Text

Activated Bleaching Earth Plant in Khulna

Company Overview:

Excellent En-Fab Incorporation, headquartered in Ahmedabad, Gujarat, India, specializes in industrial plants and equipment.

Since 2010, they have been Manufacturer, Supplier, and Exporter of Activated Bleaching Earth Plant in Khulna, Bangladesh.

Offers a wide range of products including AAC Block Plant, Flash Dryer, Dry Mix Mortar Plant, Storage Equipments, Autoclave, Rotary Dryer/Kiln, Wall Putty Plant, Spray Dryer, Agro Waste Pyrolysis Plant, Hot Air Generators, Spin Flash Dryer, and more.

Spans 10 acres and equipped with advanced technology for high-quality production.

Operational Process:

Material Preparation: Clay-based materials are dried and contaminants are removed.

Activation: Heat-treated in a furnace to enhance adsorption capacity.

Mixing: Activated clay blended with oil/fat to facilitate impurity adsorption.

Contacting Phase: Vigorous mixing ensures optimal contact between activated clay and oil/fat.

Filtration: Separation of activated clay from purified oil/fat using filtration methods.

Drying: Activated clay dried to eliminate residual moisture for reuse.

Reactivation (Optional): Spent clay subjected to high temperatures for adsorption capacity restoration.

Packaging: Purified oil/fat packaged for distribution or further processing.

Advantages of Activated Bleaching Earth:

Low Oil Residual

Fast Filtration Rate

Reduction of Free Fatty Acids

Impurity Removal

Application:

Edible oils

Mineral oils

Animal fats

Geographical Coverage:

The Activated Bleaching Earth Plant in Khulna, Bangladesh serves multiple locations including Bhairab, Bogra, Brahmanbaria, Chandpur, Dhaka, Chittagong, Sylhet, Khulna, Rajshahi, Chowmuhani, Chudanga, Comilla Sadar Dakshin, Faridpur, Feni, Jessore, Jhenaidah, Kadam Rasul, Kaliakair, Kushitia, Naogaon, Narsingdi, Pabna, Saidpur, Satkhira, Savar, Tangail, Tarabo, Tongi, Chattogram, Dhaka, Rangpur, Mymensingh, and Sylhet,

For detailed information and inquiries, please feel free to contact us.

Read the full article

#ActivatedBleachingEarthPlant#ActivatedBleachingEarthPlantinBangladesh#ActivatedBleachingEarthPlantinKhulna#Animalfats#Bangladesh#Bhairab#Bogra#Brahmanbaria#Chandpur#Chattogram#Chittagong#Chowmuhani#Chudanga#ComillaSadarDakshin#Dhaka#Edibleoils#Exporter#ExporterofActivatedBleachingEarthPlantinBangladesh#ExporterofActivatedBleachingEarthPlantinKhulna#Faridpur#Feni#Jessore#Jhenaidah#KadamRasul#Kaliakair#Khulna#Kushitia#Manufacturer#Mineraloils#Mymensingh

0 notes

Text

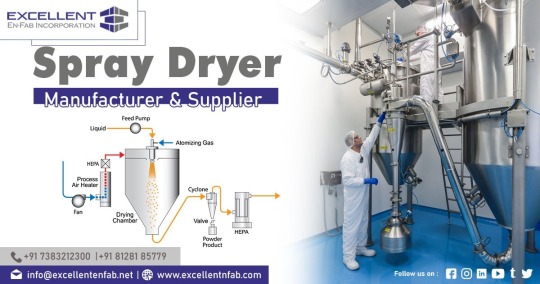

Exporter of Spray Dryer in Russia

Excellent En-Fab Incorporation, headquartered in Ahmedabad, Gujarat, India, specializes in industrial plants and equipment.

They have been a Manufacturer, Supplier, and Exporter of Spray Dryer in Russia, since 2010.

Our Spray Dryer Manufacturers in India adhere to international standards, ensuring top-notch quality.

We manufacture and supply various kinds of spray dryers tailored to meet specific customer requirements.

Spray dryers effectively separate solute as a solid and solvent as vapor from a liquid stream, with solids typically collected in a drum or cyclone.

Whether in food, pharmaceutical, chemical, or cosmetic industries, our spray dryers consistently deliver high-quality results.

We offer customized spray dryer solutions, ensuring they perfectly align with individual needs.

Key Steps:

Preparation: Liquid or slurry product is prepared for drying.

Addition: The spray dryer chamber introduces the liquid feed.

Atomization: The atomizer nozzle atomizes the liquid feed into tiny droplets.

Drying: A heated air stream dries droplets to remove moisture.

Collection: The spray dryer collects dried particles at the bottom.

Benefits of Spray Dryer Plant:

Suitable for Heat-Sensitive Foods: Controlled drying temperatures make it suitable for heat-sensitive foods.

Uniform Particle Sizes: Produces fairly uniform particle sizes, enhancing product consistency.

Free-Flowing Powder: Generates a free-flowing powder, facilitating handling and packaging.

Encapsulation Efficiency: Efficiently encapsulates active ingredients within dried particles.

Excellent En-Fab Incorporation Exporter of Spray Dryer in Russia, covering cities such as Moscow, Saint Petersburg, Novosibirsk, Samara, Omsk, Veliky Novgorod, Seversk, Norilsk, Murmansk, Belgorod, Novorossiysk, Arzamas, Kineshma, Derbent, Novoshakhtinsk, Shakhty, Vladimir, Velikiye Luki, and Kovrov.

Interested parties are encouraged to contact the company for further details and inquiries.

Read the full article

#Exporter#ExporterofSprayDryerinRussia#Kovrov#Manufacturer#SprayDryer#SprayDryerinRussia#SuitableforHeat-SensitiveFoods#Supplier#SupplierofSprayDryer#UniformParticleSizes

0 notes

Text

Exporter of Agro Waste Pyrolysis Plant in Tanzania

Company Overview:

Excellent En-Fab Incorporation, headquartered in Ahmedabad, Gujarat, India, specializes in industrial plants and equipment.

They have been Manufacturer, Supplier, and Exporter of Agro Waste Pyrolysis Plant in Tanzania, since 2010.

A specialized facility is designed to convert agricultural waste materials into valuable products through the process of pyrolysis.

The Agro Waste Pyrolysis Plant utilizes pyrolysis technology to transform various agricultural residues, such as straw, husks, stalks, and other organic materials, into useful products like biochar, bio-oil, and syngas.

Key Features:

Energy Recovery: Energy is recovered from waste based on its calorific value.

Residue Sterilization: The system sterilizes residue effectively.

Compact Design: Compared to other waste disposal facilities, the system is compact.

Carbon Content Elimination: The system facilitates the elimination of carbon content in the waste.

No Post-Treatment Required: The ash content does not require any post-treatment.

Quick Preheating: The pyrolysis reactor requires less time for preheating.

Versatile Waste Handling: The system can handle various types of waste including metallized plastics, polyethylene plastic, soiled plastic, and multi-layer plastics in an environmentally friendly manner.

Benefits:

Economical Recycling Technology: The Tyre Recycling Plant employs the most economical recycling technology, making

it a top choice for many consumers.

Zero Waste Process: The process yields virtually 100% results without any waste generated.

Environmental Friendliness: The system is environmentally benign as it produces valuable items with high market demand without polluting the environment.

Excellent En-Fab Incorporation is an Exporter of Agro Waste Pyrolysis Plant in Tanzania like Dar es Salaam, Mwanza, Arusha, Dodoma, Mbeya, Morogoro, Tanga, Kahama, Tabora,

Zanzibar City, Kigoma, Sumbawanga, Kasulu, Songea, Moshi, Musoma, Shinyanga, Iringa, Singida, Njombe, Bukoba, Kibaha, Mtwara, Mpanda, Tunduma, Makambako, Babati,

Handeni, Lindi, Korogwe, Mafinga, Nansio.

The company encourages interested parties to contact them for further details and inquiries.

Read the full article

#AgroWastePyrolysisPlantinTanzania#Arusha#Babati#Bukoba#DaresSalaam#Dodoma#Exporter#ExporterofAgroWastePyrolysisPlant#ExporterofAgroWastePyrolysisPlantinTanzania#Handeni#India#Iringa#Kahama#Kasulu#Kibaha#Kigoma#Korogwe#Lindi#Mafinga#Makambako#ManuacturerofAgroWastePyrolysisPlant#Manufacturer#Mbeya#Morogoro#Moshi#Mpanda#Mtwara#Musoma#Mwanza#Nansio

0 notes

Text

Exporter of AAC Block Plant in Zambia

About Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation is one of the leading Manufacturer and Exporter of AAC Block Plant in Zambia.

Excellent En-Fab Incorporation is a leading manufacturer of AAC Block Plants in India, producing plants that meet the highest engineering standards and comply with international regulations.

They offer AAC plants with capacities ranging from 30 cubic meters per day to 750 cubic meters per day, providing versatile solutions for various project sizes.

AAC blocks are made primarily from fly ash (pond ash or sand), cement, gypsum, lime, and aluminum powder.

The manufacturing process involves material crushing, measuring, mixing, pouring, curing, cutting, and steaming.

The company boasts a team of qualified and experienced experts dedicated to delivering high-quality products tailored to meet the unique needs of customers.

With extensive experience in designing various building material plants and equipment, they ensure the finest engineering quality.

Excellent En-Fab Incorporation offers comprehensive technical support, including planning, design drawing, construction guidance, installation, commissioning, and technical training, providing customers with a one-stop service solution.

AAC Block Plant Benefits:

Fire Resistant

Pest Resistant

Sound Proof

Earthquake Resistant

Faster Construction

Long-lasting

Cost Saving

Versatile

Non-toxic

Thermal Insulation

Environment-Friendly

High Resistance to Water Penetration

Excellent En-Fab Incorporation is Exporter of AAC Block Plant in Zambia like Lusaka, Kitwe, Ndola, Kabwe, Chingola, Mufulira, Livingstone, Luanshya, Kasama, Chipata, Lusaka, Ndola, Mazabuka, Chipata, Chingola, Kasama, Luangwa, Mumbwa, Mufulira, Mongu, Mansa, Choma.

For additional information or inquiries, interested parties are encouraged to contact Excellent En-Fab Incorporation.

Read the full article

#AACBlockPlant#aluminumpowder#cement#CostSaving#crushing#curing#cutting#ExporterofAACBlockPlant#ExporterofAACblockplantinZambia#gypsum#India#lime#Long-lasting#Manufacturer#measuring#mixing#PestResistant#pouring#Supplier#Zambia

0 notes

Text

Activate Bleaching Earth Plant in Barishal

Activate Bleaching Earth Plant in Barishal:

Company Overview:

Excellent En-Fab Incorporation, headquartered in Ahmedabad, Gujarat, India, specializes in industrial plants and equipment.

They have been a Manufacturer, Supplier, and Exporter of Activated Bleaching Earth Plant in Barishal, Bangladesh since 2010.

The company offers a wide range of products including AAC Block Plant, Flash Dryer, Dry Mix Mortar Plant, Storage Equipments, Autoclave, Rotary Dryer/Kiln, Wall Putty Plant, Spray Dryer, Agro Waste Pyrolysis Plant, Hot Air Generators, Spin Flash Dryer, and more.

Their manufacturing facility, spanning 10 acres, boasts advanced technology for producing high-quality goods.

Operational Process:

Material Preparation: We thoroughly dry clay-based materials and remove contaminants.

Activation: We heat-treat clay in a furnace to enhance its adsorption capacity, typically between 400°C to 700°C.

Mixing: We blend activated clay with the oil or fat to be purified, facilitating impurity adsorption.

Contacting Phase: Vigorous mixing ensures optimal contact between activated clay and the oil/fat.

Filtration: We separate activated clay from the purified oil/fat using filtration methods like pressure or vacuum filtration.

Drying: We dry activated clay to eliminate residual moisture for reuse in the bleaching process.

Reactivation (Optional): We may subject spent clay to high temperatures again to restore its adsorption capacity for reuse.

Packaging: Purified oil/fat is packaged for distribution or further processing.

Advantages of Activated Bleaching Earth:

Low Oil Residual

Fast Filtration Rate

Reduction of Free Fatty Acids

Impurity Removal

Application:

Edible oils

Mineral oils

Animal fats

Geographical Coverage:

Excellent En-Fab Incorporation's Activate Bleaching Earth Plant in Barishal, Bangladesh serves multiple locations including Bhairab, Bogra, Brahmanbaria, Chandpur, Dhaka, Chittagong, Sylhet, Khulna, Rajshahi Chowmuhani, Chudanga, Comilla Sadar Dakshin, Faridpur, Feni, Jessore, Jhenaidah, Kadam Rasul, Kaliakair, Kushitia, Naogaon, Narsingdi, Pabna, Saidpur, Satkhira, Savar, Tangail, Tarabo, and Tongi, Chattogram, Dhaka, Rangpur, Mymensingh and Sylhet.

The company encourages interested parties to contact them for further details and inquiries.

Read the full article

#ActivateBleachingEarthPlant#ActivateBleachingEarthPlantinBangladesh#Barishal#Edibleoils#Exporter#ExporterofActivateBleachingEarthPlant#ExporterofActivateBleachingEarthPlantinBarishal#India#Manufacturer#Mineraloils#Supplier

0 notes

Text

Exporter of Rotary Dryers in Sri Lanka

Company Profile:

Excellent En-Fab Incorporation is one of the leading Manufacturer and Exporter of Rotary Dryers in Sri Lanka.

Excellenten's rotary dryers are custom-designed to suit the unique processing needs of each material, whether it requires low or high inlet temperatures, short or long residence times, and counter-current or co-current flow.

Rotary dryers are highly efficient industrial drying options for bulk solids, chosen for their robust processing capabilities and ability to produce uniform results despite variances in feedstock.

Rotary dryers work by tumbling material in a rotating drum in the presence of drying air. They can also be indirectly heated to avoid direct contact between the material and the processing medium.

The drum is positioned at a slight horizontal slope to allow gravity to assist in moving material through the drum. Lifting flights inside the drum maximizes heat transfer efficiency by picking up the material and dropping it through the air stream.

When working with agglomerates, the tumbling action imparted by the dryer offers the added benefit of further rounding and polishing the granules.

Features:

Diameter: 3′ – 15′ (1 – 4.6m)

Capacity: 100 kg to 40 TPH

Specially designed lifting flights to maximize heat transfer between the material and hot gas stream

Heavy-duty design and construction for many years of service

Co-current (parallel flow) or counter-current configuration

Process and Mechanical Warranties

Optional Components:

Knocking Systems

Trommel Screen

Liners

Leaf Seals

Graphite Seals

Machined Bases

Screw Conveyor Feeder

Automatic Gear Lubrication System

Exhaust Handling Equipment

Ductwork

Excellent En-Fab Incorporation is Exporter of Rotary Dryers in Sri Lanka, covering regions such as Colombo, Moratuwa, Dehiwala-Mount Lavinia, Jaffna, Negombo, Sri Jayawardenepura, Kalmunai, Kandy, Vavuniya, and others.

For further details and inquiries, interested parties are encouraged to contact the company.

Read the full article

#AACBlockPlant#Agrowastepyrolysisplant#AutomaticGearLubricationSystem#Colombo#Dehiwala-MountLavinia#Exporter#ExporterofRotaryDryers#ExporterofRotaryDryersinSriLanka#GraphiteSeals#India#Jaffna#Kalmunai#Kandy#Manufacturer#ManufacturerofRotaryDryers#ManufacturerofRotaryDryersinSriLanka#Moratuwa#Negombo#SprayDryer#SriJayawardenepura#Supplier#SupplierofRotaryDryers#SupplierofRotaryDryersinSriLanka#TrommelScreen#Vavuniya

0 notes

Text

Exporter of Biochar Making Plant in Russia

Company Profile:

Excellent En-Fab Incorporation is one of the leading Manufacturer and Exporter of Biochar Making Plant in Russia.

Excellent En-Fab Incorporation, based in Ahmedabad, Gujarat, is a leading factory specializing in the production of process and construction equipment in India.

Established in 2010, the company initially focused on supplying high-pressure autoclaves to AAC block producers.

Biochar, similar to charcoal and derived from plant sources, is produced in a biochar manufacturing factory through biomass heating in an oxygen-free pyrolysis chamber.

The process results in the production and collection of biochar.

Biochar manufacturing facilities vary in size based on capacity, with large-scale plants catering to industrial needs and smaller-scale setups suitable for individual farmers or small businesses.

Applications of Biochar:

Agriculture: Enhances soil fertility, crop yields, and water retention.

Horticulture: Improves soil quality and promotes plant growth in gardening and landscaping.

Environmental Remediation: Enhances soil quality in land reclamation and environmental restoration projects.

Wastewater Treatment: Removes contaminants and improves water quality in wastewater treatment systems.

Livestock Farming: Aids in manure management, odor reduction, and carbon sequestration in livestock farming.

Carbon Credits: Some Biochar Making Plants participate in carbon offset programs by selling carbon credits generated through carbon sequestration.

Geographical Coverage in Russia:

Excellent En-Fab Incorporation Exporter of Biochar Making Plant in Russia, covering cities such as Moscow, Saint Petersburg, Novosibirsk, Samara, Omsk, Veliky Novgorod, Seversk, Norilsk, Murmansk, Belgorod, Novorossiysk, Arzamas, Kineshma, Derbent, Novoshakhtinsk, Shakhty, Vladimir, Velikiye Luki, and Kovrov.

For further details, please don’t hesitate to contact us. We are eager to engage in a professional conversation with you or your team

Read the full article

#Arzamas#Belgorod#BiocharMakingPlant#BiocharMakingPlantinRussia#Derbent#Exporter#ExporterofBiocharMakingPlant#Kineshma#Kovrov#Manufacturer#Moscow#Murmansk#Norilsk#Novorossiysk#Novoshakhtinsk#Novosibirsk#Omsk#Russia#SaintPetersburg#Samara#Seversk#Shakhty#Supplier#SupplierofBiocharMakingPlant#VelikiyeLuki#VelikyNovgorod#Vladimir

0 notes

Text

Exporter of AAC Block Plant in Tanzania

Excellent En-Fab Incorporation is one of the leading Manufacturer and Exporter of AAC Block Plant in Tanzania.

Excellent En-Fab Incorporation established in 2010. We offer comprehensive project solutions from start to finish. As a prominent manufacturer and engineering firm, we provide end-to-end services.

We provide various equipment like AAC Block Plants, Flash Dryers, Dry Mix Mortar Plants, Storage Solutions, Autoclaves, and additional items.

An AAC Block Plant is a factory setup to manufacture Autoclaved Aerated Concrete (AAC) blocks, renowned for their lightweight construction material.

Specialized equipment and processes mix raw materials like sand, cement, lime, gypsum, and aluminum powder, then pour them into molds.

The mix undergoes autoclaving, a high-pressure steam curing process, leading to the creation of AAC blocks, renowned for their lightweight.

Features:

High Efficiency in the manufacturing process.

Precision Control over production parameters.

Energy Efficiency to optimize resource usage.

Customization Options are available to meet specific project requirements.

Applications:

Residential Construction

Commercial Buildings

Industrial Structures

Infrastructure Projects

Green Building Projects

Excellent En-Fab Incorporation is Exporter of AAC Block Plant in Tanzania, catering to various locations including Dar es Salaam, Mwanza, Arusha, Dodoma, Mbeya, Morogoro, Tanga, Kahama, Tabora, Zanzibar City, Kigoma, Sumbawanga, Kasulu, Songea, Moshi, Musoma, Shinyanga, Iringa, Singida, Njombe, Bukoba, Kibaha, Mtwara, Mpanda, Tunduma, Makambako, Babati, Handeni, Lindi, Korogwe, Mafinga, and Nansio.

For additional information or inquiries, interested parties are encouraged to contact Excellent En-Fab Incorporation.

Read the full article

#Arusha#Babati#Bukoba#DaresSalaam#Dodoma#ExporterofAACBlockPlant#ExporterofAACBlockPlantinTanzania#Handeni#India#InfrastructureProjects#Iringa#Kahama#Kasulu#Kibaha#Kigoma#Korogwe#Lindi#Mafinga#Makambako#Manufacturer#Mbeya#Morogoro#Moshi#Mpanda#Mtwara#Musoma#Mwanza#Nansio#Njombe#ResidentialConstruction

0 notes

Text

Exporter of Spray Dryer in Sri Lanka

Exporter of Spray Dryer in Sri Lanka:

Company Overview:

Excellent En-Fab Incorporation, operating since 2010, is a Manufacturer, Exporter, and Supplier of Spray Dryer.

Their product range includes AAC Block Plant, Flash Dryer, Dry Mix Mortar Plant, Storage Equipments, Autoclave, Rotary Dryer/Kiln, Wall Putty Plant, Spray Dryer, Agro Waste Pyrolysis Plant, Hot Air Generators, Spin Flash Dryer, and more.

Specializes in manufacturing premium-quality spray dryers in India, meeting international standards.

Offers various types of spray dryers customized to meet individual customer needs.

Utilizes hot air to swiftly dry atomized liquid feedstock into fine droplets, producing dry particles or powders ready for subsequent processing or packaging.

Offers spray dryers in different configurations, including nozzle atomizers, rotary atomizers, and fluidized bed dryers, designed to suit specific applications and accommodate diverse requirements.

Features:

A high aspirator rate reduces the product’s remaining moisture.

Excellent results are achieved when temperature and other parameters are properly controlled.

Minimum maintenance is required for a long working life.

Long-term dependability guaranteed.

Continuous drying methods enable faster production while maintaining and managing product quality.

Application:

Food Industry

Pharmaceuticals

Chemicals

Ceramics

Export Focus:

Excellent En-Fab Incorporation Exporter of Spray Dryer in Sri Lanka, covering regions such as Colombo, Moratuwa, Dehiwala-Mount Lavinia, Jaffna, Negombo, Sri Jayawardenepura, Kalmunai, Kandy, Vavuniya, and others.

Interested parties are encouraged to contact the company for further details and inquiries.

Read the full article

#AACBlockPlant#Agrowastepyrolysisplant#Autoclave#Ceramics#chemicals#Colombo#Dehiwala-MountLavinia#DryMixMortarPlant#Exporter#ExporterofSprayDryerinSriLanka#FlashDryer#FoodIndustry#HotAirGenerators#Jaffna#Kalmunai#Kandy#Long-termdependability#Manufacturer#ManufacturerofSprayDryer#Minimummaintenance#Moratuwa#Negombo#properlycontrolled#RotaryDryer/kiln#SpinFlashDryer#SprayDryer#SprayDryerinSriLanka#SriJayawardenepura#SriLanka#StorageEquipments

0 notes

Text

Activate Bleaching Earth Plant in Chattogram

Company Overview:

Excellent En-Fab Incorporation, based in Ahmedabad, Gujarat, India, specializes in industrial plants and equipment.

Excellent En-Fab Incorporation are Manufacturer, supplier, and exporter of Activate Bleaching Earth Plant in Chattogram, Bangladesh, since 2010.

Offers AAC Block Plant, Flash Dryer, Dry Mix Mortar Plant, Storage Equipments, Autoclave, Rotary Dryer/Kiln, Wall Putty Plant, Spray Dryer, Agro Waste Pyrolysis Plant, Hot Air Generators, Spin Flash Dryer, and more.

Installed on a 10-acre facility, equipped with advanced manufacturing technology for high-quality production.

Processes clay-based materials to remove impurities, providing cost-effective options to customers.

Operational Process:

Material Preparation: Ensure proper preparation of clay-based materials, including thorough drying and removal of contaminants.

Activation: Heat treatment of clay in a furnace to enhance its adsorption capacity, typically between 400°C to 700°C.

Mixing: Blend activated clay with the oil or fat to be purified, facilitating adsorption of impurities.

Contacting Phase: Vigorous mixing to ensure optimal contact between activated clay and the oil/fat.

Filtration: Separate activated clay from the purified oil/fat using filtration methods such as pressure or vacuum filtration.

Drying: Dry the activated clay to eliminate residual moisture for reuse in the bleaching process.

Reactivation (Optional): Subject spent clay to high temperatures again to restore adsorption capacity for reuse.

Packaging: Package purified oil/fat for distribution or further processing.

Advantages of Activated Bleaching Earth:

Low Oil Residual

Fast Filtration Rate

Reduction of Free Fatty Acids

Impurity Removal

Geographical Coverage:

Excellent En-Fab Incorporation is Activate Bleaching Earth Plant in Chattogram, Bangladesh Serve multiple locations including Bhairab, Bogra, Brahmanbaria, Chandpur, Dhaka, Chittagong, Sylhet, Khulna, Rajshahi Chowmuhani, Chudanga, Comilla Sadar Dakshin, Faridpur, Feni, Jessore, Jhenaidah, Kadam Rasul, Kaliakair, Kushitia, Naogaon, Narsingdi, Pabna, Saidpur, Satkhira, Savar, Tangail, Tarabo, and Tongi.

For further details and inquiries, interested parties are encouraged to contact the company.

Read the full article

#ActivateBleachingEarthPlant#ActivateBleachingEarthPlantinBangladesh#ActivateBleachingEarthPlantinChattogram#Bangladesh#Bhairab#Bogra#Brahmanbaria#Chandpur#Chittagong#Chudanga#ComillaSadarDakshin#Dhaka#Exporter#Faridpur#Feni#India#Jessore#Jhenaidah#KadamRasul#Kaliakair#Khulna#Kushitia#LowOilResidual#Manufacturer#Naogaon#Narsingdi#Pabna#RajshahiChowmuhani#ReductionofFreeFattyAcids#Saidpur

0 notes

Text

Charcoal Making Plant in Nepal

Charcoal Making Plant in Nepal:

Company Overview:

Excellent En-Fab Incorporation, based in Ahmedabad, Gujarat, is a renowned manufacturing center specializing in construction and process equipment.

Charcoal production involves pyrolysis, heating wood or organic materials in a low-oxygen environment. This process vaporizes water and volatile components, leaving behind charcoal, a carbon-rich residue.

Charcoal plants vary in size and methods, from small-scale facilities using pit kilns to larger plants employing modern techniques like vertical retorts.

Components of a Charcoal Making Plant:

Feedstock Preparation: Sort and prepare raw materials like wood logs, sawdust, or agricultural waste for conversion.

Carbonization Chamber: Airtight chambers or kilns heat materials to convert them into charcoal.

Condensation System: Collects and condenses volatile gases and bio-oil produced during pyrolysis.

Charcoal Cooling and Collection: After carbonization, cool and collect charcoal for packaging and distribution purposes.

Emissions Control: Measures are in place to capture and treat emissions to minimize environmental impact.

Application:

Output Material will be used in Various Industries like,

Carbon Industries

Oil Distillation Plant

Fuel Industries

Pesticides Industries

Steel Industries

Cosmetic Industries

Many More.

Service Coverage:

Excellent En-Fab Incorporation serves as a Charcoal Making Plant in Nepal, catering to various locations including Kathmandu, Pokhara, Patan, Birgunj, Biratnagar, Dharan, Bharatpur, Janakpur Dham, Dhangadhi, Butwal, and Mahendranagar, Hetauda.

For detailed information and inquiries, interested parties are encouraged to contact Excellent En-Fab Incorporation.

Read the full article

#andMahendranagar#Bharatpur#Biratnagar#Birgunj#Butwal#CarbonIndustries#CharcoalMakingPlant#CharcoalMakingPlantinNepal#Dhangadhi#Dharan#Exporter#ExporterofCharcoalMakingPlantinNepal#FuelIndustries#Hetauda#JanakpurDham#Kathmandu#Manufacturer#ManufacturerofCharcoalMakingPlantinNepal#Nepal#Patan#PesticidesIndustries#Pokhara#Supplier

0 notes

Text

Exporter of AAC Block Plant in Russia

Company Profile:

Excellent En-Fab Incorporation is a leading Manufacturer, Supplier, and Exporter of AAC Block Plant in Russia.

Established in 2016, the company specializes in providing turnkey solutions for AAC Block Making Plants.

Their focus lies in manufacturing AAC Block Plants, AAC Plant, and Autoclave Aerated Concrete Block Making Plants, offering comprehensive solutions to clients.

The company produces AAC blocks, which are lightweight and versatile building materials made from sand, cement, lime, gypsum, and aluminum powder.

Utilizing autoclaving, they create cellular concrete blocks with excellent thermal insulation properties.

Process Overview:

Raw Material Preparation: Sand, cement, lime, and aluminum powder are mixed in predetermined proportions to form a slurry.

Molding: The slurry is poured into molds where it undergoes a chemical reaction and expands to form aerated concrete blocks.

Curing: Autoclaves steam cure green blocks, allowing them to cure and harden.

Cutting and Finishing: Cured blocks are cut into desired sizes using wire-cutting machines and finished as per requirements.

Key Equipment:

Mixer: Mixing raw materials to form the slurry.

Molds: Shaping AAC blocks during molding.

Autoclaves: Steam curing for strength and durability.

Cutting Machines: Cutting cured blocks into precise dimensions.

Finishing Equipment: Surface finishing such as grinding machines and painting equipment.

Applications:

Residential Construction: Used for building walls, partitions, and roofs.

Commercial Construction: Applied in offices, hotels, schools, hospitals, and shopping malls.

Industrial Construction: Suitable for industrial facilities, warehouses, and manufacturing plants.

Infrastructure Projects: Utilized in projects such as bridges, retaining walls, and sound barriers.

Supply Locations in Russia:

Excellent En-Fab Incorporation provides Exporter of AAC Block Plant in Russia, covering cities such as Moscow, Saint Petersburg, Novosibirsk, Samara, Omsk, Veliky Novgorod, Seversk, Norilsk, Murmansk, Belgorod, Novorossiysk, Arzamas, Kineshma, Derbent, Novoshakhtinsk, Shakhty, Vladimir, Velikiye Luki, and Kovrov.

The company encourages interested parties to contact them for further details and inquiries.

Read the full article

#AACBlockPlant#AACBlockPlantinRussia#Arzamas#Belgorod#CommercialConstruction#Derbent#Exporter#ExporterofAACBlockPlantinRussia#ExporterofAACBlockPlantorterofAACBlockPlant#IndustrialConstruction#InfrastructureProjects#Kineshma#Kovrov#Manufacturer#ManufacturerofAACBlockPlant#Moscow#Murmansk#Norilsk#Novorossiysk#Novoshakhtinsk#Novosibirsk#Omsk#ResidentialConstruction#Russia#SaintPetersburg#Samara#Seversk#Shakhty#SupplieerofAACBlockPlant#Supplier

0 notes

Text

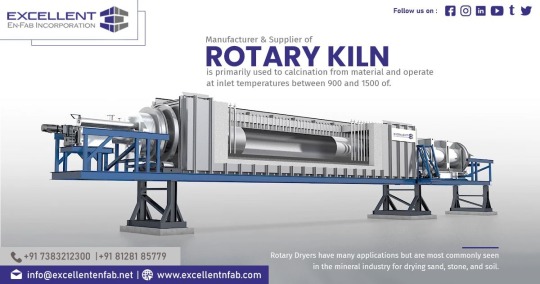

Exporter of Rotary Kiln in UAE

Exporter of Rotary Kiln in UAE:

Excellent En-Fab Incorporation is a Manufacturer, Supplier, and Exporter of Rotary Kiln in UAE.

Established in 2010 in Ahmedabad, Gujarat, India, the company specializes in various industrial plants and equipment.

Excellenten specializes in designing custom rotary dryers tailored to meet the specific processing requirements of different materials, offering flexibility in inlet temperatures, residence times, and flow configurations.

Rotary dryers are highly efficient for drying bulk solids, chosen for their robust processing capabilities and ability to produce uniform results despite variations in feedstock.

In the presence of drying air, material tumbles within a rotating drum in rotary dryers. These dryers can also be indirectly heated to prevent direct contact between the material and processing medium.

The drum is positioned at a slight horizontal slope to facilitate material movement through gravity. Lifting flights within the drum maximize heat transfer efficiency by picking up and dropping material through the airstream.

The tumbling action of rotary dryers not only dries the material but also provides rounding and polishing effects, particularly beneficial for agglomerates.

Key Features:

Diameter range: 3′ – 15′ (1 – 4.6m)

Capacity: 100 kg to 40 TPH

Specially designed lifting flights to enhance heat transfer

Heavy-duty construction ensures longevity

Offered in co-current or counter-current configurations

Process and mechanical warranties provided

Optional Components:

Knocking Systems

Trommel Screen

Liners

Leaf Seals

Graphite Seals

Machined Bases

Screw Conveyor Feeder

Automatic Gear Lubrication System

Exhaust Handling Equipment

Ductwork

Material Options:

Carbon Steel

Stainless Steel

Specialty Alloys

Explosion Bonded

AR Steel

Rotary dryers accommodate various fuel types including Fuel Oil, Natural Gas/Propane, Waste Heat, and Biogas.

Excellent En-Fab Incorporation provides Exporter of Rotary Kiln in UAE, supplying products to various locations including Hatta, Al Madam, Dhaid, Ghayathi, Liwa Oasis, Jebel Ali, Ruwais, Dubai, Abu Dhabi, Sharjah, Al Ain, Khaimah, Fujairah, Umm Al-Quwain, Dibba Al-Fujairah, Khor Fakkan, and Kalba.

For further details and inquiries, interested parties are encouraged to contact the company.

Read the full article

#AbuDhabi#AlAin#AlMadam#Dhaid#DibbaAl-Fujairah#Dubai#Exporter#ExporterofRotaryKiln#ExporterofRotaryKilninUAE#Fujairah#Ghayathi#Hatta#India#JebelAli#Kalba#Khaimah#KhorFakkan#LiwaOasis#Manufacturer#RotaryKiln#Ruwais#Sharjah#Supplier#SupplierofRotaryKiln#SupplierofRotaryKilninUAE#UAE#UmmAl-Quwain

0 notes

Text

Activate Bleaching Earth Plant in Dhaka

Excellent En-Fab Incorporation is a Manufacturer, Supplier, and Exporter of Activate Bleaching Earth Plant in Dhaka, Bangladesh.

Established in 2010 in Ahmedabad, Gujarat, India, the company specializes in various industrial plants and equipment.

Excellent En-Fab offers a wide range of products including AAC Block Plant, Flash Dryer, Dry Mix Mortar Plant, Storage Equipments, Autoclave, Rotary Dryer/Kiln, Wall Putty Plant, Spray Dryer, Agro Waste Pyrolysis Plant, Hot Air Generators, Spin Flash Dryer, and Activated Bleaching Earth Plant.

The company has installed a 10-acre Activated Bleaching Earth Plant equipped with advanced manufacturing facilities to produce high-quality products.

This facility processes clay-based materials to remove impurities. It offers customers a variety of options at cost-effective prices.

Services Offered:

Design & Detail Engineering

Fabrication & Manufacturing

Turnkey Basis Solutions

Sales Services

Operational Process:

Material Preparation: Ensure proper preparation of clay-based materials, including thorough drying and removal of contaminants.

Activation: Heat treatment of clay in a furnace to enhance its adsorption capacity, typically between 400°C to 700°C.

Mixing: Blend activated clay with the oil or fat to be purified, facilitating adsorption of impurities.

Contacting Phase: Vigorous mixing to ensure optimal contact between activated clay and the oil/fat.

Filtration: Separate activated clay from the purified oil/fat using filtration methods such as pressure or vacuum filtration.

Drying: Dry the activated clay to eliminate residual moisture for reuse in the bleaching process.

Reactivation (Optional): Subject spent clay to high temperatures again to restore adsorption capacity for reuse.

Packaging: Package purified oil/fat for distribution or further processing.

Advantages of Activated Bleaching Earth:

Low Oil Residual: Ensures minimal oil wastage.

Fast Filtration Rate: Efficient purification process.

Reduction of Free Fatty Acids: Enhances oil quality.

Impurity Removal: Eliminates substances like soap and trace metals.

Applications:

Widely used in various industries including oil refining, juice and wine clarification, and stabilizing refined oils.

Geographical Coverage:

Activate Bleaching Earth Plant in Dhaka, Bangladesh Serve multiple locations including Bhairab, Bogra, Brahmanbaria, Chandpur, Dhaka, Chittagong, Sylhet, Khulna, Rajshahi Chowmuhani, Chudanga, Comilla Sadar Dakshin, Faridpur, Feni, Jessore, Jhenaidah, Kadam Rasul, Kaliakair, Kushitia, Naogaon, Narsingdi, Pabna, Saidpur, Satkhira, Savar, Tangail, Tarabo, and Tongi.

For further details and inquiries, interested parties are encouraged to contact the company.

Read the full article

#ActivateBleachingEarthPlant#ActivateBleachingEarthPlantinDhaka#Bhairab#Bogra#Brahmanbaria#Chandpur#Chittagong#Chudanga#ComillaSadarDakshin#Dhaka#ExporterofActivateBleachingEarthPlant#ExporterofActivateBleachingEarthPlantinDhaka#Faridpur#Feni#Jessore#Jhenaidah#KadamRasul#Kaliakair#Khulna#Kushitia#ManufacturerofActivateBleachingEarthPlant#ManufacturerofActivateBleachingEarthPlantinDhaka#Naogaon#Narsingdi#Pabna#RajshahiChowmuhani#Saidpur#Satkhira#Savar#Sylhet

0 notes

Text

Exporter of Agro Waste Pyrolysis Plant in Bhutan

About Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation was established in 2016.

Excellent En-Fab Incorporation is a Manufacturer, Supplier, and Exporter of Agro Waste Pyrolysis Plant located in Bhutan.

The utilization of biomass fuels for energy production can aid in reducing the emission of greenhouse gases and other pollutants, aligning with recent emission targets.

The temperature range for slow pyrolysis of biomass is typically 300–650 °C, as indicated by Basu's literature.

The pyrolysis process involves complex and diverse chemical reactions occurring instantaneously.

The plant has a capacity ranging from 800 to 3000 Kg/Hr. for feedstock.

Process:

The mass balance for oat straw pyrolysis illustrates a significant increase in Pyrolytic gas and tar yields with increasing pyrolysis temperature.

Gas yield increases from 13.1% at 300 °C to 16.3% at 600 °C. Meanwhile, solid product yields decrease as temperature rises, with char concentration increasing from 48% at the lowest temperature to 24% at the highest.

Liquid product yields follow a similar trend to gas yield, with the highest tar content (57%) obtained at 600 °C.

Applications:

Output Material will be used in Various Industries like,

Carbon Industries

Oil Distillation Plant

Fuel Industries

Pesticides Industries

Steel Industries

Cosmetic Industries

Many More.

Exporter of Agro Waste Pyrolysis Plant in Bhutan:

The plant serves regions across Bhutan, including Chhukha, Daga, Gasa, Gelephu, Ha, Jakar, Lhuntshi, Mongar, Paro, Punakha, Samtse, Thimphu, Tongsa, Wangdue Phodrang, Zhemgang, and more.

The company encourages interested parties to contact for further details and inquiries.

Read the full article

#Agrowastepyrolysisplant#AgroWastePyrolysisPlantinBhutan#Bhutan#Chhukha#Daga#Exporter#ExporterofAgroWastePyrolysisPlant#ExporterofAgroWastePyrolysisPlantinBhutan#Gasa#Gelephu#Ha#Jakar#Lhuntshi#Manufacturer#Mongar#Paro#Punakha#Samtse#Supplier#SupplierofAgroWastePyrolysisPlant#SupplierofAgroWastePyrolysisPlantinBhutan#Thimphu#Tongsa#WangduePhodrang#Zhemgang

0 notes

Text

AAC Block Plant in Sri Lanka

About Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation is a Manufacturer, Supplier, and Exporter of AAC Block Plant in Sri Lanka.

Established in 2016, Excellent En-Fab Incorporation specializes in AAC Block Making Plants and offers turnkey projects in this field.

Focuses on manufacturing AAC Block Plants, AAC Plant, and Autoclave Aerated concrete-making Plants, providing comprehensive solutions.

Produces AAC blocks, a lightweight and versatile building material made from sand, cement, lime, gypsum, and aluminum powder.

Utilizes autoclaving to create cellular concrete blocks with excellent thermal insulation properties.

Process Overview:

Raw Material Preparation: Sand, cement, lime, and aluminum powder mixed in predetermined proportions to form a slurry.

Molding: Slurry poured into molds undergoes a chemical reaction and expands, forming aerated concrete blocks.

Curing: Green blocks allowed to cure and harden in autoclaves through steam curing.

Cutting and Finishing: Cured blocks cut into desired sizes using wire cutting machines and finished as per requirements.

Key Equipment:

Mixer: Mixing raw materials to form the slurry.

Molds: Shaping AAC blocks during molding.

Autoclaves: Steam curing for strength and durability.

Cutting Machines: Cutting cured blocks into precise dimensions.

Finishing Equipment: Surface finishing such as grinding machines and painting equipment.

Applications:

Residential Construction: Building walls, partitions, and roofs.

Commercial Construction: Offices, hotels, schools, hospitals, and shopping malls.

Industrial Construction: Industrial facilities, warehouses, and manufacturing plants.

Infrastructure Projects: Bridges, retaining walls, and sound barriers.

Supply Locations in Sri Lanka:

Excellent En-Fab Incorporation Providing AAC Block Plant in Sri Lanka, covering regions such as Colombo, Moratuwa, Dehiwala-Mount Lavinia, Jaffna, Negombo, Sri Jayawardenepura, Kalmunai, Kandy, Vavuniya, and others.

For further details and inquiries, interested parties are encouraged to contact the company.

Read the full article

#AACBlockPlant#AACBlockPlantinSriLanka#AutoclavedAeratedConcretePlant#Autoclavedaeratedconcreteplantinsrilanka#Colombo#CommercialConstruction#Dehiwala-MountLavinia#Exporter#ExporterofAACBlockPlant#ExporterofAACBlockPlantinSriLanka#IndustrialConstruction#InfrastructureProjects#Jaffna#Kalmunai#Kandy#Manufacturer#ManufacturerofAACBlockPlant#Moratuwa#Negombo#ResidentialConstruction#SriJayawardenepura#SriLanka#Supplier#SupplierofAACBlockPlant#Vavuniya

0 notes

Text

Exporter of Rotary Dryer in Nepal

We are a Manufacturer, Supplier, and Exporter of Rotary Dryer in Nepal.

Excellent En-Fab Incorporation established itself in 2010 in Ahmedabad, Gujarat, India.

Excellent En-Fab Incorporation has established a reputation for manufacturing top-quality rotary dryers tailored to meet the specific processing requirements of various materials.

We custom-design each dryer, considering factors such as inlet temperatures, residence times, and flow configurations, ensuring optimal performance for your application.

An industrial dryer, known as a rotary dryer, reduces the moisture content of materials by exposing them to heated gas. It consists of a rotating cylinder (drum or shell), a drive mechanism, and a support structure.

Also known as a tumbling dryer, the rotary dryer brings feed materials into direct contact with heated gas to minimize moisture content. It typically features an inclined long drum or cylindrical shell with internal flights or lifters for effective material tumbling.

Rotary Dryer Benefits:

Indirectly heated dryers are preferred for applications where product contamination is a concern.

Combination of direct-indirect heated rotary dryers can enhance overall efficiency.

Used primarily to remove moisture from materials, operating at inlet temperatures between 300 and 600°F.

Rotary Kilns are employed for material calcination, operating at inlet temperatures between 900 and 1500°F.

Key Features:

Sturdy construction and simple design.

Adaptability to fluctuating feed rates and moisture contents.

Capability to handle large throughputs and materials.

Heavy-duty tires and support roller assemblies with drives for drums.

Sealing arrangements tailored to specific applications.

Various internal designs for efficient heat transfer and high thermal efficiency.

High resistance to water penetration.

Applications:

Rotary dryers find widespread use in the mineral industry for drying sand, stone, and soil, among other materials.

Excellent En-Fab Incorporation serves as Exporter of Rotary Dryer in Nepal and we supply products in various locations like Kathmandu, Pokhara, Patan, Birgunj, Biratnagar, Dharan, Bharatpur, Janakpur Dham, Dhangadhi, Butwal, Mahendranagar, Hetauda.

For detailed information and inquiries, please feel free to contact us.

Read the full article

#Ahmedabad#Bharatpur#Biratnagar#Birgunj#Butwal#Dhangadhi#Dharan#dryingsand#Exporter#ExporterofRotaryDryer#Gujarat#Hetauda#JanakpurDham#Kathmandu#Mahendranagar#Manufacturer#Nepal#Patan#Pokhara#RotaryDryer#RotaryDryerinNepal#RotaryDryer/kiln#soil#stone#Supplier#SupplierofofRotaryDryerinNepal#SupplierofRotaryDryer

0 notes