#multimaterial

Photo

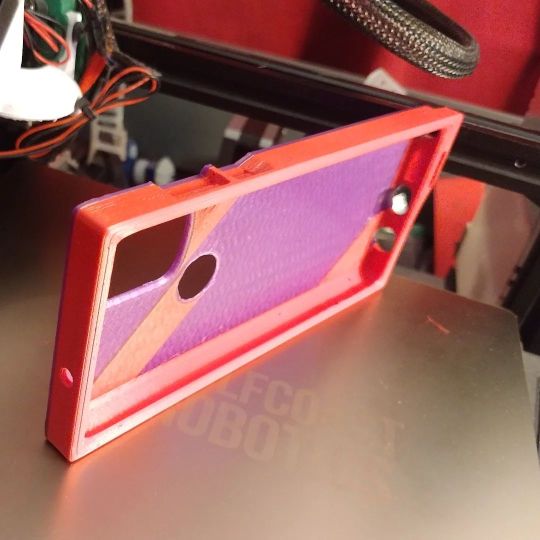

Finally I managed to figure out how to print my phone case with minimal use of #tpu , multi-material print. The purple is #petg since the two materials 1. have the same print temp on my machine, and 2. Fuse together nicely. The seam also looks flawless so for all intents and purposes they're one, for now. And of course the things i eyeballed for placement on that 3d mockup i posted a while back have the holes slightly askew. Power, volume, back camera. The second thing to address is that the case is slightly small. Seems i need 4mm wider and 1.7mm taller. I've purposely dropped it a few times already and it didnt pop out of the case and the screen was kept away from the ground when it flipped over so it's functioning as intended. Now it's time for long term testing. Lastly, the most important part, for me, is that little forward facing oval hole on the bottom bump( which makes holding the phone one-handed much easier; a plus) redirects the sound and doesn't muddy it at all; perfect outcome there. #design #3ddesign #phonecase #3dprinting #diy #custom #multimaterial https://www.instagram.com/p/CmlXtZdOqcJ/?igshid=NGJjMDIxMWI=

0 notes

Photo

The @bambulab_official X1 Carbon is insanely fast and it eats nearly anything I throw at it. It also is great at multi-color printing using the AMS unit. I had to make 40 of these little models for a customer in 4 colors. They all finished perfectly and it took only 21 hours to complete. Pretty impressive. #3dprinting #3dprintingindustry #3dprinted #3dprinter #3dprints #3ddrucker #3dp #3dimensional #3d #bambulab #bambulab3d #bambulabx1 #bambulabx1carbon #x1carbon #ams #automaticmaterialsystem #multimaterial #multicolorprinter #hardware #tech #additvemanufacturing #additive #de3dprintman (at Leiderdorp) https://www.instagram.com/p/CeUTjNyL01g/?igshid=NGJjMDIxMWI=

#3dprinting#3dprintingindustry#3dprinted#3dprinter#3dprints#3ddrucker#3dp#3dimensional#3d#bambulab#bambulab3d#bambulabx1#bambulabx1carbon#x1carbon#ams#automaticmaterialsystem#multimaterial#multicolorprinter#hardware#tech#additvemanufacturing#additive#de3dprintman

0 notes

Text

21 notes

·

View notes

Text

This 3D printer can watch itself fabricate objects

Computer vision enables contact-free 3D printing, letting engineers print with high-performance materials they couldn’t use before.

With 3D inkjet printing systems, engineers can fabricate hybrid structures that have soft and rigid components, like robotic grippers that are strong enough to grasp heavy objects but soft enough to interact safely with humans.

These multimaterial 3D printing systems utilize thousands of nozzles to deposit tiny droplets of resin, which are smoothed with a scraper or roller and cured with UV light. But the smoothing process could squish or smear resins that cure slowly, limiting the types of materials that can be used.

Researchers from MIT, the MIT spinout Inkbit, and ETH Zurich have developed a new 3D inkjet printing system that works with a much wider range of materials. Their printer utilizes computer vision to automatically scan the 3D printing surface and adjust the amount of resin each nozzle deposits in real-time to ensure no areas have too much or too little material.

Read more.

12 notes

·

View notes

Text

Scientists 3D Print Self-Heating Microfluidic Devices - Technology Org

New Post has been published on https://thedigitalinsider.com/scientists-3d-print-self-heating-microfluidic-devices-technology-org/

Scientists 3D Print Self-Heating Microfluidic Devices - Technology Org

The one-step fabrication process rapidly produces miniature chemical reactors that could be used to detect diseases or analyze substances.

MIT researchers have used 3D printing to produce self-heating microfluidic devices, demonstrating a technique which could someday be used to rapidly create cheap, yet accurate, tools to detect a host of diseases.

MIT researchers developed a fabrication process to produce self-heating microfluidic devices in one step using a multi-material 3D printer. Pictured is an example of one of the devices. Illustration by the researchers / MIT

Microfluidics, miniaturized machines that manipulate fluids and facilitate chemical reactions, can be used to detect disease in tiny samples of blood or fluids. At-home test kits for Covid-19, for example, incorporate a simple type of microfluidic.

But many microfluidic applications require chemical reactions that must be performed at specific temperatures.

These more complex microfluidic devices, which are typically manufactured in a clean room, are outfitted with heating elements made from gold or platinum using a complicated and expensive fabrication process that is difficult to scale up.

Instead, the MIT team used multimaterial 3D printing to create self-heating microfluidic devices with built-in heating elements, through a single, inexpensive manufacturing process. They generated devices that can heat fluid to a specific temperature as it flows through microscopic channels inside the tiny machine.

The self-heating microfluidic devices, such as the one shown, can be made rapidly and cheaply in large numbers, and could someday help clinicians in remote parts of the world detect diseases without the need for expensive lab equipment. Credits: Courtesy of the researchers / MIT

Their technique is customizable, so an engineer could create a microfluidic that heats fluid to a certain temperature or given heating profile within a specific area of the device. The low-cost fabrication process requires about $2 of materials to generate a ready-to-use microfluidic.

The process could be especially useful in creating self-heating microfluidics for remote regions of developing countries where clinicians may not have access to the expensive lab equipment required for many diagnostic procedures.

“Clean rooms in particular, where you would usually make these devices, are incredibly expensive to build and to run. But we can make very capable self-heating microfluidic devices using additive manufacturing, and they can be made a lot faster and cheaper than with these traditional methods. This is really a way to democratize this technology,” says Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the fabrication technique.

He is joined on the paper by lead author Jorge Cañada Pérez-Sala, an electrical engineering and computer science graduate student. The research will be presented at the PowerMEMS Conference this month.

An insulator becomes conductive

This new fabrication process utilizes a technique called multimaterial extrusion 3D printing, in which several materials can be squirted through the printer’s many nozzles to build a device layer by layer. The process is monolithic, which means the entire device can be produced in one step on the 3D printer, without the need for any post-assembly.

To create self-heating microfluidics, the researchers used two materials — a biodegradable polymer known as polylactic acid (PLA) that is commonly used in 3D printing, and a modified version of PLA.

The modified PLA has mixed copper nanoparticles into the polymer, which converts this insulating material into an electrical conductor, Velásquez-García explains. When electrical current is fed into a resistor composed of this copper-doped PLA, energy is dissipated as heat.

“It is amazing when you think about it because the PLA material is a dielectric, but when you put in these nanoparticle impurities, it completely changes the physical properties. This is something we don’t fully understand yet, but it happens and it is repeatable,” he says.

Using a multimaterial 3D printer, the researchers fabricate a heating resistor from the copper-doped PLA and then print the microfluidic device, with microscopic channels through which fluid can flow, directly on top in one printing step. Because the components are made from the same base material, they have similar printing temperatures and are compatible.

Heat dissipated from the resistor will warm fluid flowing through the channels in the microfluidic.

In addition to the resistor and microfluidic, they use the printer to add a thin, continuous layer of PLA that is sandwiched between them. It is especially challenging to manufacture this layer because it must be thin enough so heat can transfer from the resistor to the microfluidic, but not so thin that fluid could leak into the resistor.

The resulting machine is about the size of a U.S. quarter and can be produced in a matter of minutes. Channels about 500 micrometers wide and 400 micrometers tall are threaded through the microfluidic to carry fluid and facilitate chemical reactions.

Importantly, the PLA material is translucent, so fluid in the device remains visible. Many processes rely on visualization or the use of light to infer what is happening during chemical reactions, Velásquez-García explains.

Customizable chemical reactors

The researchers used this one-step manufacturing process to generate a prototype that could heat fluid by 4 degrees Celsius as it flowed between the input and the output. This customizable technique could enable them to make devices which would heat fluids in certain patterns or along specific gradients.

“You can use these two materials to create chemical reactors that do exactly what you want. We can set up a particular heating profile while still having all the capabilities of the microfluidic,” he says.

However, one limitation comes from the fact that PLA can only be heated to about 50 degrees Celsius before it starts to degrade. Many chemical reactions, such as those used for polymerase chain reaction (PCR) tests, require temperatures of 90 degrees or higher. And to precisely control the temperature of the device, researchers would need to integrate a third material that enables temperature sensing.

In addition to tackling these limitations in future work, Velásquez-García wants to print magnets directly into the microfluidic device. These magnets could enable chemical reactions that require particles to be sorted or aligned.

At the same time, he and his colleagues are exploring the use of other materials that could reach higher temperatures. They are also studying PLA to better understand why it becomes conductive when certain impurities are added to the polymer.

“If we can understand the mechanism that is related to the electrical conductivity of PLA, that would greatly enhance the capability of these devices, but it is going to be a lot harder to solve than some other engineering problems,” he adds.

“In Japanese culture, it’s often said that beauty lies in simplicity. This sentiment is echoed by the work of Cañada and Velasquez-Garcia. Their proposed monolithically 3D-printed microfluidic systems embody simplicity and beauty, offering a wide array of potential derivations and applications that we foresee in the future,” says Norihisa Miki, a professor of mechanical engineering at Keio University in Tokyo, who was not involved with this work.

“Being able to directly print microfluidic chips with fluidic channels and electrical features at the same time opens up very exiting applications when processing biological samples, such as to amplify biomarkers or to actuate and mix liquids. Also, due to the fact that PLA degrades over time, one can even think of implantable applications where the chips dissolve and resorb over time,” adds Niclas Roxhed, an associate professor at Sweden’s KTH Royal Institute of Technology, who was not involved with this study.

Written by Adam Zewe

Source: Massachusetts Institute of Technology

You can offer your link to a page which is relevant to the topic of this post.

#3d#3D printing#additive manufacturing#amazing#applications#biodegradable#biomarkers#Biotechnology news#blood#chemical#chemical reactions#Chemistry & materials science news#chips#computer#Computer Science#conference#continuous#covid#Developing countries#Developments#devices#Disease#Diseases#energy#Engineer#engineering#equipment#Fabrication#Featured life sciences news#Featured technology news

2 notes

·

View notes

Text

"Le Laboratoire Multilatéral National" and the Mk 6 Engineering Combat and Maintenance Powersuit

The LMN (Laboratoire Multilatéral National) is nothing short of a titan of R&D. A singular, all encompassing high technologies agency. It serves to aggregate, sort, and task the scientists of Espocita across multiple development projects. These projects range from the sensible, like new GMO strains, advanced steel alloys and safer trains, to the insane, like electro-optical camouflages, warp drives, and wireless brain/machine interfaces.

Their most successful recent project has been the "Miniature Multimaterial Additive Printer" which has seen battlefield deployment on the MK6 Engineering, Combat, and Maintenance Powersuit. The suit lacks armor as a principle, instead focusing on movement and low weight, meaning the suit can access most terrains where fighting is certain. In this role, it is able to print spare parts, execute modifications and replace weapon systems, so long as base materials are available.

However being an engineering rig doesn't mean the mk6 is defenceless, but rather, quite effective in some cases. It gives the Engineer the survivability to get through a hotzone, and work in relative safety in that hotzone. The force multiplication abilities of the frame also let it service heavy equipment like tanks and mechs more effectively.

3 notes

·

View notes

Text

Magnetoactive liquid-solid phase transitional matter

https://www.cell.com/matter/fulltext/S2590-2385(22)00693-2#articleInformation

Magnetically actuated miniature machines can perform multimodal locomotion and programmable deformations. However, they are either solid magnetic elastomers with limited morphological adaptability or liquid material systems with low mechanical strength.

Here, we report magnetoactive phase transitional matter (MPTM) composed of magnetic neodymium-iron-boron microparticles embedded in liquid metal. MPTMs can reversibly switch between solid and liquid phase by heating with alternating magnetic field or through ambient cooling.

In this way, they uniquely combine high mechanical strength (strength, 21.2 MPa; stiffness, 1.98 GPa), high load capacity (able to bear 30 kg), and fast locomotion speed (>1.5 m/s) in the solid phase with excellent morphological adaptability (elongation, splitting, and merging) in the liquid phase. We demonstrate the unique capabilities of MPTMs by showing their dynamic shape reconfigurability by realizing smart soldering machines and universal screws for smart assembly and machines for foreign body removal and drug delivery in a model stomach.

References

Voxelated three-dimensional miniature magnetic soft machines via multimaterial heterogeneous assembly.Sci. Robot. 2021; 6: eabf0112https://doi.org/10.1126/scirobotics.abf0112View in Article

Active scaffolds for on-demand drug and cell delivery.Proc. Natl. Acad. Sci. USA. 2011; 108: 67-72https://doi.org/10.1073/pnas.1007862108View in Article

Design and rolling locomotion of a magnetically actuated soft capsule endoscope.IEEE Trans. Robot. 2012; 28: 183-194https://doi.org/10.1109/TRO.2011.2163861View in Article

Magnetic living hydrogels for intestinal localization, retention, and diagnosis.Adv. Funct. Mater. 2021; 31: 2010918https://doi.org/10.1002/adfm.202010918View in Article

A ferrobotic system for automated microfluidic logistics.Sci. Robot. 2020; 5: eaba4411https://doi.org/10.1126/scirobotics.aba4411View in Article

Self-propelled liquid metal motors steered by a magnetic or electrical field for drug delivery.J. Mater. Chem. B. 2016; 4: 5349-5357https://doi.org/10.1039/c6tb00996dView in Article

Phoretic liquid metal micro/nanomotors as intelligent filler for targeted microwelding.Adv. Mater. 2019; 31: e1905067https://doi.org/10.1002/adma.201905067View in Article

View in Article

Remote modular electronics for wireless magnetic devices.Adv. Sci. 2021; 8: e2101198https://doi.org/10.1002/advs.202101198View in Article

Slug-inspired magnetic soft millirobot fully integrated with triboelectric nanogenerator for on-board sensing and self-powered charging.Nano Energy. 2022; 99: 107367https://doi.org/10.1016/j.nanoen.2022.107367View in Article

Droplets as carriers for flexible electronic devices.Adv. Sci. 2019; 6: 1901862https://doi.org/10.1002/advs.201901862View in Article

Robust fabrication of nonstick, noncorrosive, conductive graphene-coated liquid metal droplets for droplet-based, floating electrodes.Adv. Funct. Mater. 2018; 28: 1706277https://doi.org/10.1002/adfm.201706277View in Article

Magnetic soft materials and robots.Chem. Rev. 2022; 122: 5317-5364https://doi.org/10.1021/acs.chemrev.1c00481View in Article

Small-scale soft-bodied robot with multimodal locomotion.Nature. 2018; 554: 81-85https://doi.org/10.1038/nature25443View in Article

Decoupling and reprogramming the wiggling motion of midge larvae using a soft robotic platform.Adv. Mater. 2022; 34: e2109126https://doi.org/10.1002/adma.202109126View in Article

4D printing of magnetoactive soft materials for on-demand magnetic actuation transformation.ACS Appl. Mater. Interfaces. 2021; 13: 4174-4184https://doi.org/10.1021/acsami.0c19280View in Article

Millimeter-scale flexible robots with programmable three-dimensional magnetization and motions.Sci. Robot. 2019; 4: eaav4494https://doi.org/10.1126/scirobotics.aav4494View in Article

Printing ferromagnetic domains for untethered fast-transforming soft materials.Nature. 2018; 558: 274-279https://doi.org/10.1038/s41586-018-0185-0View in Article

Magnetic/pH-sensitive double-layer microrobots for drug delivery and sustained release.Appl. Mater. Today. 2020; 19: 100583https://doi.org/10.1016/j.apmt.2020.100583View in Article

Triple-configurational magnetic robot for targeted drug delivery and sustained release.ACS Appl. Mater. Interfaces. 2021; 13: 45315-45324https://doi.org/10.1021/acsami.1c14610View in Article

Recent progress in flexible tactile sensor systems: from design to application.Soft Sci. 2021; 1: 3https://doi.org/10.20517/ss.2021.02View in Article

A brief review of mechanical designs for additive manufactured soft materials.Soft Sci. 2021; 2: 2https://doi.org/10.20517/ss.2021.22View in Article

Tattoo-like epidermal electronics as skin sensors for human machine interfaces.Soft Sci. 2021; 1: 10https://doi.org/10.20517/ss.2021.09View in Article

A brief review on miniature flexible and soft tactile sensors for interventional catheter applications.Soft Sci. 2021; 2: 6https://doi.org/10.20517/ss.2022.05View in Article

Endoscopy-assisted magnetic navigation of biohybrid soft microrobots with rapid endoluminal delivery and imaging.Sci. Robot. 2021; 6: eabd2813https://doi.org/10.1126/scirobotics.abd2813View in Article

Reconfigurable magnetic liquid metal robot for high-performance droplet manipulation.Nano Lett. 2022; 22: 2923-2933https://doi.org/10.1021/acs.nanolett.2c00100View in Article

Reconfigurable magnetic slime robot: deformation, adaptability, and multifunction.Adv. Funct. Mater. 2022; 32: 2112508https://doi.org/10.1002/adfm.202112508View in Article

Hard-magnetic liquid metal droplets with excellent magnetic field dependent mobility and elasticity.J. Mater. Sci. Technol. 2021; 92: 60-68https://doi.org/10.1016/j.jmst.2021.04.004View in Article

Programmable digital liquid metal droplets in reconfigurable magnetic fields.ACS Appl. Mater. Interfaces. 2020; 12: 37670-37679https://doi.org/10.1021/acsami.0c08179View in Article

Liquid metal droplet robot.Appl. Mater. Today. 2020; 19: 100597https://doi.org/10.1016/j.apmt.2020.100597View in Article

Unconventional locomotion of liquid metal droplets driven by magnetic fields.Soft Matter. 2018; 14: 7113-7118https://doi.org/10.1039/C8SM01281DView in Article

Reconfigurable multifunctional ferrofluid droplet robots.Proc. Natl. Acad. Sci. USA. 2020; 117: 27916-27926https://doi.org/10.1073/pnas.2016388117View in Article

Electromagnetic three dimensional liquid metal manipulation.Lab Chip. 2016; 19: 3261-3267https://doi.org/10.1039/C9LC00503JView in Article

Magnetic liquid metal marble: characterization of lyophobicity and magnetic manipulation for switching applications.J. Microelectromech. Syst. 2016; 25: 1050-1057https://doi.org/10.1109/JMEMS.2016.2614303View in Article

Magnetically- and electrically-controllable functional liquid metal droplets.Adv. Mater. Technol. 2019; 4: 1800694https://doi.org/10.1002/admt.201800694View in Article

Magnetically powered shape-transformable liquid metal micromotors.Small. 2019; 15: e1905446https://doi.org/10.1002/smll.201905446View in Article

Ferrofluid droplets as liquid microrobots with multiple deformabilities.Adv. Funct. Mater. 2020; 30: 2000138https://doi.org/10.1002/adfm.202000138View in Article

Reconfigurable magnetic microrobot swarm: multimode transformation, locomotion, and manipulation.Sci. Robot. 2019; 4: eaav8006https://doi.org/10.1126/scirobotics.aav8006View in Article

Swarming microdroplets to a dexterous micromanipulator.Adv. Funct. Mater. 2021; 31: 2011193https://doi.org/10.1002/adfm.202011193View in Article

Fluid-like soft machines with liquid metal.Matter. 2021; 4: 336-337https://doi.org/10.1016/j.matt.2021.01.009View in Article

A stiffness-switchable, biomimetic smart material enabled by supramolecular reconfiguration.Adv. Mater. 2021; 34: e2107857https://doi.org/10.1002/adma.202107857View in Article

Octopus arms exhibit exceptional flexibility.Sci. Rep. 2020; 10: 20872https://doi.org/10.1038/s41598-020-77873-7View in Article

Beyond muscles: role of intramuscular connective tissue elasticity and passive stiffness in octopus arm muscle function.J. Exp. Biol. 2021; 224: 242644https://doi.org/10.1242/jeb.242644View in Article

Laser reprogramming magnetic anisotropy in soft composites for reconfigurable 3D shaping.Nat. Commun. 2020; 11: 6325https://doi.org/10.1038/s41467-020-20229-6View in Article

Reprogrammable ferromagnetic domains for reconfigurable soft magnetic actuators.Nano Lett. 2020; 20: 5185-5192https://doi.org/10.1021/acs.nanolett.0c01418View in Article

Magnetic multimaterial printing for multimodal shape transformation with tunable properties and shiftable mechanical behaviors.ACS Appl. Mater. Interfaces. 2020; 13: 12639-12648https://doi.org/10.1021/acsami.0c13863View in Article

Thermoset shape memory polymer variable stiffness 4D robotic catheters.Adv. Sci. 2022; 9: e2103277https://doi.org/10.1002/advs.202103277View in Article

Magnetically addressable shape-memory and stiffening in a composite elastomer.Adv. Mater. 2019; 31: e1900561https://doi.org/10.1002/adma.201900561View in Article

Magnetically tightened form-stable phase change materials with modular assembly and geometric conformality features.Nat. Commun. 2022; 13: 1397https://doi.org/10.1038/s41467-022-29090-1View in Article

Variable stiffness wires based on magnetorheological liquid metals.Int. J. Smart Nano Mater. 2022; 13: 232-243https://doi.org/10.1080/19475411.2022.2065703View in Article

Anisotropic materials based on liquid metals.Matter. 2020; 3: 613-614https://doi.org/10.1016/j.matt.2020.08.015View in Article

Liquid metal composites.Matter. 2020; 2: 1446-1480https://doi.org/10.1016/j.matt.2020.03.016View in Article

Low melting point liquid metal as a new class of phase change material: an emerging Frontier in energy area.Renew. Sustain. Energy Rev. 2013; 21: 331-346https://doi.org/10.1016/j.rser.2013.01.008View in Article

Insights into fluidic endogenous magnetism and magnetic monopoles from a liquid metal droplet machine.Soft Sci. 2021; 1: 15https://doi.org/10.20517/ss.2021.16View in Article

Surface chemistry of gallium-based liquid metals.Matter. 2020; 3: 1477-1506https://doi.org/10.1016/j.matt.2020.08.012View in Article

Ferromagnetic liquid metal putty-like material with transformed shape and reconfigurable polarity.Adv. Mater. 2020; 32: e2000827https://doi.org/10.1002/adma.202000827View in Article

A liquid gripper based on phase transitional metallic ferrofluid.Adv. Funct. Mater. 2021; 31: 2100274https://doi.org/10.1002/adfm.202100274View in Article

Phase transition science and engineering of gallium-based liquid metal.Matter. 2022; 5: 2054-2085https://doi.org/10.1016/j.matt.2022.05.031View in Article

Programmable transformation and controllable locomotion of magnetoactive soft materials with 3D-patterned magnetization.ACS Appl. Mater. Interfaces. 2020; 12: 58179-58190https://doi.org/10.1021/acsami.0c15406View in Article

Endosomal escapable cryo-treatment-driven membrane-encapsulated Ga liquid-metal transformer to facilitate intracellular therapy.Matter. 2022; 5: 219-236https://doi.org/10.1016/j.matt.2021.11.006View in Article

Article info

Publication history

Published: January 25, 2023

Accepted: December 5, 2022

Received in revised form: October 28, 2022

Received: August 18, 2022

5 notes

·

View notes

Text

Raf Simons FW98 “Radioactivity” MultiMaterial Layered Loop Knit

Raf Simons AW98 “Radioactivity” MultiMaterial Layered Knit. One of the earlier, underrated seasons, “Radioactivity” took cues from legendary synth pop group and kraut rock pioneer Kraftwerk. Footage and images available today show runway models walking down the catwalk with bold red button ups similar to what the Kraftwerk group members wore during a performance. Mock neck knit with an intricate and crudely weaved paneled knit layered over the sweater consisting of leather, suede, high gauge wool, mohair, yarn. Long loose fit

1 note

·

View note

Text

Humpday! Join the Livestream this Saturday at 12PM EST for the ERCF build!

https://www.youtube.com/live/V2SLzfp-rSI?si=h5438Pl1NYPBkkh4

#ercf #mmu #multimaterial #voron #leemerie3d #3dprinting #3d #ams

#ender 3#leemerie3d#prusa#tech#voron#x1c#3dprint#fyp#subscribetomychannel#pc build#mark rober#mr beast

0 notes

Text

I think 2024 will have more text musings from me. Idk tho.

But here is one anyways:

The dream would be 3d modeling on pc and producing 3d print works like figurines but painting is legit impossible for me due to health now lol, guess I have to wait until the Statasys PolyJet/BJP patent expires in a decade+, so that consumer level color/transparency/multimaterial printers can become available. $50,000 for the base machine is not affordable lmafo.

Honestly with the rate at which certain tech advances, it truely feels like patents in those specific fields stunt global advancement for decades. Feels criminal.

For things like 3d printers that are able to print with different materials, colors, and transparencies, it could truely save lives and at minimum drastically improve livelihoods, so it is so bizarre that tech like this is gatekept and not shared to be expanded on and innovated on by others.

This is also a problem in the gaming industry, (albeit at less severity, but still ridiculous). Tell me why there was a DECADES long patent on "mini games during loading screens" that was barely even used before it expired? And the nemesis system...

Obviously, patents have a use and can be very important in making sure creators are not taken advantage of or ripped off (in fact it will likely be a saving grace for taking down unethically sourced data for the current scummy unregulated generative ai models out there), but in certain situations like 3d printing it is straight up detrimental gatekeeping that benefits no one.

#text#musings#certified old fart yells at clouds#tell me that 3d printing full color flexible or transparent merch that looks like mold injection quality at home wouldn't be cool as hell.#with the bs 2d ink printers have now with subscriptions and other bs... i am not looking forward#to that monetization model.#designing and wearing 3d printed shoes that accommodate you sounds cool as hell too.#3d printing

1 note

·

View note

Text

Governo adia cobrança de taxa sobre embalagens de alumínio para janeiro

O Governo voltou a adiar a entrada em vigor do pagamento de uma taxa de 30 cêntimos sobre as embalagens de alumínio de uso único para refeições, segundo uma portaria publicada em Diário da República.

Inicialmente prevista para 1 de janeiro deste ano, o arranque da cobrança desta taxa sobre as embalagens de alumínio ou multimaterial com alumínio nas refeições prontas a consumir foi adiada ainda em 31 de dezembro 2022 para o dia 01 de setembro (sexta-feira). Agora, a data de entrada em vigor voltou a ser revista, passando para 01 de janeiro de 2024, face às dificuldades transmitidas pelos operadores económicos.

“Tendo em conta os constrangimentos manifestados por diversos agentes económicos, bem como a necessidade de alargar o âmbito de aplicação desta portaria a outros materiais, (…) considera-se essencial assegurar, no imediato, a prorrogação da produção de efeitos para a aplicação da contribuição sobre as embalagens de utilização única de alumínio ou multimaterial com alumínio”, lê-se na portaria.

A taxa de 30 cêntimos está, porém, a ser já aplicada desde julho de 2022 sobre as embalagens de plástico de utilização única para refeições prontas a consumir. Na origem desta medida está, segundo a portaria, “a necessidade de aprofundar o caminho de transição para uma economia circular, promovendo a redução sustentada do consumo de embalagens de utilização única e a consequente redução do volume de resíduos gerados”.

O diploma, assinado pelos secretários de Estado dos Assuntos Fiscais e do Ambiente, Nuno Félix e Hugo Pires, respetivamente, entra em vigor esta quarta-feira.

0 notes

Text

Multimaterial 3D Printer Developed For Creating Flexible Devices

http://dlvr.it/SsPmtQ

0 notes

Text

This 3D printer can watch itself fabricate objects

New Post has been published on https://thedigitalinsider.com/this-3d-printer-can-watch-itself-fabricate-objects/

This 3D printer can watch itself fabricate objects

With 3D inkjet printing systems, engineers can fabricate hybrid structures that have soft and rigid components, like robotic grippers that are strong enough to grasp heavy objects but soft enough to interact safely with humans.

These multimaterial 3D printing systems utilize thousands of nozzles to deposit tiny droplets of resin, which are smoothed with a scraper or roller and cured with UV light. But the smoothing process could squish or smear resins that cure slowly, limiting the types of materials that can be used.

Researchers from MIT, the MIT spinout Inkbit, and ETH Zurich have developed a new 3D inkjet printing system that works with a much wider range of materials. Their printer utilizes computer vision to automatically scan the 3D printing surface and adjust the amount of resin each nozzle deposits in real-time to ensure no areas have too much or too little material.

Since it does not require mechanical parts to smooth the resin, this contactless system works with materials that cure more slowly than the acrylates which are traditionally used in 3D printing. Some slower-curing material chemistries can offer improved performance over acrylates, such as greater elasticity, durability, or longevity.

In addition, the automatic system makes adjustments without stopping or slowing the printing process, making this production-grade printer about 660 times faster than a comparable 3D inkjet printing system.

The researchers used this printer to create complex, robotic devices that combine soft and rigid materials. For example, they made a completely 3D-printed robotic gripper shaped like a human hand and controlled by a set of reinforced, yet flexible, tendons.

Play video

“Our key insight here was to develop a machine-vision system and completely active feedback loop. This is almost like endowing a printer with a set of eyes and a brain, where the eyes observe what is being printed, and then the brain of the machine directs it as to what should be printed next,” says co-corresponding author Wojciech Matusik, a professor of electrical engineering and computer science at MIT who leads the Computational Design and Fabrication Group within the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL).

He is joined on the paper by lead author Thomas Buchner, a doctoral student at ETH Zurich, co-corresponding author Robert Katzschmann PhD ’18, assistant professor of robotics who leads the Soft Robotics Laboratory at ETH Zurich; as well as others at ETH Zurich and Inkbit. The research appears today in Nature.

Contact free

This paper builds off a low-cost, multimaterial 3D printer known as MultiFab that the researchers introduced in 2015. By utilizing thousands of nozzles to deposit tiny droplets of resin that are UV-cured, MultiFab enabled high-resolution 3D printing with up to 10 materials at once.

With this new project, the researchers sought a contactless process that would expand the range of materials they could use to fabricate more complex devices.

They developed a technique, known as vision-controlled jetting, which utilizes four high-frame-rate cameras and two lasers that rapidly and continuously scan the print surface. The cameras capture images as thousands of nozzles deposit tiny droplets of resin.

The computer vision system converts the image into a high-resolution depth map, a computation that takes less than a second to perform. It compares the depth map to the CAD (computer-aided design) model of the part being fabricated, and adjusts the amount of resin being deposited to keep the object on target with the final structure.

The automated system can make adjustments to any individual nozzle. Since the printer has 16,000 nozzles, the system can control fine details of the device being fabricated.

“Geometrically, it can print almost anything you want made of multiple materials. There are almost no limitations in terms of what you can send to the printer, and what you get is truly functional and long-lasting,” says Katzschmann.

The level of control afforded by the system enables it to print very precisely with wax, which is used as a support material to create cavities or intricate networks of channels inside an object. The wax is printed below the structure as the device is fabricated. After it is complete, the object is heated so the wax melts and drains out, leaving open channels throughout the object.

Because it can automatically and rapidly adjust the amount of material being deposited by each of the nozzles in real time, the system doesn’t need to drag a mechanical part across the print surface to keep it level. This enables the printer to use materials that cure more gradually, and would be smeared by a scraper.

Superior materials

The researchers used the system to print with thiol-based materials, which are slower-curing than the traditional acrylic materials used in 3D printing. However, thiol-based materials are more elastic and don’t break as easily as acrylates. They also tend to be more stable over a wider range of temperatures and don’t degrade as quickly when exposed to sunlight.

“These are very important properties when you want to fabricate robots or systems that need to interact with a real-world environment,” says Katzschmann.

The researchers used thiol-based materials and wax to fabricate several complex devices that would otherwise be nearly impossible to make with existing 3D printing systems. For one, they produced a functional, tendon-driven robotic hand that has 19 independently actuatable tendons, soft fingers with sensor pads, and rigid, load-bearing bones.

“We also produced a six-legged walking robot that can sense objects and grasp them, which was possible due to the system’s ability to create airtight interfaces of soft and rigid materials, as well as complex channels inside the structure,” says Buchner.

The team also showcased the technology through a heart-like pump with integrated ventricles and artificial heart valves, as well as metamaterials that can be programmed to have non-linear material properties.

“This is just the start. There is an amazing number of new types of materials you can add to this technology. This allows us to bring in whole new material families that couldn’t be used in 3D printing before,” Matusik says.

The researchers are now looking at using the system to print with hydrogels, which are used in tissue-engineering applications, as well as silicon materials, epoxies, and special types of durable polymers.

They also want to explore new application areas, such as printing customizable medical devices, semiconductor polishing pads, and even more complex robots.

This research was funded, in part, by Credit Suisse, the Swiss National Science Foundation, the U.S. Defense Advanced Research Projects Agency, and the U.S. National Science Foundation.

#000#3-D printing#3d#3D printing#amazing#applications#artificial#Artificial Intelligence#bearing#Brain#Cameras#Capture#computation#computer#Computer Science#Computer Science and Artificial Intelligence Laboratory (CSAIL)#Computer vision#contactless#defense#Defense Advanced Research Projects Agency (DARPA)#Design#details#devices#droplets#Electrical Engineering&Computer Science (eecs)#engineering#engineers#Environment#ETH Zurich#eyes

2 notes

·

View notes

Quote

Stimuli-responsive biomaterials show great promise for modeling disease dynamics ex vivo with spatiotemporal control over the cellular microenvironment. However, harvesting cells from such materials for downstream analysis without perturbing their state remains an outstanding challenge in 3/4-dimensional (3D/4D) culture and tissue engineering. In this manuscript, a fully enzymatic strategy for hydrogel degradation that affords spatiotemporal control over cell release while maintaining cytocompatibility is introduced. Exploiting engineered variants of the sortase transpeptidase evolved to recognize and selectively cleave distinct peptide sequences largely absent from the mammalian proteome, many limitations implicit to state-of-the-art methods to liberate cells from gels are sidestepped. It is demonstrated that evolved sortase exposure has minimal impact on the global transcriptome of primary mammalian cells and that proteolytic cleavage proceeds with high specificity; incorporation of substrate sequences within hydrogel crosslinkers permits rapid and selective cell recovery with high viability. In composite multimaterial hydrogels, it is shown that sequential degradation of hydrogel layers enables highly specific retrieval of single-cell suspensions for phenotypic analysis. It is expected that the high bioorthogonality and substrate selectivity of the evolved sortases will lead to their broad adoption as an enzymatic material dissociation cue and that their multiplexed use will enable newfound studies in 4D cell culture.

User‐Controlled 4D Biomaterial Degradation with Substrate‐Selective Sortase Transpeptidases for Single‐Cell Biology - Bretherton - 2023 - Advanced Materials - Wiley Online Library

0 notes

Text

MOSTRADOR DE VENTAS: IDEAS Y MODELOS PARA AMUEBLAR LA TIENDA

Mostrador de venta de una tienda: una elección de estilo (y utilidad)

El mostrador tienda representa el mobiliario que da la bienvenida a los clientes y determina el carácter del entorno. ¿Cómo elegir un mostrador de ventas? Parece obvio repetirlo pero, incluso en el caso del equipamiento de tiendas, siempre hay que dar preferencia a las estructuras modulares.

Gracias a sus estructuras dinámicas, los mostradores modulares pueden integrarse con otros elementos a lo largo del tiempo o, por el contrario, racionalizar su diseño. Piense, de hecho, en la importancia del espacio detrás del mostrador, para guardar el material de envolver regalos, los objetos y productos dañados o las pertenencias privadas del personal. Pero también el frente del mostrador de ventas puede verse realzado por la propia estructura del mostrador. Además de una estantería a la hora de pagar, el mostrador puede convertirse en una valiosa superficie de exposición que hay que aprovechar, sobre todo en el caso de los pequeños comercios.

¿Y los materiales? Un mostrador de ventas con encimera de cristal es, sin duda, elegante y de diseño moderno. Las tendencias modernas impulsan los mostradores multimaterial, es decir, con una estructura de materiales sólidos y detalles de ventanas para optimizar el espacio. El mostrador de venta, de hecho, puede convertirse en un espacio de exposición adicional si los distintos niveles están bien organizados, confiando en la versatilidad de los muebles modulares. Atemporal, y muy práctico, sigue siendo el laminado, el compromiso perfecto entre la necesidad de gastar poco presupuesto y el deseo de un resultado estéticamente agradable.

1 note

·

View note