#Tile Adhesive Manufacturers in Gujarat

Text

Power Grace Industries - Top Tile Adhesive Manufacturer in India

Power Grace Industries is a leading and reputable tile adhesive company in India. With a commitment to quality, innovation, and customer satisfaction, we have established ourselves as one of the best tile adhesive manufacturers in the country. Our range of products includes a variety of tile adhesives suitable for different applications and substrates. We use advanced manufacturing techniques and high-quality materials to produce our adhesives, ensuring that they provide excellent bonding strength, durability and resistance to moisture and other environmental factors. Whether you are a homeowner, builder or contractor Power Grace Industries has the perfect tile adhesive solution for your needs.

#Tile Adhesive Manufacturers in India#Tile Adhesive Companies in India#Tile Adhesive Manufacturers in Gujarat

1 note

·

View note

Text

Tile adhesive Manufacturer in India

Discover top-quality tile adhesive solutions from a leading manufacturer in India. Our innovative tile adhesives ensure strong and lasting bonds for your projects. Explore our range now!

https://www.pcbond.in/tile-adhesive-manufacturer-in-india/

#tile adhesive manufacturer in india#tile adhesive supplier in india#tile adhesive manufacturer in gujarat

0 notes

Text

The Top 5 Epoxy Flooring Manufacturers in the Industry for 2023

Epoxy flooring is the coating done on the base of concrete, wooden & steel floors. Whether it's a living area, basement, retail store, lobby, hotel, shopping mall, home, restaurant, kitchen, garage floor coating, or any other outdoor field, epoxy flooring manufacturers can make it aesthetically beautiful! With durability, strength, and resistance to cracks, scratches, bacteria, dullness, or wear & tear, it's worth the investment. Nowadays, 3D epoxy flooring solutions also let you put the desired image on the floor with the self-leveling primer layer. People don't think twice before contacting epoxy flooring manufacturers due to their anti-slip, weather-withstanding, inexpensive, sustainable, & easy installation properties. Let's now get deep into the meaning of epoxy flooring & top Epoxy Floor Coating Manufacturers in India.

What is Epoxy Flooring?

Epoch flooring is a synthetic resin floor system & a versatile chemical solution that's customizable according to the industrial flooring need. Here, epoxy's multiple layers are put across the floor reaching a 2 mm depth. Epoxy flooring is generally made with a mixture of hardeners & polymer resins and further combines well to create a rock-hard durable plastic-like material. Resinous flooring is another name for epoxy flooring & requires low-maintenance as compared to tiles. It is sustainable & can be uniquely decorated for different purposes of flooring with adhesion to wood, concrete, etc. Epoxy flooring manufacturers provide all the supplies with the necessary implementations to safeguard your surface from cracks, moisture, stains, grease, etc making it long-lasting for years.

Top 5 Epoxy Flooring Manufacturers in the Industry for 2023

Here is the list of the top 5 epoxy flooring manufacturers in 2023:

MB Enterprises, Malad, Mumbai, Maharashtra:

If you are looking for the best Epoxy Floor Coating Manufacturers in Mumbai, India, then your search stops with MB Enterprises. The top flooring contractor & adhesive dealer firm has been providing premium quality epoxy products since 2004 with 100% customer satisfaction. Some of their well-known product ranges are Epoxy resin, Glass Cleaner, Epoxy Adhesives, etc. They commit to their words & deliver products on time without any delay or hassle.

Aqua Floor Solutions, Ghatkopar, Mumbai:

They are one of the most popular epoxy flooring dealers in Mumbai since February 2013. Customers can expect top-notch waterproofing plus raised access flooring solutions. Being specialized in Epoxy & Polyurethane Coating, Raised Access Flooring & maintenance, the company has gained immense popularity lately. The firm delivers varied products & services within the local region as well as different regions of Mumbai.

Nishant Polycoats, Mumbai, Maharashtra:

With 20 years of expertise in the relevant field, the firm has prominent epoxy floor coating manufacturers in India. They operate their epoxy flooring services in the industries such as cement, automotive, machine tools, engineering, pharma, electronics & instrumentation, plastics, forging & foundry, textile, food processing, chemicals, etc.

Art Floor, Pune, Maharashtra:

The Pune-based leading firm has highly experienced epoxy flooring manufacturers. Whether you're struggling with metal erosion, concrete problems, or corrosion, they are a one-stop solution for everything. They safeguard your floors through densification, EPU, Epoxy, Polyurethane, Acrylic, Polyurea, deco floors & coatings from cans.

Chemfix Entreprise, Surat, Gujarat:

It is the leading epoxy flooring manufacturers company & is well known among its customers. This epoxy floor coating manufacturer provides numerous top-notch products & services such as Epoxy Resin, Epoxy Joint Filler, Tile Grout Filler, Epoxy Hardener, etc. The firm was established in 2011 & has developed a huge client base since then.

Every next residential, industrial & commercial area owner is adopting the idea of epoxy flooring. The lustrous shine, durability & strength is hard to resist. You will find numerous Epoxy Floor Coating Manufacturers in the relevant industry but we recommend MB enterprises. Our experience with them has been smooth, hassle-free, & worth the money.

#Epoxy Flooring Manufacturers#Epoxy Floor Coating Manufacturers#epoxy marble#italian marble epoxy#epoxy coating on marble#epoxy coating italian marble#epoxy over marble#epoxy for italian marble

0 notes

Text

AAC Block Plant Manufacturer in Gujarat

AAC Block Plant Manufacturer in Gujarat:

AAC (Autoclaved Aerated Concrete) block plant is a facility that manufactures AAC blocks, which are a lightweight, precast building material. In the construction business, AAC blocks have a wide range of uses and applications, including:

Façade cladding: AAC blocks can be used as a substrate for façade cladding, with additional materials such as brick, stone, tiles, or plaster being adhered to the AAC block wall by adhesive or mechanical fasteners. This adds a nice finishing touch to the building's façade.

Insulated roofs: AAC blocks can be used to form insulated roofs in structures, which provide thermal insulation and reduce heat gain or loss via the roof. AAC blocks can be utilized as a base layer, followed by a waterproofing layer and a suitable roofing material.

Fire-rated walls: Because AAC blocks are fire resistant, they can be used to form fire-rated walls in buildings, offering passive fire protection. Because AAC blocks can withstand high temperatures and do not emit toxic gases when burned, they are ideal for fire-rated walls in commercial, industrial, and residential buildings.

AAC blocks are good for reducing noise transmission and can be used to build sound barriers along highways, railways, and other busy places to reduce noise pollution.

AAC blocks have several uses and applications, and AAC block facilities play an important role in creating high-quality AAC blocks to suit the various needs of the building industry.

We Provide AAC Block Plant Manufacturer in Gujarat and we supplier to our products to various locations like Ahmedabad, Surat, Rajkot, Vadodara, Ankleshwar, Gandhinagar, Bhavnagar, Patan, Porbandar, Kutch, Vapi, Bharuch, Dahod, Amreli, Navsari, Kheda, Panchmahal, Sabarkantha, Surendranagar, Mehsana, Morbi, Gir Somnath, Palanpur.

Call Now:

Mail Us:

Read the full article

#AACBlockPlantManufacturerinAhmedabad#AACBlockPlantManufacturerinBhavnagar#AACBlockPlantManufacturerinDahod#AACBlockPlantManufacturerinGandhinagar#AACBlockPlantManufacturerinGujarat#AACBlockPlantManufacturerinKheda#AACBlockPlantManufacturerinKondapur#AACBlockPlantManufacturerinKutch#AACBlockPlantManufacturerinMehsana#AACBlockPlantManufacturerinPalanpur#AACBlockPlantManufacturerinPatan#AACBlockPlantManufacturerinSurat#AACBlockPlantManufacturerinVadodara#AACBlockPlantManufacturerinVapi

0 notes

Text

China Clay – A Versatile Raw Material for Everyday Products

Kaolinite is a soft, usually white and earthy clay mineral which is produced by the chemical weathering of aluminium silicates. Rocks that are rich in Kaolinite are known as Kaolin or China Clay. China Clay is also referred to as White Clay and mainly includes the composition of fine particles in the form of platelets. The clay also consists of the hydrous aluminium silicate found in rocks rich in feldspars, such as granite. The hydrothermal process under which this granite changes into a soft clay found in Kaolin deposits is called Kaolinisation. China clay has high mechanical strength and anti-cracking properties.

Kaolin was first discovered in China, and hence, it gets its name from the Kao-Ling Hill in China, where it has been mined for centuries. High grade deposits of China clay in India are found in Rajasthan, West Bengal, Orissa, Madhya Pradesh and Gujarat. Zillion Sawa Minerals Pvt. Ltd. is India's leading and reputed China clay supplier that delivers fine and premium quality at reasonable market rates!

Uses of China Clay

China clay is the main ingredient used in the manufacturing of porcelain. But nowadays, it is widely used in other industries such as paper, rubber, paints and cosmetics.

Application and Benefits of China Clay

Filler Component: China clay is used as a filler component in paints, inks, cement primers, wood primers, spray plasters and texture paints, as it has a favourable effect on finished goods. China clay has a lamellar structure that adds toughness to the coatings. Due to its property of low solubility in water, it settles slowly in water and hence, is used in water-based paints. China clay has excellent levelling and brushing characteristics and is therefore used in latex paints as well.

Adhesive Sealants: China clay gives a good rheology control to adhesive sealants. Controlling rheology means influencing the speed at which the adhesive flows, which is crucial during laminating procedures. One of the properties of China clay is a low moisture picking up characteristic, which is beneficial when using moisture sensitive adhesive sealants.

Pharmaceuticals: China clay has been used as an emulsifier or a filler in traditional medicines for years. It has excellent antibiotic, antioxidant and antifungal properties, which is beneficial to the pharmaceutical industry.

Plastic: China clay is used as filler along with other components to add smoothness to plastic products—for example, PVC cables and PE film.

Ceramics: China clay is a naturally hydrated Aluminium Silicate mineral. It has alumina, which does not swell when mixed with water. Therefore, China clay is the most crucial element for making ceramics, rubber, tiles, potteries and many other industries.

Paper: China clay has low abrasive properties, is white in colour, affordable and easily available. Thus, it is the best and primary component for a paper filler. Plus, it adds smoothness, glossiness and brightness to paper, adds strength and improves the opacity and printability of paper.

Cosmetics: China clay is added to a wide range of cosmetic products. It is added to toothpaste for a brightening effect. It is also added to many facial masks as it offers several advantages like oil absorption, preventing acne and hydrating dry skin. When applied, it leaves a gentle, cooling and satisfactory effect on the skin.

Other Uses: China clay is used in the glass manufacturing process because of its high alumina content. It also acts as an excellent pesticide, dust-control and fog removing agent. It is also used for making dinnerware!

Zillion Sawa Minerals – The Skilled China Clay Supplier in India

China clay in India was and will continue to be in demand because of the multiple advantages it offers to ease the manufacturing process of many products. Because of this reason, there are many suppliers who deliver adulterated minerals. But if you are looking for high-grade, premium quality and budget-friendly China clay in India – we are here for all your requirements!

From mining to China clay delivery, we use the best technology, fully-functional and operational machinery and a team of professional and skilled workers to deliver nothing less than high quality. We are the best China clay suppliers in India with the best prices.

Contact us today to receive a superior supply of China Clay!

1 note

·

View note

Link

Advantages of waterproofing

Waterproofing exterior walls

If the exterior walls are opened to rainwater or extreme humidity, moisture content and water could seep through the walls. As a result, walls remain damp for a longer period of time until its gets dried up. This would even lead to formation of mold and further damage. Examine the exterior walls for any flaws:

Waterproofing exterior walls is indeed one of the best available options to prevent water seepage. However, it is essential to determine the exact cause of structural dampness prior to purchase of water proofing products. For example, cracks in bricks and wall condensation, ruptured water pipe. If these issues are fixed, you may consider applying a water proofer.

1 note

·

View note

Text

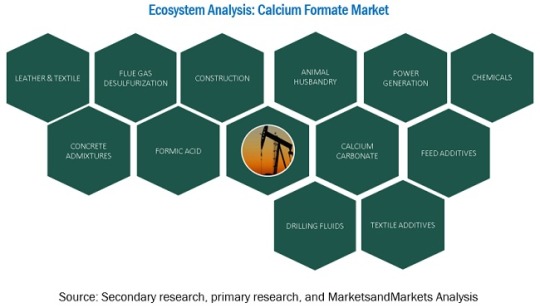

Growing demand of calcium formate in the construction industry

Calcium formate is used as cement additive and concrete accelerator, tile adhesives and cement-based mortars. The growth in the consumption of cement from the construction industry effectively boosts the demand for calcium formate market.

Calcium fromate is used as a cement additive in the construction industry for quick setting and increasing hardness of cement products. Cement is also used in the production of various products such as bricks and blocks, slabs and sheets, adhesives and concrete. In addition, calcium formate is also used as an inhibitor, PH regulator, corrosion protector to substrates of buildings and infrastructure, and for cementation of oil drilling. It is mostly used in the production of concrete in China which is one of the most dominant countries in the production and consumption of cement. Thus, the growing demand of cement in the construction industry is driving the market for calcium formate

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=191530782

The global calcium formate market size is estimated to grow from USD 545 million in 2020 to USD 713 million by 2025, at a CAGR of 5.5% during the forecast period. The market is projected to witness decent growth in the near future, owing to the wide application areas of calcium formate ranging from leather and textile to the construction industry. Increasing demand from APAC will further drive the growth of the global calcium formate market.

The construction industry will continue to lead the calcium formate market, , accounting for a share of 29.7% of the overall market, in 2019 terms of value. Increasing construction and infrastructural activities is expected to boost the rising demand for cement and concrete in the near future. The use of calcium formate as an accelerator in the concrete setting application decreses the setting time and increases the strength, thus boosting the global calcium formate market

Recent Developments

In November 2019, Perstorp, invested in the construction of a new Pentaerythritol (Penta) production facility in Gujarat, India. The Gujarat plant will produce Penta, including the renewable grades of Voxtar, providing up to a 60% reduced carbon footprint. Commercial production is planned to start in Q1 2022.

In February 2020, LANXESS completed the acquisition of Itibanyl Produtos Especiais Ltda. (IPEL). With the acquisition, LANXESS is strengthening its position as one of the world’s leading manufacturers of antimicrobial active ingredients and formulations.

APAC is estimated to be the leading calcium formate market during the forecast period. The growth in this region can be attributed to the rapidly increasing demand for calcium formate from the end-use industries, especially construction, leather & textile and animal husbandry. The market is witnessing moderate growth, owing to increasing application, technological advancements, and growing demand for these calcium formate additives in the APAC and Europe.

0 notes

Text

Kaolin Market Report by Technology, Industry Share and Size Expansion to 2027 | Fortune Business Insights™

The global kaolin market size is projected to reach USD 5,833.5 million by 2027, exhibiting a CAGR of 5.1% during the forecast period. Rising awareness about the benefits of china clay in skincare applications will be a prominent growth determinant for this market, states Fortune Business Insights™ in its report, titled “Kaolin Market Size, Share & COVID-19 Impact Analysis, By Application (Paper, Ceramic & Sanitary Ware, Fiberglass, Paints & Coatings, Rubber, Plastics, and Others), and Regional Forecast, 2020-2027”. For ages, clay has been known to fight skin-harming developments, such as acne. The increasing pollution levels, adoption of unhealthy diet regimes, and constant stress have had severe impacts on general health and skin in particular. Kaolin, or china clay, has emerged as one of the potent acne and oily skin-fighting formulations in recent times. For example, according to experts at the Mount Sinai Hospital in New York, china clay can absorb excess oil without drawing away too much of the skin’s moisture. Thus, people with inherently dry skin or sensitive skin can apply it without worrying about dryness. Further, research at Mount Sinai also showed that green kaolin clay, derived from plant matter and iron oxide, sucks out the dirt and bacteria that cause acne while removing excess oil. With the cosmetics & personal care industry growing rapidly worldwide, the employment of china clay in skincare products is likely to rise in the near future.

List of the Leading Companies Profiled in the Global Kaolin Market are;

20 Microns (Gujarat, India)

I-Minerals lnc. (Vancouver, Canada)

Quarzwerke GmbH (Frechen, Germany)

Thiele Kaolin Company (Georgia, U.S.)

Sibelco (Antwerp, Belgium)

Ashapura Group(Maharashtra, India)

Imerys S.A. (Paris, France)

W. R. Grace & Co. (Columbia, U.S.)

Sedlecký kaolin a. s. (Božičany, Czech Republic)

LASSELSBERGER Group (Budapest, Hungary)

KaMin LLC (Georgia, U.S.)

EICL Limited (Delhi, India)

BASF SE (Ludwigshafen, Germany)

Restraining Factor

COVID-19 to Negatively Impact the Paper Industry, Stall Market Growth

The COVID-19 pandemic outbreak has dealt notable blows to the paper industry as a result of lockdowns, supply chain disruptions, trade restrictions, and economic downturn. According to a study published by North Carolina State University, certain types of paper products have suffered because of the pandemic. For example, the demand for printing paper and copier paper has noticeably shrunk due to the shutdown of colleges and universities worldwide. In India, the Indian Paper Manufacturers Association stated in August 2020 that since March, paper supply chains have undergone widespread upheavals and are still in recovery mode.

Moreover, the closure of educational institutions and commercial establishments has further diminished the demand for paper, intensifying the downturn of the domestic paper industry. Kaolin is the most widely utilized mineral in the filling and coating of paper, and with the paper industry getting hit by the coronavirus, the growth of this market will inevitably get stalled.

As per the report, the global market value was at USD 4,168.8 million in 2019. The top highlights of the report include:

Detailed examination of the major market trends, drivers, and constraints;

In-depth evaluation of all segments of the market;

Exhaustive study of the leading players and their strategies; and

Granular analysis of the regional developments influencing the market.

Regional Insights

Asia Pacific to Spearhead the Market Supported by Speedy Economic Development

Asia Pacific is expected to lead the kaolin market share during the forecast period owing to the remarkable economic growth displayed by countries such as China and India. This growth has augmented the demand for high-end household consumer goods, where china clay is commonly used. The rapid expansion of the middle-class population in the region will also accelerate the growth of the regional market. In 2019, the Asia Pacific market size stood at USD 1,086.9 million.

In Europe, the heightened demand for packaged food and beverage items amid the COVID-19 pandemic has fueled the uptake of kaolin in the region’s food & beverage industry. On the other hand, in North America, technological advancements in the paper and packaging industries will stoke the regional market.

Competitive Landscape

Rising Costs to Force Key Players to Raise Product Prices

With the demand for high-performance raw materials soaring across various end-user industries, key players in the china clay market are engaged in the development of innovative offerings. However, the costs associated with the production of such materials are escalating worldwide. As a result, several companies are being forced to increase the prices of their products.

Industry Development:

December 2020: KaMin LLC and CADAM SA announced that they would be increasing the price of their kaolin performance minerals by 4% to 9% in the global markets from January 2021. According to the company, the price rise is unavoidable as it needs to offset the growing costs related to logistics and mining operations and to comply with the environmental requirements.

Browse Detailed Summary of Research Report: https://www.fortunebusinessinsights.com/kaolin-market-102352

Detailed Table of Content:

Research Scope

Market Segmentation

Research Methodology

Definitions and Assumptions

Market Drivers

Market Restraints

Market Opportunities

Key Emerging Trends – For Major Countries

Key Developments: Mergers, Acquisition, Partnership, etc.

Latest Technological Advancement

Insights on Regulatory Scenario

Porters Five Forces Analysis

Supply Chain Challenges

Steps taken by Government/Companies to overcome this impact

Potential opportunities due to COVID-19 outbreak

Paper

Ceramic & sanitary ware

Fiberglasss

Paints & coatings

Rubber

Plastics

Others

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

TOC Continued…!

Have a Look at Related Research Insights:

Paints and Coatings Market Size, Share & COVID-19 Impact Analysis, By Resin (Epoxy, Acrylic, Polyester, Alkyd, PU, and Others), By Technology (Waterborne, Solvent Borne, Powder Coating, and Others) By Application (Architectural, Automotive OEM, Marine, Coil, General Industries, Protective Coatings, Automotive Refinish, Industrial Wood, and Others), and Regional Forecast, 2020-2027

Paints and Coatings Additives Market Size, Share & COVID-19 Impact Analysis, By Type (Dispersing Agent, Rheology Agent, Leveling Agent, Anti-foaming Agent, Adhesion Promoting Agent, and Others), By Application (Automotive, Architectural, Wood, Industrial, and Others), and Regional Forecast, 2020-2027

Ceramics Market Size, Share & Industry Analysis, By Type (Traditional, Advanced), By Application (Tiles, Sanitary Wares, Abrasives, Pottery, Bricks & Pipes, Others), By End-Use Industry (Building & Construction, Industrial, Medical, Others) and Regional Forecast, 2019-2026

Pulp and Paper Market Size, Share & COVID-19 Impact Analysis, By Category (Wrapping & Packaging, Printing & Writing, Sanitary, News Print, and Others), and Regional Forecast, 2020-2027

About Us:

Fortune Business Insights™ offers expert corporate analysis and accurate data, helping organizations of all sizes make timely decisions. We tailor innovative solutions for our clients, assisting them to address challenges distinct to their businesses. Our goal is to empower our clients with holistic market intelligence, giving a granular overview of the market they are operating in.

Our reports contain a unique mix of tangible insights and qualitative analysis to help companies achieve sustainable growth. Our team of experienced analysts and consultants use industry-leading research tools and techniques to compile comprehensive market studies, interspersed with relevant data.

At Fortune Business Insights™, we aim at highlighting the most lucrative growth opportunities for our clients. We, therefore, offer recommendations, making it easier for them to navigate through technological and market-related changes. Our consulting services are designed to help organizations identify hidden opportunities and understand prevailing competitive challenges.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

308, Supreme Headquarters,

Survey No. 36, Baner,

Pune-Bangalore Highway,

Pune - 411045, Maharashtra, India.

Phone:

US: +1 424 253 0390

UK: +44 2071 939123

APAC: +91 744 740 1245

Email: [email protected]

Fortune Business Insights™

LinkedIn | Twitter | Blogs

Read Press Release:

https://www.fortunebusinessinsights.com/press-release/global-kaolin-market-10494

0 notes

Text

India Tile Adhesive Market

India Tile Adhesive Market was valued at USD 97.30 Mn in 2019 and is expected to reach USD 178.77 Mn by 2027 at a CAGR of 7.9% over the forecast period 2020-2027.

India Tile Adhesive Market

The report covers an in-depth analysis of COVID 19 pandemic impact on India Tile Adhesive Market by region and on the key players revenue affected till April 2020 and expected short term and long-term impact on the market.

India Tile Adhesive Market Dynamics;

Tile adhesive is a purpose made adhesives that come with many advantages. These adhesives help in installing two substrates by forming adhesive and cohesive bonds. Today’s tile adhesives are upgraded and specially modified for various applications. Manufacturers are adding water retention agents and polymeric binders such as methyl cellulose to improve wetting, and to achieve adhesion even on extremely smooth tiles or substrates. Various factors such as growing urbanization, increasing use of ceramic and thin porcelain decorative tiles, development of innovative adhesive solution for particular applications, growing demand from rural areas, rapidly expanding building and construction industry are driving the India tiles adhesives market over the forecast period. Along with these traditional applications tile adhesives are also used in polymer coatings, lubricant products, gypsum wallboard, and exterior/ interior grade plywood. Thus, an increasing adoption of tile adhesives in these applications is expected to crate lucrative opportunities for India tile adhesives market over the forecast period.

However, factors such as availability of substitutes, fluctuations in raw material prices, lack of transparency about enforcement directives of tile adhesive applications, less adoption & awareness in rural areas are restraining the market growth over the forecast period.

India Tile Adhesive Market is segmented by type, by construction activities, by application, and by region. By type, cementitious tile adhesive held the highest market share in 2019 and is expected to keep its dominance over the forecast period. Cementitious tile adhesives are widely used in wall tiles, floor tiles as they possess water resistant properties. They prevent leakage between two substrates very effectively. Moreover, factors such as easy availability of cement, wide adoption of from all the end users, and cost advantage are also driving the market growth of this segment over the forecast period.

Cementitious tile adhesive segment is followed by Epoxy and dispersion adhesive segment with xx% and xx% of market share respectively. Epoxy tile adhesive segment held more than 24.34% of market share in 2019 and is expected to keep its dominance over the forecast period. By construction activities, New activities segment held the highest market share in 2019 and is expected to keep its dominance over the forecast period owing to increasing new building & construction projects across the country.

Report covers in-depth analysis of key development, marketing strategies, supply-side, and demand-side indicators and company profiles of market leaders, potential players and new entrants. Major Key players covered in this report are Pidilite Industries Ltd, MYK LATICRETE INDIA PVT LTD, Saint-Gobain Weber, Fosroc India, BASF India Ltd, Huntsman Corporation, Kajaria Ceramics Limited, Bostik, Ascolite solutions and H.B. Fuller Company among others. These key players held more than 60% of market share in 2019 and is expected to keep its dominance over the forecast period. These key players are adopting various organic and inorganic growth strategies such as merger& acquisitions, joint ventures, collaborations, expansion, new product launches and patents to increase their regional presence and business operations.

Ascolite Tile solutions is emerging as major market player in India. Ascolite Tile solutions is located at the Surat, Gujarat. Ascolite Tile solutions work in accordance to the Indian Standard 15477 and have therefore established and maintained a state-of-the-art in- house testing and R&D facility which is doing research on advanced material composition of tile solutions. Ascolite Tile solutions have largest customer base in Maharashtra, Gujarat, Karnataka, and Andhra Pradesh. Many commercial and residential projects in these states are adopting Ascolite’s tile solutions as it is offering high strength and durability, giving desired adhesive which also prevents shrinkage cracks and slippage of material.

The objective of the report is to present a comprehensive analysis of the India Tile Adhesive Market including all the stakeholders of the industry. The past and current status of the industry with forecasted market size and trends are presented in the report with the analysis of complicated data in simple language. The report covers all the aspects of the industry with a dedicated study of key players that includes market leaders, followers, and new entrants. PORTER, SVOR, PESTEL analysis with the potential impact of micro-economic factors of the market have been presented in the report. External as well as internal factors that are supposed to affect the business positively or negatively have been analysed, which will give a clear futuristic view of the industry to the decision-makers. The report also helps in understanding India Tile Adhesive Market dynamics, structure by analyzing the market segments and project India Tile Adhesive Market Clear representation of competitive analysis of key players by price, financial position, Product portfolio, growth strategies, and regional presence in the India Tile Adhesive Market make the report investor’s guide.

For more information visit@ https://www.maximizemarketresearch.com/market-report/india-tile-adhesive-market/70278/

Scope of India Tile Adhesive Market

India Tile Adhesive Market Segmentation by Type

• Cementitious Tile Adhesive

• Epoxy Tile Adhesive

• Dispersion Tile Adhesive

India Tile Adhesive Market Segmentation by Construction Activity

• New Construction

• Repair & Renovation

India Tile Adhesive Market Segmentation by Application

• Residential

• Commercial

• Institutional

India Tile Adhesive Market Major Players

• Pidilite Industries Ltd

• MYK LATICRETE INDIA PVT LTD

• Saint-Gobain Weber

• Fosroc India

• BASF India Ltd

• Huntsman Corporation

• Kajaria Ceramics Limited

• Bostik

• H.B. Fuller Company

• SIKA INDIA

• ADREX Group

• Ascolite Solutions

• Henkel AG & Co. KGaA

• Morgan Ceramic Tile Adhesives

• Building Adhesives Ltd

• Norcros Group (Holdings) Ltd.

• Brit Adhesives Ltd

• Tile Magic (Pty) Ltd

This report submitted by Maximize market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name: Lumawant Godage

Organization Address: MAXIMIZE MARKET RESEARCH PVT. LTD.

Email: [email protected]

Address: Omkar Heights, Sinhagad Road, Manik Baug, Vadgaon Bk,Pune, Maharashtra 411051, India.

Contact: +919607195908

0 notes

Text

Wallnut Building Solutions - Rising name in tiles & stone fixing sector.

“Wallnut creating bond with Tile & Stone Industry. "

Indian Tile & Stone fixing Industry has mostly been using foreign products and technology for fixing of tiles & stone at site. In recent years, due to increasing demand, foreign companies have started manufacturing these products in India. However, major market is still using traditional methods and materials to fix tiles & stone on walls and floors. The industry is also witnessing accelerated change and rapid introduction of a new quality of Tiles & Stone that seems to be difficult in handling and fix at the site. With the rapid change in the building making technology and introduction of various substrates along with varieties of modern tile & stone, simply using the traditional methods is proving to be ineffective for fixing these modern materials.

Company Foundation.

Wallnut was established in 2017. Since then, keeping in step with structural changes in society and industry, Wallnut has been self-improving continuously and working on the pursuit and delivery of services in response to customers. Through research, innovation, and development, it has been able to create unique innovative products with truly unique properties. This effort has been led by its experienced (Founder & CEO) Hemant Jain, Wallnut was established with a commitment to build a modern India through industrialization. It is with this belief Wallnut formulates the highest quality products and offers unmatched technical advice and customer-centric support.

Wallnut product line consists of advanced adhesives, Grouts, screeds, glitters for Tile and Stone industry, Each Product is designed to meet specific application needs and requirements. Wallnut obtain to earn customer confidence by combining our ability to innovate through our efforts, engineering excellence, and a full spectrum of technologies, in-house. Our team of highly skilled & dedicated employees is totally focused on satisfying customer requirements.

Cooperation on an equal balance: transparency, mutual trust, and fairness define the business relationship between wallnut and its partners. In the spirit of the Chairman, these values are at the core of every company's decision and every action. For mutual success — today and in future.

In a short span of time, Wallnut products have created a strong position in the market with all competitors. Wallnut offers all its customer assurance of the long-lasting impact of its product on applied surfaces with future service and guarantees with the products.

Production, Quality Control & R&D

wallnut is actively in the development of new, game-changing products that will continue to change the way adhesives are used. Wallnut invests more than 4% of its total business revenue in R&D every year to actively integrate national and International R&D Expertise, continuing to develop our products and services with “environmental protection”, “innovation” and “Development”.

Wallnut has 2 quality control centre at Gujarat and Maharashtra and 1 high-tech R&D centre at Mumbai. Upholding a business principle of "On-going Innovation", wallnut has invested a great amount of our R&D budget in recruiting experts that are capable of developing products that meet our customers' needs. Our product line which started with 11 high-quality product in 19 different variant has grown significantly in short span of time,

Today wallnut manufactures 16 products and more than 84 variant for our customers.

Product & Solutions:

Wallnut product line which started with 11 high-quality product in 19 different variants have grown significantly in a short span of time, Today wallnut manufactures 16 product in more than 100 variant for its customers.

Wallnut manufacture and develop products that are economical, safe, and environment friendly. Wallnut products increase people’s safety and decrease burdens to the environment, also during their subsequent recycling and disposal. In line with the goal of constantly achieving the best, spreading the understanding of quality in every field and turning it into a lifestyle forms the basis of wallnut quality policy. Raw materials and other materials used in production are controlled and monitored using national and international standards. In addition, physical, chemical and applied product analysis is carried out at all production stages. We use the least possible VOC materials (Volatile Organic compounds) in all our products.

Within the framework of Total Quality Management, by giving priority to people, the contribution of educated and competent employees to the company, contribution to the quality and efficiency activities are provided

The company core products ranges are

Zeorich Series of Screed & Mortar.

Calcibond Series of high-quality adhesives for tile & stone.

Connect & Lock Series of high-quality premium grouts.

Lite Series of economic adhesives.

Tools & accessories for fixing Tiles & Stone

Wallnut is providing different packaging for retail and project customers with price benefit to each sector.

Company soon wants to add and launch more products to reach out to retail sector such as Wall Putty and tile & stone cleaner range. The work is already under progress and early 2021 will see these products comes into the market.

Wallnut Vision

Wallnut is built on a clear vision: to be the best adhesives company in India. Our vision, combined with our mission & beliefs, ground us and set the cornerstone for employee and company success. Wallnut wants to contribute its deeper understanding of the Tile and Stone industry to reflect on its

customer by its products to “Create Bonds, Forever”.

Mission

We are inspired by the desire to develop products that “Create Bonds, Forever,” Beam enthusiasm, that improves the quality of life, and that help safeguard natural resources. Our mission revelation reflects this. It outlines our values, our strengths, and our strategies.

Our mission is based on customer and people-centric values, which shape our corporate culture ranging from a focus on the future and earnings to cultural diversity.

Sustainability and Responsibility are part of this set of values and thus of our actions.

0 notes

Text

AAC Block Plant Manufacturer in Gujarat

AAC Block Plant Manufacturer in Gujarat:

An AAC (Autoclaved Aerated Concrete) block plant is a manufacturing facility that produces AAC blocks, which are a lightweight, precast building material. AAC blocks have a wide range of uses and applications in the construction industry, including:

Wall construction: AAC blocks are commonly used for constructing both load-bearing and non-load-bearing walls in residential, commercial, and industrial buildings. They provide excellent thermal insulation, are easy to handle and install, and can be easily cut and shaped to fit specific design requirements.

Façade cladding: AAC blocks can be used as a substrate for façade cladding, where other materials such as brick, stone, tiles, or plaster can be fixed to the AAC block wall using adhesive or mechanical fasteners. This provides an attractive finish to the building's exterior.

Insulated roofs: AAC blocks can be used for constructing insulated roofs in buildings, providing thermal insulation and reducing heat gain or loss through the roof. AAC blocks can be used as a base layer, which is covered with a waterproofing layer and finished with suitable roofing material.

Fire-rated walls: AAC blocks have good fire resistance properties and can be used for constructing fire-rated walls in buildings, providing passive fire protection. AAC blocks can withstand high temperatures and do not release toxic gases when exposed to fire, making them suitable for fire-rated walls in commercial, industrial, and residential buildings.

Sound barriers: AAC blocks are effective in reducing noise transmission and can be used for constructing sound barriers along highways, railways, or other noisy areas to minimize noise pollution.

The uses and applications of AAC blocks are vast, and AAC block plants play a crucial role in producing high-quality AAC blocks to meet the diverse needs of the construction industry.

We Provide AAC Block Plant Manufacturer in Gujarat and we supply our products to various locations like Ahmedabad, Surat, Rajkot, Vadodara, Ankleshwar, Gandhinagar, Bhavnagar, Patan, Porbandar, Kutch, Vapi, Bharuch, Dahod, Amreli, Navsari, Kheda, Panchmahal, Sabarkantha, Surendranagar, Mehsana, Morbi, Gir Somnath, Palanpur.

Read the full article

#AACBlockPlantManufacturerinAhmedabad#AACBlockPlantManufacturerinGandhinagar#AACBlockPlantManufacturerinGujarat#AACBlockPlantManufacturerinhavnagar#AACBlockPlantManufacturerinKheda#AACBlockPlantManufacturerinSurat#AACBlockPlantManufacturerinVadodara#AACBlockPlantManufacturerinVapi

0 notes

Photo

Construction Materials Wholesaler - Adhesives Products : non-metallic-floor-hardener, aac-block-adhesive, tile-to-tile-adhesive, filler-grout-for-tile, PAVER BLOCK HARDNER, GEL BASED FINE EPOXY GROUT, STONE ADHESIVE, etc.

For more details visit:

www.ardaindia.com/portfolio-category/adhesives/

#arda#india#gujarat#polymers#construction materials#Adhesive-Products#Wholesaler#Adhesives#floor-hardener#aac-block-adhesive#filler-grout-for-tile#epoxy-grount#stone-adhesive#paver-block-hardner#constructionmaterials#manufacturers#supplier

0 notes

Text

High Performance Fluoropolymer Market Size, Trends and Opportunities 2020 - 2023 Polymer Chameleons Market Size- Growth Drivers, Opportunities and Forecast Analysis to 2023

Market Analysis

The high performance fluoropolymer market is likely to grow at a healthy CAGR between 2016- 2023, as per the new Market Research Future (MRFR) report. High performance fluoropolymers, simply put, are fluorocarbons that have polymers with material characteristics of exceptionally high performance. They have excellent properties such as good thermal and mechanical stability, high electrical insulation, and good chemical resistance at high temperatures, thereby making it ideal for various applications including additives, film, mechanical parts and component, coatings and liner, and others.

Also Read https://www.marketwatch.com/press-release/us-tile-adhesive-market-analysis-key-growth-drivers-challenges-leading-key-players-review-demand-and-upcoming-trend-by-forecast-to-2023-2019-05-20

Various factors are adding to the global high performance fluropolymer market growth. These factors, according to the new MRFR report, include burgeoning demand for lightweight parts in the automobile and aviation sector, rising disposable income, rapid industrialization, increasing demand from the building and construction industry, and increasing use in the electrical and electronics industry.

On the contrary, slightly higher prices and increasing demand for bio-plastics are factors that may limit the high performance fluropolymer market growth over the forecast period.

Covid-19 Analysis /Covid-19 Impact on High Performance Fluoropolymer Market

The coronavirus outbreak has resulted in the shutdown or idled various auto assembly plants in China. Hyundai for instance has closed its plants in South Korea due to a shortage of parts from China as well as widespread of this virus in South Korea. And similarly, the top auto giants in Europe like BMW, Renault, and FCA are also closing down plants due to the rising spread of the novel coronavirus in European countries. All this is having an impact on the high performance fluropolymer market growth.

Market Segmentation

The MRFR report offers an inclusive segmental analysis of the global high performance fluropolymer market report based on end use industries, application, and type.

By type, the high performance fluropolymer market is segmented into polyethylenetetrafluoroethylene (ETFE), polytetrafluoroethylene (PTFE), perfluoroalkoxy polymer (PFA), fluorinated ethylene propylene (FEP), and others. Of these, the PTFE segmemt will lead the market over the forecast period.

By application, the high performance fluropolymer market is segmented into additives, film, mechanical parts and component, coatings and liner, and others. Of these, coatings and liner will dominate the market over the forecast period.

By end use industries, the high performance fluropolymer market is segmented into medical, industrial processing, electrical and electronics, aviation and automobiles, and others. Of these, the industrial processing segment will have a major share in the market over the forecast period.

Regional Analysis

Based on the region, the global high performance fluropolymer market report covers the recent trends & growth opportunities across the Americas, Europe, the Asia Pacific (APAC), Latin America, & the Middle East & Africa (MEA). Of these, North America will dominate the market over the forecast period for its increasing use in the electrical and electronics, and medical industries. Guatemala, Canada, Mexico, and the US are the major contributors in the market.

The high performance fluropolymer market in the APAC region will dominate the market over the forecast period for burgeoning demand from different end use industries, namely electrical and electronics, aviation and automobiles, and others. India, Vietnam, and China are the major contributors in the region for the increasing automobile production as well as sales, cheap labor costs, implementation of new development strategies, and easy availability of raw materials.

The high performance fluropolymer market in Europe is predicted to have moderate growth over the forecast period for its increasing use to manufacture high class scientific and lab instruments. The UK, France, Germany, and Spain are the major contributors in the region for shifting interest of manufacturers towards high performance fluoropolymer and developed end use industries.

The high performance fluropolymer market in the MEA is predicted to have moderate growth over the forecast period for increasing investments in commercial and residential construction sectors in Qatar, the UAE, and Saudi Arabia.

Key Players

Leading players profiled in the high performance fluropolymer market report include Shanghai 3F New Materials Co., Ltd. (China), Hubei Everflon Polymer CO., Ltd. (China), Gujarat Fluorochemicals Ltd. (India), AGCCE (U.K), DAIKIN INDUSTRIES, Ltd. (Japan), The Chemours Company (U.S.), Shamrock Technologies (U.S.), DuPont (U.S.), 3M (U.S.), and Solvay (Belgium).

Access Complete Report @ https://www.marketresearchfuture.com/reports/high-performance-fluoropolymer-market-4238

0 notes

Link

0 notes

Text

Magicrete Building Solutions

Magicrete Building Solutions is one of the best manufacturers of AAC Bricks, AAC blocks in India. We offer Unmatched Benefits of Energy & Cost efficient Green building materials like lightweight concrete blocks at affordable rates. Visit the website to avail more details.

Company Overview:

Magicrete Building Solutions is one of India’s leading manufacturer of AAC Bricks, light weight concrete blocks and other building materials. We offer high quality and precisely designed bricks manufactured with Autoclaved Aerated Concrete (AAC) – a path-breaking technology in the construction Industry. We also offer durable and Eco-friendly construction materials.

Light weight, high quality and impressive strength are some of the features of blocks offered by Magicrete. Magicrete Building Solutions deals in high quality pre-casted building components to make construction quick and cost effective. With their two AAC Block plants in India: one in Gujarat and another in Haryana, Magicrete Building Solutions is serving a wide range of building construction materials like AAC bricks, concrete blocks, dry mix mortar, wall panels, ready mixed plaster, wall tile adhesive, ready mix cement plaster and many other high quality building material.

Address-

101-102, Ritz Square,Near Narmad Library,GhodDod Road,Surat-395002

The post Magicrete Building Solutions appeared first on E-Bizda International Business Directory.

source https://www.e-bizda.com/listing/magicrete-building-solutions/

0 notes