#sewage treatment plant on ships

Text

https://www.advanceequipment.in/effluent-treatment-plant-manufacturer-supplier-in-punjab-india.php

#sewage treatment plant#water treatment plant#sewage treatment plant process#water treatment#sewage treatment#sewage treatment plant on ships#wastewater treatment#sewage treatment process#sewage treatment plants#marine sewage treatment plant#sewerage treatment plant#wastewater treatment plant#sewage treatment plant animation#sewage treatment plant working model#effluent treatment plant#marine sewage treatment plant working principle#treatment process

3 notes

·

View notes

Text

"In Washington D.C., a sophisticated sewage treatment plant is turning the capital’s waste into a form of capital: living capital that is fertilizing the gardens of farms of the Mid-Atlantic region and saving vast quantities of resources.

Described by the workers’ there as a “resource recovery plant,” D.C. Water run a biogas plant and high-quality fertilizer production in the course of their dirty duty to ensure the city’s waste finds a safe endpoint.

The nation’s capital is exceptional at producing waste from the toilet bowls of the 2.2 million people who live, work, and commute through the city and its suburbs.

Reporting by Lina Zeldovich reveals that rather than trucking it all to a landfill, D.C. Water extract an awful lot of value from the capital crap, by looking at it as a resource to send through the world’s largest advanced wastewater treatment plant, which uses a “thermal hydrolysis process” in which it is sterilized, broken down, and shipped off for processing into “Bloom,” a nitrogen-rich, slow-release fertilizer product.

The other “Black Gold”

At their facility in southwest Washington, huge aeration tanks percolate the poo of everyone from tourists to the President. After it’s all fed into enormous pressure cookers where, under the gravity of six earth atmospheres and 300°F, the vast black sludge is rendered harmless.

Next this “Black Gold,” as Zeldovich described it, is pumped into massive bacterial-rich tanks where microbes breakdown large molecules like fats, proteins, and carbs into smaller components, shrinking the overall tonnage of sewage to 450 tons per day down from 1,100 at the start of the process.

This mass-micro-munching also produces methane, which when fed into an onsite turbine, generates a whopping 10 megawatts of green energy which can power 8,000 nearby homes. [Note: Natural gas (which is mostly methane) is definitely greener than coal and oil, but it still causes a significant amount of emissions and greenhouse gases.] The 450 tons of remaining waste from the D.C. feces are sent into another room where conveyor belts ring out excess fluid before feeding it through large rollers which squash it into small congregate chunks.

D.C. Water sends this to another company called Homestead Gardens for drying, aging, and packaging before it’s sold as Bloom.

“I grow everything with it, squashes, tomatoes, eggplants,” Bill Brower, one of the plant’s engineers, tells Zeldovich. “Everything grows great and tastes great,” he adds.

“And I’m not the only one who thinks so. We’ve heard from a lot of people that they’ve got the best response they’ve ever seen from the plants. Particularly with leafy greens because that nitrogen boost does well with leafy plants. And the plants seem to have fewer diseases and fewer pests around—probably because Bloom helps build healthy soils.”

While farms around the country are facing nutrient depletion in soils from over-farming, turning to synthetic fertilizers to make up the difference, introducing more such thermal hydrolysis plants could truly revolutionize the way humans look at their feces—as a way of restoring the country’s soils rather than polluting them. As Mike Rowe would say, it only takes a person who’s willing to get their hands dirty."

-via Good News Network, November 23, 2021

Note: You can buy this fertilizer yourself here!

#older news but still relevant#you can go buy this fertilizer yourself!#sewage#sanitation#fertilizer#sustainability#circular economy#sustainable agricuture#nitrogen#waste#waste management#waste disposal#good news#hope#hope posting#washington dc#dc#united states#district of columbia#urban farming#solarpunk#urban gardening#environmentalism#farming#rooftop garden#gardening#edible gardening#toilet#soil#soil quality

128 notes

·

View notes

Text

The Grand Eureka Colony Tour!

It's here at last! The Grand Finale Colony tour! Woo! I'm very proud of this colony, I hope you like it too.

For a sample, let's begin with a shot of the whole of Eureka:

Ta-dah! Isn't it gorgeous? It's a very big colony, so once again I'm going to put the rest of it under the cut so it won't clog up people's dashboards with my screenshots and rambling.

Starting on the left, we've got our first animal pens. The large pen is home to a variety of animals, listed as follows:

Laser, Dominator, Tryst, Clementine, Quintin, Nikita, Safari, Excalibur and Ragdoll the alpacas

Devotion and Mozart the neutrolopes (like boomalopes but for neutroamine, from the 'ReGrowth: Core' mod)

Verona the Cyrenian hind (from the 'Alpha Mythology' mod)

Samson the teratogenic originator (from the 'Alpha Animals' mod)

Teacup, Hayley, Portia, Nadine, Aiko, Fraiser, Salty, Chaplin and Smarmer the horses

Also sleeping in the large pen's barn but not confined by the fences is:

Calvin, Honcho, Whoopie, Zombie, and Paprika the nightling cubs (from the 'Alpha Animals' mod)

Kiki the murkling (from the 'Alpha Animals' mod)

Bryanna and Marauder the red pandas (from the 'Vanilla Animals Expanded' mod)

Tommy Brock the badger, one of only two animals in the colony who does not have a randomized name (from the 'Vanilla Animals Expanded' mod)

Elegance the baby razorjack (from the 'Alpha Animals' mod)

The small pen is where we keep our ducks. They are named Olivia, Pepe, Shrimp, Dynamo, Zack, Tipsy, Augusta, and Adele. They're very useful for eggs, and we cycle through the duck population every few quadrums so we have fresh meat to make kibble (don't tell the ducks that, though).

Speaking of meat, next to the pens are our abattoir/kibble-making freezer, our nutrient paste dispenser, and the prison. Prisoners (and suspected-mime Eva) are put on a strict nutrient-paste-only diet, so the proximity helps.

You can also see three of our twelve chemfuel-powered generators and a teeny-tiny secret patch of smokeleaf that we're growing to keep hippie-drug-cultist Gracie happy. Below that are some decorative chemfuel barrels and our sewage treatment plant.

Next there's the hot tub room with its adjoining facilities, famous for its romantic pink lighting and for being the place where Wookshys proposed to Albina back when I didn't like him.

Also pictured is the children's bedroom, with high-tech illuminated beds, dresser, and end tables so they don't need to worry about being scared of the dark.

Moving on, we have the classroom that has seen so many of my colonists pass on their knowledge to the children in a variety of sweet and amusing interactions. Next to the classroom is the obligatory schoolyard vegetable patch, which provides most of the vegetarian component for the kibble made in the abattoir next to it.

Don't mind Jesse and his square, by the way. I was already drafting this post before a lovely anonymous ask helped me fix the Curse of Jesse's Box (I love you, anon)

Here is the ship we have worked so painstakingly to construct, pictured alongside the tomb for cuterpillar Bernie, a patch of opuntia (prickly-pear) cacti from when Albina was testing one of her psycasts, and the thrumbo barn where Pharaoh, Brandi, Big Dipper, Caramel, Bellboy, Ray, Belladonna, Dollie, Apollo, and Dallas sleep at night.

The Ancient Danger has been transformed into a delightful hybrid space, as it is one part laboratory for mechanitor Fafo to muck about in, one part rec room with a billiards table, a dartboard, and even a television set, and one part drug operation because it is where we grow our psychoid plants ready for when Hussar Henry is old enough to need them (along with some mint and uranium root for funsies).

There are also six more chemfuel generators, an infinite chemreactor, and the legendary monument that Fafo carved depicting her then-fiance now-husband Kaz, which is used as a meditation for all colonists with the artistic focus type.

This is the pool room, which comes with an arcade machine, longwave radio, and roulette table. Next to it are the last three chemfuel generators.

Underneath, there are two barrack rooms. The one on the left is home to Gracie, Emerald, Grump, Hot Minute, and Sam the razorjack. The barracks on the right is currently only home to Jesse and Kelorul, along with Beau the razorjack. There's also a bathroom close by for easy access.

The devil sheep pen is home to many adorable little red devilstrand-producing sheep from the 'Alpha Animals' mod. Sixteen of them to be exact! Their names are Blossom, Petit, Persephone, Tank, Clarence, Crockett, Stellar, Dudette, Violator (my favourite), Honed, Soldier, Heather, Seargent, Fabian, Adonis, and Cassandra. Ingrid the red panda also sleeps in the devil sheep pen for some reason.

To the right you can see a neat little dining area with some sculptures and an industrial radio for recreation, and below that is the temple used by followers of Wendy, Laurie, and Jesse's ideology. There's also a horseshoes pin, for anybody who feels like some low-tech recreation.

Then there are the boomalope pens, made out of granite instead of wood to avoid any potential fire mishaps. They contain the main providers of the chemfuel we use to power our twelve chemfuel generators. The top pen contains our two male boomalopes, Hunter and Dude, and the bottom pen has the three females, Margarita, Missile, and Liability.

I am of the opinion that "Missile" and "Liability" are the best randomly generated names a boomalope could ever have.

Here is our Wedding Chapel/music room, a lovely little space that the couples of Eureka like to frequent in order to enjoy some musical romance with one another (demonstrated here by Kaz playing the drums for his lovely wife).

Outside we also have a little barbecue and dining area for those few colonists who aren't vegetarian, and in the top left corner, you can see the band node that Fafo is tuned to so that she can hopefully get more mechs in the future!

This is Eureka's clothing closet (and where we keep the caravan bedrolls too). That long rectangle building in the bottom left is a "monument" we built for the Empire, which is now a fireproof chemfuel storeroom, and also where we brew chemshine to sell to traders (and to satiate Eva's chemical interest trait).

Fafo made both of those monuments, but only one of them (the pyramid) is of legendary quality. The other is only excellent quality, and depicts "a politician playing blackjack with a thousand hooligans".

Some of the planting zones are here, too, including our blueberry field and apiary, one of our chickpea patches, some rice, some cotton, and some sugarcane.

Some more planting zones (rice, chickpeas, potatoes, onions, more rice and chickpeas, even more chickpeas, gold fern, allspice, plasteel bulbs), along with our only wind turbine and the first solar panel we ever built.

The bedroom at the top right is Albina and Wookshys' room, they share it with Rogan the rottweiler (from the 'Vanilla Animals Expanded' mod). The bedroom below that is Kaz and Fafo's room, which they share with Kaz's bonded razorjack Roxy (from the 'Alpha Animals' mod). The bedroom in the middle is where Hazrov and Candlelight sleep, along with Reaper the razorjack and Anatoly the Tasmanian devil (from the 'Vanilla Animals Expanded - Endangered' mod).

Four more bedrooms here:

Top left is Wendy and Tamarind's room, shared with Stabber the razorjack (from the 'Alpha Animals' mod)

Top right is Kawoo and Andrei's room, shared with Frisbee the pulmonoscorpius (from the 'Megafauna' mod). Outside their bedroom are also three cheese presses, where we... ~drumroll please~... make cheese!!

Bottom left is Vu and Laurie's room

Bottom right is Baz and Zonovo's room, which they share with Jellybean the razorjack.

Moving on, we can see the temple of The Wavian Path (Wookshys' sub-cult), with the tomb we built for Wendy and Pearl underneath it. Pearl is still buried there, alongside Fafo's nephew Pinovo because Wendy was resurrected.

Across from the tomb is the landing pad for shuttles and such, along with our ground-penetrating scanner and long-range mineral scanner. In the top left corner, you can also see our main workshops, which contain our smelter, smithy, machining table, fabrication bench, and animal bionics tables. The room with the fabrication bench is also where Buccanneer the drebbbd (from the 'Ebbbs' mod) sleeps.

Outside the workshops are our weapons shelves.

I'm glad I eventually decided to like Wookshys, look how content he is hanging out here on his little fishing bridge. He's close by a lovely picnic table, some bathrooms, an obelisk, and some plantations of almond trees and water chestnuts. He's having a grand time. This site is so pretty, it's one of my favourite places in the whole colony.

There's also a bathing zone on the other side of the bridge, but I... Uh... I wouldn't swim there for a while. The recent raids might have polluted the water a bit.

Here's our natural meditation area, home to our beloved Anima tree, three Gauranlen trees, and a little jade nature shrine.

Connie is connected to one of the Gauranlen trees, and she has two berrymaker dryads named Herbert and Mortimer. They're very sweet, and I love them both.

Jesse is connected to another Gauranlen tree and currently has a medicinemaker dryad named Wiseguy. A big help to the colony and an all-around cute little guy.

The last Gauranlen tree is connected to colony leader Albina, and she has a funky little acidic spitter dryad from the 'Vanilla Ideology Expanded - Dryads' mod. His name is Rolland, and I adore him. He's so snakey and fun. I should try to draw him someday.

Here's our freezer, our kibble shelves with Colonist-Gracie's secret smokeleaf-joint-rolling crafting spot hidden between them, one of the bathrooms, the water pumping/treatment facilities for said bathroom, and our single mortar with the shelf that has shells for it.

This is the majestic temple for The Path of Animism, the one true ideology for The Animist Alliance. We don't do a whole lot in here, but it's nice to look at. Below the temple is the storeroom for things that don't have to be in the freezer, which is mostly wood and silver at the moment.

We also have the crematorium and some of our fruit trees (four lemon trees, two avocado trees, a blood orange tree, and an apple tree). In the weird divet in the wall of the crematorium is an animal sleeping spot for our geriatric salamander Orion, from the 'Alpha Mythology' mod.

Here we have the obelisk marking our crash-landing site, next to our patch of peas and our outdoor dining area. In the top left corner is Debby and Eva's bedroom, which they share with Polly and Limbo the nightlings (from the 'Alpha Animals' mod).

Beneath that room is the room Brennan used to share with Debby, but now sleeps in alone since the divorce. There are sleeping spots in there for Cinnamon and Moonstruck, Brennan's steel and rock constructs, but I don't think they actually sleep, so the spots aren't used. Behind her room is the stonecutting bench.

In the middle, above the pea patch, is Barghest's room. He's ascetic and doesn't care for fancy things, so it's just him, his bed, and a sleeping spot for Flicker the razorjack (from the 'Alpha Animals' mod). Sleeping along the outside of Barghest's room are:

Hood, Elias, and Huck the red pandas (from 'Vanilla Animals Expanded')

Sinbad the thrumebbb (from the 'Ebbbs' mod)

Witch the cave bear (from the 'Vanilla Animals Expanded - Caves' mod)

Echo the short-faced bear (from the 'Megafauna' mod)

Asset the ankylosaurus (from the 'Biomes! Prehistoric' mod)

And then on the right side, we've got the kitchen/dining room, alongside the art and tailoring benches.

Eureka has a very well-equipped hospital, with plenty of high-tech medical facilities and a sterile drugs lab which has been put to use making lots of medicine to tend injuries and go-juice for when Henry is old enough to be dependant on it.

The research lab is where Brennan spends most of her time, and often one of the kids will hang out in there with her, radiotalking to get their learning desire up.

You'll never be short a bathroom in Eureka, there are plenty to choose from, and most of them are quite nice (in my humble opinion). There's also a lovely hot spring surrounded by manicured lawn, should you choose to relax that way. It is situated quite close to our rock/bone pile, but I can't be bothered rearranging it, so it remains an eyesore, I'm afraid.

There are also some transport pods that are used for the occasional trip out-of-colony or to dispose of toxic wastepacks until we finish researching the wastepack atomizer.

If hot springs aren't to your taste, you could always relax in the saunas! They're found right beside the bedroom that Irwin and Connie share with Bartholomew the ripper hound (from the 'Alpha Animals' mod) and Energizer the angora rabbit (from the 'Vanilla Animals Expanded - Royal Animals' mod), who is the only animal aside from Tommy Brock the badger to not have a randomized name.

Next to Irwin and Connie's room is a small table and two more animal sleeping spots, one for Chianti the boombat (from the 'Vanilla Animals Expanded' mod) and Bernardo the dimorphodon (from the 'Biomes! Prehistoric' mod).

Eureka has plenty of guest rooms for hosting friends and family from other factions, mostly our allies from The Android Alliance. We don't charge for staying here, as the bounties of The Animist Alliance should be free of charge for everyone to enjoy!

In the top right, you can also see most of the water treatment facilities attached to the prison bathrooms and the hot tub room.

Finally, we have some more solar panels and our cocoa tree plantation, surrounded by coral coconut trees grown by another of Albina's psycasts gone awry.

And that concludes the endgame colony tour! I hope you like Eureka as much as I do. It's been a lot of fun playing with the City Builders meme, as I usually go for the "massive superstructure" instead of "quaint village", so it was a nice change of pace. I also think the end result is a very homey feeling community, so that's nice.

First | Next | Previous

#rimworld#gracie plays#The Animist Alliance#rimworld colony tour#long post#This is one of the best colonies I ever built#I'll be sorry to see it go#But I am super excited to see what the next one will bring!!#I hope you are too <3#Please enjoy this look at my haphazard building ability#You can tell I prioritize form over function#So it looks nice despite being impractical#Well I think it looks nice anyway#Thank you so much for sticking with me this far!!#I love you all so much#Have an amazing day <3 <3

25 notes

·

View notes

Note

I've been thinking about getting Workers and Resources but have a two questions about it:

1. how low can you get those graphics to increase performance? my laptop is NOT built for gaming but I crave a planned economy simulator

2. does it have similar issues to cities skylines? either in terms of bugginess or gameplay plateauing and getting boring

thx so much :)

1: I do have a gaming laptop but to reduce its operation to about the same as a standard consumer laptop, I run 4 firefox windows each with 30 tabs and also have MATLAB constantly running. This eats about 80% of its functional ram and CPU/GPU power. Despite this sadist torture of my beloved silicon sister, she can still run W&R:SR adequately with their lowest auto settings. The game runs on unity (afaik) so you can customize most of the major things in the initial startup menu.

2: In my humble opinion, W&R:SR is in a completely different league to any other city builder. I would argue that it is the quintessential economy management sim.

It is a a slow game. It challenges your patience as much as it does your planning, management, and calculation skills. Expect to have the calculator open on your phone on in another window when playing and a notepad for tracking required manpower and economic consumption vs output. Does the game get boring? I would say sometimes it does! Waiting for an entire city to build up by itself can take several hours on maximum time speedup, which may or may not be your cup of tea.

Comparing W&R:SR to city skylines is like comparing a construction site to a lego set.

Sim management is about as specific as you can go without controlling each individual citizen. Command your citizens to go to specific buildings to work or wait for transit. Command your citizens to go to which stations or buildings for work or for play or for education, etc..

The biggest example of difference I like to use is the water management. In cities skylines, you drop a sewage dump, and a well then you connect magical underground pipes and call it a day. This will not work in W&R:SR. Water must reach a certain quality of treatment of your citizens will get sick. You have to power these facilities and also take sewage out from them. Water must be supplied to every building which workers work. Sewers must run on a downwards slope and pumps must be built if there is an unfortunate slope. Sewage can be treated to reduce pollution or to return some fresh water back into the system. Some factories, such as the concrete plant, requires water as a resource. If you cannot afford pipes or do not want to run pipes down to some stupid wood-cutting shack, you can use the water distributor/sewage hub as a water tank/septic tank and have your maintenance depots take care of them.

This doesn't even touch on having to supply heat and clear snow during winter, having enough granaries to survive the winter when crops don't grow, managing the waste, demolition, and recycling of materials, maintaining your aging vehicles with repair shops and supplying fuel for all your cars, trucks, planes, ships, trains, and buses, and much, much more.

Oh and there is a very vibrant modding scene; the devs even hold contests/votes to put popular mods into the vanilla game (with compensation and credit, ofc). It's also the only game where you can get tankie memes in the community page and actual propaganda.

It's a very dense game, to say the least, and it kicks my ass a lot but im too much of a commie and a masochist to say no.

19 notes

·

View notes

Text

What’s under the waterline on a cruise ship?

I often get asked questions about the design of cruise ships and ocean liners. One of the most common is “what’s under the waterline” - or variants of that question.

There’s a lot going on below the waterline on a ship. Most of the large mechanical spaces for the engine room can be found here.

This can include the diesels (or on ships of old, the steam turbines). Newer ships may have gas turbines, LNG engines or even a hybrid power plant.

If the ship is propeller driven you’ll also find the propulsion motors here, as well as the long tunnels for the propeller shafts to run through and exit the ship.

For ships that use podded propulsion, the access points to enter the giant pods are found in the engine room space.

If a ship has bow thrusters and stern thrusters they’ll be located below the waterline. And all ships with stabilisers have them stored here. These items all need to be below the water to work. You can actually identify the location of these from the surface by looking for special markings on the hull. To learn what they look like, check out my explainer video here:

youtube

Additionally much of the water treatment facility is located below decks. Sewage treatment plants can be found here, along with a separate desalination plant on most modern cruise ships - to generate drinking water.

Aside from mechanical items, there’s a lot of other interesting areas below decks.

These include the massive store rooms that house all the food and drinks for the voyage. Ships have dry stores, cold stores and freezers to keep all the perishable food fresh. Corridors and lifts link these areas with the kitchens and restaurants.

You can also find crew recreation areas and sometimes even passenger facilities below the water line. This can include fitness centres and pools (especially on older ships) where there isn’t the need for windows.

Above: On the builders model of Aurora you can see the stabilisers extended and the ships keel.

On a sadder note, the ship’s morgue is usually located below the waterline. This is quite often situated just below the medical centre - which you’ll notice is on one or the lowest accessible decks on passenger ships.

Most cruise ships will also feature a main crew corridor which is generally located near or below the waterline.

This gives crew quick access to move from the forward to aft areas of a ship, bypassing the busy passenger areas.

2 notes

·

View notes

Text

The Importance of Fasteners

One of the categories of preps that are of top importance are fasteners. Now, we are talking primarily for the purpose of bugging out. That is, if you are forced to leave your home for a safer location.

My personal opinion is that you should "bug in", or stay at home, if possible when the SHTF event occurs. Unless you are in danger, and it would be safer to leave your home, you should plan to remain there and "shelter in place".

However, it may indeed be safer, in some scenarios, to leave your home and seek a more remote, protected location. For example, if you live in a large city, bugging out may turn out to be the best option for survival. Let's say your water supply is compromised due to a grid-down situation where sewage treatment plants cannot continue to operate. Without a supply of potable water, your life is definitely in danger. Cities will also be quick to devolve into rampant crime and wandering hoards of criminals and hungry people. Bugging out may be your best option, in a case like this.

However, even if you are able to remain at home, FASTENERS will be important to have on hand. You need fasteners to hang blankets on doorways, for example, to keep heat in one area of the house in cold weather. You certainly need them for building and maintaining a shelter if you're bugging out. They will come in handy for innumerable purposes, especially if the crisis lasts a significant period of time.

Below is a checklist of fastening materials you should have in abundance in your prepper stash. Most are very inexpensive and can be found at discount stores, hardware stores, etc. as well as online. As you peruse the list, you will see why these items could well be needed in an emergency survival scenario.

Clips: You'll need a variety of clips for fastening, particularly in fashioning shelters. These include; binder clips, kitchen food bag clips, clothespins, carabiner clips, paper clips and some good, strong spring clamps

Rope and String: Make sure you have plenty of these on hand before the SHTF! Cotton string, twine, yarn, fishing line, dental floss, shoe laces, boot laces, clothesline rope, acrylic rope, cotton braid rope, sisal rope, paracord (lots of paracord) [make sure you teach yourself how to make a variety of KNOTS - there are plenty of instructional books and videos to help you]

Hardware: Have an assortment of various sizes of nails, screws, small tacks, thumb tacks, nuts, washers, hinges

Adhesives: Super glue, gorilla glue, apoxy glue, all-purpose adhesive

Tape: Electrical tape, duct tape, shipping tape, masking tape, scotch tape, foam tape, painter's tape

Wire: floral wire, galvanized steel wire

Kitchen type fasteners: bread ties, elastic bands, plastic zip ties in various sizes

Additional fasteners: bungy cords, velcro, safety pins, adhesive waterproof patches

If you can think of additional fasteners that would be good to have, please message me and let me know, and I'll add them!

1 note

·

View note

Text

Ball Valve Manufacturer in Italy

Valvesonly Europe is a preeminent Ball Valve Manufacturer in Italy. Ball valve stands tall as a versatile and important player. Ball Valve is a quarter-turn rotary motion valve that uses ball shaped disk to start or stop the flow of gas or liquid. It helps in regulating the flow of liquids or gases through pipeline and piping system, It take 90 degree turn to open or close the flow . When the valve is parallel to the pipeline it allows the flow and when its perpendicular to the pipe it stops the flow. They are used industry where there is a need of fast shut off capability. The ball valves has reliable sealing that prevents any form of leakage. It can withstand high pressure and temperatures and requires low maintenance .

Parts : All internal components of a ball valve are contained inside a casing or housing . It’s made up of hard materials, that protects the internal components of the valve .A ball valve body consists of the following components:

Ball: The ball is a sphere that has a hole in the centre and that centre is called bore. It controls the flow of fluid. The ball being parallel to the system ensures smooth flow, while being cross stops the flow .

Shaft: The shaft connects the ball to the control mechanism that turns it. It has seals to prevent fluid leaks. The shaft can be manually operated or controlled electronically or by pneumatic or hydraulic means.

Bonnet: The bonnet is an extension of the housing, covering the shaft and its seals. It can be welded or bolted to the body and made of hard metal . It provides protection to the shaft .

Seat: Seats are where the ball seals with the body, ensuring no fluid leaks. There's an upstream seat on the inlet side and a downstream seat on the outlet side. They create a tight seal when the valve is closed.

Understanding Ball Valve Types:

Floating Ball Valve: We can picture a freely moving ball adjusting itself to ensure a tight seal, like a perfectly fitting puzzle piece.

Trunnion-Mounted Ball Valve: In this type, the ball remains steady, ideal for situations where stability under high pressure is necessary to maintain flow control

Fully Welded Ball Valve

Top Entry Ball Valve

Jacketed Ball Valve

Double block and bleed ball Valve

Side Inlet Ball Valve

Forged Ball Valve

Cast Iron and Cast Steel Ball Valve

Heavy Duty Investment Casting Ball Valve

Wafer Ball Valve

Industry Applications:

Oil and Gas Industry: They are often employed in pipelines, wellheads, and storage facilities.

Chemical Industry: They find application in chemical processing plants for controlling the flow of acids, bases, and other corrosive chemicals.

Water and Wastewater Treatment: They are also employed in sewage treatment plants for managing the flow of wastewater.

Power Generation: Ball valves play a crucial role in power plants, controlling the flow of water, steam, and other fluids in boilers and cooling systems.

Petrochemical Industry: Ball valves are widely used in petrochemical plants for regulating the flow of various petrochemical products.

Marine Industry: They are utilized in marine applications for controlling the flow of water, fuel, and other fluids on ships and offshore platforms.

Mining Industry: Ball valves are used in mining operations for controlling the flow of water, slurry, and chemicals in various processes.

Description:

Available materials: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M , F55, F51, F53, Monel, Ductile Iron.

Available Size: ½” to 48”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: LNG, Cryogenic application, Water, Air, Steam, Oil

Ends: Flanged, Threaded, Buttweld, Socket weld

Operations: Lever Operated, Electric Actuated and Pneumatic Actuated., Gear

Our website visit us : https://www.valvesonlyeurope.com/product-category/top-entry-ball-valve

1 note

·

View note

Text

Hot Dip Galvanised Bolts & Nuts Coating Manufacturer and Exporter in India | BigBoltNut

BigBoltNut is manufacturer of hot dip galvanised bolts coating in India. These bolts are used in energy sector like wind, solar, thermal and hydro energy. We produce products according to iso ( international standard organization). Bigboltnut export in various country like USA, Europe, Asia, Africa, middle east, etc. We have in-house team to manufacture bolts and nuts. Our product is long-life durability to the clients. Available iso grades are 10 and 10.9 as per clients requirement.

Application of bolts and Nuts 1- Wind Energy Sector 2- Solar thermal sectors 3- Nuclear Power plants 4-Bolts and Nuts For Railways 5- Bolts and Nuts For Ship Building 6-Bolts and Nuts used in photovoltaic plants 7- Bolt and nuts used in water projects like dams 8- Sewage treatment 9- Bolts and nuts used in petrochemical industry

0 notes

Text

Where are Buttweld fittings used for?

Buttweld fittings are an essential component in various industries, ensuring seamless connections and structural integrity in piping systems. These fittings, manufactured and supplied by reputable companies like Buttweld Fittings Manufacturer- Bu-Lok, serve critical roles in diverse applications across different sectors.

Introduction

Buttweld fittings play a pivotal role in connecting pipes of various diameters and materials, enabling safe and efficient transfer of liquids, gasses, and other substances. They are commonly used in industries such as oil and gas, petrochemical, chemical processing, pharmaceuticals, power plants, and more.

Understanding Buttweld Fittings

Buttweld fittings, provided by Buttweld Fittings Supplier- Bu-Lok, are welded to the piping system through a process called butt-welding. This technique involves welding the fittings directly onto the pipes to create a smooth, continuous flow within the system, minimizing turbulence and pressure drop.

Applications of Buttweld Fittings

Oil and Gas Industry: Buttweld fittings find extensive usage in oil refineries, pipelines, and gas processing plants. They facilitate seamless connections for transporting crude oil, natural gas, and petroleum-based products.

Chemical and Petrochemical Industry: These fittings are integral in chemical processing units, ensuring safe conveyance of chemicals and maintaining the integrity of the system.

Pharmaceutical Industry: The pharmaceutical sector utilizes buttweld fittings in sanitary applications, maintaining hygiene and preventing contamination during the production and distribution of pharmaceutical products.

Power Generation: Buttweld fittings are employed in power plants for the transfer of water, steam, and other fluids crucial for electricity generation.

Construction and Infrastructure: They are used in construction projects for plumbing, HVAC (Heating, Ventilation, and Air Conditioning), and infrastructure development, providing reliable connections in various structural frameworks.

Automotive Industry: Buttweld fittings are utilized in automotive applications for fuel and fluid transfer systems, ensuring efficient operation and safety.

Food and Beverage Industry: Buttweld fittings play a crucial role in food processing facilities, ensuring hygienic and leak-free connections for transporting liquids and gasses used in food production and packaging.

Water Treatment Plants: These fittings are integral in water treatment facilities, facilitating the smooth flow of treated water, chemicals, and effluents within the plant infrastructure.

Aerospace and Defense: In the aerospace and defense sectors, buttweld fittings are utilized for hydraulic and fuel systems in aircraft, providing secure connections that withstand high pressures and extreme conditions.

Mining and Minerals: Within the mining industry, buttweld fittings are essential components for transporting abrasive slurries, chemicals, and minerals through pipelines.

Marine Industry: Buttweld fittings find applications in shipbuilding and marine engineering, ensuring reliable connections for plumbing, fuel systems, and hydraulic lines on ships and offshore structures.

Renewable Energy: In renewable energy sectors like solar and wind power, these fittings are used for piping systems in solar thermal plants and wind turbine installations.

Wastewater Management: Buttweld fittings are employed in sewage treatment plants and wastewater management systems, handling the safe conveyance of treated and untreated wastewater.

Biotechnology: In biotech industries, these fittings are crucial for fluid handling systems in laboratories and manufacturing units, maintaining a sterile environment for sensitive processes.

Textile Industry: Textile manufacturing units utilize buttweld fittings for efficient conveyance of dyes, chemicals, and water in dyeing and treatment processes.

Nuclear Power Plants: Buttweld fittings play a vital role in nuclear facilities, ensuring the safe transfer of coolants and other fluids within the plant's complex systems.

Research and Development: Laboratories and research facilities rely on buttweld fittings for precise fluid handling in experimental setups and scientific equipment.

Agriculture and Irrigation: These fittings assist in irrigation systems, helping transport water and fertilizers efficiently in agricultural fields and greenhouses.

Pharmaceuticals and Biopharmaceuticals: Besides conventional pharmaceuticals, buttweld fittings are critical in biopharmaceutical industries for sterile and aseptic processing.

Chemical Laboratories: Laboratories dealing with chemical research and analysis use these fittings for their chemical-resistant properties in handling corrosive substances.

Quality and Reliability

Buttweld fittings are manufactured using high-quality materials such as stainless steel, high nickel steel, alloy steel, and carbon steel by Buttweld Fittings Manufacturer- Bu-Lok. These fittings exhibit excellent durability, corrosion resistance, and tolerance to extreme temperatures and pressures, ensuring long-term performance.

Conclusion

In conclusion, the versatility and reliability of buttweld fittings make them indispensable across multiple industries. Whether it's for seamless piping connections in the oil and gas sector, chemical processing units, pharmaceuticals, power generation, construction, or automotive applications, these fittings are instrumental.

For top-quality buttweld fittings, reach out to Bu-Lok, a leading manufacturer, trader, and buttweld fittings supplier of a wide range of stainless steel, high nickel steel, alloy steel, and carbon steel products. With a commitment to quality, durability, and customer satisfaction, they provide exceptional products like pneumatic fittings, ensuring reliability and performance in every application.

Contact them for quotations, detailed information, and premium-quality buttweld fittings that meet your specific industrial needs.

0 notes

Text

Water treatment plant manufacturer in India .

#sewage_treatment_plant_manufacturer_supplier_in_noida#sewage_treatment_plant_manufacturer_supplier_in_ncr#sewage_treatment_plant_manufacturer_supplier_in_gurgaon#water_treatment_plant_manufacture_supplier_in_india#sewage_treatment_plant_manufacturer_supplier_in_rajasthan#effluent_treatment_plant_manufacturer_supplier_in_punjab#MBBR_sewage_treatment_plant_manufacturer_supplier_in_india#MBR_sewage_treatment_plant_manufacturer_supplier_in_india#Sewage_treatment_services_in_sector_8_noida#demineralisation_plant_services_provider_in_noida#sewage treatment#sewage treatment plant on ships#marine sewage treatment plant working principle#marine sewage treatment plant#stp#effluent treatment plant#water treatment#sewage treatment plant#water treatment plant#sewage treatment plant animation

0 notes

Text

This is how blue finance works in Latin America and the Caribbean

Climate change is hitting the region's seas. Blue finance can be a shield to protect them

A combination of climate change, overfishing and pollution is bringing the planet's vibrant oceans to the brink of collapse. The pain inflicted to the oceans by climate change is especially intense in Latin America and the Caribbean, where many economies and the livelihoods of millions of people are closely linked to the sea.

The sea represents 60% of the territory in 22 countries in the region, with a coast that extends for more than 70,000 km. In Latin America alone, 25% of the population lives in coastal areas, while almost 100% do so in the Caribbean.

The looming crisis facing the oceans will be a key point in the COP28 discussions taking place at the end of November in Dubai, where world leaders will seek to deploy an arsenal of initiatives to confront the challenge of climate change. One of the pillars of these efforts will likely be a nascent set of financial tools, including blue bonds and blue loans[1], which have already taken their first steps in the region and contain enormous potential in the battle against climate change.

These instruments raise funds for water-related projects, such as preserving access to clean water, wastewater treatment plants, plastic recycling, restoration of marine ecosystems, sustainable shipping, eco-tourism and offshore renewable energy.

Similarly, investments in sustainable salmon production in Chile represent an investment potential of $5 billion and could help increase sector income, boost exports and support local jobs, while preserving natural resources.

Some countries are already paving the way for the development of blue finance in the region. This is, for example, Ecuador, where Banco Internacional became the first bank in the region in 2022 to issue blue bonds. The issue, which had the support of the International Finance Corporation (IFC)[2], could be a benchmark in a country that is home to the largest small-scale artisanal fishing fleet in the southeastern Pacific Ocean and which also has enormous growth potential in the blue economy. The Ecuadorian fishing sector contributes around 1.5% of the country's Gross Domestic Product and 13% of its non-oil exports, and employs 108,000 people.

Since 2020, IFC has provided more than $1.3 billion in loans and blue bonds to financial institutions and private sector companies. In Colombia, one of the five most diverse nations on the planet, BBVA[3] became, with the support of IFC, the first financial entity in the country to issue blue bonds. This is a first tranche for 50 million dollars destined to finance projects for the construction of water and sewage treatment plants, preservation of the oceans and protection of lakes, moors and mangroves.

In the middle of last year, IFC granted a loan of $150 million to the Companhia de Saneamento Básico do Estado de São Paulo (SABESP)[4], one of the largest water and sanitation companies in the world. The impact of the loan is huge, as it will be used to finance investments focused on improving water quality and expanding wastewater collection and treatment in the poorest neighbourhoods of São Paulo.

Despite these cases, there are still many tasks to be accomplished for blue finance to take root in the region. It is key, for example, to develop duly defined taxonomies, certifications and standards so that blue finance becomes tools that meet its impact expectations. The Blue Finance Guidelines[5], a document developed by IFC that identifies eligibility criteria for blue projects, seeks precisely to translate the general principles of blue economy financing into guidelines for blue bond issuances and blue loans.

This story is not only an opportunity for growth, but also a commitment to the preservation of our environment. Investing in the blue economy, supported by strong financial institutions and regulations, can make a difference in preserving our oceans and fighting climate change.

According to an estimate by the Organization for Economic Cooperation and Development (OECD), the blue economy represents about 2.5% of global GDP. Likewise, its scope can provide a substantial change in problems such as the scarcity of fresh water or the use of renewable energy, thereby promoting a better quality of life for people who live linked to the sea.

Today, the blue economy has already confirmed its potential by generating palpable benefits in some cases such as the decarbonization of maritime transport in Brazil, support for sustainable tourism in Chile, the protection of marine biodiversity in the Eastern Caribbean and the Galapagos Islands, the restoration coralline in Belize and the preservation of species in the Mar del Plata in Argentina, to mention a few.

There is no sustainable horizon without private innovation

Efforts to combat climate change will not succeed without massive increases in private capital to developing economies, which account for more than 60% of global decarbonization investment needs. According to its annual report[6] (Building a Better Future), IFC committed a record global amount of $14.4 billion in climate finance by 2023. Starting July 1, 2023, 85% of all new IFC investments will be consistent with the goals of the Paris Agreement, increasing to 100% on July 1, 2025, meaning it will include climate mitigation and adaptation. climate change in all investment decisions. Mere financing is not enough: innovation also plays a fundamental role, especially in protecting the planet's carbon reserves. In the field of blue finance, for example, IFC published a study[7] this year that detects opportunities to finance projects that contribute to safeguarding the carbon stored in the world's coastal ecosystems. In Latin America and the Caribbean, the safeguarding of so-called blue carbon - that which is stored in the form of biomass and sediments in coastal ecosystems - will be one of the main areas to explore in terms of blue finance in the years to come.

Source

Grupo Banco Mundial, Así funcionan las finanzas azules en América Latina y el Caribe, in:El Pais, 16-11-2023; https://elpais.com/america/termometro-social/2023-11-16/asi-funcionan-las-finanzas-azules-en-america-latina-y-el-caribe.html

[1] Blue bonds are debt issues that are intended to preserve and protect the oceans and their ecosystems. They seek, through the mobilization of public and private capital, to promote projects that have a favourable impact on the achievement of the Sustainable Development Goals (SDG) and the blue economy. https://www.bbva.com/es/sostenibilidad/que-son-los-bonos-azules-y-por-que-son-importantes/

[2] The International Finance Corporation (IFC) is an international financial institution that offers investment, advisory, and asset-management services to encourage private-sector development in less developed countries. The IFC is a member of the World Bank Group and is headquartered in Washington, D.C. in the United States.

[3] Banco Bilbao Vizcaya Argentaria, S.A., better known by its initialism BBVA, is a Spanish multinational financial services company based in Madrid and Bilbao, Spain. It is one of the largest financial institutions in the world, and is present mainly in Spain, Portugal, Mexico, South America, Turkey, Italy and Romania

[4] Sabesp is a Brazilian water and waste management company owned by the state of São Paulo. It provides water and sewage services to residential, commercial and industrial users in São Paulo and in 363 of the 645 municipalities in São Paulo State, typically under 30-year concession contracts. It provides water to 26.7 million customers, or 60% of the population of the state. It is the largest water and waste management company in Latin América. It provides basic sanitation services, which include all phases (abstraction, treatment, processing, distribution) and the collection, treatment and reuse of sewage. The São Paulo Metropolitan Region and the Regional Systems accounted for 74.5% and 25.5% of the sales and services rendered during the year ended December 31, 2004 respectively. Sabesp also supplies water on a bulk basis to municipalities in the São Paulo Metropolitan Area, in which it does not operate water systems to local operators.

[5] Blue Finance is an emerging area in Climate Finance with increased interest from investors, financial institutions, and issuers globally. It offers tremendous opportunities and helps address pressing challenges by contributing to economic growth, improved livelihood, and the health of marine ecosystems. The ocean economy is expected to double to $3 trillion by 2030, employing 40 million people, as compared to 2010. Innovative financing solutions are key to enhancing ocean and coastal preservation and increasing clean water resources, and Blue Finance has a huge potential to help realize these goals. This document identifies eligible blue project categories to guide IFC’s investments to support the blue economy, in line with the Green Bond Principles and Green Loan Principles. The market has been seeking guidance on project eligibility criteria, translating general Blue Economy Financing Principles, such as the Sustainable Blue Economy Principles and the Sustainable Ocean Principles, towards guidelines for blue bond issuances and blue lending. https://www.ifc.org/en/insights-reports/2022/guidelines-for-blue-finance

[6] In FY23, IFC committed a record $14.4 billion in climate finance, mobilizing $6.8 billion of additional capital alongside our own investment of $7.6 billion to help client countries address the climate crisis. This represented a record 46 percent of the total of long[6]term investments for our own account. Our work accelerates an inclusive transition by catalysing green growth, supporting private companies to decarbonize and manage risks, and supports societies adapting to a warmer planet. As a result, we help create markets and jobs so that countries continue to reduce poverty and improve living standards while increasing resilience and shifting to a low-carbon world. https://www.ifc.org/en/insights-reports/annual-report/download

[7] Deep Blue: Opportunities for Blue Carbon Finance in Coastal Ecosystems. https://www.ifc.org/en/insights-reports/2023/blue-carbon-finance-in-coastal-ecosystems

0 notes

Text

Civil Construction Services

Heavy civil construction projects require a wide range of skills to design, build & manage. Having a firm experienced in all aspects of this type of project can make the difference between success & failure.

Building the infrastructure our world needs can be incredibly rewarding for construction companies and their professional teams, especially when it comes with no to very little extra cost to those who use these structures daily.

Roadways

Roads are a critical piece of transportation infrastructure that can provide access to businesses, homes and other facilities. They can be paved or unpaved and can be made of asphalt, concrete or other materials.

Road construction is a major part of civil engineering and includes excavation, dredging, demolition and land surveying. It can also involve the mining, crushing, screening, washing and hauling of sand, gravel and crushed stone. It may also include the creation of tunnels and bridges.

Roads are a key element in the global economy and must be well-maintained to reduce costs. They can improve economic efficiency, provide access to health services and education, and help solve social problems like poverty and illiteracy. They can also reduce pollution and increase safety. Road construction projects are complex and require a lot of coordination.

Bridges

Bridges are a vital part of transportation infrastructure. They help to connect people, transport goods and provide access across valleys, rivers, lakes and cliffs.

Bridge construction is an important part of civil engineering, involving planning, design and maintenance processes. These structures must be able to handle traffic loads, as well as resist floods and seismic events.

Structural engineers are responsible for ensuring that all buildings and bridges are safe and secure. They use computer software to plan out a structure and then build it using the best materials, equipment and labor available. They also ensure that any structure is cost efficient and complies with local site restrictions. They also perform a number of other functions, such as supplying equipment, installing utilities, performing seismic retrofitting and providing fire protection services.

Railroads

Railroads provide crucial transportation services for many industries. For example, building materials and lumber travel to construction sites by rail. Pulp and paper, used to make everything from cardboard and food packaging to bandages and LCD screens, is shipped to factories by trains.

Civil construction companies do more than build infrastructure; they also manage natural and existing environments like water reservoirs, mountain ridges, and forests. Contractors bidding on civil projects need to understand grading, erosion control, access rights, environmental impact, and legal regulations.

Railroad construction requires the use of heavy machinery and equipment that must be able to support massive train weights traveling at high speeds. A minor error in the design or construction process could result in huge costs and even injuries. To avoid such risks, railroad contractors must use steel that is both durable and reliable.

Wastewater Treatment Plants

Wastewater treatment plants (WWTP) are responsible for taking contaminated wastewater and turning it into a usable resource that can be returned to the water cycle or reused for other purposes. This is achieved through a series of physical and chemical processes known as preliminary, primary, secondary and tertiary treatments.

The first step, called preliminary treatment, involves removing objects that could damage or clog machinery at the plant. This includes separating large objects, such as toys, bottles and rocks, using bar screens before the water enters a grit removal chamber to reduce sand, coffee grounds, egg shells, jewelry and coins.

Next, physico-chemical treatment processes reduce the organic material in the sewage by using aerobic or anaerobic oxidation processes and secondary settling. Finally, disinfection ensures the treated water is safe to return to the environment.

Dams

Civil construction services are responsible for building all sorts of infrastructure, including dams. Dams are built to control the flow of water and are often used to help mitigate flood conditions. They are also used to store water in times of drought.

Dams can be constructed of concrete or earth fill. Concrete is typically used for massive gravity and thin arch dams, while earth fill is generally used for embankment dams.

The construction of a dam is usually a large project that requires the expertise of many different types of professionals. Civil engineers are responsible for turning the project design into a physical reality, while environmental engineers ensure that the dam is built in a way that won’t have a negative impact on the environment.

0 notes

Text

Wastewater Pumping and Aerobic Repair Solutions for Your Needs

Appropriate administration of wastewater is fundamental for the well-being and prosperity of networks. With a developing populace, the interest in wastewater treatment and the executives has expanded hugely. This has brought about the improvement of new and trend-setting innovations to guarantee that wastewater is dealt with and overseen most successfully and effectively. Two such innovations are high-impact fixes and wastewater siphoning, which are fundamental for keeping a sound and maintainable climate.

Aerobic Repair Bixby is a natural cycle that utilizes oxygen to separate natural matter in wastewater, and this cycle is completed in uncommonly planned oxygen-consuming fix frameworks introduced in homes and business structures. The high-impact fix process is a practical and effective approach to treating wastewater, as it requires less energy and creates less slime contrasted with customary treatment strategies. Moreover, vigorous fix frameworks are relatively easy to keep up with and have a long life expectancy, making them an optimal answer for overseeing wastewater in private and business settings.

Wastewater Pumping Bixby then again, is a cycle that includes the utilization of siphons to move wastewater starting with one area and then onto the next. This cycle is commonly utilized in regions where the wastewater treatment plant is situated at a lower height than the wellspring of the wastewater. Wastewater siphoning guarantees that wastewater is moved to the treatment plant productively and successfully. Without legitimate wastewater siphoning, untreated sewage can uphold into homes and business structures, representing a well-being peril to the local area.

At Anytime Septic, we offer aerobic repair and wastewater pumping services in Bixby and the encompassing regions. Our specialists are profoundly prepared and experienced in giving productive and successful wastewater the executives answers for private and business clients. We use cutting-edge innovation and hardware to guarantee that our administrations are of the most excellent quality, and we are focused on giving outstanding client assistance.

With our high-impact fix administrations, we can assist you with keeping a solid and supportable climate by guaranteeing that your wastewater is dealt with and overseen appropriately. We can likewise give wastewater siphoning administrations to ensure that your wastewater is shipped to the treatment plant proficiently and really. Our group is accessible daily to give crisis administrations, so you can depend on us to be there when you want us the most.

In conclusion, proper wastewater management is essential for maintaining a healthy and sustainable environment. High-impact fixes and wastewater siphoning are two advancements that are pivotal for guaranteeing that wastewater is dealt with and overseen actually. At Whenever Septic, we offer these administrations in Bixby and the encompassing regions, and we are focused on providing our clients the most significant types of assistance. Reach us today at anytimesepticok.com to dive deeper into our administrations and how we can assist you with dealing with your wastewater.

For more info:-

Septic Service Claremore

Septic Tank Pumping Claremore Ok

Septic Repair Claremore

Septic Claremore Ok

Septic Tank Maintenance Claremore

Septic Pumping Claremore

Source URL:- https://sites.google.com/view/septic-cleaning-bixby/home

0 notes

Text

MOBILE WASTEWATER TREATMENT

Containerized, modular, mobile wastewater treatment systems offer a flexible solution for management of sewage from a range of applications. Mobile wastewater treatment systems can be used for both temporary and permanent wastewater treatment solutions. Containerized, decentralized sewage treatment systems can handle populations from 30 to 10,000 persons and can be designed to achieve any effluent standard required.

Sector

Wastewater Treatment Construction and wastewater sewage systems can be used in a very wide range of applications. They can be used for short term, mobile wastewater treatment where portable solutions are needed. But they can also be used for long term, fixed applications.

They are specifically suited to applications such as:

Refugee camps

Military camps

Worker camps or mining camps

Oil and gas drilling sites

Construction sites

Currently, mobile wastewater treatment is faced with new challenges. Increased demands on sanitary equipment and the protection of health and the environment require solutions for wastewater treatment at refugee camps and military camps as well as for construction sites, oil fields and mining camps.

Every application requires a problem-oriented, case-specific approach. Some of the sewage treatment plants have to be available in a short time, they have to be mobile and pre-assembled ready for use. They also need to be robust and easy to use.

All required effluent standards must be achieved and complied with. Depending on the local requirements, this ranges from discharge into watercourse, sea, to ground for irrigation or into the main sewer. In certain cases, drinking water production from sewage or wastewater reuse is also required.

Attention must be paid to climate conditions and spatial constraints and footprint. Our Wastewater Biological Treatment plant using treatment modules offers a quick and optimal solution for wastewater, sludge and water reuse.

Mobile/ Portable & Modular Container Design with CSC Certificate

All components are fully installed in ISO sea containers. The ClearFox® Wastewater Treatment Construction meet all safety requirements for international freight transport. They are marked according to ISO 6346 and verifiably suitable for transport on container ships.

This is evidenced by the certificate of the International Convention for Safe Containers (CSC). This results in considerable advantages for transportation. The sea containers are 100% insurable. The largely standardized and prepared procedure enables inexpensive transport. Customs clearance is also faster, which in many cases is time-limited.

0 notes

Text

Investigating the Uses and Advantages of Submersible Slurry Pumps

Submersible slurry pumps are a kind of pumping gear that is intended to deal with rough and thick materials in mining, development, and wastewater enterprises. These pumps are normally used to ship slurries, which are a combination of solids and fluids and are fit for taking care of solids with a high grouping.

The utilization of submersible slurry pumps enjoys a few upper hands over different kinds of pumps, including expanded productivity, diminished upkeep, and further developed well-being. In this article, we will examine the purposes and benefits of submersible slurry pumps.

Utilizations of Submersible Slurry Pumps:

Mining: In the mining business, submersible slurry pumps are utilized to ship rough and destructive slurries like coal, iron metal, gold, and copper. These pumps are utilized in different mining applications, for example, dewatering, mineral handling, and underground mine water seepage.

Development: In the development business, submersible slurry pumps are utilized to deal with slurries that are produced during unearthing and boring activities. These pumps are additionally utilized for burrowing, profound establishment development, and marine development.

Wastewater: Submersible slurry pumps are utilized in the wastewater business to ship sewage, slop, and different sorts of waste materials. These pumps are utilized in sewage treatment plants, modern wastewater treatment offices, and different applications where the transportation of rough and thick materials is required.

Benefits of Submersible Slurry Pumps:

Expanded Proficiency: Submersible slurry pumps are exceptionally productive and can deal with a higher volume of solids than different kinds of pumps. The plan of these pumps takes into consideration the vehicle of thick slurries with a high centralization of solids, lessening the number of outings expected to move the material.

Diminished Support: Submersible slurry pumps are intended to work in unforgiving conditions and can deal with grating and destructive materials without exceeding their maximum mileage. This lessens the requirement for regular support and fixes, bringing about lower working expenses and expanded uptime.

Improved Security: Submersible slurry pumps are designed to work submerged, lowering the risk of mishaps and wounds associated with conventional pumps. These pumps are additionally furnished with cutting-edge well-being elements, for example, overheat security, spillage sensors, and programmed shut-off frameworks, guaranteeing safe activity in all circumstances.

FOR MORE INFO :-

submersible slurry pump

0 notes

Text

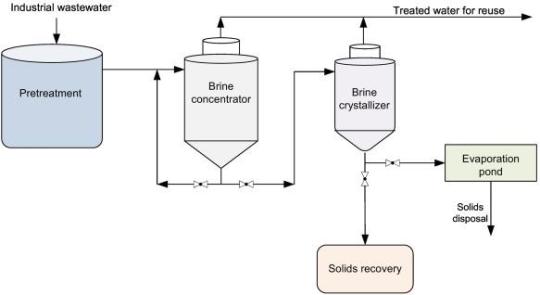

Comparison of Zero Liquid Discharge Systems With Other Wastewater Treatment Technologies

Zero liquid discharge (ZLD) systems aim to completely eliminate all the liquid effluent from a plant. This reduces wastewater volume that needs further treatment, economically processes waste and produces a clean stream of water suitable for reuse.

While ZLD is becoming more common in some industries, it may not be the right solution for all plants. It is critical to perform a thorough cost analysis and evaluate its overall impact.

Cost

Zero Liquid Discharge Systems (ZLD) are an effective method to recycle water and recover valuable by-products from industrial wastewater. Moreover, they can be cost-effective compared to other treatment technologies as they require less energy and capital investments.

According to Research, the global market for Zero Liquid Discharge Systems is projected to grow at a rate of 12% per year through 2030. This is attributed to technological advances, rising water costs and regulations aimed at reducing surface water pollution.

As a result, many industrial plants and power generation companies are switching to Zero Liquid Discharge technology to reduce their water costs and environmental impact. ZLD systems can save up to 2-5 times the CAPEX of traditional wastewater treatment technologies and are highly efficient in removing high-quality water and salts.

The cost of the ZLD systems depends on various factors, including the water quality and flow rates. Generally, the thermal treatment section accounts for around 60-70% of the total equipment price. In addition, the system automation, shipping and regulatory fees are also important considerations when pricing a ZLD system.

Evaporation is the most common technology used in ZLD solutions because it can treat a broad range of waste streams and does a great job of concentrating waste. It also requires less labor than other techniques, resulting in lower overall costs.

In addition, evaporation can process a large variety of different water compositions, such as hard-to-treat and acidic waters. This means that ZLD can handle a wide range of industrial waste, from mining and flue gas desalination wastewater to sewage and industrial process effluents.

Using an evaporation process can also save considerable energy because it only needs heat to evaporate the water. In fact, a majority of the energy consumed by these processes can be achieved through waste heat.

Another advantage of evaporation is that it can be applied to wastewater from a variety of industrial processes and waste types, such as mine wastewater, flue gas desalination wastewater and oil field brines. In addition, a number of solids can be recovered and reused in industry as valuable by-products, such as lithium.

Efficiency

Zero Liquid Discharge (ZLD) systems are an increasingly common alternative to traditional wastewater discharge methods in many industries. ZLD processes reduce the volume of industrial waste water discharges and provide a means for solids to be reused or disposed, as well as recycle high quality water that can be beneficially used.

The most common ZLD systems are based on a sequence of thermal processes, typically involving membrane brine concentrators and crystallizers that use evaporation to generate and recycle pure water and solid dry product. While these technologies are the most common, other systems are emerging with promising technology combinations.

Regardless of the type of system used, water quality is a critical consideration for successful operation and long term sustainability. This requires a sound water chemistry design basis that minimizes the capital investment and system operating cost, while ensuring safe and reliable operation.

A thorough knowledge of the chemistry of the wastewater stream is essential for evaluating ZLD options. In addition, the ability to recycle valuable solids from the concentrated stream is an important feature that should not be overlooked.

As discussed in the previous sections, ZLD can dramatically increase the efficiency of waste disposal. This is because it eliminates the need for off-site disposal. It also decreases the volume of waste and lowers the costs of waste management.

Another advantage of ZLD is the reduced energy consumption compared to other treatment processes. This can be especially true of membrane based technologies.

Other technologies, such as electrodialysis (ED), can significantly increase the amount of electricity needed to process wastewater, which can increase CO2 emissions. In addition, ED may not be effective at high concentrations and may require the use of additional equipment.

Alternatively, a zero liquid discharge system can be designed to use less energy to concentrate the waste and achieve higher recoveries. This is a unique benefit of ZLD that can help reduce the carbon footprint of an inland facility.

Zero liquid discharge systems can be designed to meet the specific needs of an individual plant and reduce waste production. This is especially useful in industrial applications where water usage is critical to plant operations, such as the power industry and oil & gas, chemical, petrochemical and mining industries.

Recyclability

Zero Liquid Discharge (ZLD) systems recycle the waste water within the system to limit the amount of wastewater that is discharged into the environment. The dissolved solids and other pollutants that are present in the wastewater are recovered through various treatment processes, which can include physical and chemical treatment followed by biological treatment.

In many industries, including the power industry, oil & gas, petrochemicals, mining, and chemical manufacturing, industrial wastewater is generated that can impact the surrounding environment. For these reasons, it is imperative that the water be disposed of in a safe and environmentally responsible manner.

The most common type of ZLD process is a thermal-based system that uses a series of brine concentrators and crystallizers to evaporate the waste water. The condensed distillate is then collected for reuse or stored (in evaporation ponds) for further processing or salt recovery.

Although this system is a highly effective and sustainable method of reducing industrial wastewater, the energy consumption per cubic meter of treated effluent treated in the ZLD system can be very high. This can lead to significant operating costs and decreased efficiencies.

Other ZLD systems that pre-concentrate the waste water using membrane technologies or electrodialysis can be much more cost effective than a thermal-based system. This is because the membranes are able to filter out much of the impurities in the waste water, thus reducing the load on the thermal evaporators.

However, the membranes used in these systems must be able to stand up to the high organic load and total dissolved solids concentration that can be found in industrial wastewater. Moreover, they must be able to survive the pressure that can result from the high salt concentration.

Lastly, the membranes must be able to withstand biofouling and scaling problems that can occur in the ZLD system. These challenges can be overcome by choosing a membrane that has been designed specifically for these applications.

In many cases, ZLD is an option to consider when other wastewater treatment technologies do not offer the desired level of recoveries or costs are prohibitive. This is especially true in the power industry, where EPA has recently issued new effluent limits for toxic metals. The tighter standards are likely to motivate more power plants to adopt ZLD.

Environmental Impact

Industrial facilities such as oil & gas, chemical, petrochemical, power, and mining industries generate a large volume of waste water that must be treated. These wastewaters are usually discharged via plant outfalls to surface water bodies, evaporation ponds, or in some cases deep well injected. These discharges can have an adverse impact on surrounding water bodies.

Zero Liquid Discharge Systems aim to remove all liquid discharge from a system and recover clean water that is suitable for reuse in various industrial processes. These systems are growing in popularity worldwide as a result of stringent government regulations regarding the discharge of wastewater.

A key element of ZLD technology is the use of a concentration process that concentrates dissolved salts into crystallized salts and water that can be harvested for reuse or sale. This is achieved through an evaporation process that can utilize membrane or multiple-effect evaporation technologies, as well as crystallizers and spray dryers.

While a concentration process can help eliminate the need for disposal of sludge, it is not always cost effective in small to medium-sized facilities. For these operations, practical reuse and recycling methods may be more cost effective and have less environmental impact.

In addition to reducing the need for disposal of sludge, ZLD technology helps reduce energy consumption by not allowing the plant to operate at its maximum capacity and by utilizing a more efficient reject management system. Developing an effective method to quantify energy consumption in these facilities is essential to developing realistic performance and cost projections.

Another important feature of ZLD technology is the abatement of refractory organics in the brine. These materials are difficult to coagulate and adsorb, so oxidation processes are often used in conjunction with other treatment steps. Advanced oxidation processes (AOPs) use strong oxidants such as hydrogen peroxide to degrade refractory organics and other chemicals in the waste stream.

The environmental impact of ZLD is dependent on the type of industrial plant or facility it is applied to, as well as the composition and volume of the waste water being processed. This can vary by country, as can the cost of the equipment needed to treat the waste stream.

youtube

0 notes