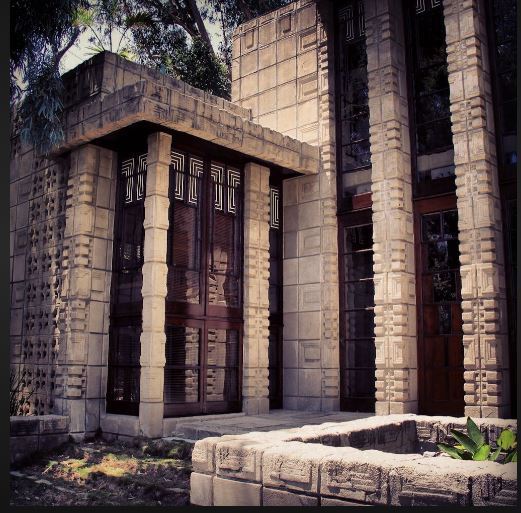

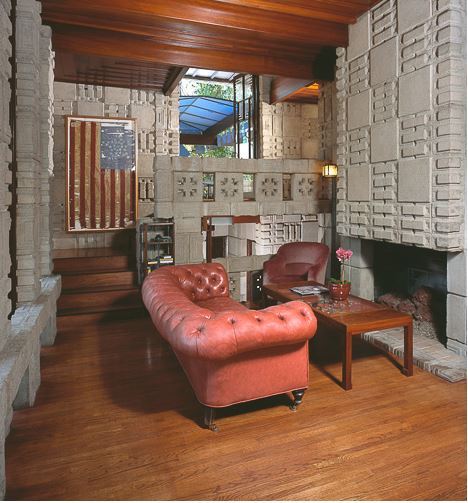

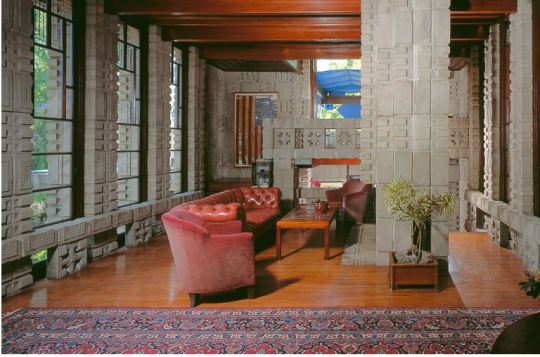

This is very unusual. It’s a Mayan Revival style home built in 1923, made of cement blocks and designed by Frank Lloyd Wright. Located in Los Angeles, California, the John Storer House is something different.

The house was built without a front door. The entrance is in the rear, "as if to finalize the metaphor of privacy and retrenchment." Wright used the textile-block motif to "fit" the home into the hillside, trying to create the impression that the home was "a man-made extension of the landscape."

The house is dominated by a large upstairs living room with a high ceiling,

The dining room and kitchen are on the main floor.

The textile-block houses were named for their richly textured brocade-like concrete walls. It was an experiment by Wright in modular construction that he called the Textile Block System

Fantastic Medieval-looking kitchen table.

He wanted to develop an inexpensive and simple method of construction that would enable ordinary people to build their own homes with stacked blocks, tied together with steel rods

One of 3 bds. in the home.

Outside is a walkway with a koi pond.

This looks like a lap pool, but it could be a gazing pool

Look at the mirrored glass art above the roof- that is amazing. It’s one of only 4 Mayan Revival style homes.

https://en.wikipedia.org/wiki/Storer_House_(Los_Angeles)

https://franklloydwright.org/site/john-storer-house/

#mayan revival home#cement block construction#john lloyd wright#houses#house tours#home tour#unusual homes#unqiue homes

280 notes

·

View notes

Text

Browse and Shop Different Cement Products Online

Cement Blocks: Also known as concrete masonry units (CMUs) or concrete blocks, they are large, rectangular bricks typically made from a mix of cement, water, and aggregates like sand, gravel, or crushed stone. The composition and production process of cement blocks gives them notable characteristics and uses.

Types of Cement Blocks:

Solid Concrete Blocks: Heavier and denser, used for load-bearing walls and other structural applications.

Hollow Concrete Blocks: Lighter with hollow cores, used for non-load-bearing walls, offering better insulation and easier installation for electrical and plumbing systems.

0 notes