#sheet cutting machine

Text

#SLTL Group#Laser Experts#Laser cutting Machine#sheet cutting machine#fiber laser cutting machine#cnc laser cutting machine#Imtex 24

0 notes

Text

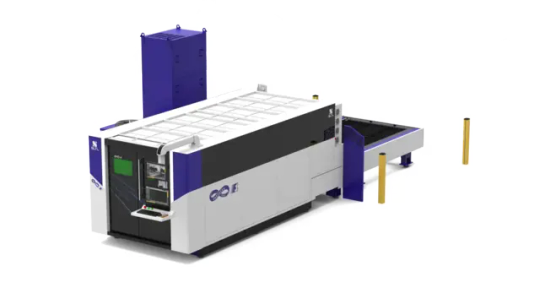

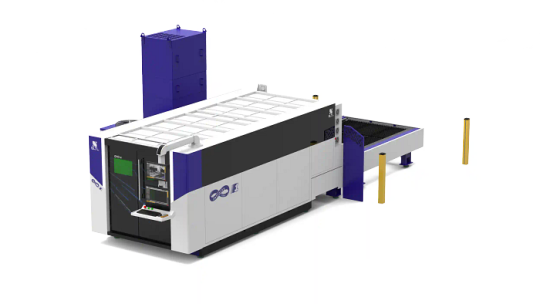

Beyond Limits: Unveiling the Might of High-Power Lasers on 40mm Metal Sheets

Exploring the Capabilities of up to 30KW Laser Cutting Machines and the Advantages of SLTL Infinity Metal Cutting Laser Machine

The world of metal fabrication is undergoing a transformative phase, powered by cutting-edge technology that pushes the boundaries of what was once considered impossible. We delve into the awe-inspiring domain of high-power lasers, where up to 30KW laser cutting machines take center stage. The spotlight is on the remarkable SLTL Infinity Metal Cutting Laser Machine, a marvel that defies limits and sets new standards in precision and efficiency.

1. Laser Precision: A Glimpse into the Future

The introduction of high-power lasers in metal cutting has been a game-changer, revolutionizing an industry that has long grappled with the challenges of cutting thick metal sheets. With the capability to slice through 40mm metal sheets like a hot knife through butter, the technology raises questions that intrigue and inspire.

2. The Power of 30KW Laser Cutting Machines

"30KW Laser Cutting: Redefining Metal Fabrication"

The 30KW laser cutting machines represent a monumental leap in the world of engineering. Imagine harnessing energy equivalent to the powerhouses that fuel entire cities, all focused onto a precise beam that can carve through metal with surgical precision. This level of power is not just about might; it's about rewriting the rules of metal fabrication.

3. The Star of the Show: SLTL Infinity Metal Cutting Laser Machine

"Infinite Potential: Unraveling the Features of SLTL Infinity"

Amidst the universe of high-power lasers, the SLTL Infinity Metal Cutting Laser Machine stands out as a testament to human ingenuity. Designed to handle the toughest challenges, its adaptive controls and state-of-the-art technology redefine what's achievable in metal cutting. The machine's versatility shines as it seamlessly transitions from intricate designs to slicing through 40mm metal sheets.

4. Advantages That Illuminate Possibilities

"Cutting through Advantages: Illuminating the Benefits of SLTL Infinity"

The advantages offered by the SLTL Infinity are a beacon for industries seeking innovation and efficiency. The machine's ability to maintain precision across varying metal types, reduced heat-affected zones, and minimal post-processing are advantages that not only streamline production but also raise the quality bar.

5. Beyond Metal Cutting: Expanding Horizons

"Expanding Boundaries: Beyond Metal Cutting with SLTL Infinity"

While the primary focus is metal cutting, the impact of the SLTL Infinity transcends this singular domain. It has the potential to shape industries that rely on intricate metalwork, from automotive to aerospace. The machine's capabilities become a catalyst for imagination and innovation, propelling industries into uncharted territory.

Conclusion: Carving a New Era in Metal Fabrication

As we conclude this journey through the realms of high-power lasers and the remarkable SLTL Infinity Metal Cutting Laser Machine, the answers to the questions posed at the beginning become evident. The boundaries of what can be achieved with metal cutting have expanded beyond our wildest dreams. The synergy of human ingenuity and technological prowess has birthed a new era where 40mm metal sheets are no longer obstacles but opportunities.

In the world of metal fabrication, limits are no longer barriers; they are merely indicators of what can be surpassed. As we embrace the capabilities of the SLTL Infinity, we are ushered into a future where innovation is boundless, and metal is shaped not just by machines, but by the audacity of human imagination.

In this journey of innovation, the SLTL Infinity Metal Cutting Laser Machine is not just a tool; it's an emblem of progress and a tribute to human determination to reach beyond the confines of what was once considered feasible.

#SLTL Infinity#cnc laser cutting machine#sheet cutting machine#metal cutting machine#fiber laser cutter

0 notes

Text

Cult of the Lamb Mini - Demon Sticker sheet I made (+ Nari & Lamb because I felt like the sheet had too much empty space so they're mini stickers too) And our girl Heket🐸

Made for Patreons for April. These will be available on my KoFi shop soon maybe >.>

#i really like how the demon sticker sheet came out#my sticker cutting machine also has an easier time cutting it out than some other designs so its a double win#doodles#cult of the lamb#cotl narinder#cotl lamb#cotl heket#cotl demons#sticker stuff

937 notes

·

View notes

Text

Sheet Cutting Machine - Pathak Machine tools - Howrah, Kolkata

We "Pathak Machine Tools Pvt. Ltd." are supplying a wide array of Sheet Cutting Machine that is developed and designed by our engineering team with the best quality raw materials as per industrial norms. We are the most reliable Sheet Cutting Machine Manufacturers in India.

#Sheet Cutting Machine#Sheet Cutting Machine Manufacturers#Sheet Cutting Machine Suppliers#Sheet Cutting Machine exporters#Sheet Cutting Machine Manufacturers in India#Sheet Cutting Machine Suppliers in India#Sheet Cutting Machine Exporters in India

0 notes

Note

do you have any advice for making stickers? your designs are all so pretty!!

ahh thank u sm!! yessir here's some tips i keep in mind when i design/make stickers (mostly from the perspective of someone selling stickers but these can be for personal sticker making too):

design:

try to use the same brush size/type if youd like all of your stickers to look similar. i personally have two i like to alternate between whether I'd like a smooth vs sketch look

also try to use the same size canvas if youre gonna make a lot of 3 inch stickers or 4x6 in sticker sheets (for example) to keep everything looking consistent

find artists you're inspired by and that'll be very helpful to avoid art block. for me, i adore artists who have similar taste and it helps me feel so happy and inspired to make my own art.

people like stickers that are all kinda the same vibe! i like to design stickers that are cute and vibrant and either feature characters i like or aesthetics i like. you gotta like what you make! (they dont all have to have the exact same vibe of course. but ive found that people will like getting all my cute fandom stickers bc they look like they all go together for example)

printing:

if youre cutting these out yourself, rotate the paper, not the scissors for better control. take breaks too! you don't wanna strain your hand! also its worth it to have big girl scissors (i am a big girl with big girl scissors btw ahahaha)

if youre using a cricut or silhouette machine to cut, please consider making all of your stickers easy peel (basically making the sticker its own mini sticker sheet so you remove the outer border so it's easier to peel) because this helps make sure that people from many backgrounds and lives can enjoy your work! It would break my heart to find that someone who has joint pain, for example, can't use the stickers they bought from me because they're too difficult to peel. (If you're hand cutting your stickers, I have no idea how you'd do this so don't worry! Maybe in the future if you decide to invest in a machine, this is something to think about)

if you're using a cutting machine, yes it will take up a lot of time and supplies running tests to see what works with your stickers! and yes you will have to readjust how you do things with the life cycle of the machine's blades. augh........ such a hassle sdjfhksd

when printing for the first time, you may need to spend time running tests and adjusting the colors. some printers need help with the vibrancy and stuff!

when printing your stickers, please only have a few pages loaded in your printer if you're still testing (or in general! i have my paper loaded in one at a time JUST in case I forgot a setting)

if you're printing at a print shop, make sure your file is PDF and that they're printing "actual size" bc otherwise it may change. this would be bad especially if you're planning on using your machine to cut later.

i personally would not recommend ordering your first several stickers outsourced bc you may end up with stock that never sells.

i hope these helped! some may not apply bc theyre for like,,, a sticker biz but maybe someone out there wants this info too :3 ill leave my current supply list in the tags so i can change it if i find that something changes and i dont wanna recommend it anymore

basically read op tags for recommendations :3

#sticker paper (not waterproof) : online labels OL177WX#vinyl sticker paper: koala matte sticker paper#lamination (glossy) : Avery 73601 Self-Adhesive Laminating Sheets#lamination (sparkly): idk theyre like... star style sparkly lamination sheets?? i got em on amazon!#cutting machine: cricut maker (i get so frustrated with this machine tbh once you wrangle your beast its fine tho)#printer: canon pixma g7020 (i LOVE THIS THING...... i understand you lady redundant woman.......)#drawing software: procreate on my ipad 7th gen & 1st gen apple pencil (you could use anything tbh i just like having a stabilizer)#editing software: photoshop (for color editing and placement editing and adding text mostly... this comes in handy with my sticker sheets!)#and if you wanna buy any of this stuff and help support me lemme give you an amazon affiliate link!!! it doesnt cost anything extra and-#amazon has to give me some sweet sweet cash for it#i promise ill be responsible with that money like going to whataburger everyday for a week >:3c#jk jk it would go toward po box costs! its so expensive waaahhhh#djsadbean answers#stickers resource#artist resource#faq

25 notes

·

View notes

Note

Please please tell me about printers, I would like to know <b>everything</b>

You asked for it /lh

Ok so some clarification: I spent three years at Staples working with a Xerox C70 color laser printer, so that's where my "expertise" lies.

FIRST OFF - DO NOT EVER GET YOUR PHOTOS PRINTED AT A STAPLES/OFFICE MAX/FEDEX/UPS/ANY OTHER OFFICE STORE!!!!!

All office stores (that I have been to) use laser printers. Laser printers are high capacity (meaning they can print loads of stuff before the toner needs to be changed), and use toner, which is a powder version of the ink that is electrically fixed and baked onto the paper. (Forgive the oversimplification) This means that the color will not soak into the paper/past the coating if there is one. So, if you want a glossy photo printed, you will literally be baking the color over top of the gloss, and the color will not be glossy. It will be ugly. I've made like at least 300 family photos and other shit on a laser printer. Don't do it.

Sometimes you can play with the printer settings (the Xerox C70 has pretty in-depth settings because obv it's for office printing) and you can set the color load to be "glossy" but that really just means a thicker layer of toner. It's a little shinier but not glossy.

Also, laser printers just can't get that tight, crisp color quality that an inkjet can. So many people came in wanting to make their Christmas cards with these ultra high quality photos and wanted them cheap and same-day, and then would complain that they were "fuzzy". Personally, I always thought they looked fine, but white suburban mom Karens complained all the damn time about the "fuzziness" of their fancy professional photos. Inkjet can get the crisp, sharp lines that you see in digital photos and art, whereas the toner, being powder based, just can't quite get it.

ALSO also! The colors on your computer screen will always be a little brighter and nicer than what comes out of the printer! That is because your computer is back lit, it's shining light at your eyes. Paper cannot do that, so sometimes the colors look a little "dark" or "muddy". Personally, I've seen this with really light lavender, beige, and cyan the worst. Combine this with the more limited scope of color mixing with a laser printer, and sometimes you get weird ass colors coming out. If you have a specific idea for your colors, inkjet is the better bet.

Tldr: get your photos printed at Walgreens or Walmart, or send them somewhere that specializes in photo printing.

There are two main categories of printers, Laser and Inkjet. You have an inkjet if you have a printer in your home.

Inkjet printers have the liquid ink in the cartridge, that's why you have to wait a little bit before it dries, especially for specialty papers or really old printers. The liquid ink can soak into the paper/through the coating, so that's where you get the nice glossy photo prints. ((You can also buy sheets of primed canvas for inkjet printers, which is super cool and I definitely have a bunch of it for some of my favorite digital artworks from friends)).

Ink can come in two types - dye based and pigment based. You have dye based ink if you have a printer at home. Pigment based inkjet is for like,,, the top of the top art printing. It's expensive as hell, but it doesn't fade from light exposure, like dye ink can. (Don't worry, the things you print at home are not likely to fade very much, unless you have them in direct light and never turn the lights off. I have seen photos fade because of light exposure, but that's because Staples never turns any of the lights off for whatever reason, and we had printed pictures using the poster printer to get the nice gloss without realizing.) Pigment based is also apparently a powder, but I'll be honest I don't know how it's fixed to the paper. I assume heat as well. (I've never gotten to work with a pigment printer, I only know about them because I was looking for good printers to print art and found out about them, then I saw the price tag and was like lolol)

When buying specialty paper to print on (like photo paper or canvas), you need to check the label!!!! There are papers designed for laser printers that can withstand the heat and accept the toner, and there are papers designed for inkjet that can hold the liquid ink as it soaks through. The coating on an inkjet safe paper is not as heat resistant as ones made for laser. If you put it in the laser printer, the coating will melt, and you will ruin the internal machinery. I have seen it happen. Don't do it.

Speaking of specialty paper! Have you ever heard of pearlized paper??? It's my favorite paper!!! It's sparkly!!!! 😍

Pearlized paper is typically for laser printing; I've tried to print on it with an inkjet but it came out looking really weird. It's shimmery without having chunky glitter on top that will fall off and go everywhere. Go to your local Staples and ask if they have pearlized paper, just to look at. Pictures can't do it justice. (My business cards for my fairies are printed on soft pearl, which is ivory colored, because I printed and made them myself so I got to do what I wanted /lh) We mainly used it for weddings and stuff, but I recommended for all kinds of stuff because I thought it was so cool.

Other papers: the two main types of paper you will work with at home are regular paper and cardstock. Cardstock just means thick. Both can come in tons of cool colors and textures (linen texture is my personal favorite, you usually buy it as 'resume' or 'business' paper.) you know how thick a piece of paper is by its "weight" which is measured in pounds. I don't know why it's measured in pounds, it just is.

If you want a nice quality paper to print on that's still flexible and foldable, you want to look for something that's 24-30lbs. Typical cheap copier paper is 20lbs, and a lot of the time you can see through it, i.e. if you print something double sided you'll be able to see a little of the text on the back showing through. I have found that 24lbs is thin enough to be more affordable (per ream), but thick enough to not have the bleed through. We had a 32lb paper that was thick nice thickness and super smooth, and we called it "ultra premium". It was nice, but I wouldn't print like flyers and stuff on it. I did a lot of booklets with that one.

If you're gonna get a cardstock, get something 60~lbs and up. 65lb is a really good thickness if you're printing coloring pages because it soaks up the marker ink and holds it nicely. Use 100lb if you're making a coloring *book* that's going to be double sided.

Cardstock cannot be machine folded without a really heavy duty machine, and it's very annoying because those machines are usually at the high-volume production centers and not in-house, so customers complain that they have to wait for their booklets. >.>

When working with business cards, post cards, and the like, you will hear about "bleed area" or "print to bleed". That just means whether or not the ink can go all the way to the very edge of whatever is being printed. When you design a business card or other card to be printed, you will typically have a bleed area, where you want the background to go a little farther than the actual size of the card to allow for cutting, but you want to keep any important text or photos to a certain area so it doesn't accidentally get cut off. The bleed area is not a negotiation. If you don't have space for the bleed, something will get cut off.

At Staples, our business cards were 2x3.5 inches, but the designs had to be about 2.25x3.75 to allow for bleed. The number of times I had to go in and manually fix some idiot's card because they didn't understand what a bleed was is absolutely absurd.

You can get full page size (8.5x11) printed to bleed, for things like flyers with special borders and letter heads, but those also require specialized printers that are at the production facility. The number of people who outright refused to understand this was also absurd. If you have a printer at home, there is a 99.99% chance it is not able to print to bleed for a full 8.5x11, and that's why you still have a white edge if you try to print something that is supposed to have color all the way to the edge of the paper.

My final bit of advice before I end my rant: when you're financially independent and able to/want to buy your own printer, if you plan on making your own art prints to sell, do NOT get an HP printer. HP is fine for general use, it prints well and it's pretty ink-efficient, but it's just not got the super fine quality. Brother and Canon are the two brands I personally recommend for art and photography; they're more expensive but they have a really nice quality of printing. I had to do a lot of training for HP printers and computers, and it's a lot of big words that mean very little in the grand scheme of things.

#warcats answers#ranting about printers#new friend#toaster friend#i hated management at staples#but if i owned my own xerox c70 i would be unstoppable#i didnt even go into printing settings and all the weird shit you can do there#gangup printing! double sided half-sheet-size books!!#alignment and how it affects paper weight#all the other little machines we had#i have a spiral binding hole punch on my Christmas wishlist#ream cutter that can cut 100 sheets of paper in half in three seconds#the poster printer in general#lamination#copying#faxing#types of bindings#i have to stop myself lol#those topics can be for some other day#thank you for the question 💜#it really perked up my day 💜

3 notes

·

View notes

Text

here's my knitting machine life hack: if you are using a die cutting machine to make your punch cards (eg. a cricut) don't bother with those plastic binder dividers from the dollar tree. what you wanna do is get a roll of cake acetate online. just get one wide enough for your machine (measure how wide your punch card reader is, get a roll at LEAST that wide) and bam. now you can cut a punch card as long as your little heart desires with NO need to tape multiple binder sheets together. just trim the acetate to the length you need.

the cake acetate is a little thicker than the binder dividers, so the finished cards are a little sturdier too. but it also means you may have to trial and error your cut settings to get them to cut all the way through. i have no advice for you here, every machine and acetate brand is a little different.

#all my punch cards are cake acetate cards#except for a few i cut on binder plastic BEFORE i realized most of the designs i wanted were longer than the binder sheet#but i mostly have lace cards and lace cards tend to be a little longer bc there are ~4+ rows of punched card#for every 2 rows of knitted fabric#machine knitting#knitting machine

7 notes

·

View notes

Text

figuring out to use my sticker cutting machine means i can get back into making stickers!! it was one of my favourite things to design but i dont have the capabilities to sit down and cut out hundreds of stickers by hand anymore,, 15/16 year old me was strong but 20 year old me wants to have a healthy wrist

#genuinely so excited!!!#ive loved designing stickers#my uni has a sticker cutting machine but it ONLY does kisscut and the ink sits on top of the paper meaning the design just scratches off#and i do not like outsourcing my stickers bc i like beign able to play around with sizes/textures/effects#currently running tests with my snufmin sticker#ill be able to do sticker sheets now too!! and put them up on etsy!!#ive avoided putting individual stickers on etsy simply bc theyre not super profitable but i might do a like?? build ur own set??#sorry to talk so much about product making/etsy but ive a market soon so its On The Mind

6 notes

·

View notes

Video

youtube

Auto CNC Groove Lathe Machine for PEM Hex Blind Standoff Self Clinching Rivet Nut Cabinet Metal Sheet Fasteners.

Whatsapp: +86 13431255254

#youtube#CNC Lathe machine#groove cutting machine#self clinching rivet nut#standoff rivet nut machine#cold forging#standoff rivet nut groove cutting machine#hex blind rivet nut#fasteners#auto cnc lathe machine#metal sheet rivet nut#rivet nut manufacturer#rivet nut supplier#self clinching rivet nut price#standoff self clinching nut#cnc machine#groove cutting machine supplier

2 notes

·

View notes

Text

utterly enthralled by short tiktok-esque videos of professional jewelers carefully, precisely, and obviously with a lot of love creating from scratch the most god awful ugly gaudy rings

#its just SO funny#bc it starts out and its like 'oh wow theyre like melting the metal from scratch to create a sheet. like. this is really involved'#and then the end result is the ugliest fucking thing youve ever seen#and its like. a fucking platinum huge brilliant cut diamond absolutely COVERED in diamonds#like! its expensive as hell!! its not a lil jeweler doing it as a hobby lmao!!!!!!!!!!!#its a lot of fucking money and it looks like it came from a gumball machine!!!!!!

3 notes

·

View notes

Text

https://ceslasermachine.com/sheet-plus-tube-pipe-laser-cutting-machine/

Sheet Plus is a leading supplier of modern tube laser cutting machines, specializing in high-precision and more proficient solutions for various industries. Their advanced machines are designed to handle complex cutting tasks with ease, giving superior accuracy and speed. Sheet Plus stands out for their commitment to standard, innovative technology, and exceptional customer service, making them a top choice for businesses seeking loyal and less expensive tube laser cutting solutions

#Pipe Laser Cutting Machine Suppliers#Single pallet laser cutting machine Manufacturer#Laser welding machine#Double laser cutting machines#Sheet Plus tube laser cutting machine suppliers

0 notes

Text

CNC Shearing Machine: The Cutting-Edge of Precision Metalwork

Designed for durability, accuracy, and efficiency in industrial metalworking applications, our state-of-the-art CNC Shearing Machine can produce faultless cuts.

0 notes

Text

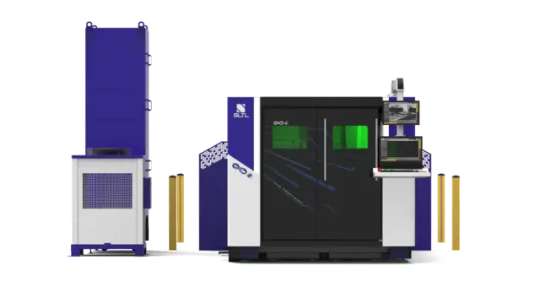

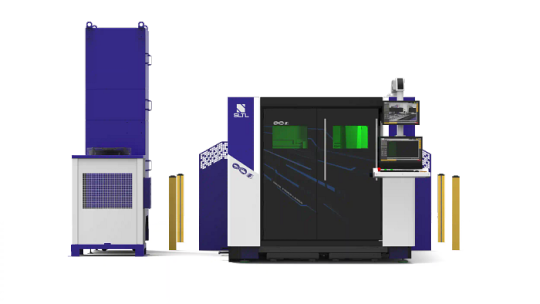

Cutting Through Boundaries: How High Power Fiber Lasers Are Reshaping the Metal Fabrication Industry

Innovation and technology continue to reshape the landscape of metal manufacturing. One such innovation that has been causing a significant stir is the emergence of high-power fiber lasers. These cutting-edge tools are revolutionizing the metal fabrication industry, pushing the boundaries of what was once thought possible. We’ll look at high-power fiber lasers and how they’re changing the metal fabrication business, with an emphasis on the SLTL Laser Cutting Machine — Infinity F1 and other cutting-edge laser technologies.

youtube

Unveiling the Power of High-Power Fiber Lasers

High-power fiber lasers have become the gold standard in precision cutting and welding. Unlike traditional CO2 lasers, fiber lasers utilize optical fibers as their gain medium, allowing for a more concentrated, intense beam of light. This concentrated beam results in superior precision and efficiency in metal laser cutting machine, making it a game-changer for various industries.

The Advantages of Fiber Lasers

Unmatched Precision: Fiber lasers offer an exceptional level of precision, enabling manufacturers to achieve intricate cuts and designs that were once considered too complex. This level of accuracy reduces material waste and rework, ultimately saving time and resources.

Speed and Efficiency: The concentrated beam of fiber lasers translates to faster cutting speeds. This efficiency is crucial in meeting tight production deadlines and handling large-scale projects without compromising quality.

Versatility: High-power fiber lasers can effectively cut a wide range of materials, from metals like Mild steel, Stainless steel, Aluminum, Brass, Copper, Galvanized Iron, Coated Sheet, Others. This versatility opens up new possibilities for manufacturers across different industries.

Cost Savings: While the initial investment in fiber laser technology might be higher, the long-term cost savings are substantial. The combination of reduced material waste, energy efficiency, and minimal maintenance leads to a more cost-effective operation.

The SLTL Laser Cutting Machine — Infinity F1: Redefining Metal Fabrication

Unparalleled Precision and Speed

The Infinity F1 boasts a cutting-edge design that maximizes precision and speed. With its high-power fiber laser source, it can effortlessly handle intricate designs and complex cuts, all while maintaining exceptional accuracy. This makes it a sought-after tool for industries requiring intricate components and high-volume production.

Smart and Intuitive Operation

The machine’s user-friendly interface and software make it accessible to both experienced operators and newcomers. Its intuitive controls allow for easy customization and quick setup, reducing downtime between tasks. This ensures a seamless workflow and optimal utilization of resources.

Adaptable to Diverse Materials

One of the standout features of the Infinity F1 is its ability to cut a wide variety of materials with precision. Whether it’s thin sheets of metal or thicker materials, this machine can handle the task effectively, making it a versatile asset for businesses dealing with diverse materials.

Exploring Laser Cutting Possibilities

Fiber Laser Cutter

Fiber laser cutters, in general, are becoming synonymous with efficiency and accuracy. Their solid-state design, absence of moving parts, and minimal maintenance make them an attractive choice for businesses looking to optimize their operations.

CNC Cutting Technology

Computer Numerical Control (CNC) technology has taken laser cutting to new heights. The precision and automation offered by CNC laser cutting machines enhance productivity and reduce human error, leading to consistent, high-quality output.

High Power Laser Cutter: Pushing the Limits

High-power laser cutters, such as the Infinity F1, demonstrate the potential of pushing laser technology to its limits. With power ratings of up to 60 KW, these machines can tackle thick materials and achieve remarkable speeds without compromising precision.

Embracing the Future: The Impact and Beyond

The integration of high-power fiber lasers into the metal fabrication industry is not just a technological leap; it’s a paradigm shift. As these tools continue to evolve, we can expect even greater precision, faster speeds, and expanded material capabilities. However, as with any advancement, questions arise.

What Lies Ahead for Traditional Methods?

The rise of high-power fiber lasers prompts us to question the relevance of traditional cutting methods. While they may not become obsolete, their limitations are more apparent, pushing industries to consider upgrading their equipment to stay competitive.

Balancing Automation and Craftsmanship

As automation becomes more prevalent, there’s a concern about the loss of craftsmanship. Striking a balance between automated precision and the artistic touch of skilled craftsmen will be a challenge the industry must navigate.

Environmental Considerations

With greater power comes increased energy consumption. The industry must address the environmental impact of high-power fiber lasers and work towards sustainable solutions without compromising productivity.

Conclusion: Shaping the Future of Metal Fabrication

In conclusion, the advent of high-power fiber lasers, exemplified by the SLTL Laser Cutting Machine — Infinity F1, marks a turning point in the metal fabrication industry. Their precision, speed, and versatility are rewriting the rules and opening doors to new possibilities. As we journey into this future, it’s imperative for businesses to embrace the potential of these technologies while staying mindful of the challenges and responsibilities that come with them. The fusion of human ingenuity and cutting-edge tools will define the next chapter of metal fabrication’s evolution.

#Laser Cutting Machine#CNC Laser Cutting Machine#Fiber Laser Cutter#CNC Laser Cutter#High Power Laser#Sheet Cutting Machine#sheet metal fabrication#Youtube

0 notes

Link

#Sheet Cutting Machine#Sheet Cutting Machine Manufacturers#Sheet Cutting Machine Suppliers#Sheet Cutting Machine Exporters#Sheet Cutting Machine Manufacturers in India#Sheet Cutting Machine Suppliers in India#Sheet Cutting Machine Exporters in India

0 notes

Text

Precision Perfection- Introducing The Gallant's Laser Sheet Cutting Machine

Unveil a world of seamless precision with The Gallant's state-of-the-art laser sheet cutting machine. This cutting-edge solution redefines accuracy and efficiency in sheet metal processing, delivering flawless results every time.

Powered by advanced laser technology, our laser sheet cutting machine effortlessly slices through a wide range of materials, including mild steel, stainless steel, aluminium, and more. Experience unparalleled cutting quality, intricate detailing, and unmatched consistency with this high-performance system.

Elevate your metal fabrication capabilities and embrace the future of sheet cutting with The Gallant's laser sheet cutting machine. Contact us today to explore this revolutionary solution.

0 notes

Text

Executive dysfunction really is the strangest thing. I have 1 task I really need to do and 5 others of lesser importance. I can do the other 5 tasks easily but its like there is a barrier mentally keeping me from doing the 1 task.

I've been trying to do it for a month now... I tried breaking the 1 task down into steps to give myself bite size bits I can do. I set up my area to do the task and put all the tools there, but actually doing the main task is my problem. The ACTUAL start of the task after setup, for some reason, is just barred in my mind. Even thinking about the task gives me the same reaction as nails on a chalkboard. It feels so stupid to struggle with something so seemingly simple.

I can only assume my brain is giving signals of frustration and pain because I attempted said task a few months ago with bad results.

But I want to get this done so I can move on to a bigger project which I've also had trouble working on. So the incentive is just low I guess. If only the sense of accomplishment was more than "thank god that is over"

#the task is getting my cameo silhouette to actually cut sticker sheets#i've watched so many videos and it seems so easy!#but every one has different settings and different papers#plus the machine is loud as shit

1 note

·

View note