#direct 3d printing

Link

#3d printing online quote#direct 3d printing#3d printing service australia#3d printing melbourne#3d printing quote#3d printing service#3d printing service sydney#3d printing service melbourne#3d printing perth

0 notes

Link

#3d printing online quote#direct 3d printing#3d printing service australia#3d printing melbourne#3d printing quote

0 notes

Text

Spent 4 hours out in the heat today working on the Outrage. Side 1 is basically done but side 2, the darker side here, still needs sanded since I just got it covered in Bondo today. Hoping that using a thick primer paint or multiple layers of primer will further smooth out some issues like the cracks between segments and the layer lines in areas I struggled to sand (mostly the inner side plates). Getting closer... Wanna have this sanded and painted before the cold months get here so all the work I have to do to it outside is out of the way.

Guessing maybe another 6 hours of sanding left to do.

#photopost#3d printing tag#Got a gnarly blister on my right thumb from working on this today...#It was about 90f (~28c) out and I have to work in nearly direct sun#The PLA started melting when I sanded too fast so I had to go slow haha

27 notes

·

View notes

Text

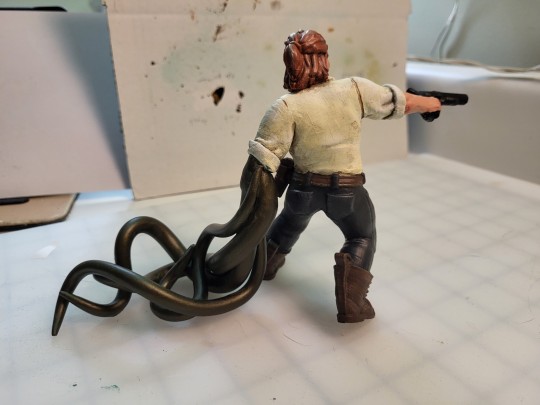

I had a voucher for a free stl download from heroforge, so I 3d printed and painted a statuette of my dearly departed motw npc, sloane as a fun side project.

The only part I get credit for are the tentacles (made with sculpey) and the paints, but turning your oc into something you can hold in the palm of your hand is a Powerful feeling

#ragsycon exclusive#ragsymakes#3d printing#heroforge#i fucked up the direction her eyes are looking#but at least they're both pointing the same direction so I'm not going to sweat it too much lol

15 notes

·

View notes

Text

Can I offer you some (dragon) eggs in this trying time?

#trying to get the dual color filament to work but I think it’s just not going to go well if I don’t have direct drive#egg is Dragon Egg on thingiverse#and dragon is crystal dragon by cinderwing3D#3D printing

4 notes

·

View notes

Text

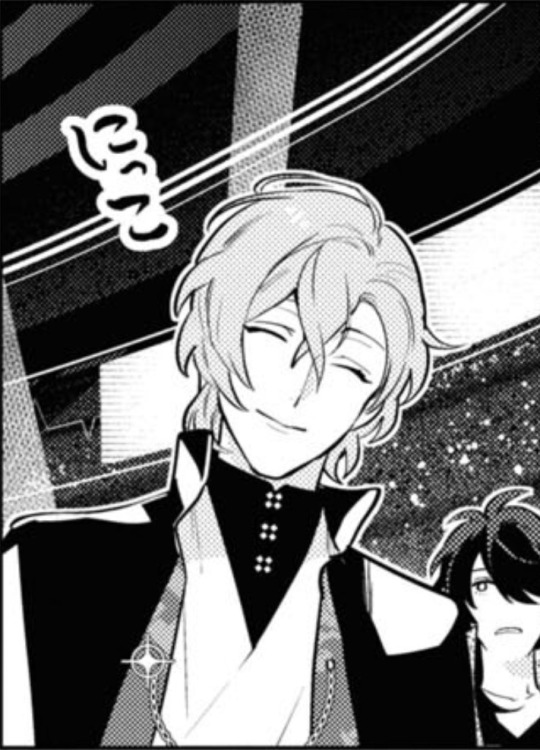

juto and gentaro have been btching at each other with a smile like this for the entire battle AND DICES FACE LMAO

#this is vee speaking#i completely forgot what day it was lmao 😭😭😭😭😭😭😭😭😭😭😭😭😭😭😭😭😭😭😭#like i made a mental note the chapter comes out on the 28th but forgot the most important note for me with my ass sense of time:#what’s the date lol (i did not know today was march 27 😭😭😭😭😭😭😭😭😭😭😭😭)#and i even saw people vaguing about the chapter lmao vee where’s your brain#the chapter was dope kiiko jyo hype train her art FCKS ALL THE TIME#i’m sooooooo happy they’ve been depicting everyone’s speakers combined lately it was a big want for me in my early hypmic days#so much so i sketched mtr’s hoping to eventually pick up 3d modelling and make it myself lol#we had scary samatoki 🥰🥰🥰🥰 slightly unhinged juto 🥰🥰🥰🥰 riodice with no beef 🥰🥰🥰🥰#lol ramuda is visibly dying during this battle it is incredible that fp will win in this context lol#ALSO THE CHAPTER TITLE PAGE???????? STELLA???????? BUT ALSO KINDA BLACK JOURNEY BY NATURE OF IT BEING BLACK AND WHITE PRINT???????#ooooooh wait i’m not done gushing about the speakers art direction the way juto’s were depicted was really cool#as well as samatoki’s from the gate lol he’s so terrifying y’all 💙💙💙#c: juto#c: gencha

19 notes

·

View notes

Text

Started painting minis recently!

#moxie#orlan#miniatures#my minis#my art#grogu#need to test colour schemes for my tyranids#I know I want something frosty but im not sure what direction to go yet#these are all 3d printed by mav

4 notes

·

View notes

Text

ffs this thing refuses to be photographed but I tried

I MADE THIS!! I DIGITALLY SCULPTED IT AND 3D PRINTED IT! ME!! WHAT THE FUCK!!!

That tumblr post about how if you’re learning to play guitar you’re probably going to stick with it more if you start by trying to play slayer riffs instead of practice exercises was soooooooooo right I’m so glad I did this I’ve been binging art tutorials and I can’t wait to try everything

#my art#3D printed#although realistically you should do *both*#learn to play slayer riffs but balance it with practice exercises#but it’s okay to lean more in the riffs direction :)

15 notes

·

View notes

Text

Dialed in after first print. Let's fucking go.

#big printer can print#now to make it print big replacement parts that the little printer can't#then use those replacement parts to upgrade the big printer#custom brackets for a direct drive filament feeder#brackets to stabilize the bed#gonna upgrade the print head#this thing is gonna be insanely good#3d printing

6 notes

·

View notes

Photo

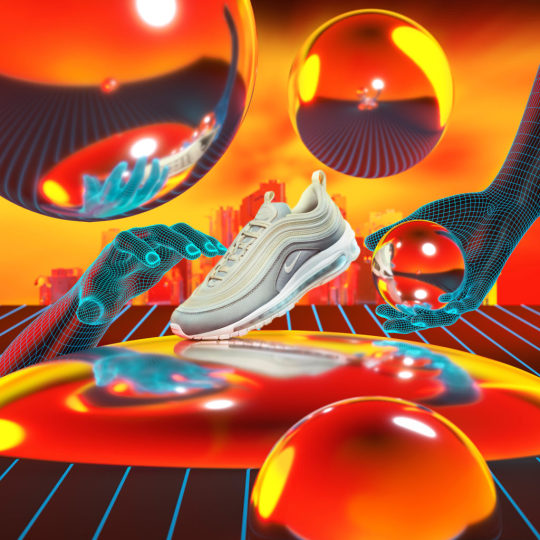

Sucuk Und Bratwurst is a creative studio run by alessandro belliero, david gönner, denis olgac & lukas olgac.

Made up of the same precious materials as the devotional objects, the campaign suggests that the sole of the Nike shoe is as valuable as any museum-grade item, and so should be collected like one.

https://sucukundbratwurst.de/

#ad#nike#shoes#art#direction#print#cool#museum#german#germany#adobe#creative#studio#reference#modern#contemporary#design#3d#4d#cinema#cinema4d

2 notes

·

View notes

Text

Study: Under extreme impacts, metals get stronger when heated

New Post has been published on https://thedigitalinsider.com/study-under-extreme-impacts-metals-get-stronger-when-heated/

Study: Under extreme impacts, metals get stronger when heated

Metals get softer when they are heated, which is how blacksmiths can form iron into complex shapes by heating it red hot. And anyone who compares a copper wire with a steel coat hanger will quickly discern that copper is much more pliable than steel.

But scientists at MIT have discovered that when metal is struck by an object moving at a super high velocity, the opposite happens: The hotter the metal, the stronger it is. Under those conditions, which put extreme stress on the metal, copper can actually be just as strong as steel. The new discovery could lead to new approaches to designing materials for extreme environments, such as shields that protect spacecraft or hypersonic aircraft, or equipment for high-speed manufacturing processes.

The findings are described in a paper appearing today in the journal Nature, by Ian Dowding, an MIT graduate student, and Christopher Schuh, former head of MIT’s Department of Materials Science and Engineering, now dean of engineering at Northwestern University and visiting professor at MIT.

The new finding, the authors write, “is counterintuitive and at odds with decades of studies in less extreme conditions.” The unexpected results could affect a variety of applications because the extreme velocities involved in these impacts occur routinely in meteorite impacts on spacecraft in orbit and in high-speed machining operations used in manufacturing, sandblasting, and some additive manufacturing (3D printing) processes.

The experiments the researchers used to find this effect involved shooting tiny particles of sapphire, just millionths of a meter across, at flat sheets of metal. Propelled by laser beams, the particles reached high velocities, on the order of a few hundred meters per second. While other researchers have occasionally done experiments at similarly high velocities, they have tended to use larger impactors, at the scale of centimeters or larger. Because these larger impacts were dominated by effects of the shock of the impact, there was no way to separate out the mechanical and thermal effects.

The tiny particles in the new study don’t create a significant pressure wave when they hit the target. But it has taken a decade of research at MIT to develop methods of propelling such microscopic particles at such high velocities. “We’ve taken advantage of that,” Schuh says, along with other new techniques for observing the high-speed impact itself.

The team used extremely high-speed cameras “to watch the particles as they come in and as they fly away,” he says. As the particles bounce off the surface, the difference between the incoming and outgoing velocities “tells you how much energy was deposited” into the target, which is an indicator of the surface strength.

Three photos show a particle bouncing off of a surface. The particle bounces higher when the temperature is increased. These three images are labeled “20 °C, 100 °C, and 177 °C.”

The team used extremely high-speed cameras to track particles. This sequence, from research data, shows a particle flying in and rebounding off of a surface.

The tiny particles they used were made of alumina, or sapphire, and are “very hard,” Dowding says. At 10 to 20 microns (millionths of a meter) across, these are between one-tenth and one-fifth of the thickness of a human hair. When the launchpad behind those particles is hit by a laser beam, part of the material vaporizes, creating a jet of vapor that propels the particle in the opposite direction.

The researchers shot the particles at samples of copper, titanium, and gold, and they expect their results should apply to other metals as well. They say their data provide the first direct experimental evidence for this anomalous thermal effect of increased strength with greater heat, although hints of such an effect had been reported before.

The surprising effect appears to result from the way the orderly arrays of atoms that make up the crystalline structure of metals move under different conditions, according to the researchers’ analysis. They show that there are three separate effects governing how metal deforms under stress, and while two of these follow the predicted trajectory of increasing deformation at higher temperatures, it is the third effect, called drag strengthening, that reverses its effect when the deformation rate crosses a certain threshold.

Beyond this crossover point, the higher temperature increases the activity of phonons — waves of sound or heat — within the material, and these phonons interact with dislocations in the crystalline lattice in a way that limits their ability to slip and deform. The effect increases with increased impact speed and temperature, Dowding says, so that “the faster you go, the less the dislocations are able to respond.”

Of course, at some point the increased temperature will begin to melt the metal, and at that point the effect will reverse again and lead to softening. “There will be a limit” to this strengthening effect, Dowding says, “but we don’t know what it is.”

The findings could lead to different choices of materials when designing devices that may encounter such extreme stresses, Schuh says. For example, metals that may ordinarily be much weaker, but that are less expensive or easier to process, might be useful in situations where nobody would have thought to use them before.

The extreme conditions the researchers studied are not confined to spacecraft or extreme manufacturing methods. “If you are flying a helicopter in a sandstorm, a lot of these sand particles will reach high velocities as they hit the blades,” Dowding says, and under desert conditions they may reach the high temperatures where these hardening effects kick in.

The techniques the researchers used to uncover this phenomenon could be applied to a variety of other materials and situations, including other metals and alloys. Designing materials to be used in extreme conditions by simply extrapolating from known properties at less extreme conditions could lead to seriously mistaken expectations about how materials will behave under extreme stresses, they say.

The research was supported by the U.S. Department of Energy.

#3d#3D printing#additive manufacturing#aircraft#alloys#Analysis#applications#Arrays#atoms#Cameras#course#crystalline#data#devices#Difference Between#direction#DMSE#effects#energy#engineering#equipment#experimental#form#gold#Heat#heating#how#human#hypersonic#hypersonic aircraft

1 note

·

View note

Link

#3d printing online quote#direct 3d printing#3d printing service australia#3d printing melbourne#3d printing quote#3d printing service#3d printing service sydney#3d printing service melbourne#3d printing perth

0 notes

Link

#3d printing online quote#direct 3d printing#3d printing service australia#3d printing melbourne#3d printing quote#3d printing service

0 notes

Text

Get the Most Out of Custom Direct-to-Film Transfers

https://eazydtf.com/ - At EazyDTF, we specialize in delivering top-notch custom Direct-to-Film Transfers, ensuring your designs come to life with unparalleled quality and affordability. Our DTF technology allows for high-resolution prints on various materials like cotton, polyester, leather, and more, offering vivid colors and exceptional durability. With quick turnaround times and low prices for both small and large orders, our process guarantees intricate designs and gradients, making it ideal for any scale of operation. Whether you need same-day DTF printing or want to order DTF transfers, contact us today for exceptional results and efficient service.

#custom-dtf-transfers#best-dtf-transfer-printers#direct-to-film-printing-services#3d-puff-htv-heat-transfer-vinyl#custom-holographic-stickers#dtf-gang-sheet-builder#reflective-htv-heat-transfer-vinyl#glitter-htv-heat-transfer-vinyl#glow-htv-heat-transfer-vinyl

0 notes

Text

#tshirt design#collection#design#streetwear#art#unique prints#3d printing#print#art print#designer clothes#digital fashion#printmaking#personalized clothing#forestpunk#graphic design#art direction#digital illustration#digital drawing#digital art#digital painting#the amazing digital circus#artwork#illustration#artists on tumblr#digitalart

1 note

·

View note

Text

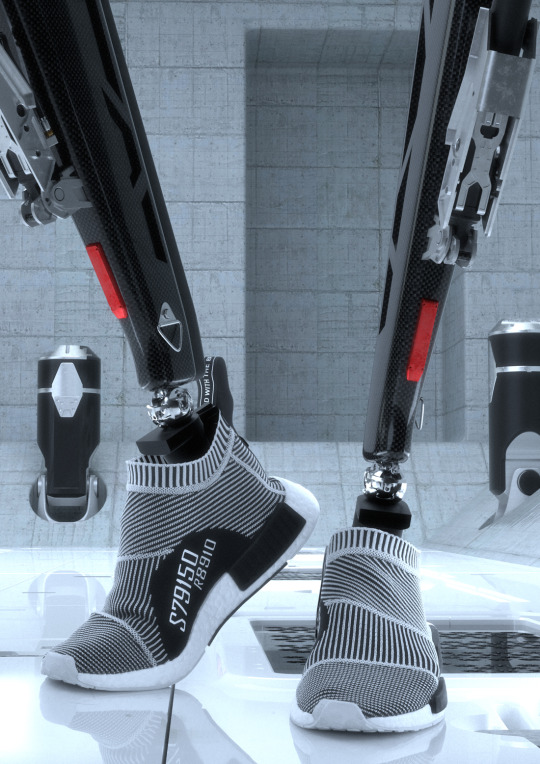

Sustainable Fashion Becomes Mainstream

Illustration commissioned by Sun Plaza Mall in Bucharest, for their 10th anniversary. The image is based on a text about imagining the world in the future where the digitalization of fashion and using recyclable materials and futuristic technologies become mainstream.

Curated by Visual Playground

#illustration#digital art#drawing#textures#art direction#fashion#fashion design#fashion illustration#shoes#future#futuristic#technology#sustainability#sustainable fashion#ecofriendly#recycling#3d printing#shopping

0 notes