#Ceramic Chemicals

Text

Industrial, Cleaning, Oil Field, Water treatment, Painting, Food, Mining, Construction, Power plant, Ceramic Chemicals Dubai, UAE | Coil cutting Service Dubai, UAE

The chemical industry in Dubai and the United Arab Emirates (UAE) is a vital component of the country's economy, as it is used in a wide range of industries such as construction, manufacturing, and oil and gas. The region is known for its high-quality chemicals, which are exported to various countries worldwide. However, with so many chemical suppliers in the market, it can be challenging to find the right one that meets your needs. This is why it is important to have a reliable and trustworthy chemical supplier that you can count on for all of your chemical needs.

In this blog post, we will discuss the role of chemical suppliers in Dubai and the UAE, the factors to consider when selecting a chemical supplier, and key players in the chemical supplier market. We'll also give tips on how to research and compare chemical suppliers in the region, so you can make an informed decision when choosing the right supplier for your business.

The role of chemical suppliers in Dubai and the UAE

The role of chemical suppliers in Dubai and the UAE is to provide a variety of chemical products to different industries in the region. These products include raw materials, industrial chemicals, and specialty chemicals that are used in a wide range of applications.

Construction industry is one of the major industries that rely on chemical suppliers in Dubai and the UAE. These chemicals are used in the production of construction materials such as cement, concrete, and asphalt. They are also used in the construction process, for example, as a waterproofing agent, fire-resistant coating, and for surface treatment.

Manufacturing industry is another sector that heavily depends on chemical suppliers. Chemicals are used in the production of various products such as plastics, textiles, and pharmaceuticals. These chemicals play a crucial role in the manufacturing process, as they are used as raw materials, catalysts, and intermediates.

Oil and gas industry is also a major user of chemicals. In the exploration, production, and refining process of oil and gas, various chemicals are used. These chemicals are used for drilling, production enhancement, and refining process.

Specialty chemicals are also an important part of the chemical industry in Dubai and the UAE. These chemicals have specific properties and are used for specific applications, such as in the food and beverage industry, personal care products, and agriculture.

In summary, chemical suppliers in Dubai and the UAE play a crucial role in supplying a wide range of chemicals to various industries, which in turn, enables the smooth functioning of these industries, and contributes to the overall economic growth of the region.

Choosing a chemical supplier in Dubai and the UAE

Choosing a chemical supplier in Dubai and the UAE can be a challenging task due to the large number of suppliers in the market. However, by considering the following factors, you can ensure that you select a supplier that meets your needs and provides you with high-quality chemicals at a reasonable price.

Quality: The quality of the chemicals supplied is of utmost importance. Make sure that the supplier has a good reputation in the market and that their chemicals meet the required industry standards.

Price: Compare the prices of different suppliers and choose one that offers competitive prices without compromising on quality.

Customer Service: A good supplier should provide excellent customer service, including timely delivery of products and prompt response to any queries or concerns you may have.

Certifications: Ensure that the supplier is certified by relevant authorities and that their chemicals have passed all necessary safety and quality tests.

Product Range: Check if the supplier has a wide range of products, so you can find all the chemicals you need from a single supplier, which can save you time and money.

Location: It is important to consider the location of the supplier, as this can affect delivery times and costs.

Environmental & Safety Consideration: Consider the supplier's environmental and safety policies, to ensure that the supplier is following the regulations and not impacting the environment negatively.

When researching potential suppliers, it is important to read reviews, check their websites, and ask for references from other businesses that have used their services. By thoroughly researching and comparing different chemical suppliers in Dubai and the UAE, you can make an informed decision and choose a supplier that meets your needs.

Key players in the chemical supplier market in Dubai and the UAE

Dubai and the UAE have a large number of chemical suppliers, but some stand out as key players in the market. Here are a few examples of major chemical suppliers in the region:

Al Rama International: Al Rama International Chemical Suppliers Company in Dubai, UAE. We are Specialized Chemicals Our Service Industrial Chemical, Cleaning Chemical, Oil field Chemical, Water treatment Chemical, Painting Chemical, Food Chemical, Mining Chemical, Construction Chemical, Power plant Chemical, Ceramic Chemical in Dubai, UAE. Al Rama has been a significant player in the G.C.C. & East African chemical trade, for over 20 years. We stock a wide variety of products ranging from food ingredients, oil exploration chemicals, sanitization chemicals, petroleum derivatives and industrial process raw materials. We possess extensive in-house expertise in blending and repacking of various products. Our facilities include open, closed ambient storage, as well as temperature-controlled storage. We operate our own fleet of road tankers, ISO tanks and pick-up trucks, to ensure full supply chain traceability.

Gulf Petrochem Group: Based in Dubai, Gulf Petrochem is a leading supplier of industrial and specialty chemicals in the region. They have a wide range of products, including petrochemicals, base oils, and lubricants. They also have a strong presence in the Africa, Asia, and Europe market.

National Chemical Corporation (NCC): NCC is a well-established chemical supplier based in Abu Dhabi. They have a wide range of products, including specialty chemicals, petrochemicals, and fertilizers. They also have a strong presence in the Africa, Asia, and Europe market.

Emirates National Chemical Industries (ENCI): ENCI is a leading chemical supplier based in Dubai. They have a wide range of products, including petrochemicals, specialty chemicals, and fertilizers. They also have a strong presence in the Africa, Asia, and Europe market.

These are just a few examples of major chemical suppliers in Dubai and the UAE. There are many other suppliers in the market, and it's important to research and compare different suppliers to find the one that best meets your needs.

Conclusion

In conclusion, chemical suppliers play a crucial role in the UAE and Dubai by supplying a wide range of chemicals to various industries. These industries include construction, manufacturing, oil and gas and specialty chemicals. When choosing a chemical supplier in Dubai, UAE, it is important to consider factors such as quality, price, customer service, certifications, product range, location and environmental & safety consideration. The key players in the chemical supplier market in Dubai and the UAE include Gulf Petrochem Group, National Chemical Corporation (NCC), Emirates National Chemical Industries (ENCI), and Al Rama International. By thoroughly researching and comparing different chemical suppliers in Dubai and the UAE, you can make an informed decision and choose a supplier that meets your needs and helps you to run your business efficiently.

#Chemical Suppliers#Industrial Chemicals#Cleaning Chemicals#Oil Field Chemicals#Bulk Chemicals#Water Treatment Chemicals#Painting Chemicals#Food Chemicals#Mining Chemicals#Construction Chemicals#Ceramic Chemicals#Powerplant Chemicals#Coil Cutting Service

2 notes

·

View notes

Text

You must fix your heart and you must build an altar where it swells

#my art#my chemical romance#ceramics#3d art#anatomical heart#art#plastic#mcr#gerard way#foundations of decay#sharp objects#ethel cain#hannibal#bones and all

156 notes

·

View notes

Text

428 notes

·

View notes

Text

we have a glaze at the studio- well actually two. two glazes that are meant to be blue. but every time someone else uses them they are green but when i use them they are perfectly fine and blue and im like what are yall DOING to make this happen.

#its the UGLIEST green too#i wonder if ppl dont mix it enough but it happened to rlly experienced artists and im like um#someone accidentally made purple also and im like huh#for context glazes are chemical mixtures and its not like ''add blue and red and get purple'' that other paints can do#and i have this issue explaining all the time to people who come in from classes to glaze when looking at the test tiles#where theyre like oh it will look like this? and im like actually no it might not#actually theres a really good chance it wont look at all like the test tile esp if its diff clay#sorry infodumping abt ceramic glaze i really like to do this

10 notes

·

View notes

Text

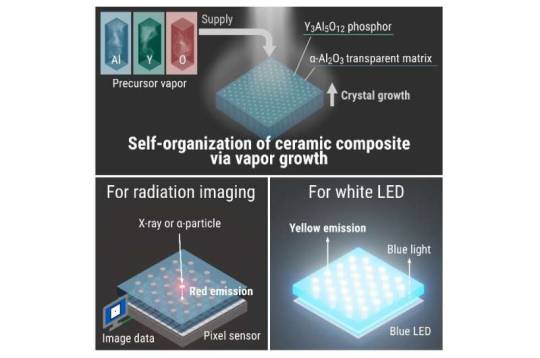

3D pattern generation via chemical vapor deposition of ceramic eutectic system for novel solid-state phosphors

The eutectic structure of metals and ceramics occurs when multiple solid phases solidify from a liquid phase, forming a three-dimensional (3D) pattern through a self-organizing phenomenon. Traditionally, it was believed that eutectic structures could only be obtained through a melt-solidification process.

Researchers at Yokohama National University (YNU) have developed a chemical vapor deposition (CVD) process that allows precursor gases to react and generate solid-state composites with ordered structures in a YAG (yttrium alumina garnet)-alumina ceramic eutectic system.

In their study, they observed the growth of spatially ordered rod- and lamellar-shaped YAG crystals within an alumina matrix on a sapphire wafer under Al-rich conditions. Conversely, under Y-rich conditions, they observed the growth of ordered alumina crystals with a YAG matrix. The choice of sapphire seed crystal and the composition of the precursor determined the 3D patterns. Compared with the melt-solidification process, the CVD process expanded the range of chemical compositions that could generate such patterns.

Read more.

#Materials Science#Science#Chemical vapor deposition#Ceramics#Phosphors#Eutectic#Phases#Yttrium alumina garnet#Yttrium#Alumina#Yokohama National University

14 notes

·

View notes

Text

killjoys, make some noise

na, na na, na na, na na, na na

put an "x" on the floor

gimme more, gimme more, gimme more

shut up and sing it with me

#my killjoys cup that came from a failed jar !!! she’s got lots of mistakes and quirks but i love her#toad.txt#mcr#my chemical romance#killjoys#mcr killjoys#pottery#handmade ceramics#clay sculpting#first time posting my pottery ahhhhh#.png

32 notes

·

View notes

Text

Emo owl </3

[image ids: six pictures of a small ceramic owl that seems to be wearing black eyeliner. It is pale gold or cream in color, with tiny spots of dark brown in the glaze. The owl has no wings or features except two tiny feet and its eyes; its head is marked only by an indentation in the smooth oval of the owl's body. The eyeliner on the left side of its face is heavily smudged and seems to drip down the owl's cheek.]

#lil smudgy makeup guy#he was fun to make#and has a good feel in my hand too#very solid and thick. good for playing with#the glaze is basically glass chemical-composition-wise so it's very very smooth#owl#ceramics#ceramic sculpture#clay sculpture#animal sculpture#rutile glaze#cone six#quarter for size comparison as usual!#unsold but reserved

47 notes

·

View notes

Text

Hey so I bought this mug a while ago cuz I really wanted one like in DS9 and they’re hard to find and kinda pricy online but I found this one at the antique store for like $7 so I got it and felt really awkward buying it but figured I could get the logo off somehow and then I would deepclean it and have a blue DS9 mug but so far nothing is taking the logo off besides like scratching it for a really long time but that’s super time consuming and I want to know if there’s a better, more chemical way to do this?

I’m not a fan of the NRA I just want a space mug🥲

Help

#star trek#DS9#ds9 mug#mug#space mug#why#how do I chemically remove logos off of ceramic/stone wear I don’t know anything about this#star trek deep space 9#raktajino mug#Klingon#coffee#help#advice

6 notes

·

View notes

Text

#Cladding Systems Market by Material (Ceramic#Wood#Brick & Stone#Vinyl#Stucco & EIFS#Metal#Fiber Cement)#Use#Application (Residential#Non-Residential)#and Region (North America#Europe#APAC#MEA#South America) - Global Forecast to 2026#According to a research report published by MarketsandMarkets#the cladding systems market is projected to grow from USD 234.1 billion in 2021 to USD 306.9 billion by 2026#at a CAGR of 5.6% from 2021 to 2026. Cladding systems market is expected to grow in accordance to the growth of construction industry acros#along with the demand for durability of cladding systems with the ability to withstand various weathering actions and resist chemical attac#Ceramic is mainly used for tile cladding#hence play an important role in the construction industry. The ceramic tiles enhance the overall atmosphere of a residential or commercial#durability#comfort#safety#style#and design templates. Foot traffic plays an important role in the selection of the type of ceramic tiles. The wall tiles are employed in th#restaurants#medical centers#shopping centers#schools

8 notes

·

View notes

Text

Ceramic Raw Material for tiles and sanitarywares, Ceramic India

Ceramic Raw Material for tiles and sanitarywares, Ceramic India

Mouldtech Industries

Ceramic Raw Material, Ceramic Machinery Spare & Parts, Raw Material & Chemicals, Ceramic Roller & Grinding Media, China Clay, Digital Ink, Ceramic Color, Frit & Zinc Oxide, Refractories, Feldspar (Soda & Potash), Quartz, ceramic india

#ceramic#raw#materials#machinery#spareparts#chemical#roller#grinding#chinaclay#digitalink#color#frit#zincoxide#refractory#feldspar#sodapotash#tiles#sanitarywares#india#morbi#gujarat

0 notes

Link

#Chemical Suppliers#Industrial Chemicals#Cleaning Chemicals#Oil Field Chemicals#Bulk Chemicals#Water Treatment Chemicals#Painting Chemicals#Food Chemicals#Mining Chemicals#Construction Chemicals#Ceramic Chemicals#Powerplant Chemicals#Coil Cutting Service

1 note

·

View note

Text

Examining lunar soil for moon-based construction - Technology Org

New Post has been published on https://thedigitalinsider.com/examining-lunar-soil-for-moon-based-construction-technology-org/

Examining lunar soil for moon-based construction - Technology Org

Most people are familiar with the iconic photograph of astronaut Buzz Aldrin’s boot print on the moon’s surface. But what, exactly, is in the soil that holds the imprint of that famously “small step for man”?

Sample of a lunar soil simulant in Steven Jacobsen’s laboratory. Illustration by Shane Collins

The answer to this question is more than a fleeting curiosity — it’s essential knowledge for NASA’s Artemis program, which aims to build a permanent base on the moon. While researchers understand the general makeup of the lunar soil, Northwestern University mineralogist Steven Jacobsen has received funding from NASA’s Marshall Space Flight Center to unravel the mystery of the dubious dust further.

Because the cost of bringing traditional building materials from Earth is incredibly high, NASA has partnered with robotics and artificial intelligence company ICON Technology Inc. to explore new methods for building a lunar outpost using the moon’s own resources. But before ICON can build structures with the moon’s soil, the team must first understand the soil’s exact composition, which can change drastically from one sample to the next.

To characterize these samples, Jacobsen is working closely with his former student Katie Koube, now a materials scientist at ICON, to analyze various samples using Northwestern’s facilities. Their end goal is to create a library of potential sample compositions, which will be used to optimize parameters for the building process.

“Off-world construction comes with many challenges,” said Jacobsen, the project’s principal investigator. “The moon’s soil is not like that on Earth. On the moon, soil is formed from meteoroid impacts that have crushed the surface. So, the moon is essentially coated in a thick layer of pulverized flour. The types of minerals and glass found in lunar soil depend on many factors. The material can vary widely within even a small area.”

Jacobsen is a professor of Earth and planetary sciences at Northwestern’s Weinberg College of Arts and Sciences. He also is a faculty affiliate with the Paula M. Trienens Institute for Sustainability and Energy and the Center for Engineering Sustainability and Resilience. Members of the project also include Laura Gardner and Tirzah Abbott, who are Ph.D. candidates in Jacobsen’s lab.

The dangers of dust

With plans to travel back and forth to the moon more regularly, NASA first needs a reliable landing pad. Otherwise, every time a lunar lander makes contact with the moon’s surface, it will kick up destructive dust that could gum up equipment and damage the surrounding habitat.

“Each particle of dust on the moon is jagged and angular,” Koube said. “When you think of grains of sand on Earth, they are rounded because weathering removes all those rough edges. Without weathering, the particles remain bumpy and sharp. So, if a rocket lands directly on the moon’s surface, it stirs up abrasive dust that basically sandblasts the whole area.”

In November 2022, NASA selected ICON for a $57.2 million grant to develop lunar construction technology. The contract builds upon previous NASA and Department of Defense funding for ICON’s Project Olympus to research and develop space-based construction systems to support planned exploration of the moon and beyond. ICON’s Olympus system is intended to be a multipurpose construction system primarily using local lunar and Martian resources as building materials to further the efforts of NASA as well as commercial organizations to establish a sustained lunar presence. ICON is already using its advanced 3D-printing technology to build homes on Earth. By putting multipurpose in situ resource utilization (ISRU)-based lunar construction systems on the moon, the team aims to use lunar resources as the building blocks for construction.

“It’s not feasible to send traditional Earth-based construction equipment and materials to the moon,” Jacobsen said. “The payload would be too heavy. So, this plan is a lot more practical. Just as the first bricks on Earth were made out of terrestrial soil, the first bricks on the moon will be made out of lunar soil.”

Simulated soil samples

After ICON received NASA’s funding, Koube, who graduated with a dual degree from Northwestern’s materials science and Earth and planetary sciences programs in 2014, contacted Jacobsen to lead sample analysis. The pair assembled a team that works with NASA’s Marshall Space Flight Center in Huntsville, Alabama, under the Space Technology Mission Directorate’s Moon to Mars Planetary Autonomous Construction Technologies (MMPACT) project.

At Northwestern, analysis is already underway. Gardner and Abbott currently are using various microscopy techniques to analyze eight lunar simulants — faux moon soil that is designed to mimic the real thing — and synthetic plagioclase, a brittle, greyish-white mineral that is a major constituent of moon rock. Then, the team will compare the lunar simulants to actual samples collected from the Apollo missions.

“Of course, we know from Apollo missions what’s in lunar dirt — and that it’s very heterogenous (or variable),” Jacobsen said. “Our job is to anticipate the likely variability in lunar soil and come up with a way to measure it on the fly, onboard the 3D printer.”

So far, the researchers have noticed vast differences among the lunar simulants. In some minerals, the team has detected hydrogen — a component of water, which is not abundant in minerals on the moon. They also are on the lookout for mineral impurities in the simulants that are not expected on the lunar surface. The team can then focus on materials and chemical variations that the construction processes are more likely to encounter.

No scoop is the same

After determining variability in realistic samples, the researchers will probe how the composition of dirt can affect the melting process used in robotic construction. Once on the moon, ICON’s multi-purpose ISRU-based lunar construction systems will scoop up lunar soil and melt it for printing. After printing, the melted dirt will harden and cool into a ceramic material.

“On Earth, you can gather clay and fire it in a kiln to make ceramics,” Jacobsen said. “But the properties of lunar soil are such that it needs to be melted first. Different minerals in lunar dirt melt at different rates, so the 3D-printing process is very sensitive to changes in mineralogy.”

And, of course, no sample is the same. One scoop of lunar dirt might have a different melting point than the next scoop. The 3D-printing technology needs to be nimble enough to know how to handle these subtle differences. That’s where Jacobsen’s sample library comes into play. By enabling the 3D printer to be prepared for all potential compositions, it can perform diagnostics of each scoop and then adjust its laser parameters for heating and cooling.

“Without understanding the characteristics of the soil, it’s difficult to understand the variability of the final printed materials,” Jacobsen said. “Using the library that we create from simulants — cross-checked against the lunar soil — the printer will know how to process each piece to produce the best ceramic. That detailed library of information will play a part in making the imagined outpost a reality.”

Source: Northwestern University

You can offer your link to a page which is relevant to the topic of this post.

#2022#3d#Analysis#Angular#Artemis Program#artificial#Artificial Intelligence#Arts#Astronomy news#Building#ceramics#change#chemical#college#Composition#construction#cooling#course#curiosity#defense#diagnostics#dust#earth#energy#engineering#equipment#Facilities#Faculty#flight#focus

0 notes

Text

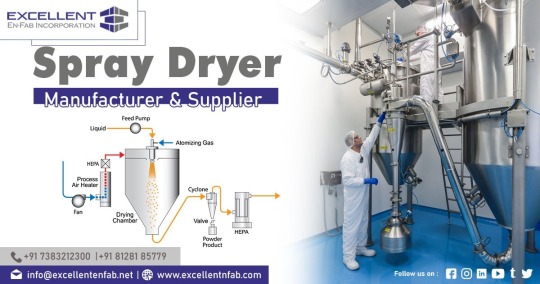

Exporter of Spray Dryer in Sri Lanka

Exporter of Spray Dryer in Sri Lanka:

Company Overview:

Excellent En-Fab Incorporation, operating since 2010, is a Manufacturer, Exporter, and Supplier of Spray Dryer.

Their product range includes AAC Block Plant, Flash Dryer, Dry Mix Mortar Plant, Storage Equipments, Autoclave, Rotary Dryer/Kiln, Wall Putty Plant, Spray Dryer, Agro Waste Pyrolysis Plant, Hot Air Generators, Spin Flash Dryer, and more.

Specializes in manufacturing premium-quality spray dryers in India, meeting international standards.

Offers various types of spray dryers customized to meet individual customer needs.

Utilizes hot air to swiftly dry atomized liquid feedstock into fine droplets, producing dry particles or powders ready for subsequent processing or packaging.

Offers spray dryers in different configurations, including nozzle atomizers, rotary atomizers, and fluidized bed dryers, designed to suit specific applications and accommodate diverse requirements.

Features:

A high aspirator rate reduces the product’s remaining moisture.

Excellent results are achieved when temperature and other parameters are properly controlled.

Minimum maintenance is required for a long working life.

Long-term dependability guaranteed.

Continuous drying methods enable faster production while maintaining and managing product quality.

Application:

Food Industry

Pharmaceuticals

Chemicals

Ceramics

Export Focus:

Excellent En-Fab Incorporation Exporter of Spray Dryer in Sri Lanka, covering regions such as Colombo, Moratuwa, Dehiwala-Mount Lavinia, Jaffna, Negombo, Sri Jayawardenepura, Kalmunai, Kandy, Vavuniya, and others.

Interested parties are encouraged to contact the company for further details and inquiries.

Read the full article

#AACBlockPlant#Agrowastepyrolysisplant#Autoclave#Ceramics#chemicals#Colombo#Dehiwala-MountLavinia#DryMixMortarPlant#Exporter#ExporterofSprayDryerinSriLanka#FlashDryer#FoodIndustry#HotAirGenerators#Jaffna#Kalmunai#Kandy#Long-termdependability#Manufacturer#ManufacturerofSprayDryer#Minimummaintenance#Moratuwa#Negombo#properlycontrolled#RotaryDryer/kiln#SpinFlashDryer#SprayDryer#SprayDryerinSriLanka#SriJayawardenepura#SriLanka#StorageEquipments

0 notes

Text

Parylene Conformal Coating Process & Services

Parylene conformal coating process is a critical step in ensuring the longevity and performance of electronic components. At Dawntechsb, we specialize in providing top-notch Parylene Coating Process services to protect your devices from environmental factors such as moisture, chemicals, and temperature fluctuations. Our team of experts is well-versed in the intricacies of the coating process, ensuring a flawless application every time. Trust Dawntechsb to safeguard your electronics with our superior Parylene coating services.

#coatings chemicals suppliers#parylene coating in malaysia#parylene af4 polymer#parylene coating process#conventional coating suppliers#nano ceramic coatings manufacturer

0 notes

Text

Thermal Ceramic Market, valued at USD 4.2 Billion in 2022, is projected to surpass USD 7.4 Billion by 2032, indicating a robust CAGR of 5.9%

0 notes

Text

Our Brass Viscosity Cup (B4, B6) - is the perfect tool for measuring the viscosity of your liquids with precision and ease! Made from high-quality brass, this cup is durable and built to last. Its simple design allows for quick and accurate readings, making it an essential tool For any Laboratory, Industries, paints industries, Chemical, Ceramic Industries, lab or workshop.

#viscositycup#precision#measurement#labtools#workshopessentials#Laboratory#Industries#paintsindustries#paint#Chemical#ChemicalIndustrie#CeramicIndustries#Ceramic

0 notes