#r12

Photo

1980s Renault 12 TS.

Hidden away from the mediterranean sun, we spotted this gem years ago. A little rallye livery and Stromberg sports rims give it a little more of a sportier look.

24 notes

·

View notes

Text

10 notes

·

View notes

Text

that one serano excerpt does kind of point to a division between people who treat the so-called queer community as a big tent party and those who treat it more as a coalition... to be clear, i have also believed in this for some time myself as well, given the divisions between (most prominently in my interactions) transfems and lesbians (individually speaking) from the broader community, due to widespread transmisogyny and lesbophobia respectively (both being developments on traditional misogyny)

5 notes

·

View notes

Text

La mítica BMW R nineT cambia de nombre. A partir de ahora pasa a llamarse R 12 sin perder su carácter y estilo de moto roadster clásica. Para este nuevo modelo la marca sigue montando el preferido: el clásico motor boxer bicilíndrico refrigerado por aire. ¡Inimitable!

9 notes

·

View notes

Text

What Are The Important Stages of Steel Detailing Development in Construction Projects?

The process and work of steel structure detailing are precarious and want detailed understanding. From having a multi-layered phase to getting a holistic look at the structure that's made from steel, Steel Detailing services are required.

For the development projects where anything is made out of steel, the engineers use steel detailing services. It could be the team of structural engineers and architects who place their efforts and strength into the project.

It is the team of contractors and owners who share their drawings and design that is certainly associated with mechanical systems. These systems further require systems that relate to fabrication as well as in context to steel members.

The undertaking of steel detailing services is extremely crucial and tedious work. The accuracy a higher level this particular service is 99.9% which adds value towards the time and expense both. Structural steel detailing is a mandatory process undertaken by manufacturing and construction units.

Moreover, this complete process is playing a huge role and is also can be a communication link. It connects key professionals and personnel who're collectively responsible for project deliverables.

Let us now proceed further and check important stages of steel detailing. The process involves two major drawings the first is shop drawings along with the other is erection drawings.

Development Stages of Steel Detailing

Shop Drawings

When implementing a steel detailing project, it will be the steel detailers who help convert and cover the steel drawings and design. The making of steel components, pieces, and fashions that cover the drawings these are known as Shop Drawings. It will be the set of drawings that helps classify important components and specifications of the project. This further, continues with all the fabrication of person pieces and members of a structure.

It will be the steel fabricators who're determined to utilize these drawings also called detailed drawings. The use and wish for having this drawing are to produce steel members. With a comprehensive approach and classification, steel fabrication shop drawings include each amount of individual pieces which are part of the project.

The means of shop drawings emphasizes every bit and part of information that creates a project successful. With this said, the important points are the size of the project, its material specifications, the necessary dimensions, preparation with the surface, plus much more. This further continues with some important features like bolting, welding, painting, conventions, manufacturing process, and some fabricating guidelines.

Erection Drawings

It will be the list of drawings that refers for the steel detailing process. At the construction site, it could be the steel erectors who demand these drawings. These drawings reference knowing when, how, and where you should build fabricated steel pieces.

The work of erection drawings is usually to focus on dimensional plans that help identify details. This identification is to understand the steel members and focus on the project that is required once your there. Also, the project required on the site includes installation, welding, bolting, and masonry anchors.

Being a steel detailer, some additional roles and responsibilities are essential in the steel detailing process.

Detailed observance of structural design , drawings, and detailing with necessary industry standards.

reo mesh Sydney from the drawings and designs by structural engineers and architects before handing them over for the fabricator.

If the structural drawings are insufficient, the engineers offer support and assist with sanction them.

If the detailer is just not sure in regards to the drawings/information they send a request to get the data from your relevant parties. This will be the process taken before continuing the project.

For accuracy and completeness, the drawings are delivered to another detailer who is referred to as the checker.

If you can find any changes within the drawings, they must be monitored with accuracy and precision. These revisions are marked with codes and numeric to be aware of the detail perfectly.

Techniques

The age-old practice that has been used by steel detailing was performed manually. It was within the type of handmade drawings, designs, sketches, and templates. Later, with the use of CAD technology, specific software program is used. It could be the way that is only useful for designing 2D models understanding that too with primitive methods and techniques.

As people say, necessity may be the mother of invention. Same way while using use of advanced technology, the CAD drafting services were replaced. This process helped make the project work easier. faster, and cost-effective. It further, helps deliver an increased amount of work and outcome, as never before.

Though the expense of steel detailing development is at a better level, the program used is Tekla and AutoCAD. It is the process that delivers utmost efficiency which is highly scalable, reliable, and workable.

For a project's success, it is crucial to undertake the right list of services that assists increase the project tracking with proper scheduling.

Final Words

The steel detailing development inside project is an important factor. The blog shared clearly shows quite stages that make a project successful. Since steel detailing services is tedious work and process, they ought to be finalized with utmost precision and care.

#steel rebar suppliers Sydney#reinforcement suppliers Sydney#reinforcing steel suppliers Sydney#steel reinforcement mesh Sydney#reinforcement mesh Sydney#Steel Suppliers near me#galvanized bar#galvanised reo Sydney#galvanised steel Bar#galvanised reinforcing Supply#galvanised rebar supplier Sydney#Galvanised Mesh Sydney#R12#R16#R20#R24#R28 Galvanised Dowel Bar Sydney#S12 Pool steel Sydney#SL72/SL82/SL81/SL102 Galvanised Mesh Sydney#N12#N16#N20#N24#N28#N32 rebar Sydney#SL62/SL72/SL82/SL92 MESH supplier Sydney#SL72 Mesh#Ligature#Bondek Slab Sydney#Dowel Bar

0 notes

Video

Untitled by Matt Csenge

Via Flickr:

New York City Transit Authority (NYCTA) R14 no. 5956 and R12 no. 5716 are the first two cars on a Flushing-bound 7 train seen arriving at Queensboro Plaza Station on the IRT Flushing Line on November 4, 1956. These cars were built by American Car and Foundry in 1949 and 1948, respectively, and would serve the City of New York into the 1980s. Unknown photographer, Matt Csenge collection

0 notes

Text

big #manufacturer for #hydraulichose that you can trust in #China, 16 years experience. #Smooth & #wrapped cover hydraulic hose (#R1AT #R2AT #R3/R6 R#16/R17 #1SN #2SN #4SP #4SH #R12 #R13 #R15 #R9 #1SC #2SC #R5 #R7 #R8 JET WASH HOSE , #R14 ) Whatsapp : +86~152 9760 7201

#big#manufacturer for#hydraulichose that you can trust in#China#16 years experience.#Smooth &#wrapped cover hydraulic hose (#R1AT#R2AT#R3/R6 R#16/R17#1SN#2SN#4SP#4SH#R12#R13#R15#R9#1SC#2SC#R5#R7#R8 JET WASH HOSE#R14 )#Whatsapp : +86~152 9760 7201

0 notes

Text

Prätkämessut

Prätkämessut oli kolmen vuoden tauon jälkeen ja sen huomasi, syillä jo heti perjantai aamuna oli jengiä todella paljon suorastaan ruuhkaksi asti.

mukava oli pitäst aikaa käydä katselemassa mopoja ja fiilistelemäs.

Kuva: Jari Holopainen

View On WordPress

0 notes

Text

Gather Schema Statistics

@oracle @oracleapps @oarcleebs @oarclapplication #gatherschema #ebs #oracleapps #oracleappication #ebs #oracle #oracleebs

This concurrent program gathers the specified schema level statistics

This program also creates histograms on the columns seeded in the FND_HISTOGRAM_COLS table

For a detailed description of the procedure used by this concurrent program, see information on the GATHER_SCHEMA_STATS procedure

Parameters

Schema Name

Schema for which statistics are to be gathered. Specify ALL for all Oracle…

View On WordPress

0 notes

Text

make life a ride

#bmw motorcycles#bmw motorbike#BMW R12 nineT#moto love#motorcycle#motorbike#lifestyle#moto adventure#classic bike#moto life#motorcyclelove#caferacer#cafe racer

57 notes

·

View notes

Text

R12 NINE T mod 2024

12 notes

·

View notes

Text

7 notes

·

View notes

Text

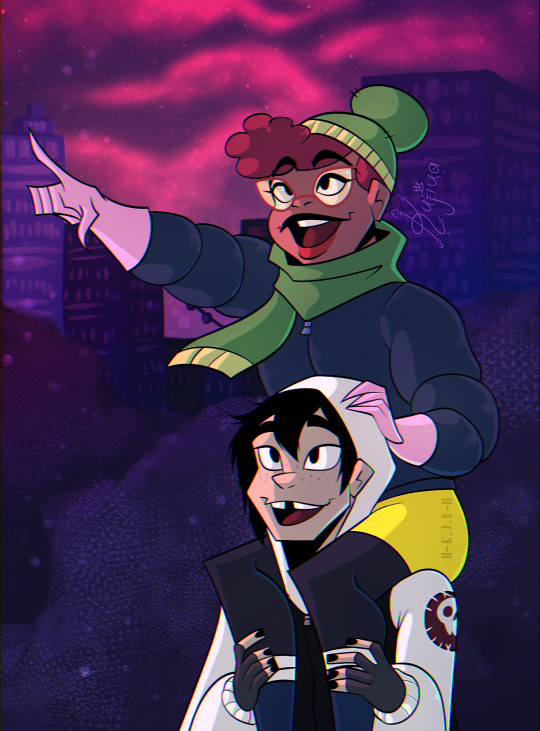

[TMNT] - A New Year!

Happy final day of December/New Year!

As with most things in my life, this year was...a mixed bag.

A lot of good things happened, and a lot of really shitty stuff happened. But that's life I guess.

I decided to draw some r12!Capril as my final art piece of the year, cause I absolutely love these two, and love that some people are getting into/enjoying the ship with me.

this is also the first piece to have my new signature (actually second, cause I hated the first piece).

Here's the minilapse in case you wanna see how I draw::

#speeddraw#art#fan art#winter#crossover ship#ship#tmnt#rise of the teenage mutant ninja turtles#teenage mutant ninja turtles 2012#rise april#casey jones 2012#tmnt casey jones#new year#cute#r12! capril

51 notes

·

View notes

Text

HE'S AT IT AGAIN GANG HE'S BACK AND HE'S AFTER ME

10 notes

·

View notes

Text

7 Reasons Why Rebar Detailing Is Key To The Construction Process

Rebar is really a basic steel bar or block which is popular in reinforced concrete and reinforced masonry structures. These rebars are often created from carbon steel and may be recounted as reinforcing steel or simply just reinforcement. Under Structural BIM Services Rebar detailing is really a discipline of creating fabrication or shop drawings of steel reinforcement for your construction process. The site fabrication drawings that are generated depending on design drawings for reinforcing steel are Rebar Detailed drawings. Engineers and Architects make design drawings to bring about the mandatory strengths based on the rebar detailing that delivers diameter, bar shapes, quantities, length of bars to facilitate the website for avoiding delays and wastage thereby speeding your entire construction process.

Each rebar is detailed representing a shape, length, and diameter determined by the requirements with the design drawing. The Rebar placement might be shown in greater detail which indicates the concrete cover, exact location, and special way of placement if required. The rebar details and bar bending schedules can have bar diameter, bar notation, the amount of bars, weight of the bars, and amount of each bar along with mentioning the complete weight for that entire pair of bars placed inside drawing. During the preparation of rebar details, the stock lengths of bars are kept in view to ensure there isn't any wastage with the material.

Rebar Detailing and Reinforcement concrete detailing is now able to modeled and designed in 3-dimension with all the 3D Modelling technology like BIM Modelling Services. The specialized rebar detailing software like Rebar CAD and AutoCAD used by this purpose will help every member with the structural engineering to get ready designs, document, track, whilst overall control.

Having understood the fundamental thought of rebar detailing a piece of structural BIM modeling, allow us to make an effort to view the significance of it in the overall construction process is. Some with the reasons are:

Importance of Rebar detailing in Structural BIM Modeling

While 2D drawings and bending schedules are likely to be created and given, the 3D model can be issued to all or any they members starting from the consulting engineer and contractor departments into the steel fixers that are on the ground level on-site. The combination of the two become especially useful for site personnel where site restrictions or congestion of reinforcements remain unidentified until there are reinforcement and fixation on location. For every single bar, the actual position of fixing is shown in the 3D model in addition to any hindrances or obstructions.

Creating detailing reinforcements in 3D over the 2D process is not only faster but modeling rebar in a very 3-dimensional environment helps remove clashes. While modeling you can visualize if any of the bars tend not to fix in a decided area, thereby identify all such clashes within the rebar drawings. There is the facility to review the reinforcement in complete detail as a precise detail representation prior to it being being ordered in the fabricator and complicated cages are assembled off-site.

When you have the right rebar detailing solution available, a competent and accurate reinforcement model can be done by importing structural calculations through the structural analysis program. With Automation involved the alterations are typically reflected inside 3D rebar detailing in addition to necessary updates to drawings and schedules swiftly when changes are manufactured elsewhere unlike having to do manual changes to 2D sections and views.

Instead of according to manual input from paper schedules, the rebar fabricator can extract data directly in the model to the machinery. The concrete pours might be well-defined inside model along with other details like quantities and volumes to ensure more accuracy in managing material deliveries. This will allow greater control and cause less wastage and reduction of overall costs.

Having 3D detailed digital models won't restrict the benefit to some single-phase that way from the engineering and detailing phase but could be used in all the phases. Having reinforcement fully modeled in 3D, the contractor is assured that it'll easily fit into areas when the time comes for it to be fixed on-site. The data from the model may be used within the field to allow contractors to conduct a model-based layout by utilizing robotic total station devices along with tracking rebar and materials and identifying when and where they'll be required.

Fixers present on-site will be inside model environment for the rebar detailing to accurately understand its application, i.e. precisely what is required location as an alternative to counting on their interpretation of traditional 2D drawings.

The structural engineers can easily plus much more quickly generate design reports, schedules, and drawings from your 3D model as compared to 2D designs, thereby enhancing design efficiency. There is more accuracy in price projection determined by the rebar quantities produced in the 3D model as is also more reliable compared to the 2D drawing take-offs. Not just this the quantities are completely traceable, allowing comparisons and checks to become conducted effortlessly.

With these reasons, we could conclude that Rebar Detailing a discipline of Structural BIM Modelling Services is one with the crucial criteria for that overall success of the project life cycle. To summarize, having Rebar Detailing the rebar contractor can focus on producing rebars high will be no should estimate reinforcement requirements for procurements at the website on account of efficient 3D models. The model will depict the necessity for anchors and laps inside drawings thereby ensuring design adequacy together with reducing wastage. The overall waste and time delays are decreased at your website because each of the shape drawings are often available. Based on R12,R16,R20,R24,R28 Galvanised Dowel Bar Sydney info the bars could be easily fabricated according to the shapes and amount of bars required.

#steel rebar suppliers Sydney#reinforcement suppliers Sydney#reinforcing steel suppliers Sydney#steel reinforcement mesh Sydney#reinforcement mesh Sydney#Steel Suppliers near me#galvanized bar#galvanised reo Sydney#galvanised steel Bar#galvanised reinforcing Supply#galvanised rebar supplier Sydney#Galvanised Mesh Sydney#R12#R16#R20#R24#R28 Galvanised Dowel Bar Sydney#S12 Pool steel Sydney#SL72/SL82/SL81/SL102 Galvanised Mesh Sydney#N12#N16#N20#N24#N28#N32 rebar Sydney#SL62/SL72/SL82/SL92 MESH supplier Sydney#SL72 Mesh#Ligature#Bondek Slab Sydney#Dowel Bar

0 notes

Text

based on @golldenvallion 's HC of 12!Casey spray-painting designs on April's clothes, and I decided to doodle up a few designs.

#doodle#scribble#art#fanart#rise april#rise of tmnt#tmnt 2012#r12! capril#april o'neil#rise of the teenage mutant ninja turtles

59 notes

·

View notes