#machining parts

Text

Everything You Should Know Regarding CNC Lathe Machines

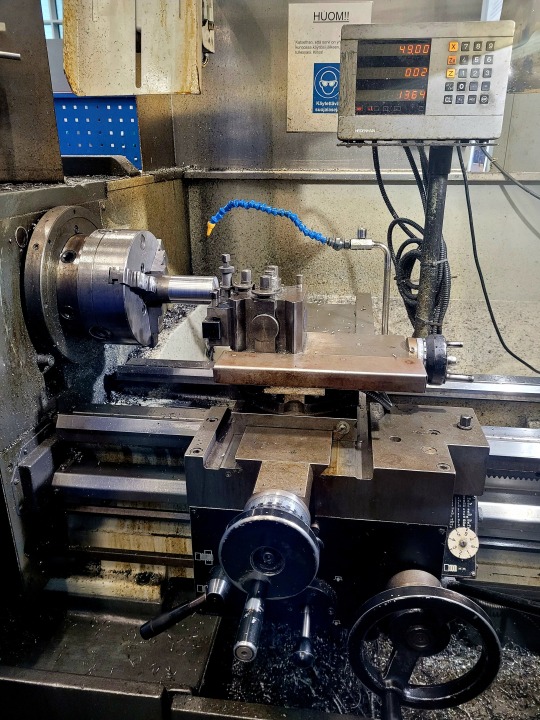

There are several types of CNC machining processes available today. CNC turning Parts, for example, employ a helix route to cut through the material, whereas CNC milling uses rotary cutters to remove the extra material. All of these need the use of specialized machining tools for the workpiece to perform the appropriate function. A CNC lathe is one such essential piece of equipment. The lathe is regarded as the first metal-cutting machine.

Let's take a closer look at the operation, characteristics, and different types of CNC lathe machines.

Introduction

A lathe machine with CNC lathe parts is primarily used to shape the material into the required shape by eliminating extra material from a particular workpiece (generally cylindrical). A lathe is used to accomplish sophisticated operations such as knurling, deformation, metal spinning, woodturning, thermal spraying, metallurgy, and more, in addition to cutting and facing.

The manual lathe was invented by reformers in Ancient Egypt and Greece, according to machine historians. The European nation commonly used the two-person lathe variant, with the former rotating the workpiece (wood) and the latter cutting off the extra material with a single-point cutting tool. The modern lathe arrived with the Industrial Revolution; it was sophisticated, quick, and better!

How Does a CNC Lathe Machine Work?

A standard lathe consists of a bed, headstock, tailstock, chuck, tool turret, carriage, and a spindle for feeding purposes, as detailed in the previous section. The following steps describe how this machine works:

· First, a cylindrical workpiece is mounted to the chuck after the machine has been checked for operational flaws. Its location might change depending on the situation.

· Second Step: We now adjust the spindle to the desired speed, causing the chuck and workpiece to rotate. The spindle speed must be monitored closely since any variation might result in cutting mistakes. Examine if the workpiece is rotating correctly.

· Third, move the tool turret and carriage to place the cutting tool at the appropriate feed. Pay close attention to the feeding rate. Remove any superfluous metal by moving the carriage to obtain the completed result in CNC machining parts.

Follow our Facebook and Twitter for more information about our product.

2 notes

·

View notes

Link

We provide high-quality mechanical or machinery parts at the best price in the USA. We have a wide range of CNC machining parts, metal casting, forgings, stamping, steel metal fabrications, and more. Order online now!

2 notes

·

View notes

Text

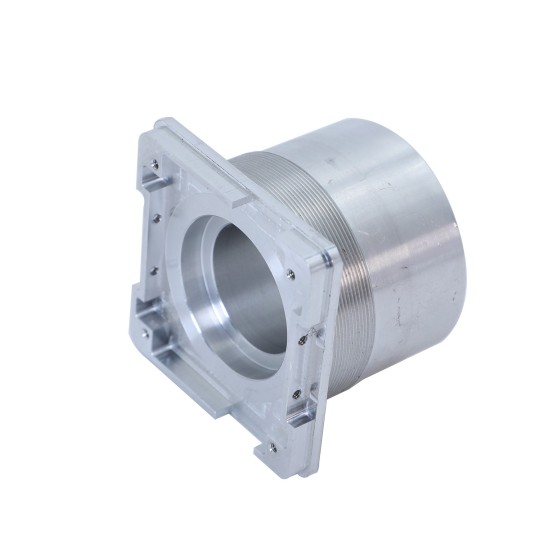

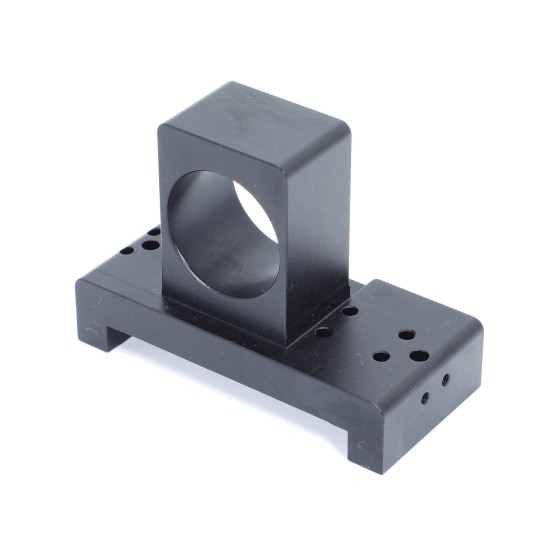

Precision CNC machining service for defence, automotive, medical, government, mining, aerospace, electronics and telecommunication industries.

#machinery#cnc machined components#electronic components#spareparts#manufacturer#factory#cnc machining#machining parts#precision machining#machinist

0 notes

Text

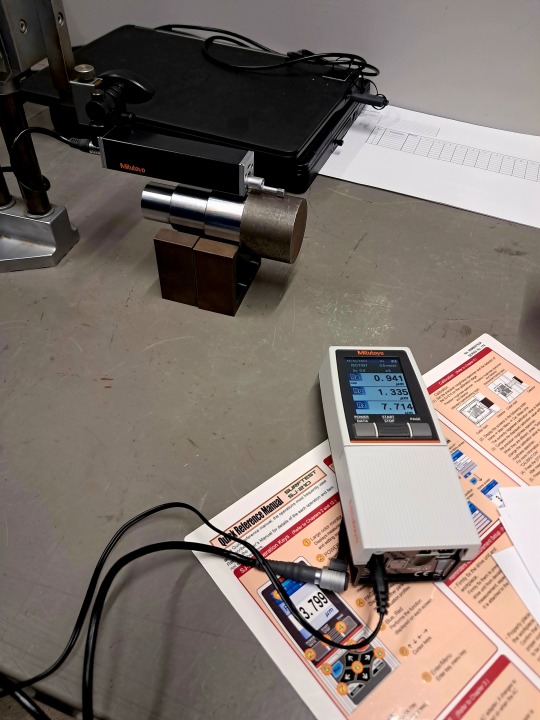

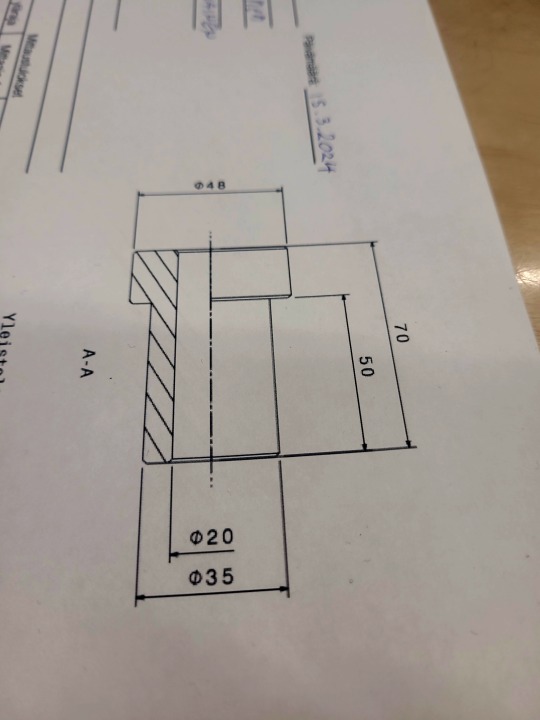

29.3.2024.

Nyt tuntuu, että oon saanut vähän paremman otteen opiskelusta tänä keväänä. Olen aika kovasti tosin joutunut karsimaan sosiaalista elämää, jotta pysyisin ajantasalla kaikissa aineissa.

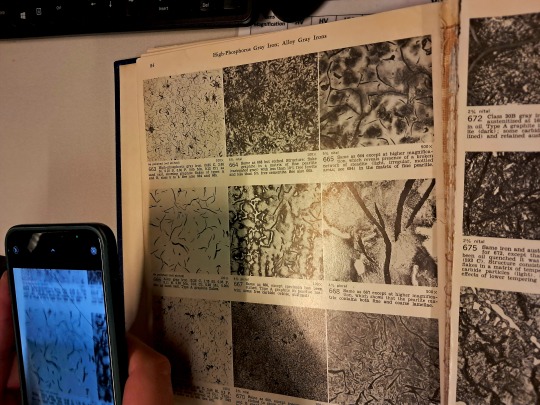

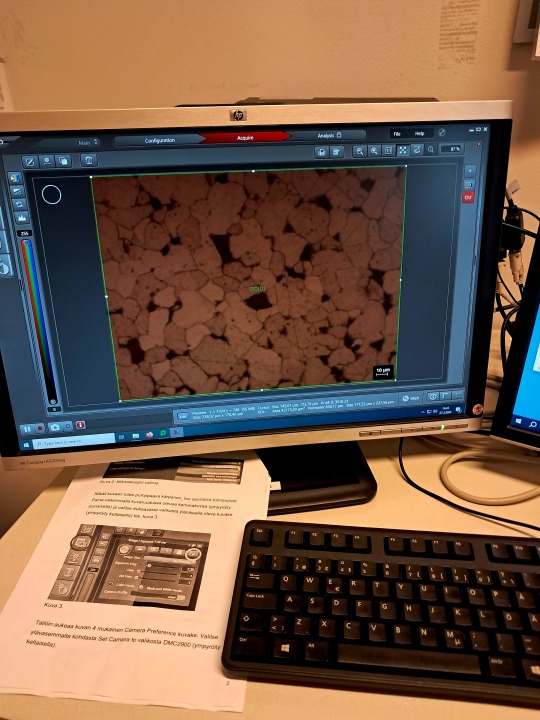

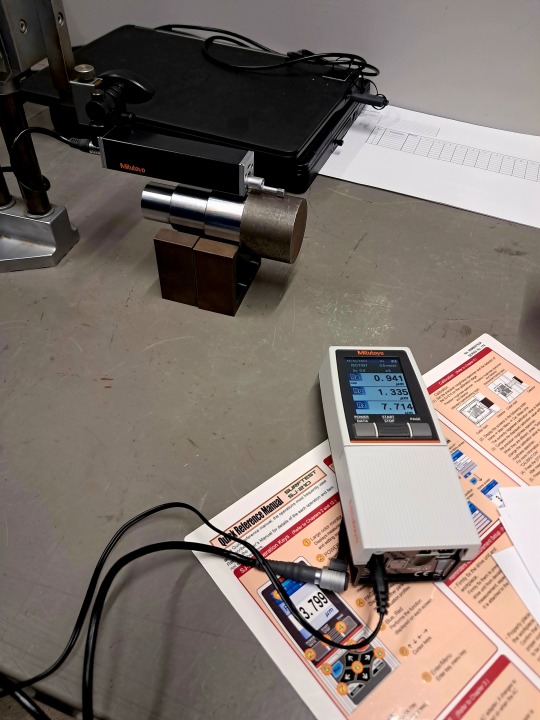

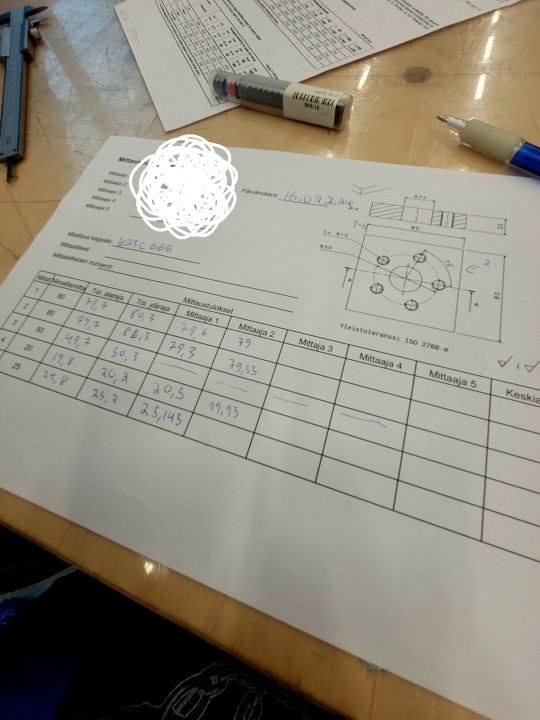

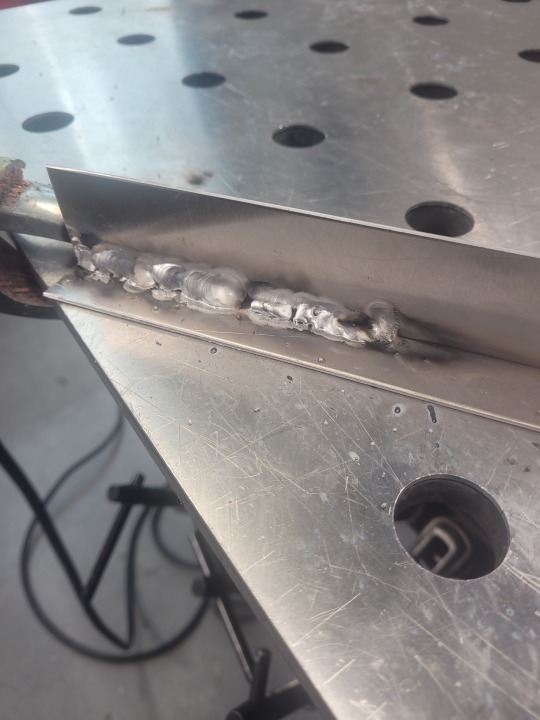

Uusia aineita tullut ja ollaan niissä pureuduttu aika perusasioihin. Materiaali-ja hitsaustekniikassa ollaan tutustuttu labrojen kautta ihan itse hitsaustekniilkaan ja materiaalitekniikassa tutkittu mikroskooppisesti metallin rakenteita jne. Valmistustekniikassa on taas tutustuttu erilaisiin metallin työstömenetelmiin. (sorvaus, poraus, jyrsintä, laserleikkaus).

Haastavana uutuutena tuli myös statiikka, jossa kyllä olen kovalla opiskelulla pysynyt ihan hyvin kärryillä. 🥳 Katotaan hyytyykö hymy sitte lujuusopissa 😱

Lisäksi meillä on meneillään johdantoprojekti. Eli eka pikku projektityö. Siitä voin kertoa lisää kevään lopulla.

Alla vähän kuvia koululta...

#konejametalli#konetekniikka#insinööriopinnot#physics#machining parts#student#metropolia#Metropolia Ammattikorkeakoulu#engineering

0 notes

Text

5 Facts You Should Know About Machined Parts

Machined parts are integral components in manufacturing and engineering processes, contributing to the creation of precise and intricate components used in various industries. Understanding the critical aspects of machined parts is essential for design, production, and quality control professionals. This article will elaborate broadly on the five crucial facts about machining parts in Texas, shedding light on their significance and the considerations involved in their production.

Machining Processes and Techniques:

Machining is a manufacturing technique that removes material from a workpiece to gain the desired shape, size, and surface finish. Several machines are employed, each suited for specific applications. Standard machining parts techniques include milling, turning, drilling, grinding, and electrical discharge machining (EDM).

Milling: Comprises rotating cutting tools to remove material from a stationary workpiece.

Turning: The workpiece rotates, and a cutting tool removes material to create cylindrical shapes.

Drilling: Creates holes in the workpiece using a rotating drill bit.

Grinding: Achieves high-precision surface finishes through abrasive cutting.

EDM: Uses electrical discharges for intricate and precise shaping of conductive materials.

The choice of machining process depends on factors such as material properties, part geometry, and production volume.

Materials for Machining Parts:

Turned components can be produced from various materials, including metals, plastics, and composites. Typical metals used in machining include aluminium, steel, stainless steel, and titanium. Each material has distinct properties that impact the machining process, such as hardness, thermal conductivity, and machinability. For example, aluminium is known for its excellent machinability, making it suitable for applications where lightweight and corrosion resistance is essential.

The preference for materials is a critical element of machining, as it directly influences the tool selection, cutting speeds, and overall machining strategy.

Tolerances and Precision:

One of the defining characteristics of machining parts in Texas is the high level of precision that can be achieved. Tolerances relate to the allowable deviation from a specified dimension, and machining processes can achieve tight tolerances, often measured in micrometers. Precision is crucial in aerospace, automotive, and medical industries, where components must fit together seamlessly and meet strict performance criteria.

Achieving precise tolerances requires careful planning, tool selection, and monitoring of machining parameters to ensure consistent and accurate results.

CNC Machining:

Computer Numerical Control (CNC) machining has revolutionized the production of machined parts. CNC machines use computer agendas to control the movement of cutting tools and workpieces, enabling highly automated and precise machining. This technology creates complex shapes and intricate details efficiently and repeatably.

CNC machining offers advantages such as increased productivity, minimizing human error, and the ability to produce prototypes and small batches quickly. The versatility of CNC machining components makes it a cornerstone of modern manufacturing.

Surface Finishes and Treatments:

Machining components often undergo additional processes to achieve specific surface finishes or enhance their properties. Depending on the application requirements, surface finishes can range from rough to mirror-like. Procedures such as polishing, anodizing, plating, and coating are commonly employed to improve aesthetics, corrosion resistance, and wear resistance.

Polishing: Enhances surface smoothness and appearance.

Anodizing: Forms a protective oxide layer on the surface of aluminium parts.

Plating: Deposits a metal layer onto the surface for improved corrosion resistance.

Coating: Applies a protective layer to enhance properties such as hardness or lubricity.

These additional treatments are crucial for ensuring that machined parts meet the functional and aesthetic standards of the final product.

The Bottom Line

Turned components are fundamental in manufacturing and pivotal in creating precise and intricate components across diverse industries. Understanding the various machining processes, material considerations, tolerances, the impact of CNC machining, and post-machining treatments is crucial for professionals involved in designing and producing these components. The ability to make high-precision machined parts is a critical factor in the success of industries that demand accuracy, reliability, and performance in their end products.

#machining parts#machine parts manufacturer texas#machining parts texas#turned components#machining components

0 notes

Text

Professional manufacturer customized Actuating shaft #cusn

0 notes

Text

Production of connector lamp hardware accessories

0 notes

Text

Really funny that Colin insists that Alice shouldn't give the computers a personality JUST MOMENTS AFTER he claimed that the computers are fucking with him and him specifically due to their hateful and capricious nature

#i mean part of that is just how you feel working in IT i guess#but its funnier that he wants to pretend nothing weird is going on while also expressing his undying hatred for these sentient machines lol#tmagp#tmagp spoilers#tmagp 3#the magnus protocol#colin becher#also lets not gloss over the jmj error. and the sassy beeps when it refuses to run. you know they are getting salty cooped up in there

4K notes

·

View notes

Text

tsum events really are just the best, huh

#art#twisted wonderland#twisted wonderland spoilers#tsumsted wonderland#to be fair this is from mal's card story so it's more...event-adjacent#i-it still counts right#poor malleus tsum is having such a time#first it blows up the kitchen and then it almost gets spin-cycle'd to tsum-death#the poor little guy just wanted to help with the party! it was trying its BEST 😭#and instead it accidentally recreated every other tuesday from my college days#i am so genuinely delighted to read two entire chapters of malleus bragging about knowing how to use household appliances#(he knows what he's doing! he READ the MANUAL)#(you know that manual has copious notes covering the margins in perfect copperplate)#and the callback to his dorm ssr story. perfect.#we all knew this was going to end in malleus punching a washing machine into smithereens#i'm disappointed that the next part is probably just going to be a fun party or whatever#and not malleus showing off how close he is to finally mastering the toaster#twst please where is my spinoff game where we have to help a dragon fae prince learn how to do household tasks#i have an indescribable need to see malleus attempt to use a vacuum#he is very enthusiastic and also very stupid and we love him for it

3K notes

·

View notes

Text

#mikayla demaiter#in motion#blue sweater#part 2#beautiful ass#perfect butt#amazing body#perfection#fit girls#18+ only#ultimate sex machine#so damn sexy

3K notes

·

View notes

Text

FOOL MASK (GITM BY @venomous-qwille)

Handbuilt porcelain with slip, overglaze, glaze, and gold lustre accents. Paint and lacquer detailing added post fire. Handsewn fool's cap and bells added post fire.

This mask is a part of a (loosely connected) mask series, all hand-built and fired using a range of different temperatures and techniques.

My favourite mask to date, Fool from Ghost in the Machine by the wonderful @venomous-qwille !! GITM is absolutely incredible and I cannot put into words eloquently how much I adore it and Fool so instead I made this mask! Hi!

My word was this mask a struggle to make. The mask itself is entirely one piece, and entirely porcelain!! That's right, those long thin rays are solid porcelain!! The eyes and tips of the blades are done in 22 carat gold lustre. All colouring save for the black and the satin sections of darker red on the face were done with only slips and underglazes. The red colour was correct without the paint, but I thought a contrast from the rest of the gloss would look nice :)

Made to scale, the mask measures 50.8x60.96cm without the hat, and 50.8x116.84cm with it! (20x24in without hat, 20x46in including hat). He is Large, but turned out absolutely lovely and I send my many many thanks to the kiln gods for producing him unscathed.

(naku & wall for scale)

(he's so big guys i have large walls (the top of my head is only slightly above the top of the bookcase beneath him) look at him at the wall it's nuts)

#eyenaku#proudnaku#seriously so proud of this naku please interact with this my magnum opus of porcelain i hate porcelain but i love fool#my prof. encouraged me to make THE REST OF FOOL?? LIKE HIS BODY?? thats so much. i'm not gonna but that was a funny thing to experience#ANYWAYS HI QWILLE IF YOU'RE READING THIS THE TAGS!!#fool is such a guy#thas all! love ur stuff btw#art#pottery#ceramics#mask#masks#decorative masks#porcelain#fool#fool gitm#fool ghost in the machine#ghost in the machine au#fool eclipse#ghost in the machine#gitm au#gitm fool#eyenaku masks#hehe happy fool day#I think the funniest part of making him was the tactical smooch I had to make to save his face it’s a whole thing#clip next.

1K notes

·

View notes

Text

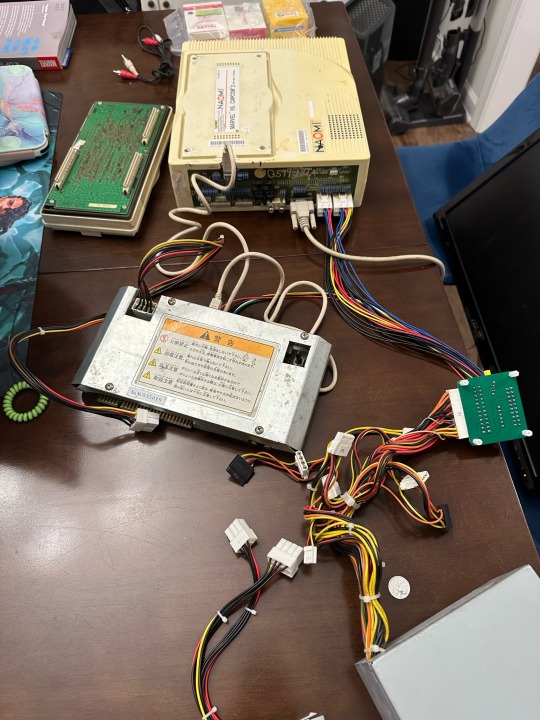

Last year I got ahold of the arcade PCB for a game called Biohazard: Gun survivor 2 Code Veronica. I’ve always wanted to play this game, so I decided to build the rest of the arcade cabinet.

It’s been a while, but I have an update!

The game runs!!! I still have to build out all the controls for the game, and a physical cabinet to house the game, but it runs!!!!!

#I’m so excited yall!#I have a lot more parts I need to get#and the actual light gun controller is a weird thing#it’s a joystick/light gun that wasn’t used in a lot of other machines#and it isn’t well documented#but this is progress!!!!

1K notes

·

View notes

Text

Know About CNC Machining Design Parts

Know About CNC Machining Design Parts

To assist you to get the greatest outcomes for your bespoke components, we’ve combined fundamental & advanced design methods and advice in this comprehensive guide to designing for CNC lathe parts.

You may prepare your designs for computer numerical control (CNC) machining by following a few simple procedures. You may maximize the potential of CNC machining by adhering to…

View On WordPress

0 notes

Text

Kinda miss drawing pinups. Plus, I just think this weirdo is neat.

also,

I find it really funny how DCAs are canonically shirtless but if you put a shirt on one of them and have them take it off??-- Scandalous.

COVER UP, HUSSY.

GITM -> @venomous-qwille

(Close up under cut)

#cw suggestive#fnaf dca#dca fandom#gitm au#soleil#ghost in the machine#ghost in the machine au#LattoMacchiatoDraws#sun fnaf#sundrop fnaf#gitm sol#sol#sol just scratches that creepy/cute part of my brain#i'm in love with an emotionally constipated robot

1K notes

·

View notes

Text

Understanding the Essential Elements of Precision Machined Components

In the realm of modern manufacturing, the creation of precision machined components stands as a testament to engineering excellence and meticulous craftsmanship. Texas, known for its industrious spirit, serves as a hub for machining parts, showcasing a mastery in producing intricately designed components that fuel various industries. Let's delve into the intricacies of precision machined components and their pivotal role in driving innovation and efficiency across diverse sectors.

Exploring Precision Machined Components:

Precision machined components are the cornerstone of many industries, ranging from aerospace and automotive to healthcare and beyond. These components undergo a meticulous manufacturing process that demands precision, accuracy, and expertise. Machining parts in Texas exemplify this commitment to perfection, blending cutting-edge technology with skilled craftsmanship to create components with exacting specifications.

The Art of Machining Components:

Crafting precision machined components involves a symphony of techniques, including milling, turning, drilling, and grinding. Each process requires a deep understanding of materials, tooling, and machining methodologies. In Texas, manufacturers leverage state-of-the-art CNC (Computer Numerical Control) machines that operate with unparalleled accuracy, ensuring that even the most complex designs are replicated flawlessly.

Quality and Consistency:

One hallmark of precision machined components is their unwavering quality and consistency. Texas-based machining facilities adhere to stringent quality control measures at every stage of production. From raw material selection to final inspection, rigorous protocols are in place to maintain superior standards, meeting or exceeding industry specifications.

Applications Across Industries:

The versatility of precision machined components transcends industries. In aerospace, these components contribute to the construction of aircraft engines, ensuring optimal performance and safety. Automotive sectors rely on them for precision parts within transmissions and braking systems. Moreover, in healthcare, these components play a pivotal role in medical devices, promoting accuracy and reliability.

The Role of Technology:

Advancements in technology continually reshape the landscape of precision machining. Texas-based manufacturers embrace cutting-edge innovations, such as 5-axis machining and computer-aided design (CAD), to push the boundaries of what's achievable. These technologies enable intricate designs and enhance the efficiency of production processes, allowing for faster turnaround times without compromising on quality.

Ensuring Safety and Compliance:

Amidst the pursuit of precision, safety remains paramount. Machining facilities in Texas prioritize a safe working environment, implementing robust safety protocols and adhering to industry regulations. Additionally, they emphasize sustainability by adopting eco-friendly practices and optimizing resource utilization, contributing to a greener future.

The Future of Precision Machined Components:

Looking ahead, the trajectory of precision machining in Texas appears promising. The synergy between human expertise and technological innovation continues to drive advancements in component manufacturing. With a relentless focus on precision, adaptability, and innovation, these components will remain indispensable in shaping the industries of tomorrow.

Precision machined components represent the pinnacle of engineering finesse and manufacturing excellence. In Texas, the fusion of cutting-edge technology and skilled craftsmanship elevates the creation of these components to an art form. As these components continue to evolve, their impact will reverberate across industries, fueling progress, innovation, and technological breakthroughs.

#machining components#machine parts manufacturer texas#machining parts#machining parts texas#turned components

0 notes

Text

Professional manufacturer customized Actuating shaft

0 notes