#tile adhesive manufacturers

Text

Strengthen Your Construction Projects with Aplicatec Puente Fisuras PCC

Elevate the durability of your structures with Aplicatec Puente Fisuras PCC! Engineered for excellence, this flexible waterproofing mortar offers unmatched crack bridging capabilities, ensuring resilience against moisture and environmental factors.

Why Choose Aplicatec Puente Fisuras PCC? 🔹 Superior Crack Bridging Performance 🔹 Long-lasting Protection Against Water Damage 🔹 Versatile Application on Various Substrates 🔹 Weatherproof and Chemical Resistant 🔹 Suitable for Indoor and Outdoor Use

Embrace quality and reliability in your construction endeavors. Opt for Aplicatec Puente Fisuras PCC today! Learn more: https://capaindia.in/product/aplicatec-puente-fisuras-pcc/

#Waterproofing mortar#Waterproofing system#waterproofing solutions for crack bridging#best tile adhesive in india#tile adhesives for vitrified tiles#top building materials companies in india#tile adhesive manufacturers#high strength flooring mortars#floor repairs mortars in india#top tile adhesive brands in india#tile adhesive companies in india#tile adhesives for fixing natural stones#block jointing mortar manufacturers in india#flexible waterproofing mortar for crack bridging#affordable waterproofing solutions#“tileadhesive”

0 notes

Link

#construction chemical companies#construction chemical manufacturer india#tile adhesive manufacturers#tile adhesive manufacturers in india

0 notes

Text

YQXPOLYMER Epoxy Resin 0614/0614DL were Launched into International Market

April 9, 2024, YQXPOLYMER, a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider is pleased to launch its 0614/0614DL epoxy resin worldwide. To expand its business operations, YQXPOLYMER is now open to exploring partnerships with like-minded organizations, businesses, and individuals interested in the epoxy industry.

YQXPOLYMER 0614/0614DL are diluted liquid epoxy resins, which is manufactured from C12~C14 aliphatic glycidyl ether and bisphenol A epoxy resin.

YQXPOLYMER 0614/0614DL are special low viscosity liquid epoxy resins, which are widely used in Stone adhesive. YQXPOLYMER 0614/0614DL can be used to paste fiberglass mesh on the back of marble to enhance the strength and stability of the stone, prevent the stone from falling off and improve the impact resistance of the stone. Also they are used in Ceramic tile adhesive, Epoxy floor, Road bridge tunnel filling, and so on.

A wide variety of curing agents is available to cure liquid epoxy resins at ambient conditions. The most frequently used are aliphatic polyamines, polyamides, alicyclic amines, cycloaliphatic amines and modified versions of these curing agents. Elevated temperature cures are necessary and long post-cures are required to develop full end properties if anhydrides or catalytic curing agents are employed.

YQXPOLYMER 0614/0614DL Typical Properties

YQXPOLYMER 0614/0614DL Key Features

Low viscosity and strong fluidity, good performance at room temperature, and easier to paint and construct.

It can better penetrate into the surface to be coated or bonded, improving performance stability and durability.

Widely used in Stone adhesive, Ceramic tile adhesive, Epoxy floor, Road bridge tunnel filling, etc.

Packing variety: drums, IBC container, or customization.

YQXPOLYMER 0614/0614DL Typical Applications

This product is suitable for use in applications such as:

• Stone adhesive

• Ceramic tile adhesive

• Epoxy floor

• Building repair adhesive( Road bridge tunnel filling)

• Solventless coatings

• Composite materials

• Liquid molding compounds

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally. And we provide highly cost-effective products, short lead time, in-time after-sales service, even OEM service.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy adhesive#epoxy resin supplier#epoxy floor#tile adhesive#YD-114#Kukdo YD-114E#stone adhesive

0 notes

Text

Enhancing Quality and Reliability: BIS Certification for Tile Adhesives

BIS Certification for Tile Adhesives

In the ever-evolving realm of construction materials, the significance of adhering to stringent quality standards cannot be understated. Tile adhesives, the unsung heroes behind the durability and aesthetic appeal of tiling installations, play a pivotal role in ensuring that surfaces remain intact for extended periods. To address concerns regarding the quality and reliability of tile adhesives, the Bureau of Indian Standards (BIS) has introduced a certification process that brings a new level of credibility and trust to the industry.

Introduction to Tile Adhesives: Form and Function

Tile adhesives, also known as thin-set mortars, are specialized compounds used for bonding tiles to various substrates, including walls, floors, and countertops. These adhesives serve as the foundation upon which the overall longevity, stability, and aesthetic of the tiling project rely. Properly chosen and expertly applied adhesives can prevent tiles from dislodging, cracking, or shifting due to environmental stressors, ensuring a safe and visually appealing environment.

The Role of BIS Certification: Elevating Industry Standards

BIS certification for tile adhesives serves as a hallmark of quality and consistency. This certification process involves rigorous testing, meticulous assessment, and compliance with predefined standards to ascertain that the product meets the expectations of performance, safety, and durability.

1. Stringent Testing Procedures

BIS certification demands adherence to a comprehensive battery of tests designed to evaluate the adhesive's physical, chemical, and mechanical properties. These tests encompass assessments of adhesion strength, open time, water resistance, shrinkage, and workability, among others. Through these assessments, the certification ensures that the adhesive is formulated to withstand the specific conditions it will encounter during application and throughout its service life.

2. Conformity to Established Standards

Certification requires that the tile adhesives adhere to standards that have been established through extensive research and industry collaboration. These standards outline the minimum requirements that an adhesive must fulfill to ensure reliable performance in real-world scenarios. By adhering to these standards, manufacturers demonstrate their commitment to producing high-quality products that contribute to safe and durable construction practices.

3. Building Trust and Consumer Confidence

BIS certification fosters consumer confidence by providing assurance that the product has undergone thorough scrutiny and met predetermined benchmarks. This trust is invaluable, especially in industries where the consequences of product failure can be substantial, both in terms of financial costs and safety hazards. Architects, contractors, and homeowners can rely on BIS-certified tile adhesives to deliver the promised performance and longevity.

Conclusion

In the intricate world of construction materials, every detail matters. BIS certification for tile adhesives stands as a testament to India's commitment to quality, safety, and long-term reliability in the construction industry. By subjecting tile adhesives to rigorous testing and adhering to established standards, BIS certification brings peace of mind to professionals and consumers alike. This milestone not only elevates the performance of tile adhesives but also contributes to the overall excellence of construction practices, ensuring spaces that stand the test of time.

1 note

·

View note

Text

Tile adhesive Manufacturer in India

Discover top-quality tile adhesive solutions from a leading manufacturer in India. Our innovative tile adhesives ensure strong and lasting bonds for your projects. Explore our range now!

https://www.pcbond.in/tile-adhesive-manufacturer-in-india/

#tile adhesive manufacturer in india#tile adhesive supplier in india#tile adhesive manufacturer in gujarat

0 notes

Text

Tips for Restoring Old Tiles: Reviving the Beauty of Vintage Flooring

Vintage tiles can add a touch of timeless elegance to any space, be it a historic home or a modern apartment. However, over time, these treasured tiles may lose their luster due to wear and tear. Restoring old tiles requires careful attention and a gentle touch to revive their original beauty without causing any damage. In this article, we'll provide you with Yoast-approved tips for restoring old tiles, helping you bring back the charm of vintage flooring and preserve its allure for years to come.

Assess the Condition of the Tiles

Before diving into the restoration process, it's essential to assess the current condition of the tiles. Check for any cracks, chipping, or missing pieces. Determine the type of tile material, as different materials may require specific restoration techniques. Assessing the state of the tiles will help you plan the restoration process accordingly and set realistic expectations.

Thorough Cleaning

The first step in restoring old tiles is a thorough cleaning to remove years of dirt, grime, and old sealant. Start by sweeping or vacuuming the tiles to get rid of loose debris. Next, use a mild detergent or a pH-neutral tile cleaner mixed with warm water to gently clean the surface. Avoid harsh chemicals that may damage the tiles. For stubborn stains, make a paste with baking soda and water and apply it to the affected areas. Let it sit for a few minutes before scrubbing with a soft brush.

Repairing Cracks and Chips

To restore the tiles to their former glory, addressing cracks and chips is crucial. Use a high-quality tile filler or epoxy resin to repair minor cracks and chips. Fill the damaged areas carefully and smooth out the surface with a putty knife. Allow sufficient drying time before proceeding with the next step.

Removing Old Sealant

Old tiles are often protected with layers of sealant, which can become discolored and dull over time. Removing the old sealant is essential before applying a new one. Use a sealant remover or a mixture of equal parts vinegar and water to dissolve the old sealant. Be patient, as this process may take some time. Once the old sealant is removed, clean the tiles again to ensure a fresh surface for the new sealant.

Restoring Grout Lines

Grout plays a crucial role in vintage tile restoration. Inspect the grout lines for any signs of mold or discoloration. Use a grout cleaner or a mixture of baking soda and water to clean the grout lines thoroughly. For severe grout issues, consider regrouting the entire floor. Choose a grout color that complements the tiles and gives them a refreshed appearance.

Applying New Sealant

After cleaning and repairing the tiles, it's time to apply a new sealant to protect and enhance their beauty. Choose a high-quality, breathable sealant suitable for the tile material. Apply the sealant evenly using a clean cloth or brush, following the manufacturer's instructions. Allow the sealant to dry completely before walking on the restored floor.

Conclusion

Restoring old tiles is a labor of love that rewards you with a stunning and timeless vintage flooring. By following these Yoast-approved tips, you can successfully revive the beauty of vintage tiles and create an exquisite backdrop for your living spaces. Remember to take your time, use gentle cleaning methods, and choose high-quality products for the best results. With proper care, your restored vintage tiles will continue to charm and delight for generations to come.

1 note

·

View note

Text

What is the main polymer ingredient used in tile adhesives?

The main polymer ingredient used in tile adhesives is a cementitious polymer. This is a type of polymer that is made by blending cement with synthetic polymers such as vinyl acetate and acrylics. Cementitious polymer is used to improve the bonding strength, flexibility, and durability of tile adhesives. It is commonly used in thin-set tile adhesives, which are used to install ceramic, porcelain, and natural stone tiles. The addition of cementitious polymer allows the adhesive to adhere better to the surface and also helps to prevent the tiles from cracking or shifting over time. Cementitious polymer is also resistant to water and moisture, which makes it ideal for use in bathrooms, kitchens, and other areas where tiles are exposed to moisture.

Buy the best construction glue for wood for getting better strength on your construction work.

0 notes

Text

Power Grace Industries - Top Tile Adhesive Manufacturer in India

Power Grace Industries is a leading and reputable tile adhesive company in India. With a commitment to quality, innovation, and customer satisfaction, we have established ourselves as one of the best tile adhesive manufacturers in the country. Our range of products includes a variety of tile adhesives suitable for different applications and substrates. We use advanced manufacturing techniques and high-quality materials to produce our adhesives, ensuring that they provide excellent bonding strength, durability and resistance to moisture and other environmental factors. Whether you are a homeowner, builder or contractor Power Grace Industries has the perfect tile adhesive solution for your needs.

#Tile Adhesive Manufacturers in India#Tile Adhesive Companies in India#Tile Adhesive Manufacturers in Gujarat

1 note

·

View note

Text

Honoring Strength, Courage, and Hope

On World Cancer Day, CAPA stands with warriors, survivors, and caregivers around the globe. Let's unite in the fight against cancer, spreading awareness, supporting research, and offering love and compassion to those affected.

Together, we can make a difference. Together, we can bring light to the darkness. Join us in honoring the resilience and determination of cancer fighters everywhere. #WorldCancerDay #CAPACares #StrengthInUnity

To know more tile adhesives and waterproofing floors, epoxy grouts visit: https://capaindia.in/product/capa-flex/, https://capaindia.in/product/capaproof-hybrid-w/

#best tile adhesive in india#top tile adhesive brands in india#top building materials companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#high strength flooring mortars#tile adhesive companies in india#floor repairs mortars in india#tile adhesives for vitrified tiles#block jointing mortar manufacturers in india#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#floor repairs mortars in India#best flooring solutions in india#best waterproofing mineral mortars in india#aliphatic polyurethane waterproofing coating#elastomeric waterproofing coating#flexible waterproofing mortar for crack bridging#waterproofing solutions for crack bridging#affordable waterproofing solutions

0 notes

Link

Tile adhesive is a paste-like material that is used as an adhesive to affix tiles to a surface. It has many benefits over other traditional…

#tile adhesive manufacturer India#tile fixing adhesive manufacturer#tile fixing adhesive#tile adhesive cement#wall tile adhesive

0 notes

Link

0 notes

Text

#Dolphin PU Foam for 15 months from the date of manufacturing.#Where is it used?#Doors and windows assembly is the most effective utilization region of Dolphin PU#Foam. It is used for the insulation of electrical installations#hot and cold water pipes#adhesion of roofing tiles#tightness of terraces#concrete shear wall buildings#industrial roof insulation#cold storage houses#and ice plants#decks of ships and#yachts#filling of the voids between external thermal insulation materials#adhesion of#insulation materials#filling of the voids and insulation of dry food storages and for a#lot more purposes.#The biggest benefit of PU foam: keeps the pests away#PU foam is made up of self-expanding material and hence offers the biggest#advantage of filling up even the hard-to-reach cracks and crevices. These small#holes are the favorite places for the pests to grow and multiply. By covering these#holes with PU foam#you get protection from insects and other pests.#Special features of Dolphin PU foam by Al Muqarram#• Durable airtight seal: prevents air infiltration and energy loss#• High insulating value saves energy and money.#• Environment friendly: contains no CFC’s#no HCFC’s#ozone friendly

1 note

·

View note

Text

The Significance of ISI Certification for Tile Adhesives: Ensuring Quality and Safety

Introduction

In the realm of construction materials, tile adhesives play a pivotal role in ensuring the longevity and stability of tiles in various applications. These adhesives not only bond tiles to surfaces but also provide structural integrity and durability. With the growing emphasis on quality and safety in the construction industry, regulatory bodies have introduced various certification standards to guarantee the efficacy of products. The Indian Standards Institute (ISI) certification is one such benchmark that has become mandatory for tile adhesives. This article explores the reasons behind the mandatory ISI certification for tile adhesives, its benefits, and its impact on the construction industry.

The Need for Certification

The use of uncertified or substandard construction materials can have severe consequences, ranging from aesthetic issues to structural failures. Tile adhesives, which are responsible for securing tiles to substrates, require a high degree of adhesive strength, flexibility, and resistance to environmental factors such as moisture and temperature fluctuations. Subpar adhesives can lead to tile displacement, cracks, and even safety hazards, putting both the structural integrity of the building and its occupants at risk.

The ISI certification for tile adhesives is a direct response to the need for standardized quality. By adhering to the ISI standards, manufacturers are compelled to produce adhesives that meet specific criteria of performance, durability, and safety. This certification helps in curbing the proliferation of substandard products in the market, ensuring that only those adhesives that fulfill stringent requirements are made available to consumers and construction professionals.

Benefits of ISI Certification

Assured Quality: ISI certification serves as a mark of quality assurance. Adhesives that bear this certification have been rigorously tested and found to meet the prescribed standards. This assurance of quality provides peace of mind to consumers and professionals alike, reducing the risk of product failure and subsequent financial losses.

Enhanced Durability: Tile adhesives certified by ISI are designed to withstand the test of time. They exhibit better resistance to moisture, temperature variations, and mechanical stresses, resulting in longer-lasting installations. This is particularly important in areas prone to extreme weather conditions or heavy foot traffic.

Safety Compliance: In construction, safety is paramount. ISI-certified adhesives undergo thorough testing to ensure they do not pose any health or safety risks during or after installation. These adhesives are less likely to emit harmful chemicals or fumes that could be detrimental to human health.

Reduced Maintenance Costs: High-quality tile adhesives reduce the need for frequent repairs and replacements, thereby lowering long-term maintenance costs. The initial investment in ISI-certified adhesives pays off in the form of decreased upkeep expenses.

Industry Credibility: Manufacturers that choose to obtain ISI certification demonstrate their commitment to producing reliable and superior products. This helps build their credibility and reputation within the industry, fostering trust among customers and partners.

Impact on the Construction Industry

The mandatory requirement of ISI certification for tile adhesives has a far-reaching impact on the construction industry:

Quality Standardization: The certification acts as a common quality benchmark, encouraging manufacturers to continuously improve their products. This fosters healthy competition and drives innovation in adhesive technology.

Consumer Empowerment: With ISI-certified products, consumers can make informed choices without having to navigate through a sea of options with varying quality levels. This empowerment leads to more satisfactory outcomes and higher levels of trust between consumers and suppliers.

Project Longevity: The use of high-quality adhesives enhances the lifespan of tile installations, minimizing the need for premature replacements. This contributes to the overall sustainability of construction projects by reducing waste and resource consumption.

Regulatory Compliance: The construction industry is subject to various regulations and standards to ensure safety and quality. ISI certification helps construction professionals adhere to these regulations by providing access to reliable materials that meet the necessary standards.

Conclusion

In conclusion, the mandatory ISI certification for tile adhesives is a critical step towards ensuring the quality, durability, and safety of construction materials. By establishing a set of rigorous standards that manufacturers must adhere to, this certification guarantees that only high-quality adhesives are available in the market. The benefits of ISI certification, including enhanced durability, safety compliance, and reduced maintenance costs, have a positive impact on both the construction industry and end-users. As the construction sector continues to evolve, the emphasis on quality assurance through certifications like ISI will undoubtedly play a pivotal role in shaping a safer and more reliable built environment.

0 notes

Text

transforming soffits

reorganizing keys

formalizing immersion joints

justifying kick extractors

advising aggregates

managing elbows

recasting connectors

achieving aluminum trowels

officiating disks

exhibiting absolute spigots

progressing coil hydrants

jerry-building reflectors

informing casters

inventing rubber hoists

performing wrenches

judging chalk adapters

upgrading ignition paths

regrowing flashing

recommending ratchets

approving barriers

sweeping impact fillers

sewing mirrors

detailing collectors

enforcing measures

distributing systems

presenting plugs

interwinding registers

piloting ash diffusers

gathering cranks

supplying eave pockets

undertaking scroll stops

accelerating straps

designing fittings

protecting diamond boilers

logging downspouts

correlating shingles

uniting mallets

qualifying electrostatic lifts

sharing clamps

obtaining circular fluids

ranking foundation gauges

sensing miter brackets

originating space networks

translating drills

regulating guards

selecting gable padding

utilizing pellet dowels

reconciling artifacts

altering pulleys

shedding space filters

determining vents

representing mortar

remaking flash rakers

supporting funnels

typecasting rotary chocks

expressing junctures

resetting auxiliary vises

professing strip treads

inlaying matter trowels

questioning drivers

forming edge fittings

sketching blanks

overshooting spark breakers

rewriting controls

playing tunnels

inventorying buttons

enduring joint handles

effecting ratchet bibbs

unwinding couplings

forsaking vapor conduits

defining sockets

calculating heaters

raising grids

administering tiles

measuring resources

installing ignition remotes

extracting corners

manufacturing ventilators

delegating consoles

treating mounting stones

enacting jig deflectors

intensifying alleys

improvising cargo

pinpointing bobs

prescribing arc masonry

structuring metal chucks

symbolizing lathes

activating plumb kits

adapting coatings

fixing channels

expediting cordage

planning compressors

enlisting hangers

restructuring keyhole augers

shearing ridge hardware

collecting reciprocating bolts

maintaining corrugated dimmers

whetting hole collars

conducting mandrels

comparing assets

compiling sealants

completing paths

composing equivocation wheels

computing dampers

conceiving electrostatic treatment

ordering cotter grates

organizing ties

orienting ladders

exceeding materials

targeting thermocouples

demonstrating emery stock

expanding latch bases

training wardrobe adhesives

overcomming[sic] fasteners

streamlining storm anchors

navigating springs

perfecting turnbuckles

verifying gate pegs

arbitrating arithmetic lifts

negotiating outlets

normalizing strips

building surface foggers

checking key torches

knitting grinders

mowing planers

offsetting stencils

acquiring bulbs

adopting rivets

observing avenues

ascertaining coaxial grommets

slinging wing winches

instituting circuit generators

instructing wicks

integrating pry shutters

interpreting immersion lumber

clarifying coils

classifying wood bits

closing cogs

cataloging matter strips

charting holders

conceptualizing push terminals

stimulating supports

overthrowing shaft spacers

quick-freezing connectors

unbinding ground hooks

analyzing eyes

anticipating gateways

controlling proposition rollers

converting power angles

coordinating staples

correcting benders

counseling joist gaskets

recording gutter pipes

recruiting drains

rehabilitating rafter tubes

reinforcing washers

reporting guard valves

naming freize sprues

nominating rings

noting straps

doubling nailers

drafting circuit hoses

dramatizing flanges

splitting framing compounds

refitting stems

interweaving patch unions

placing sillcocks

sorting slot threads

securing mode cutters

diverting catharsis plates

procuring load thresholds

transferring syllogism twine

directing switch nuts

referring time spools

diagnosing knobs

discovering locks

dispensing hinges

displaying hasps

resending arc binders

retreading grooves

retrofitting aesthetics portals

seeking stocks

shrinking wormholes

assembling blocks

assessing divers

attaining lug boxes

auditing nescience passages

conserving strikes

constructing braces

contracting saw catches

serving installation irons

recognizing fluxes

consolidating fuse calipers

mapping shims

reviewing chop groovers

scheduling lag drives

simplifying hoists

engineering levels

enhancing tack hollows

establishing finishing blocks

20 notes

·

View notes

Note

oh there are lab grown pearls but i thought it meant the pearls are grown without a mollusk :^(

There are pearls you can get without an animal involved, fortunately! And some are still good quality! But they're still not lab grown, and I'm being pedantic because the reason we can't make fully synthetic pearls is pretty cool actually!

Fake pearls are not *grown* at all, and not made in labs the way some gemstones are. As a shorthand, some companies call them lab grown, but they are always "manufactured pearls" or "imitation pearls." They're mass produced in factories out of other materials.

Lab grown gemstones are really really cool, but this isn't that process, and no lab is involved. In theory, you could take the materials a pearl is made out of and coax it into growing...something. But that mineral would end up being crystalline (trying to grow it slowly into its natural form) or flat (trying to grow it in deposited layers).

The cool thing about pearls is that they get their shape, lustre, and physical properties from the way the calcium carbonate is layered up in a sphere from around the initial nucleation site! Even their unique colors have to do with the microstructures and what's incorporated into the material as it grows. It's so far completely impossible to make them synthetically. You *have* to use a natural material (mollusk shell) or fake it (glass, plastic).

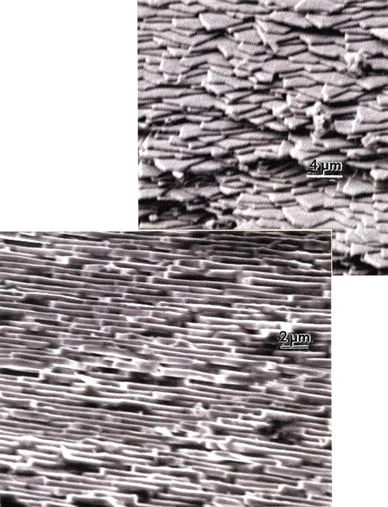

SEM images at different angles of observation on a cultured pearl curved surface region showing aragonite mesolayers and polygonal tile edges. Magnification markers are 4 and 2 microns, respectively. Murr, L.E., Ramirez, D.A. The Microstructure of the Cultured Freshwater Pearl. JOM 64, 469–474 (2012).

We haven't spent as much time trying to come up with a way to lab-grow (genuinely grow) pearls. They don't have as many uses as, say, sapphire (which we lab grow a lot, perfectly!). BUT.

A LOT of research has been done on another cool thing about bivalves...

Muscle foot glue! There are a ton of applications and inspiration we can use muscle foot protein for, like using this glue instead of stitches or rods for shoulder surgeries, or for underwater adhesive applications for structures, boats, pipes, etc.

Bivalves have a lot of their coastal territories in danger because of climate change and development. They clean water and actively sequester carbon and they're super super high in protein so they are all around super cool creatures that don't get enough love!

#pearls#gemstones#pearl is my birth stone and i am a materials scientist so i have read so much about pearls#mimicking natural materials is a whole field it's super cool!!#we're not there yet tho#the muscle article is about just one group's work but hundreds of groups are working on it?#its so cool???!#anyway now my weird bivalve interest is public

6 notes

·

View notes