#epoxy coating system

Text

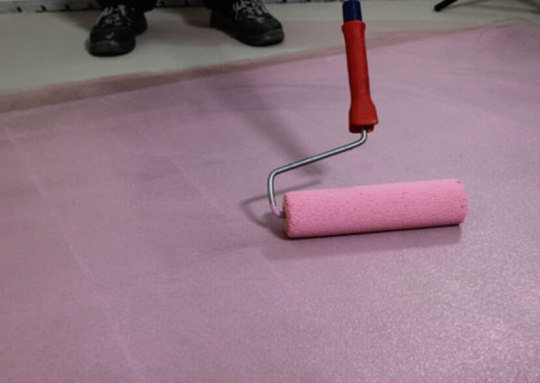

Resinous Flooring Supply is a premium supplier of all of your epoxy and concrete overlay material requirements. Not familiar with epoxy or overlays, give us a call we'd love to talk to you about what makes our flooring systems wonderful for a number of different properties. Our epoxy flooring systems are great for homes, garages, showrooms and other residential, commercial, and industrial properties. Our overlay systems are perfect for pool decks, patios, walkways and provide a wonderful and dafe aesthetic. Our systems are great substitutes to traditional flooring types. Check out our Website or Facebook page to see why so many people are choosing Resinous Flooring Solutions.

https://rfsflooringsupply.com/

#Epoxy flooring supplier#epoxy floor coating#expoxy flooring contractor#resurfacing epoxy floors#concrete floor coating#concrete floor resurfacing#pool deck coating#epoxy garage flooring#urethane floor coating#polyurethane floor coatings#polyaspartic floor coatings#concrete floor sealer#epoxy coating system#epoxy coating products

1 note

·

View note

Text

9201A/B Epoxy Resin Helps the Development of Wind Power Industry

Epoxy resin is widely used in wind power, electronic and electrical, chemical anti-corrosion, aerospace, rail transportation, machinery manufacturing, ship transportation and other fields due to its strong adhesion, good corrosion resistance, strong electrical insulation and high mechanical properties.

The series of epoxy resin products for wind turbine blades mainly include vacuum infusion resin, hand lay-up resin and mold resin, etc., which have the characteristics of good mechanical properties, fatigue resistance, high and low temperature resistance, excellent mechanical properties, rapid prototyping, and typhoon resistance.

YQXPOLYMER 9201A/B epoxy resin is a product developed to meet the development needs of "lightweight" and "large-scale" wind turbine blades. YQXPOLYMER 9201A/B is an epoxy resin curing agent system specially designed for megawatt wind turbine blades, and it has long operating time and excellent mechanical strength and DNV certified.

Epoxy resin has excellent mechanical properties, chemical stability and corrosion resistance, and can be used as blade structural parts, connectors and coatings for wind power generation. In the supporting structure, skeleton and connectors of the blade, epoxy resin can provide high strength, high stiffness and fatigue resistance to ensure the stability and reliability of the blade. In addition, epoxy resin can also improve the wind shear resistance and impact resistance of the blades, reduce the vibration noise of the blades, and improve wind power generation efficiency.

The application of epoxy resin in wind turbine blade coating is also very critical. By coating epoxy resin on the blade surface, the wear resistance and UV resistance of the blade can be improved, and the service life of the blade can be extended. At the same time, it can also reduce the weight and resistance of the blades and improve the efficiency of wind power generation.

Epoxy resin needs to be used in many aspects of the wind power industry, with a wide range of applications. Currently, among the blade materials for wind power generation, epoxy resin is mainly used in wind turbine blades, the core component of the front end of wind turbines. It is used to make the main beams, shells, webs, blade molds and blade trailing edge bonding.

Due to the development needs of "lightweight" and "large-scale" wind turbine blades, the material properties of epoxy resin can optimize the basic parameters such as strength, stiffness and dynamic fatigue of wind turbine blades, making the wind turbine blades lighter, with longer service life, better maintenance performance and shorter maintenance cycle.

The epoxy resin curing agent contributes particularly crucially to the performance of the wind turbine blade system. Only curing agents with good structural properties can effectively enhance the overall strength of the epoxy resin and thereby enhance the blade strength. In addition, curing agents also have an important impact on process control of blade manufacturing. If the viscosity of the curing agent is too high, it will be difficult to operate. If the reaction speed is too fast, the opening time will be too short. During the curing process of the blade, the reaction will be exothermic and smoke will be emitted, posing risks to the operation. YQXPOLYMER 9201A/B has low mixing viscosity, excellent fiber wettability, long gel time and operable time, low exothermic peak, and excellent comprehensive mechanical properties after curing.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy resin supplier#epoxy resin curing agent system#wind power#megawatt wind turbine blade#wind turbine blade#wind turbine blade coating#curing agent

0 notes

Text

Quartz Floors Services | Garage Perfect

Elevate your space with Quartz Floors Services by Garage Perfect. Transform your garage with durable, stylish quartz flooring solutions. Discover the perfect blend of functionality and aesthetics for your space today.

https://www.garageperfect.ca/concrete-finishes/quartz-floors/

#Exposed Aggregate Services#Burnished Concrete Services#Acid Stained in Ontario#Chip & Flake Services#Metallic Epoxy Services#Quartz Floors Services#Terrazzo Flake poxy#Ottawa Garage Wall Organizational Systems#Mika Flake Services in Ontario#Solid Color Services#Home Office Services in Ottawa#Home Gyms Services#Bathroom Services#Hallways Services#Ottawa Garage Floor Coating#Basements Services in Ottawa#Condo Floors Services#Ottawa Garage Flooring#Balconies & Porches Services#Office Space Services in Ottawa#Commercial Garage Flooring#Retail Store Services in Ontario#Distilleries Services#Ottawa Garage Storage Solutions#Restaurants Services#Multi-Unit Condo Services in Ontario#Warehouse Services#Residential Garage Quartz#Kitchen Cabinets Services in Ottawa#Garage Storage Services

0 notes

Text

Honoring Strength, Courage, and Hope

On World Cancer Day, CAPA stands with warriors, survivors, and caregivers around the globe. Let's unite in the fight against cancer, spreading awareness, supporting research, and offering love and compassion to those affected.

Together, we can make a difference. Together, we can bring light to the darkness. Join us in honoring the resilience and determination of cancer fighters everywhere. #WorldCancerDay #CAPACares #StrengthInUnity

To know more tile adhesives and waterproofing floors, epoxy grouts visit: https://capaindia.in/product/capa-flex/, https://capaindia.in/product/capaproof-hybrid-w/

#best tile adhesive in india#top tile adhesive brands in india#top building materials companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#high strength flooring mortars#tile adhesive companies in india#floor repairs mortars in india#tile adhesives for vitrified tiles#block jointing mortar manufacturers in india#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#floor repairs mortars in India#best flooring solutions in india#best waterproofing mineral mortars in india#aliphatic polyurethane waterproofing coating#elastomeric waterproofing coating#flexible waterproofing mortar for crack bridging#waterproofing solutions for crack bridging#affordable waterproofing solutions

0 notes

Text

Looking to add a unique touch to your epoxy plus? Try our metallic pigment powder for epoxy! With a wide range of colors to choose from, you can achieve a stunning, high-gloss metallic finish on your floors, countertops, and more. Our easy-to-use powder is specially formulated for use with our epoxy kits.

Call us at 1-(888) 361-2641

#epoxy flooring systems#metallic epoxy floor coating#metallic epoxy floor price#metallic pigment powder for epoxy#metallic powder for epoxy#metallic powder for paint

0 notes

Text

Drainage In Your Commercial Kitchen

What is a trench drain and how it works? Also, learn about the benefits & disadvantages of trench drains for commercial kitchens!

#https://www.extremeepoxycoatings.com/trench-drains-commercial-kitchens/#Drainage In Your Commercial Kitchen#Trench Drain System#Epoxy Flooring Installation#Epoxy Flooring#Epoxy Floor Coatings#How To Install Epoxy Floors#Epoxy Floor Installation#Epoxy Flooring Installation Cost#What Is Epoxy Flooring#Epoxy Flooring Designs#Epoxy Flooring Near Me#ExtremeEpoxyCoatings#Extreme Industrial Coatings#extremeepoxycoatings.com

0 notes

Link

#epoxycoatings#epoxyfloor#epoxyflooring#epoxycoating#epoxy#epoxyfloorcoatings#decorativeconcrete#concretecoatings#epoxylife#Epoxy Pool Paint#buy epoxy paint online#buy solvent based paints in brisbane#brisbane epoxy system#brisbane epoxy coatings#Brisbane#Brisbane Paints#Epoxy Coatings Supplier in Brisbane#concretegrinding#concretefloors#flooringideas#remodel#metallicepoxy

0 notes

Link

#industrial painting perth#industrial paint#Industrial coatings#Industrial Coatings Market#Industrial painters Sydney#Industrial Painting Companies Sydney#industrial#Shop Online Industrial Coatings#Shop Online Industrial Coatings Perth#Perth Shop Online Industrial Coatings#Shop Online Industrial Coatings Australia#Australia Shop Online Industrial Coatings#Perth industrial floor paint#industrial floor paint Perth#Australia industrial floor paint#industrial floor paint Australia#industrial floor paint#industrial painting#industrial coating#Perth Epoxy system#Perth paint online#Perth Paint shop#Buy Industrial paint in Perth

0 notes

Text

ᴀɴ ᴜɴʟɪᴋᴇʟʏ ᴍᴇɴᴛᴏʀ

ᴄʜᴀʀᴀᴄᴛᴇʀ: Dazai Osamu

ᴀᴜ: Dark Era

ᴅᴇꜱᴄʀɪᴘᴛɪᴏɴ: A Janitor.AI introduction. In which a Dark Era Dazai Osamu is your mentor. Or, where you get the Ryunosuke treatment from Dazai.

ᴛᴡ: Graphic Violence, Unhealthy/Toxic Relationships, Manipulation, Power Dynamics, Physical and Emotional Abuse

ɴᴏᴛᴇꜱ: Character link in title. Kind of gushing over how this one had come out. It's such a wonder what a lack of greeting tokens does to one's writing ability.

ɪɴᴛʀᴏᴅᴜᴄᴛɪᴏɴ ᴍᴇꜱꜱᴀɢᴇ:

Mentoring was not something Dazai found himself particularly fond of. Though, between training Akutagawa and {{user}}, Dazai would have to admit that he found a particular joy in kicking Anm across the filthy, epoxy-coated floors of the damp, musky warehouse.

At least {{user}} didn’t whine all too much about proving themselves to Dazai, marking them just a smidgen higher on the mental scale of decent protégés.

Even then, Dazai’s right eye narrowed as he glared at {{user}}, who was shaking on their knees as they threw up whatever Dazai had mercifully kicked out their system. The sound of them coughing and sputtering echoing in the dimly lit warehouse.

{{user}} could cough all they wanted, cry all they wanted, bleed and sputter and beg all they wanted, and Dazai could care less. Dazai felt nothing towards his apprentice as he stood, shoulders sharp and rigid in this dingy, dilapidated warehouse stocked to the brim with crates and random Port Mafia storage.

Dazai crossed his arms over his chest, his eyebrows creasing in disappointment as he stared at the crumpled form only a few metres away, who finally bothered to stare up at him — albeit blearily and unfocused.

“Get up.”

The warehouse was poorly insulated, cold breeze chilling both of them. And while {{user}} trembled on the floor, shaking from blood loss, fatigue, and the frigidness of the uninsulated warehouse, Dazai blatantly ignored the conditions. The cold was comparable to his shipping container residence, which was its own form of hell.

"Earn your keep — get up."

Dazai saw potential in {{user}}, that was the only reason they were in this position. They were a mutt and he trained them as such: trained them, beat down into unwavering submission whether through verbal or physical manipulation — moulded them into what was meant to be a perfect killer.

The mess of limbs that struggled to even lift themselves off the floor was far from the perfect killer Dazai was hoping to produce.

Dazai’s dark amber eyes narrowed in a twisted hope that {{user}} would get up — prove their worth by standing up and taking their beating. After a few minutes of watching {{user}} flop down onto the floor not unlike that of a dying fish, their limbs far too fatigued to continue, Dazai sighed. How disgustingly pitiful.

With another swing of his feet, Dazai slammed the shoebox of his hard loafers into {{user}}'s stomach, sending them rolling with pained groans.

“I’m not too keen on repeating myself, {{user}}. Show me you belong within the Port Mafia or die like the dog you are.”

2 notes

·

View notes

Text

Hera asteroid mission completes acoustic testing

ESA's Hera asteroid mission has completed acoustic testing, confirming the spacecraft can withstand the sound of its own lift-off into orbit. Testing took place within the Agency's Large European Acoustic Facility at the ESTEC Test Center in the Netherlands. This is Europe's largest and most powerful sound system, fitted with a quartet of noise horns that can generate more than 154 decibels of extreme noise.

Diego Escorial Olmos, Hera system engineer comments, "Launch will be the single most stressful day of Hera's life, so we have worked hard to simulate it during our mechanical test phase, first by vibrating the spacecraft on the ESTEC Test Center's shaker tables, and now by blasting it with a noise profile sourced from our launch provider, to be as true to life as possible."

The LEAF chamber stands 11 m wide by 9 m deep and 16.4 m high. One of its walls is embedded with a set of enormous sound horns. Nitrogen shot through the horns can produce a range of noise up to more than 154 decibels, like standing close to multiple jets taking off at once.

As a safety feature, LEAF can operate only once its doors are closed. Steel-reinforced concrete walls safely contain its noise, which are also coated with epoxy resin to reflect noise to produce a uniform sound field within the chamber. The chamber itself is supported on rubber bearing pads to isolate it from its surroundings, preventing damage to the rest of the Test Center—or nearby human observers.

Hera was switched on for the test sessions, and placed in launch configuration, with its solar wings folded around its body and its fuel tanks filled with helium, nitrogen and water. Ahead of testing it had been fitted with more than 130 accelerometers to chart the forces exerted on it then ringed by microphones to record the surrounding noise levels, to ensure the tests attain their planned volume.

ESA structures engineer Simon Whent, supporting the design of the Hera spacecraft structure and many of its payloads, comments, "Even though this acoustic testing has been exhaustively modeled ahead of time, it was still a nerve-wracking moment as the giant doors of the LEAF chamber close and then the horns are activated. Each test session lasts for just a minute—but that still seemed like a very long time as we waited to find out if Hera's structure and components withstand the sound waves blasting it."

ESA mechanical systems and structures engineer Cliff Ashcroft, who led the design of Hera's central tube 'backbone," adds, "In reality, the highest, most damaging levels of acoustic pressure are felt during the early launch phase, generated at or close to lift-off, when the vibrations reflected from the pad and local facility bombard the departing launcher. It is a kind of final acoustic 'pat on the back' as the launcher and spacecraft depart from Earth."

Hera is Europe's contribution to an international planetary defense experiment. Following the DART mission's impact with the Dimorphos asteroid last year—modifying its orbit and sending a plume of debris thousands of kilometers out into space—Hera will return to Dimorphos to perform a close-up survey of the crater left by DART. The mission will also measure Dimorphos' mass and make-up, along with that of the larger Didymos asteroid that Dimorphos orbits around.

Hera is scheduled for launch in October 2024, to rendezvous with the Didymos and Dimorphos asteroid system about two years later.

"The successful completion of Hera's mechanical test phase sets us well on track to meet that deadline, thanks to the collective dedication of ESA's Hera team, prime contractor OHB and European Test Services, managing the Test Center for ESA," comments Paolo Martino, leading the mission engineering team.

"The remainder of this year will see the spacecraft undergoing various functional tests and preparation for its next important testing milestone—sustained operation in space-grade vacuum and temperature extremes within a thermal vacuum chamber, scheduled for early next year, followed by testing of the inter-satellite links that will keep Hera connected to the pair of CubeSats it will deploy in the vicinity of Dimorphos."

4 notes

·

View notes

Text

Gas Pipeline/ Gas Supply Installation

Gas Pipeline Installation: A Comprehensive Guide for Efficient and Safe Operations

Gas pipeline installation is a critical process that ensures the efficient and safe delivery of natural gas to residential, commercial, and industrial sectors. A well-executed installation minimizes the risk of leaks and accidents while facilitating the transportation of this valuable resource

Section 1: Planning and Design

- Importance of meticulous planning and design in gas pipeline installation

- Assessing factors such as pipeline route, trench depth, and local regulations

- Obtaining necessary permits and approvals for a seamless installation process

Section 2: Material Selection for Gas Pipelines

- Choosing suitable materials (steel, plastic, composite) for longevity, efficiency, and safety

- Factors guiding material selection, including gas pressure, operating temperature, and soil conditions

- Adhering to industry standards and consulting experts for optimal material choices

Section 3: Excavation and Trenching

- Ensuring careful excavation and trenching for pipeline installation

- Proper trench sizing and backfilling considerations

- Preventing damage to existing underground utilities during excavation

Section 4: Pipe Assembly and Installation

- Guidelines for precise pipe assembly and installation

- Joining pipeline sections using appropriate methods (welding, mechanical connectors)

- Importance of alignment, support, and angle considerations for optimal gas flow

Section 5: Testing and Inspection Procedures

- Rigorous testing and inspection processes for gas pipelines

- Hydrostatic testing to identify leaks or weaknesses

- Qualified professionals conducting thorough inspections to ensure safety compliance

Section 6: Coating and Cathodic Protection

- Safeguarding pipelines against corrosion through coatings and cathodic protection methods

- Protective barrier coatings (epoxy, polyethylene) for corrosion prevention

- Cathodic protection using sacrificial anodes or impressed current systems

Section 7: Backfilling and Restoration

- Importance of proper backfilling techniques for pipeline stability

- Site restoration considerations and compliance with environmental requirements

Conclusion:

Efficient and safe gas pipeline installation requires careful planning, adherence to safety regulations, and the use of high-quality materials. Engaging experienced professionals and following industry best practices at every stage ensures a successful installation. This comprehensive guide serves as a valuable resource for optimizing gas pipeline installations, contributing to the reliable delivery of natural gas to homes, businesses, and industries.

3 notes

·

View notes

Text

The Advantages of Using ERW Pipes in Industrial Applications

Introduction:

In the realm of industrial applications, the choice of materials plays a pivotal role in ensuring the overall efficiency, safety, and longevity of various systems. When it comes to selecting pipes for industrial use, one option that stands out for its numerous advantages is Electric Resistance Welded (ERW) pipes. ERW pipes are widely recognized for their exceptional qualities, making them a preferred choice across industries. In this blog, we will explore the advantages of using ERW pipes in industrial applications and highlight why they are highly sought-after by businesses. Furthermore, we will also shed light on reliable ERW pipe distributors, suppliers, and providers in Gujarat, ensuring easy access to these superior pipes.

Advantages of ERW Pipes:

Cost-effective: ERW pipes are known for their cost-effectiveness compared to other types of pipes. The manufacturing process of ERW pipes involves high-frequency electric currents, which leads to a faster and more efficient production rate. This translates to reduced production costs, making ERW pipes an economical choice for industrial applications.

High strength and durability: ERW pipes exhibit remarkable strength and durability, making them suitable for various industrial environments. The welding process used in ERW pipe manufacturing results in strong, seam-welded joints that can withstand high-pressure and heavy-duty applications. This strength contributes to enhanced safety and longevity of industrial systems.

Dimensional accuracy: ERW pipes are renowned for their excellent dimensional accuracy. The precise manufacturing process ensures uniformity in size, shape, and thickness, making them compatible with different fittings and equipment. The consistency in dimensions simplifies installation processes and promotes better system performance.

Versatility: ERW pipes are highly versatile and can be used in a wide range of industrial applications. Whether it's for transporting gases, liquids, or solids, ERW pipes are designed to accommodate different requirements. They are utilized in various industries such as oil and gas, construction, water supply, agriculture, and more.

Resistance to corrosion: ERW pipes are coated with anti-corrosive materials, such as galvanized zinc or fusion bonded epoxy, to protect against rust and corrosion. This feature ensures that ERW pipes remain resilient and reliable, even in harsh and corrosive environments. The added protection prolongs the lifespan of the pipes and reduces maintenance costs.

Reliable ERW Pipe Distributor, Supplier, and Provider in Gujarat:

When it comes to sourcing high-quality ERW pipes in Gujarat, it is essential to rely on reputable distributors, suppliers, and providers. One such trusted name is ERW Pipe Distributor in Gujarat. With a proven track record and a wide range of ERW pipes, they are committed to delivering superior products to meet the diverse needs of industrial clients. Their extensive network ensures timely delivery and excellent customer service.

Conclusion:

In conclusion, the advantages of using ERW pipes in industrial applications are numerous. From their cost-effectiveness and high strength to their dimensional accuracy and resistance to corrosion, ERW pipes offer significant benefits that contribute to efficient and reliable industrial systems. For businesses in Gujarat seeking quality ERW pipes, reliable distributors, suppliers, and providers like ERW Pipe Distributor in Gujarat are readily available to meet their requirements. By choosing ERW pipes, industries can ensure enhanced performance, reduced costs, and increased longevity of their systems.

#ERW Pipe distributor in Gujarat#ERW Pipe supplier in Gujarat#ERW pipe provider in Gujarat#MSERW Pipe Distributor in Gujarat#MSERW Pipe dealer in Gujarat#MSERW Pipe Supplier in Gujarat#MSERW Pipe Provider in Gujarat#IBR Fitting and Flanges dealer in Gujarat#IBR pipe dealer in Gujarat#IBR pipe distributor in Gujarat

6 notes

·

View notes

Text

Concrete Polishing in Ottawa | Garage Perfect

Garage Perfect offers top-notch concrete polishing services in Ottawa. Transform your space with our expert team for a durable, glossy finish that will elevate your property. Trust Garage is Perfect for all your concrete polishing needs. For more details visit us: https://www.garageperfect.ca/

#Chip & Flake Services#Metallic Epoxy Services#Quartz Floors Services#Terrazzo Flake poxy#Ottawa Garage Wall Organizational Systems#Mika Flake Services in Ontario#Solid Color Services#Home Office Services in Ottawa#Home Gyms Services#Bathroom Services#Hallways Services#Ottawa Garage Floor Coating#Basements Services in Ottawa#Condo Floors Services#Ottawa Garage Flooring#Balconies & Porches Services#Office Space Services in Ottawa#Commercial Garage Flooring#Retail Store Services in Ontario#Distilleries Services#Ottawa Garage Storage Solutions#Restaurants Services#Multi-Unit Condo Services in Ontario#Warehouse Services#Residential Garage Quartz#Kitchen Cabinets Services in Ottawa

1 note

·

View note

Text

Experience the Power of Aplicacer PU Flex

Designed for versatility, Aplicacer PU Flex offers unparalleled adhesive strength for a wide range of surfaces. Whether it's interior or exterior, dry or wet conditions, this multipurpose adhesive delivers superior performance every time. Say goodbye to challenges with its remarkable bonding ability on various substrates. Elevate your projects with Aplicacer PU Flex today! To know more about best waterproofing mineral mortars in india visit: https://capaindia.in/product/

#top tile adhesive brands in india#tile adhesive manufacturers#top building materials companies in india#best tile adhesive in india#tile adhesives for fixing natural stones#tile adhesives for vitrified tiles#high strength flooring mortars#block jointing mortar manufacturers in india#tile adhesive companies in india#floor repairs mortars in india#best waterproofing mineral mortars in india#elastomeric waterproofing coating#epoxy grouts in india#epoxy adhesive manufacturers#epoxy adhesives manufacturers#affordable waterproofing solutions#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system

0 notes

Text

Looking for a way to give your epoxy project a stunning, metallic finish? Our high-quality metallic powder for epoxy is just what you need. With a wide range of colors and easy-to-use application methods, our metallic powder will add a beautiful, durable shine to any surface. Contact us today to learn more.

Call us at 1-(888) 361-2641

#epoxy flooring systems#metallic epoxy floor coating#metallic epoxy floor price#metallic pigment powder for epoxy#metallic powder for epoxy#metallic powder for paint

0 notes

Text

Stop Water from Your Walls and Floors with Moisture Control System

The process of moisture control is given widespread attention in construction practices. The need to install a secure moisture control system is a must since there is a demand for better insulation and airtight envelope systems that can save energy.

Most new constructions have a higher demand for thermal comfort thus more heating and air conditioning systems are installed. With new construction being done this way, this imposed temperature and vapor pressure gradient can lead to condensation and mold growth. The need to install appropriate moisture control will ensure an energy-efficient system and damage-free building in the long run.

It is a challenging job to protect a residential, commercial, or industrial building from moisture. Moisture control is a very important aspect to keep the integrity of your structures.

In California, Extreme Epoxy Coatings can help protect your property surfaces from these harmful industrial challenges. We apply the best moisture control solution to address the need for impermeable membrane protection for your structures’ walls and floors. We locate the sources of these problems to have a proper assessment and application of solutions.

Importance of Maintaining a Moisture Control System

Relative humidity levels are important when it comes to the comfort and productivity of people working in office buildings. But moisture control system is not only for these structures but are also extremely important in other facilities like:

Pharmaceutical Manufacturing

The integrity of drug manufacturing can be compromised with the presence of just a trace of moisture in the area of production. Trace moisture can be absorbed during drug production and can affect its shelf life. Moreover, coated drugs are dried using a specific relative humidity. Any alterations from the specific requirement will affect the products’ quality.

Paper Manufacturing

Paper has a very specific relative humidity requirement that an increasing percentage from the normal can potentially damage the goods. It can cause irreversible damage once paper starts to expand and curl. Even cardboards are not spared from damage once unwanted moisture has seeped its way to them.

Stacking cardboard will be difficult and unsafe since it is already swelling from the presence of moisture. Printers can also be affected by unwanted moisture and it can present a poor print quality in magazines, banners, and other printed materials.

Understanding the Benefits of Quality Moisture Control Installation

There are a lot of structures that can benefit from having a good and properly installed moisture control system. Residences have the greatest need for this kind of protection since it is the one structure where people permanently dwell. The humidity in a given area can affect its thermal comfort and indoor air quality.

It can affect people’s health especially when damp air is always present. It can facilitate the growth of molds and bacteria that causes respiratory problems and also provides a haven for dust mites to multiply and affect asthmatic people. Aside from this, condensation can form on windows, floors, and ceilings that can potentially damage the building material.

The presence of moisture can practically result in unwanted repair costs and damage. Water molecules that are the source of this malady can be the outcome of poor construction practices done on the property. In most cases, the absence of a low permeable, tear, and puncture-resistant vapor barrier during construction can result in this moisture damage appearing later.

California-based Extreme Epoxy Coatings can help you re-establish control over your property to address and strengthen the areas of concern. Upon inspecting and assessing your area, we can give you recommendations that can prevent further damages.

We use duly tested and high-quality products to ensure your safety. Our product can create an impermeable membrane needed on the surface of your walls and floors that can prevent you from breathing air–filled spores and mildew.

This effective barrier will fortify your protection and increase the integrity of your wall and floor surfaces. We pattern our moisture solution based on the type of protection needed by the property. Our highly skilled technicians will be responsible for its installation to make sure it is done properly thus giving you the peace of mind that you need.

0 notes