#CNC Laser Cutting Machine

Text

Shaping the Road Ahead: 30 kW Lasers in Automotive Innovation

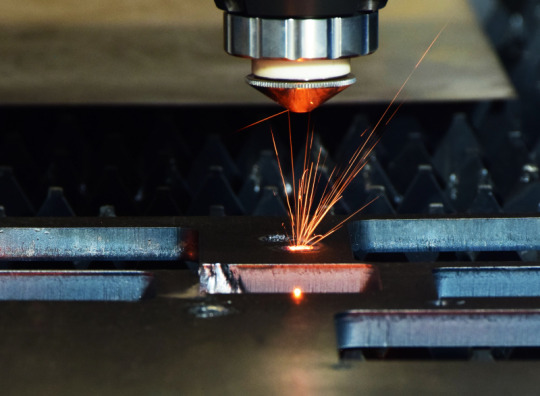

In recent years, 30 kW fiber laser cutting machines have emerged as a revolutionary technology in the automotive manufacturing industry. These machines utilize advanced fiber laser technology to achieve high-power cutting capabilities, enabling precise and efficient fabrication of automotive components. The impact of these machines on the industry has been profound, leading to improved productivity, cost-saving benefits, and enhanced customization opportunities.

Understanding Fiber Laser Cutting Machines

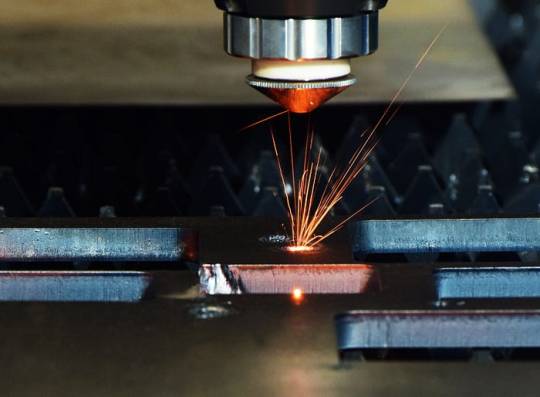

Fiber laser cutting machines are state-of-the-art tools that use fiber lasers to cut through various materials, including metals, with remarkable precision. The core of these machines is the fiber laser source, which generates an intense laser beam guided through an optical fiber. This highly focused and coherent laser beam is then directed onto the material to be cut, melting and vaporizing it with exceptional accuracy.

Advantages of fiber laser cutting machines over traditional cutting methods are numerous. Firstly, they offer higher cutting speeds and increased productivity, making them ideal for mass production in the automotive industry. Secondly, fiber lasers consume significantly less energy compared to CO2 lasers, reducing operating costs and environmental impact. Additionally, these machines are known for their excellent beam quality, resulting in smooth, burr-free cuts and minimizing post-processing requirements.

The key components of a fiber laser cutting machine include the laser source, optical fiber, cutting head, and CNC (Computer Numerical Control) system. The CNC system allows for precise control of the cutting process, ensuring accurate and repeatable results. The machine's software plays a crucial role in generating cutting patterns and nesting layouts to optimize material usage and minimize waste.

Transformation

The adoption of 30 kW fiber laser cutting machines has brought about a transformative impact on automotive manufacturing processes. One of the most significant advantages is the improved precision and speed of cutting operations. These machines can cut complex shapes and intricate patterns with unparalleled accuracy, leading to tighter tolerances and higher quality components. The enhanced speed allows for faster production cycles, reducing lead times and increasing overall manufacturing efficiency.

Moreover, fiber laser cutting machines offer exceptional versatility, capable of cutting a wide range of materials used in automotive manufacturing. From steel and aluminum to composites and plastics, these machines can handle various automotive-grade materials with ease, expanding the possibilities for design and innovation.

youtube

Benefits for Automotive Manufacturers

The utilization of 30 kW fiber laser cutting machines provides several compelling benefits for automotive manufacturers. One of the most notable advantages is cost-saving. Due to their high cutting speeds and reduced energy consumption, these machines lead to lower production costs, making them cost-effective for large-scale manufacturing.

Furthermore, fiber laser cutting machines result in minimal material waste. Their precise cutting abilities allow for optimized nesting layouts, maximizing material utilization and minimizing scrap. This reduction in waste not only saves costs but also contributes to a more sustainable and environmentally-friendly manufacturing process.

Another advantage is the level of customization and flexibility these machines offer. With their ability to cut intricate shapes and patterns, automotive manufacturers can cater to customer demands more effectively. Additionally, the adaptability of these machines enables rapid prototyping and quick design iterations, accelerating the product development cycle.

Several leading automotive manufacturers have successfully implemented 30 kW fiber laser cutting machines in their production processes. Hyundai Motor Company for instance, increased their production output by 40% after integrating fiber laser cutting machines into their assembly line. This efficiency gain allowed them to meet rising market demands while maintaining high product quality.

Another example is Volkswagen Group, which achieved significant cost savings by minimizing material waste through precise cutting patterns generated by fiber laser cutting machines. This reduced their overall material expenses and made their operations more sustainable.

In conclusion, 30 kW fiber laser cutting machines have revolutionized automotive manufacturing, offering increased precision, speed, and material versatility. These machines are driving the industry towards enhanced productivity, cost-effectiveness, and customization opportunities, making them a pivotal technology for automotive manufacturers in the 21st century.

2 notes

·

View notes

Text

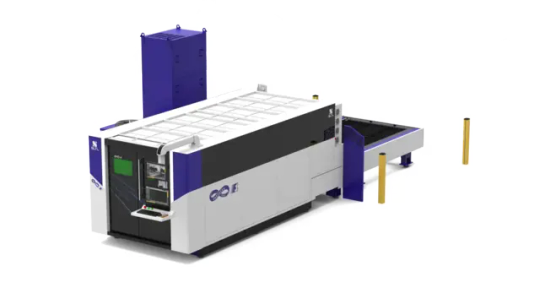

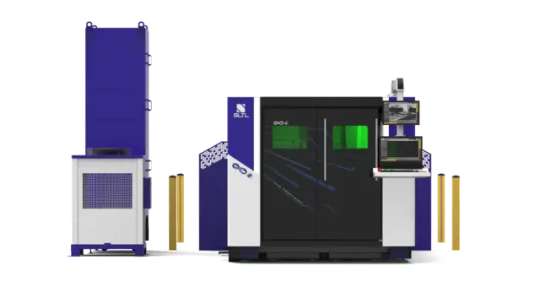

The SLTL Group is a renowned manufacturer of sheet metal laser cutting machines With their expertise and cutting-edge technology, they offer a wide range of machines suitable for various applications. Their machines are designed to provide efficient and precise cutting solutions for sheet metal fabrication.

The SLTL Group's sheet metal laser cutting machines come with power options ranging from 1.5 kW to 10 kW, allowing customers to choose the right power capacity for their specific cutting needs. These machines feature advanced features such as fume suction systems and filtered fume extractors, ensuring a clean and safe working environment by effectively removing fumes generated during the cutting process.

To enhance productivity, SLTL Group machines are equipped with a pallet changer, enabling quick and automated material handling. The tube cutting mechanism expands the versatility of the machines, allowing for precise cutting of tubes and pipes.

Safety is a top priority, and SLTL Group machines feature a Class 1 enclosure and a light curtain. The enclosure ensures the laser cutting process is contained, minimizing the risk of exposure to laser radiation, while the light curtain detects obstructions and triggers safety measures to prevent accidents.

Additionally, SLTL Group machines are equipped with an auto focus cutting head, enabling automatic adjustment of the laser beam focus for optimal cutting conditions. This results in consistent and precise cuts.

Overall, SLTL Group's sheet metal laser cutting machines combine cutting-edge technology, safety features, and efficient performance to meet the diverse needs of sheet metal fabrication.

#laser cutting machine#cnc laser cutting machine#metal laser cutting machine#Fiber laser cnc cutting machine

3 notes

·

View notes

Text

Find the best laser cutting machines in UAE on TradersFind

Discover the finest laser cutting machines in UAE on TradersFind. Explore a curated selection of top-notch machines known for precision, efficiency, and quality output. From industrial to small-scale applications, find reliable laser cutting machines solutions to meet your diverse cutting needs effectively and efficiently. Contact Now!

#laser cutting machines#laser cutting machines in UAE#laser cutting machine suppliers#laser cutting machine manufacturers#laser cutting machine companies#industrial laser cutting machines#3d laser cutting machine#fiber laser cutting machine#cnc laser cutting machine

0 notes

Text

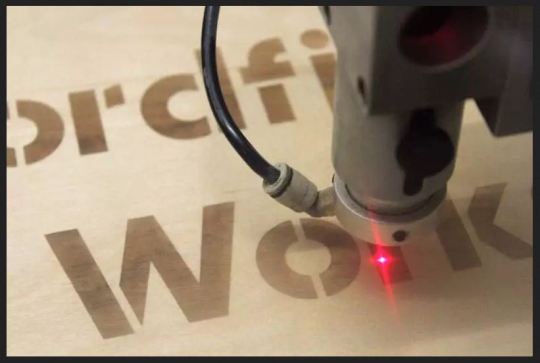

CO2 Laser Cutting Machine in Singapore

Signvec is a premier manufacturer and supplier of cutting-edge CO2 laser cutting machines in Singapore. Renowned for their precision and reliability, Signvec's laser cutting machines are at the forefront of industrial innovation. With a commitment to quality craftsmanship and advanced technology, they offer tailored solutions to meet diverse cutting needs across various industries. Trusted by businesses for their efficiency and accuracy, Signvec stands as a leader in the laser cutting machine market, delivering exceptional performance and unmatched value.

In Order To Find Out More Details Laser Cutting Machine Please Be Touch With Us Today Onwards..!

#CO2 Laser Cutting Machine#CO2 Laser Cutter#CO2 Laser Cutter Singapore#Laser Cutting Machine#Laser Cutter#Cnc Laser Cutter#Cnc Laser Cutting Machine

0 notes

Text

Revolutionizing Precision: Unveiling the Power of Fiber Laser Cutting Machines in 2D, 3D, and Tube Cutting

In the dynamic landscape of manufacturing, the advent of Fiber Laser Cutting Machines has emerged as a transformative force, redefining precision in 2D, 3D, and Tube Cutting processes. This comprehensive article explores the capabilities of these cutting-edge machines, shedding light on their applications, advantages, and the future they herald.

Understanding the Basics: Fiber Laser Technology

1. The Essence of Fiber Lasers

Fiber lasers operate on a unique principle, utilizing optical fibers doped with rare-earth elements to amplify light. This results in a highly concentrated and powerful laser beam, ideal for intricate cutting tasks. The technology’s inherent efficiency and precision make it a game-changer in various industries.

2. 2D Cutting Mastery

In the realm of 2D Fiber Laser Cutting Machines stand out for their unparalleled precision and speed. From intricate patterns to straight cuts, these machines excel in transforming raw materials into precise components. The flexibility they offer caters to diverse industries, from automotive to electronics.

youtube

3. Breaking into the Third Dimension

Venturing into the 3D Fiber Laser Cutting Machines bring a new dimension to manufacturing. Their ability to navigate complex geometries with precision opens doors to limitless design possibilities. Whether it’s creating artistic sculptures or crafting intricate components, the versatility of these machines knows no bounds.

youtube

Specialized Expertise: Tube Cutting Capabilities

4. Mastering Tube Cutting Challenges

The unique challenges posed by tube cutting find an effective solution in fiber laser tube cutting machines. With advanced focusing capabilities and rapid cutting speeds, these machines ensure clean and precise cuts on various tube profiles. The adaptability of Fiber Lasers makes them indispensable in industries where tube cutting is a critical component.

youtube

Advantages That Redefine Manufacturing Standards

5. Unrivaled Speed and Efficiency

Laser Cutting Machines are synonymous with speed and efficiency. The rapid cutting speeds, coupled with minimal downtime, translate to enhanced productivity. Manufacturers embracing this technology witness a significant boost in overall operational efficiency.

6. Precision Beyond Comparison

Precision is the hallmark of Fiber Laser Technology. The ability to make micro-cuts with utmost accuracy not only reduces material waste but also elevates the quality of finished products. In industries where precision is non-negotiable, Fiber Lasers are the ultimate choice.

The Future Landscape: Innovations on the Horizon

As technology continues to evolve, so do Fiber Laser Cutting Machines. The integration of artificial intelligence, automation, and enhanced connectivity promises a future where these machines operate seamlessly in smart manufacturing environments. This evolution not only enhances efficiency but also sets the stage for unparalleled advancements in the manufacturing sector.

Conclusion: Transforming Possibilities with Fiber Laser Cutting

In conclusion, Fiber Laser Cutting Machines have emerged as the driving force behind a manufacturing revolution. From mastering 2D and 3D cutting to tackling the intricacies of tube cutting, these machines redefine the possibilities in precision engineering. As industries increasingly adopt Fiber Laser Technology, they not only keep pace with current manufacturing demands but also position themselves at the forefront of innovation, ready to shape the future of manufacturing.

#Laser Cutting machine#Fiber Laser cutting machine#laser cutting solution#Tube cutting machine#2d laser cutting machine#3D laser cutting machine#ultra high power laser machines#cnc laser cutting machine#cnc fiber laser cutting machine#Youtube

0 notes

Text

Quality CNC Lathes & CNC Lathes Machine Manufacturer in Maharashtra - Sahil Technocrats

Sahil Technocrats is your trusted source for the highest quality CNC Lathes, CNC Lathe Machines, and CNC Metal Cutting Machines in Maharashtra. As the leading wholesaler in India, we offer precision engineering solutions for your machining needs. Sahil Technocrats provides best quality CNC Lathes, CNC Lathes Machine & CNC Metal Cutting Machines in Maharashtra. We are the best wholesaler in India.

#CNC Lathes#CNC Lathes Machine#Cnc Metal Cutting Machines#CNC Laser Cutting Machine#Cnc Laser & Forming Machines#Profile Projector#Repairing Services

0 notes

Text

Beyond Limits: Unveiling the Might of High-Power Lasers on 40mm Metal Sheets

Exploring the Capabilities of up to 30KW Laser Cutting Machines and the Advantages of SLTL Infinity Metal Cutting Laser Machine

The world of metal fabrication is undergoing a transformative phase, powered by cutting-edge technology that pushes the boundaries of what was once considered impossible. We delve into the awe-inspiring domain of high-power lasers, where up to 30KW laser cutting machines take center stage. The spotlight is on the remarkable SLTL Infinity Metal Cutting Laser Machine, a marvel that defies limits and sets new standards in precision and efficiency.

1. Laser Precision: A Glimpse into the Future

The introduction of high-power lasers in metal cutting has been a game-changer, revolutionizing an industry that has long grappled with the challenges of cutting thick metal sheets. With the capability to slice through 40mm metal sheets like a hot knife through butter, the technology raises questions that intrigue and inspire.

2. The Power of 30KW Laser Cutting Machines

"30KW Laser Cutting: Redefining Metal Fabrication"

The 30KW laser cutting machines represent a monumental leap in the world of engineering. Imagine harnessing energy equivalent to the powerhouses that fuel entire cities, all focused onto a precise beam that can carve through metal with surgical precision. This level of power is not just about might; it's about rewriting the rules of metal fabrication.

3. The Star of the Show: SLTL Infinity Metal Cutting Laser Machine

"Infinite Potential: Unraveling the Features of SLTL Infinity"

Amidst the universe of high-power lasers, the SLTL Infinity Metal Cutting Laser Machine stands out as a testament to human ingenuity. Designed to handle the toughest challenges, its adaptive controls and state-of-the-art technology redefine what's achievable in metal cutting. The machine's versatility shines as it seamlessly transitions from intricate designs to slicing through 40mm metal sheets.

4. Advantages That Illuminate Possibilities

"Cutting through Advantages: Illuminating the Benefits of SLTL Infinity"

The advantages offered by the SLTL Infinity are a beacon for industries seeking innovation and efficiency. The machine's ability to maintain precision across varying metal types, reduced heat-affected zones, and minimal post-processing are advantages that not only streamline production but also raise the quality bar.

5. Beyond Metal Cutting: Expanding Horizons

"Expanding Boundaries: Beyond Metal Cutting with SLTL Infinity"

While the primary focus is metal cutting, the impact of the SLTL Infinity transcends this singular domain. It has the potential to shape industries that rely on intricate metalwork, from automotive to aerospace. The machine's capabilities become a catalyst for imagination and innovation, propelling industries into uncharted territory.

Conclusion: Carving a New Era in Metal Fabrication

As we conclude this journey through the realms of high-power lasers and the remarkable SLTL Infinity Metal Cutting Laser Machine, the answers to the questions posed at the beginning become evident. The boundaries of what can be achieved with metal cutting have expanded beyond our wildest dreams. The synergy of human ingenuity and technological prowess has birthed a new era where 40mm metal sheets are no longer obstacles but opportunities.

In the world of metal fabrication, limits are no longer barriers; they are merely indicators of what can be surpassed. As we embrace the capabilities of the SLTL Infinity, we are ushered into a future where innovation is boundless, and metal is shaped not just by machines, but by the audacity of human imagination.

In this journey of innovation, the SLTL Infinity Metal Cutting Laser Machine is not just a tool; it's an emblem of progress and a tribute to human determination to reach beyond the confines of what was once considered feasible.

#SLTL Infinity#cnc laser cutting machine#sheet cutting machine#metal cutting machine#fiber laser cutter

0 notes

Video

youtube

STVCNC Retro S TV

On various products, including metal, wood, paper, glass, and others, CNC laser cutting machines are easier to program and have crisper cuts. Many businesses have employed CNC laser cutting equipment to work precisely and fast. STV CNC has produced goods under the direction of highly skilled technical professionals. STV CNC with improved CNC laser cutting machine helps to maintain high product standards. Get high-quality products at affordable prices. Visit: https://stvcnc.com/cnc-plasma-tables/ or contact: (888) 701-7101

1 note

·

View note

Text

Best CNC laser cutting machine in India

As of my last knowledge update in January 2022, I don't have specific information on the latest CNC laser cutting machines available in India. However, I can provide you with some popular CNC laser cutting machine manufacturers that were well-regarded globally. It's important to note that advancements in technology and new models may have been introduced since then.

TRUMPF:

TRUMPF is a globally recognized company for manufacturing high-quality CNC laser cutting machines. They offer a range of laser cutting solutions for various industries.

Amada:

Amada is another well-known brand in the CNC machinery industry, including laser cutting machines. They have a reputation for producing reliable and efficient equipment.

Bystronic:

Bystronic is a Swiss manufacturer known for its advanced laser cutting systems. They provide solutions for sheet metal processing and have a presence in India.

Mazak:

Yamazaki Mazak Corporation, commonly known as Mazak, is a Japanese company that produces CNC laser cutting machines. They are known for their precision and innovation.

Han's Laser:

Han's Laser is a Chinese company with a global presence, manufacturing laser cutting machines. They offer a variety of models suitable for different applications.

LVD:

LVD is a Belgian company specializing in sheet metalworking equipment, including laser cutting machines. They are known for their innovative solutions.

When considering the best CNC laser cutting machine for your specific needs, factors such as the machine's power, cutting capabilities, ease of use, support services, and overall reputation of the manufacturer are important to consider.

To find the latest and best CNC laser cutting machines in India, it's recommended to check with local distributors, attend industry exhibitions, and explore online reviews and forums for updated information. Additionally, contacting the manufacturers directly or consulting with industry experts can help you make an informed decision based on your specific requirements.

We Provide:-

Best CNC laser cutting machine in India

CNC punching services in pune

Best MIG Welding Machine

Pre-Treatment for Surface Preparation in pune

Best CNC bending services India

Best SS fabrication services in India

Best spot welding services in pune

Best tube, pipe, and angle cutting services in pune

Best automotive manufacturers in pune

Best manufacturing and assembly services

#best cnc laser cutting machine in india#CNC punching services in pune#best MIG Welding Machine#Pre-Treatment for Surface Preparation in pune#best CNC bending services india#best SS fabrication services in india#best spot welding services in pune#best tube#pipe#and angle cutting services in pune

2 notes

·

View notes

Text

https://berlin-machineries.com/

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes

Text

High Quality Laser Cutting and Services in london

London, a hub of innovation and technology, has witnessed a surge in the utilization of laser cutting services across various industries. Laser cutting has revolutionized manufacturing processes, offering unparalleled precision, speed, and versatility. In this article, we will explore the significance of laser cutting services in London and delve into the benefits they bring to businesses and…

View On WordPress

#cnc cutting london#CNC cutting Shoreditch#CNC Machining London#CNC routing London#High Quality Laser Cutting Services#Laser cutting#Laser cutting east London#laser cutting london#laser cutting services#Laser Cutting Services in London#laser cutting shoreditch

3 notes

·

View notes

Text

Igniting Innovation: Unleashing the Potential of Fiber Laser Cutting Machines

Fiber laser cutting machines have emerged as a game-changer in the manufacturing industry, offering unparalleled precision, speed, and versatility. Unlocking the full potential of these advanced machines is crucial for businesses seeking to stay competitive and drive growth

Fiber laser cutting machines are cutting-edge tools that employ a high-powered laser beam focused through a fiber optic cable to cut through various materials with exceptional precision. These machines boast several notable features, such as high cutting speeds, narrow kerf width, minimal heat-affected zones, and the ability to process a wide range of materials. Additionally, they offer superior reliability, energy efficiency, and low maintenance requirements compared to other types of laser cutting machines.

Fiber laser cutting machines come in various configurations to suit different cutting needs. The most common types include:

Fiber Sheet Laser Cutting Machines

Designed for precise cutting of flat sheet materials, such as metal sheets and plates.

Fiber Tube Laser Cutting Machines

Specialized for cutting and profiling cylindrical and tubular materials, such as pipes and tubes.

Fiber 3D Laser Cutting Machines

Used for intricate cutting of three-dimensional objects and complex shapes.

youtube

The adoption of fiber laser cutting machines offers numerous advantages for businesses:

Unparalleled Precision

Fiber lasers provide exceptional cutting accuracy and edge quality, enabling intricate designs and minimizing material waste.

High Cutting Speeds

Fiber lasers can achieve faster cutting speeds than other laser cutting technologies, resulting in increased productivity and shorter lead times.

Versatility in Material Processing

Fiber lasers can efficiently cut various materials, including metals, plastics, composites, and even reflective surfaces.

Reduced Operating Costs

These machines are energy-efficient, requiring lower power consumption and offering longer lifespan for consumables.

Minimal Maintenance Requirements

Fiber laser cutting machines are designed for reliability and require minimal maintenance, reducing downtime and maintenance costs.

To unleash the full potential of fiber laser cutting machines, businesses should consider the following strategies:

Upgrade the Software and Hardware

Regularly update the machine's software and hardware components to access the latest features, enhancements, and improved cutting algorithms.

Optimize Cutting Parameters

Fine-tune cutting parameters such as laser power, speed, focus, and assist gas settings to achieve optimal cutting results for different materials and thicknesses.

Train Operators to Maximize Efficiency

Provide comprehensive training programs for operators to enhance their knowledge and skills in operating and maintaining fiber laser cutting machines, optimizing efficiency and minimizing errors.

Fiber laser cutting machines find extensive use in various industries, including:

Automotive Industry: Used for precision cutting of automotive components, chassis parts, body panels, and custom designs.

Aerospace Industry: Employed in the manufacturing of aircraft parts, engine components, turbine blades, and complex geometries.

Medical Industry: Used for precise cutting of medical devices, implants, surgical instruments, and custom prosthetics.

In conclusion, unleashing the potential of fiber laser cutting machines is vital for businesses aiming to excel in precision cutting applications. By understanding their capabilities, upgrading software and hardware, optimizing cutting parameters, and providing adequate operator training, companies can maximize the efficiency, accuracy, and versatility of these advanced machines. The automotive, aerospace, and medical industries are just a few examples of sectors benefitting from the transformative power of fiber laser cutting machines. It is crucial for businesses to invest in these technologies, embrace innovation, and explore new opportunities for growth and success in an increasingly competitive marketplace.

1 note

·

View note

Text

It is our Pleasure to introduce our company HITZE ENGINEERING PVT LTD., Which has been incorporated as manufacturing of sheet metal components Since 2019.

6 notes

·

View notes

Video

youtube

STARMA cnc setting manual CCD camera of co2 laser cutting machine

#youtube#STARMA cnc setting manual CCD camera of co2 laser cutting machine This video to show how to setting the parameters of the CCD camera of Co2

2 notes

·

View notes

Text

Laser Cutting An Innovation For Highly Accurate And Precision Cutting

Laser cutting is a methodology that uses a laser beam on the surface of the material which has to be cut. This methodology is mostly used in the industrial sector where large blocks of materials like iron and steel have to be cut to the required sizes. The process technically is similar to laser, marking and laser engraving. Even in this case, high power laser beam is directed onto the metal surface through optical devices like convergent lenses.

Computer numerical controls are used to direct the laser beams onto the material surface, which either melts or vaporises the material surface at the point of requirement, thereby living a very high quality finish at that point of cutting. Before the laser cutter or the laser cutting machine, became to be used extensively. These kinds of laser machines are mostly used to drill holes on the material surface. Advanced technology later on was used to cut material surfaces for aerospace applications, which needed a very fine finish. The disadvantages of mechanical cutting on certain material surfaces gave room to the invention of laser cutting machines. The process of laser cutting has its own advantages over the mechanical cutting like easier, cutting, more precision, accuracy, no wear and tear and so on.

Basically, there are three types of laser cutting machines in which the carbon dioxide laser is the best suited for cutting, drilling, and engraving. The ND lasers are used where very high power is needed in case of cutting very thick sheet metal materials. However, both carbon dioxide lasers and ND lasers can be used for the purpose of welding. While carbon dioxide lasers are used for the industrial cutting of many materials, including titanium and stainless steel, the ND lasers are primarily used for cutting ceramics. The laser cutting machine are dependent on the type of a gas flow that is used in it.

The usual types of gases that are used in these machines are carbon dioxide, helium, nitrogen, or a mixture of any of these. A laser cutting machine generates a good amount of heat within itself and hence requires a proper cooling process also. In most of the cases, water is commonly used as a coolant and is circulated during the process. A micro jet of water is integrated at a low pressure, which is used to perform laser cutting functions, which is also helpful in removing the debris and cooling the material.

Another advanced type of laser cutting machine is the fiber laser which is a solid state laser. Here the fiber technology is used to produce a laser beam which is then amplified and is known as fiber with a suitable wavelength. These lasers are very much suitable for cutting metals and metal sheets which reflect the light which is the main advantage of fiber laser cutting machine. Signvec is an organization that deals with laser cutting and engraving machine, known to have a number of advantages like less energy consumption, higher reliability, and performance, less maintenance, very low, operational cost and so on.

In Order To Find Out More Details On Laser Cutter Please Be Touch With Us Today Onwards..!

#Fiber Laser Cutting Machine#Laser Cutting Machine#Laser Cutter#Cnc Laser Cutter#Cnc Laser Cutting Machine#Laser Cutter Singapore

0 notes