#castingindustry

Text

What materials are used in pressure die casting?

Looking for quality Tool & Die Steels for your Pressure Die Casting Industry?

At Virat Special Steels, we specialize in supplying high-quality tool and die steels to the pressure die casting industry. Our comprehensive range includes: DIN 1.2344 (H13), DIN 1.2343 (H11), DIN 1.2581 (H21)

Pressure die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

DIN 1.2344 (H13) is a hot work tool steel that has excellent machinability and polishability, good high toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance. It is widely used for aluminum, magnesium and zinc die casting, as well as metal extrusion tools, shear knives, and hot forging dies.

DIN 1.2343 (H11) is also a hot work tool steel that has similar properties to DIN 1.2344 (H13), but with less vanadium content, which gives it higher toughness and lower wear resistance. It is suitable for die casting molds for light metal processing, cylinders and pistons on cold chamber machines, and hot forming tools.

DIN 1.2581 (H21) is a tungsten-chrome-vanadium steel for hardening in oil and possibly in air with very good hardenability, very high firmness during the heat and resistance to the tempering, high resistance to the hot tempering and good toughness. It is mainly used for hot-working dies and tooling, such as extrusion, die casting and hot-forming of parts.

Virat Special Steels is one of the largest importer, exporter and stockist of die blocks, tool steels, die steels, special steels and alloy steels in various grades in India. The company maintains a high level of inventory of special steels from the world’s leading manufacturers and provides technical advice and support to its customers.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Learn more :

https://www.viratsteels.com/hot-work-steel.html

Any queries feel free to contact us :[email protected] or

Call on mobile number +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#PressureDieCasting#DieCasting#MetalCasting#CastingIndustry#MetalFabrication#MoldMaking

2 notes

·

View notes

Text

Iron Casting: Navigating Opportunities and Challenges in the Sector

The global iron casting market size is expected to reach USD 172.66 billion by 2030, according to a new report by Grand View Research, Inc., expanding at a CAGR of 6.1% over the forecast period. The increasing investments in the infrastructure & renewable energy industry are expected to propel the demand for the product. Iron castings are produced by pouring melted cast iron into casts or molds to make products of desired shape and size, via various methods such as sand and investment casting. Different product types available in the market include gray, ductile, and malleable, which are used according to their application requirements.

Iron Casting Market Report Highlights

Based on the product, ductile cast iron is anticipated to register the fastest CAGR of 6.4%, in terms of revenue, from 2022 to 2030. The product is preferable in various end-use industries such as automotive, water system & sanitization, and renewables as it offers higher toughness and strength than gray cast iron.

Based on application, the railway is expected to grow at a CAGR of 7.4%, in terms of revenue, across the forecast period. This growth is attributable to increasing investments by countries to develop their rail infrastructure to promote transportation of goods via rail and improve connectivity.

Based on region, North America is expected to register a CAGR of 5.5%, in terms of revenue, over the forecast period. Rising emphasis on shifting towards renewables, investment in railways, up-gradation & development of water system & sanitization, and advancement of machines & tools is expected to drive the market growth in the region.

For More Details or Sample Copy please visit link @: Iron Casting Market Report

Based on product, gray cast iron held the largest revenue share of the global market in 2021, and this trend is expected to continue across the forecast period. It is preferred owing to the benefits it offers such as abrasive resistance, vibration damping capacity, and better castability than other types. The product is used for making machine tool bases, soil pipes, automobile engine blocks, and internal combustion engine head manifolds.

Based on region, Asia Pacific held the largest revenue share of the global market in 2021. In the region, China was the key market in 2021 but India is expected to register the fastest growth rate across the forecast period. The increasing demand for the product from various industries such as railways, renewables, machines & tools, and infrastructure is propelling competition in the region.

In February 2022, Bharat Forge announced the acquisition of JS Autocast Foundry India, a manufacturer of ductile iron castings for hydraulics, wind energy, automotive, and off highways. The acquisition is anticipated to help Bharat Forge expand its product portfolio as well as manufacturing presence.

The global market is highly competitive in nature. Key players in the industry are carrying out mergers & acquisitions for the development of their business. For instance, In November 2021, Wisconsin-based Charter Manufacturing acquired Aarrowcast Inc., a gray and ductile iron casting manufacturer. Aarrowcast Inc. has a production capacity of 42,000 tons per year. This acquisition is expected to help Charter Manufacturing to expand the manufacturing of its metal offerings and diversify its customer base.

#IronCasting#FoundryIndustry#MetalCasting#IndustrialManufacturing#Metallurgy#GlobalMarket#FoundryTechnology#CastingProcesses#IronFoundry#Metalworking#FoundryEquipment#CastingIndustry#MarketAnalysis#IronProduction#FoundryTrends

0 notes

Text

Industries | Foundry CastingAluminium Die Casting

Roadmap IT Solutions pioneers in providing ERP Software for Aluminium Die Casting to digitize the workflow and to empower the businesses to attain global progress

#foundryerpsystem#casting and moulding software#erpsoftwareforfoundrymanagement#erpfoundrysoftware#castingindustry#deicasting#erpsoftwarecompany#erpsoftwareinpondicherry#erpsoftwareinchennai#erpsoftwareinbangalore#erpsoftwareincoimbatore

0 notes

Text

Industrial Promotion and Investment Corporation of Odisha Limited

We are proud to announce that the Industrial Promotion and Investment Corporation of Odisha Limited has given approval to IFGL Refractories to set up a new manufacturing facility for Continuous Casting Refractories in Odisha, with an installed capacity of 240,000 pieces per annum.

Odisha has been selected for its mineral wealth, excellent infrastructure, abundance of well-trained people, and future high concentration of steel manufacturing. This ₹150 crore project will have a commercial production target of March 2025 and will be our second manufacturing facility in Odisha and fourth in India. Read the full news… https://shorturl.at/juJT4

#IFGL#IFGLRefractories#GrowthUpdates#IFGLGrowthStory#WeAreIFGL#SteelManufacturing#SteelIndustries#CastingIndustry#Refractory

0 notes

Text

Both regular and savings casting make tough, well-built parts with trustworthy quality, and both are utilized in moving applications, industrial tools, equipment, and structure. steel casting manufacturers will alter itself during the calm-down process, which provides the finished product with more tolerances than the new material and evaluates savings casting.

It is not unusual to find a condition where extensive savings could be obtained by altering valve casting manufacturers types. Factoring in the energy-efficient valves lesser installation, protection, and mechanization cost in addition to the bigger uptime, it will almost also be more inexpensive over time when evaluated to well-liked gate valves.

0 notes

Photo

Casting the “Gold Mine Industrial” Please read carefully! Only Filming in San Diego, CA. In studio. Covid-19 precautions will be observed and respected by all cast and crew. The filming will be done sometime in either late June or July 2020. Please Do not submit any talent who cannot meet these guidelines & date requirements, thank you! If you are right for any of these 2 Male roles please call me immediately at my cell 619 823 2378 RATE: This will be for a ½ day shoot (no more then 4 to 5 hours) & talent do their own make up. Male roles / $300 + 20% if represented. There is only an additional $50 to those who live outside San Diego areas & are traveling from LA or Orange County to work & have been hired for one of the two listed roles. There are no other available Travel or hotel (1) Crazy Eddie’s Lines for the Self tape… Crazy Eddie (male / late 40’s - 50’s) Older prospector type. Crazy Eddie has set up all the traps and puzzles for the escape room participants and has lost his mind a little as a result! Must be able to pull off an over the top old west accent. Crazy Eddie is like the guide for the participants, so he must balance being intense with an ability to draw folks in, like a storyteller. (2) Psychotic Man (male / 30’s - 40’s) A former factory worker, now disheveled, dirty, and completely out of his mind. He warns escape room participants of the dangers they will face in the mine. Must be able to play over the top, with exaggerated facial expressions. Looking for a fun performance, more silly than scary. More details & how to submit are list at my website link: https://www.samuelwarren.com/acting-classes.html & then scroll all of the way down at that link to where reads the "Casting Call Notices' & click onto the button that is "Titled: “Gold Mine Industrial” & follow the pdf's instructions and submit before the deadline as listed within the document, thank you! @samuelcastingservices #castingindustrial #talentforbiz #maleactors https://www.instagram.com/p/CBD7SVVD-er/?igshid=1ifjks1qwxfg3

0 notes

Text

There are two main types of dewaxing casting methods

Until the predetermined shell thickness is obtained. better dimensional stabilityA precision casting mold for stainless steel precision casting obtains a casting method for precision castings.

The shell Precision casting Suppliers mold method until the wax type is produced in the same way as the solid mold, but after one damp and sand (or floating sand), the mold-free operation is not carried out, but the dipping and sanding are repeated several times.Stainless steel precision casting process There are two main types of dewaxing casting methods: the Solid Mold method and the Ceramic Shell Mold method, the latter being the former method of improvement.

Drying, heating, melting and waxing, high temperature heating and casting, this method is widely used by the current dewaxing precision castingindustry, because it has the following advantages: The process can be partially automated to save manpower and increase production rate Lower production costs The ceramic shell mold is thin, and the casting rate of the casting after casting is high and uniform, so the mechanical properties are better.

1 note

·

View note

Photo

The reality of business and e-commerce today makes data management a necessary component of operations. For e-commerce companies with large data pools and significant analytics needs.

This also means investing heavily in staff and resources to keep this data organized so analytics tools can run smoothly. More and more, companies are seeking data lakes as an answer to many of their analytic and data storage needs.

#datamanagement #data #bigdata #nondestructivetesting #qualitycontrol#innovation #castingindustry #digitaltransformation #digitalimaging

0 notes

Text

Is it a Good Time to Invest in ERP

🕜Time waits for none and the same does apply to business too. Your business may stagnate simply because of an outdated business management system and manual processing. There is no wrong time to speculate about investing in a well-optimized, robust ERP system.

So don’t wait!

🤓Choose Roadmap ERP system and transform your business operations with integrated, streamlined, and automated business processes.

👉Tap the link below to know more: www.roadmapit.com

#businesstips#investment#businessgrowthtips#timemanagement#timetoinvest#smallbusiness#investments#profit#entrepreneurmindset#business#growbusiness#growyourbusinessonline#erpsoftwareinpondicherry#erpsoftwareinchennai#erpfordairyindustry#dairyindustry#foundry erp system#castingindustry

0 notes

Text

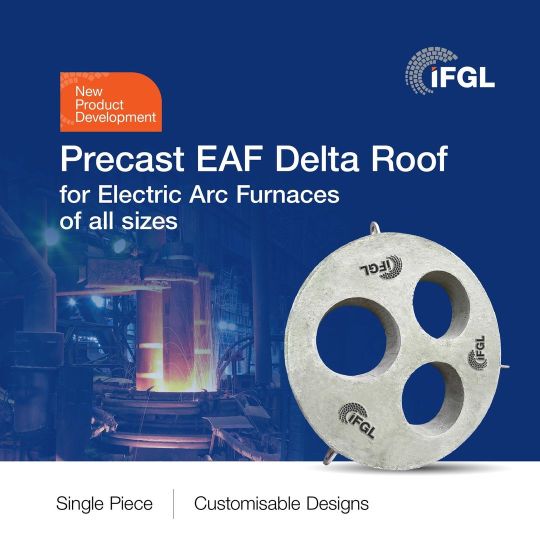

Precast EAF Delta Roof for Electric Arc Furnances of all sizes

IFGLRefractories is constantly looking to push the boundaries of refractory performance, with new products and technologies. We have developed a single-piece Precast #EAF Delta Roof for electric arc furnaces of any size. With easy assembly & installation, and option to create different shapes, the product is designed to meet precise customer requirements.

#IFGL#IFGLRefractories#EAF#ElectricArcFurnace#IndustrialSolutions#SteelManufacturing#SteelIndustries#CastingIndustry#Refractory

0 notes

Text

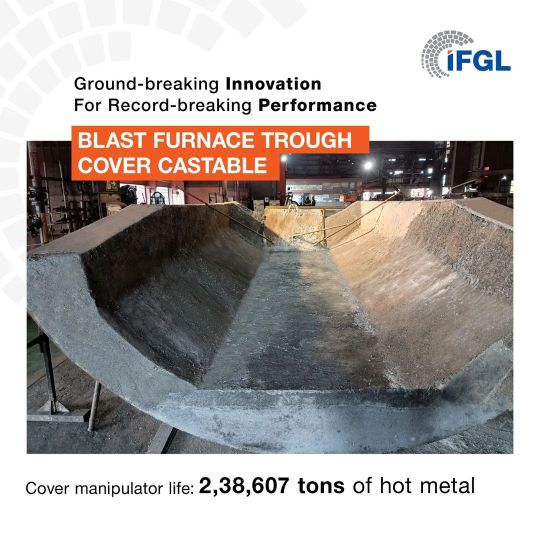

Blast furnace trough cover castable

Through continuous innovation, we push the boundaries of refractory performance, delivering value to our customers worldwide.

Our new alumina-silicon carbide-carbon-spinel trough cover castable (no cement) for blast furnaces was recently used for one of our esteemed customers, to enhance Cover Manipulator life to a record 2,38,607 tons of hot metal. We thank them for their constant support, and promise to keep setting the bar higher.

#IFGL#IFGLRefractories#Refractory#BlastFurnace#Furnace#Innovation#SteelManufacturing#SteelIndustries#CastingIndustry

0 notes

Text

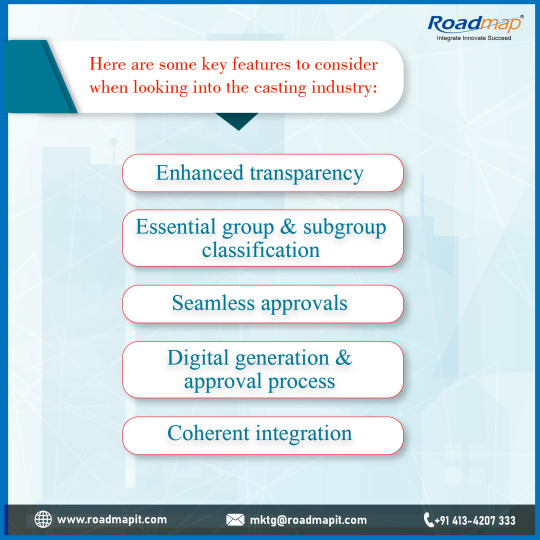

Roadmap ERP for Casting Industry

As far as the casting industry is concerned, it has unique and complicated processes requiring greater precision and absolute control.

Roadmap ERP system comes in handy and solves these complex challenges in the everyday routine.

It automates and simplifies the entire production process from molding, melting, and metal treating to knockout, cleaning, and inventorying with adequate accuracy and visibility👁️.

👉Tap the link to view our business services https://roadmapit.com

#erpimplementation#erp#erpconsultant#foundry#casting#molding#castingindustry#automobile#automation#industryprocess

0 notes

Text

Industrial valve casting manufacturers plays an important role in the manufacture of various types of medical devices. And many major industry players seize the opportunity to combat the deadly Coronavirus pandemic. Different regions have different certifications and policies on valves.

The market is divided into segments: oil and gas, water and wastewater, Energy & Power, Chemicals, Food & Beverages, Pharmaceuticals, Building & Construction, etc. The oil & gas industry had the most significant industrial valve market share in 2019 due to the increasing transportation sector. However, the world is currently facing an economic crisis due to the COVID-19 pandemic.

0 notes

Text

Manufacturing is complex because it is a multi-step process. It is less avoidable that some investment casting defects occur due to incorrect operations. With the help of this blog, you will know about common defects in our investment casting foundry.

Cavities may be paired with dendritic fractures. Large shrinkage cavities can undermine the integrity of the casting and may eventually fracture under stress. This is one of the common defects of our investment casting foundry.

0 notes

Text

There are a variety of casting procedures available to pick from; nonetheless, it may be challenging to choose which approach to use based on the necessities of the equipment. So how can you determine which method is the most effective? Your product’s technical specs will determine how you respond to this question.

The process of investment casting manufacturers in India utilizes a one-time-use ceramic mould. The mould is shaped using a wax template, which creates very accurate details or elaborate patterns.

0 notes

Link

The steel casting foundry is a class for casting steel. A steel casting is a metal part that is determined by pouring molten steel with the cavity of a mold. The steel after warming then becomes cool and then compresses within the mold cavity. The shape of the mold can be changed, to fit the conditions.

#steelcastingfoundry#SteelCastingCompany#SteelCastingManufacturer#SteelCasting#CastingCompany#CastingIndustry

0 notes