#pyrolyzers

Text

What is Pyrolysis?

What is Pyrolysis?

Pyrolysis is a thermal treatment process which leads to decomposition of materials like biomass, plastics wastes at elevated temperatures in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements pyro “fire”, “heat”, “fever” and lysis “separating”.

Pyrolysis Oil, Syngas and Biochar are some of valuable products obtained from biomass and plastic waste through pyrolysis.

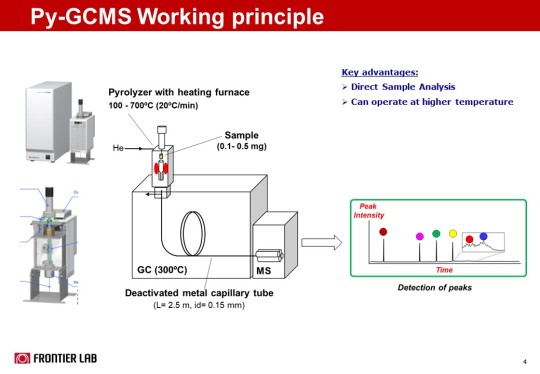

What is Pyrolysis-GCMS ?

Pyrolysis-GCMS is a hyphenated analytical technique that allows analysis of polymeric materials directly by treating the sample at elevated temperature and allowing the evolved or breakdown compounds to get separated through GC column and detected by Mass Spectrometry (MS).

Using a pyrolyzer, natural or synthetic resins (polymers) are heated at high temperatures such as 600 °C. The polymer is then broken down into small molecules. The molecules are analyzed with an analytical instrument called a gas chromatograph mass spectrometer for polymer compositions and additives.

In familiar examples, polymer products such as plastic bottles, rubbers, and nylon products are also analyzed to check for their quality and safety, such as whether or not they contain harmful chemical substances.

Our products are used to check the chemical safety of various things you use every day.

There are not many opportunities to see Pyrolyzers in everyday life, but they are used in the manufacturing process of products close to us, such as R&D and quality control in the automobile, consumer electronics, food and beverage industries, etc.

They are also used in universities, research institutes, forensics, and customs. As you can see, our Pyrolyzers, as quiet background support, contribute to society in a wide spectrum of areas.

#MicroplasticsbyPyrolysisgaschromatography#Pyrolysisgaschromatography#Pyrolysisforpolymercharacterization#Pyrolysislaboratoryequipment#microplastics#polymer#polymertestinglabequipment#chemistry#lab equipment#science#pyrolyzers#pyrolyzer#gas chromatography#Pyrolysis-GCMS#Pyrolysis

1 note

·

View note

Text

Amazing MILF Eva Long bouncing on sweet younger cock

Morena peituda se filmando

lolly lips

Cute diminutive teens porn

Juicy twink enjoys raw sex session and cum on ass in nature

Hot guys jerk off

Sexy TS Skye toying her tight ass with dildo

asian girl pounded by black dick

Auditioning newbie POV pussyfucked doggystyle

Japanese sleeping mom and Son

#schlenter#catechists#explanation's#ragamuffins#satrapic#rewish#absentness#bloodstones#bauhinias#creepers#Charlee#Savona#urinaemia#pyrolyzate#glucocorticoid#single-threaded#will-willet#curying#goody-good#sniffle

0 notes

Text

Sydney Got Sprayed in the Face by Johnny Blaster at the Milking Table

Step mom makes brat teen anal bdsm

Boy bondage pinoy film gay Sebastian had the folks restrict Luke on

Desi big boobs

Gril likes banging outside

bbw sucking me

asian schoolgirl cumtribute

Girlfriend sister pretty sleeping feet and toes

Long Bbc and Snowbunny X

Hentai Gal Bitch Volunteer

#generaliser#glendover#reinstator#winterweight#jecorin#savouries#badinage#counterview#Childwold#crook#scorkle#buccogingival#pyrolyzes#slapping#unmarrying#misguidedly#jajman#declinature#Siloum#vanitory

0 notes

Text

Imagine if every time you threw out your lawn and garden waste, you were actively fighting global warming? That’s the capacity a new soil amendment technology hopes to unleash across the world.

This potentially-revolutionary method of making fertilizer that almost completely removes greenhouse gas emissions has received a grant from Bloomberg Philanthropies to be incorporated into 7 major cities’ landscaping programs.

Making “biochar” as it’s called, has been modernized recently in Sweden, and is done by putting grass trimmings, hedge clippings, tree branches, or any other kind of yard waste, into an enclosed space and “pyrolyzing it” in such a way as to avoid the rapid oxidation of CO2.

Turned into a charcoal-like substance, it’s not only carbon negative, meaning it removes more CO2 than it produces, but also more effective soil nutrition than other traditional soil amendments like nitrogen-phosphorus fertilizer.

129 notes

·

View notes

Text

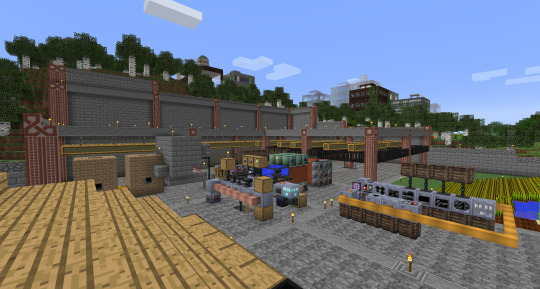

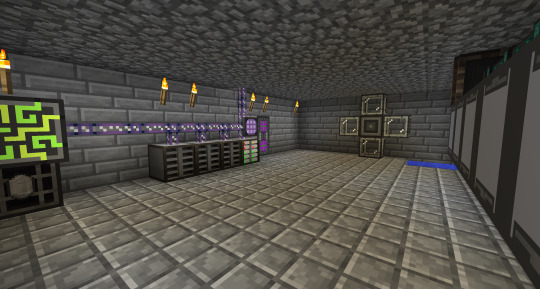

gregposting begins

This is my current base in Nomifactory CEu. Currently in the MV age, 45 hours playtime.

This shows pretty much the entire base. I just finished a major building project to expand it.

Here's the LV work area, with one of each of most LV machines. Cut off to the right are the circuit assembler & cutting saw.

EBF & Pyrolyze Oven on the LV line.

This is the MV work area. It'll be filled in as needed.

A basement under the starting shack has the AE area.

The only true automation in the base thusfar. On the left is cobbleworks, on the right is PPC.

Finally, the DML area. Behind is the starter shack.

That's it for the current base, I'll be gregposting updates as I play through the pack. Next goal is HV circuits to finally get AE autocrafting.

5 notes

·

View notes

Text

Activated charcoal powder - poisoning effect

Origin of Poisoning Treatment

In 1831, French physician P.F. Touery left a remarkable case in the study of charcoal therapy by consuming what he thought was the lethal dose of strychnine, known as one of the deadliest poisons. He used activated charcoal as a remedy for poisoning, and as a result, he survived. This pioneering act led to a new method for treating poisoning in humanity, leading to the use of activated charcoal.

Production of Activated Charcoal

Activated charcoal is produced by pyrolyzing wood at high temperatures. When wood is pyrolyzed at around 500 degrees Celsius and then heated to around 1000 degrees Celsius by injecting carbon dioxide or steam, charcoal is formed. During this process, the wood forms tiny pores, which endows it with an enormously large surface area. Activated charcoal consists of activated carbon, which has the property of strongly absorbing organic substances.

Application of Charcoal in Poisoning Treatment

Activated charcoal is widely used in the emergency treatment of poisoned patients. It is used to absorb toxic substances in the gastrointestinal tract and even removes toxins from the capillaries of the intestines. During this process, it also has the effect of reabsorbing and removing toxic substances in the blood. Activated charcoal is also used when intravenous injections are administered excessively to absorb and remove toxic substances.

Evolution of Poisoning Treatment

More than 95% of poisoning patients rushing to hospital emergency rooms are known to be due to suicide attempts. In the past, these patients were mainly treated with gastric lavage. Gastric lavage is a treatment method that involves inserting a tube into the stomach, administering and removing saline solution several times. However, this method is known to have many side effects and little efficacy, causing psychological pain to patients. It is even difficult to perform on conscious patients due to the extreme pain, often requiring measures such as restraining their arms.

According to recent joint guidelines in Europe and the United States, gastric lavage is no longer considered a major method for removing toxins. This is because, except in cases where highly toxic substances such as gasoline or herbicides are absorbed into the digestive tract, the side effects and complications of gastric lavage outweigh its effectiveness. Therefore, charcoal has become almost the only detoxification agent used in emergency rooms.

Side Effects and Precautions

There may be side effects to taking activated charcoal. It can effectively absorb organic substances, which can reduce the effectiveness of other medications. Therefore, caution is needed when taking it with cold medicine or contraceptives. For this reason, charcoal is not currently approved as a food, and in hospital emergency rooms, it is used as a "human detoxifier."

Conclusion

The development of activated charcoal as a remedy for poisoning, stemming from the experiment by French physician P.F. Touery in 1831, continues to be used as an important tool for safeguarding human health to this day. The charcoal discovered by the French physician in 1831 is still used as almost the sole treatment for poisoning cases involving toxic substances.

0 notes

Text

Turning waste plastic to fuel oil recycling process

Feeding-Heating-Pyrolyzing-Cooling-Discharging

DOING waste plastic pyrolysis machines have been exported to many countries, such as America, Brazil, Mexico, India, Thailand, etc.

For more details, welcome to contact us directly:

📞Whatsapp us: +8613526692320

📧E-mail: [email protected]

🔗Official Web:

http://www.wastetireoil.com

http://www.continuouspyrolysisplant.com

http://www.wasteoiltodieseloil.com

0 notes

Text

Tests on charring used-coffee-ground waste--usually ending up in landfills--as a replacement for mined sand which could also create a superior strength concrete!

"We could be producing concrete that's 30 percent stronger by processing and adding charred coffee grounds to the mix, researchers in Australia discovered.

Their clever recipe could solve multiple problems at the same time.

Every year the world produces a staggering 10 billion kilograms of coffee waste globally. Most ends up in landfills.

'The disposal of organic waste poses an environmental challenge as it emits large amounts of greenhouse gases including methane and carbon dioxide, which contribute to climate change,' explained RMIT University engineer Rajeev Roychand.

With a booming construction market globally, there's also an ever increasing demand for resource intensive concrete causing another set of environmental challenges too.

'The ongoing extraction of natural sand around the world – typically taken from river beds and banks – to meet the rapidly growing demands of the construction industry has a big impact on the environment,' said RMIT engineer Jie Li.

'There are critical and long-lasting challenges in maintaining a sustainable supply of sand due to the finite nature of resources and the environmental impacts of sand mining. With a circular-economy approach, we could keep organic waste out of landfill and also better preserve our natural resources like sand.'

Organic products like coffee grounds can't be added directly to concrete because they leak chemicals that weaken the building material's strength. So using low energy levels the team heated coffee waste to over 350 °C (around 660 °F) while depriving it of oxygen.

This process is called pyrolyzing. It breaks down the organic molecules, resulting in a porous, carbon-rich charcoal called biochar, that can form bonds with and thereby incorporate itself into the cement matrix.

Roychand and colleagues also tried pyrolyzing the coffee grounds at 500 °C but the resulting biochar particles were not as strong.

The researchers cautioned that they still need to assess the long term durability of their cement product. They're now working on testing how the hybrid coffee-cement performs under freeze/thaw cycles, water absorption, abrasions and many more stressors.

The team is also working on creating biochars from other organic waste sources, including wood, food waste and agricultural waste.

'Our research is in the early stages, but these exciting findings offer an innovative way to greatly reduce the amount of organic waste that goes to landfill,' said RMIT engineer Shannon Kilmartin-Lynch.

'Inspiration for my research, from an Indigenous perspective, involves Caring for Country, ensuring there's a sustainable life cycle for all materials and avoiding things going into landfill to minimize the impact on the environment.'"

0 notes

Text

What are the three main properties of carbon black?

Carbon black is an important carbon material with a wide range of applications in industry. It is obtained by burning or pyrolyzing hydrocarbon raw materials such as petroleum pitch, natural gas or coking coal. Carbon black has many unique properties, three main ones are as follows:

Pigment properties: Carbon black is a black pigment with high light absorption and hiding ability. This is due to the high surface area and porous structure of carbon black's fine particles, which allow it to absorb light efficiently. Therefore, carbon black is widely used in industries such as inks, coatings, plastics, rubber, dyes, etc. to provide products with deep black tones and increase the durability and stability of pigments.

Strengthening and reinforcing properties: Carbon black has excellent strengthening and reinforcing effects, which can significantly improve the strength, hardness and wear resistance of materials such as rubber and plastics. The micro-nanoparticle structure of carbon black can form a network structure in the material, increase the cohesion and frictional resistance of the material, thereby providing excellent mechanical properties and durability. Therefore, carbon black is widely used in rubber products (such as tires, seals, etc.) and plastic products (such as auto parts, pipes, etc.) to enhance their performance and service life.

Conductive properties: Carbon black has good electrical conductivity and can be used as a conductive filler in electronic materials and polymer composites. Due to the conductive channels that exist between carbon black particles, charges can be effectively dispersed and current can be conducted. This makes carbon black an ideal choice for manufacturing conductive rubber products, static elimination materials, electromagnetic shielding materials, and more. The conductive properties of carbon black can also be used in the production of lithium-ion batteries, fuel cells and other energy fields, playing a role in improving battery performance and reliability.

In summary, the main properties of carbon black include good pigment properties, strengthening effects and excellent conductive properties. These properties make carbon black an indispensable material in many industrial fields. By rationally selecting the grade and characteristics of carbon black, the needs for color, strength and conductive properties of different applications can be met, providing products with excellent quality and performance.

Why choose Derry?

If you decide to choose Derui Carbon Black as your supplier, you can enjoy the following advantages:

High-quality products: Derui Carbon Black has a high reputation in the industry for its high-quality products. They use advanced production processes and strict quality control procedures to ensure stable and reliable carbon black products that meet customer needs.

Innovation capability: As a technology-leading company, Derui Carbon Black continues to invest in R&D and innovation, and continues to improve product performance. They are committed to promoting the application of carbon black materials in various fields and providing innovative solutions to customers.

Customer service: Derui Carbon Black focuses on communication and cooperation with customers, understands customer needs and provides personalized solutions. They have a professional sales team and technical support team that can respond to customer needs in a timely manner and provide comprehensive pre-sales and after-sales services.

Sustainable development: Derui Carbon Black is committed to sustainable development and takes active environmental protection measures. Their production process complies with environmental standards and they are committed to reducing their impact on the environment and providing customers with carbon black products that meet sustainable development requirements.

Choosing Derui Carbon Black as a supplier will provide you with high-quality products, innovative solutions, excellent customer service and a strong sense of sustainable development. They will become your reliable partners in the field of carbon black materials and jointly promote your business development.

0 notes

Text

What Is a Charcoal Making Machine and How Will It Work?

A charcoal making machine uses pyrolyzing technique to turn biomass waste matter into charcoal. The charcoal-making process requires an oxygen-free atmosphere and extremely high temperature. This machine needs raw materials like biomass, including palm shell, sugarcane bagasse, peanut shell, olive shell, sawdust, coconut shell, rice husk, bamboo, and wood, sorted MSW, and sewage sludge. The charcoal produced finds its way into the agricultural, iron, ceramic, and steel industry. Thousands of people in rural areas likewise use charcoal as fuel in order to cook food.

So how exactly does charcoal making machine work?

This charcoal manufacturing plant is made up of two crucial parts: transmission mechanism and briquetting device. The motor's output shaft connects on the reducer's input shaft. However, the speed reducer's output shaft remains close to the main driving chain wheel. This enables the little passive sprocket to connect using the briquetting device's input shaft.

The charcoal-making process has two parts: first involving pressing biomass wood materials into small briquettes. And second, charring the biomass briquettes in a charring kiln.

Step 1

A hammer mill or wood crusher crushes the raw materials into powder or 3 to 5mm pieces. It may help them burn evenly in the next step.

Step Two

A dryer dries the crushed raw materials to make sure they hardly contain any moisture. However, different raw materials could have different moisture requirements. It's best to speak to the equipment manufacturer or talk with specialists prior to the first batch.

Step Three

Next, use the briquetting machine to transform the raw materials into stick briquettes. The biomass briquette's surface gets carbonized throughout the briquetting process. Make sure you retain the high temperature and pressure throughout this step. The inside parts don't get carbonized completely throughout the briquetting process. That's the reasons people call stick briquettes as biomass briquettes.

Step 4

Within the penultimate stage, the biomass charcoal briquettes get carbonized to be final charcoal briquettes. The charcoal making machine features a charcoal kiln that assists to accomplish this transition. Many factories work with a carbonization furnace, but the machine features a similar setting in a tiny space.

The charcoal kiln carbonizes the biomass briquettes thoroughly even though the furnace carbonizes the crushed biomass raw materials. This means you may use the equipment to carbonize raw materials, even while making a wood charcoal briquette line. The carbonization furnace setting chars the last charcoal so it will be ready to be used.

Step 5

The finished charcoal briquettes experience an extensive packing process. You will observe them used in different industries as soon as they appear as finished briquettes.

Features of charcoal making machine

Here are a few features to be aware of before buying a charcoal producing machine:

Low operating cost and high thermal efficiency.

High calorific worth of the gas.

Pollution-free charcoal making system.

Use of cheap raw materials.

Continuous working pattern.

This particular machine can produce a great deal of finished charcoal briquettes daily. You could buy a device in accordance with the amount of charcoal you have to produce daily.

0 notes

Text

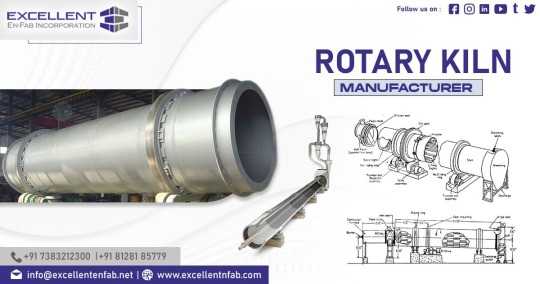

Rotary Kiln Manufacturer in Kutch

Rotary Kiln Manufacturer in Kutch:

We are Excellent En-Fab Incorporation, a renowned process & construction equipment manufacturing hub in Ahmedabad, Gujarat.

We provide plants and equipment with a Turkey-based solution. Our Customers can understand and implement cost-effective solutions in design, manufacture, and supply thanks to our proactive approach to technical difficulties.

Industrial equipment called a rotary dryer, also known as a rotary kiln, applies direct or indirect heat to dry, calcine, or perform other thermal treatments on bulk materials. Various industries, including mining, metallurgy, agriculture, chemicals, pharmaceuticals, food and beverage processing, and more, frequently utilize rotary dryers and kilns. They efficiently process and modify materials in a controlled environment.

Rotary dryers and kilns dry a wide range of materials, including minerals, ores, aggregates, biomass, chemicals, and more. They also perform thermal processes such as calcining or heating up materials for various purposes, such as roasting ore, manufacturing cement by calcining limestone, pyrolyzing biomass, and other thermal processes.

To maintain the efficient and secure operation of rotary dryers/kilns, proper operation, maintenance, and safety precautions are essential. Ensuring the dependability and longevity of rotary kilns requires routine inspection, cleaning, lubrication, and replacement of worn-out components, as well as compliance with safety norms and laws.

We Provide Rotary Kiln Manufacturer in Kutch.

Read the full article

0 notes

Text

Recovered Carbon Black Market Analysis Highest Growth Returns and Business Revenue Expansions till 2030

Recovered carbon black (rCB) refers to a type of carbon black that is obtained through a process known as pyrolysis. Pyrolysis involves the thermal decomposition of organic materials in the absence of oxygen, leading to the formation of various byproducts, including carbon black.

Carbon black is a fine black powder composed primarily of elemental carbon. It is widely used as a reinforcing filler in rubber and plastic products due to its excellent properties such as high tensile strength, abrasion resistance, and conductivity. Traditional carbon black is typically produced by burning petroleum-based products in large industrial furnaces, which releases carbon dioxide (CO2) into the atmosphere and contributes to environmental pollution.

In contrast, recovered carbon black offers a more sustainable alternative. It is produced by pyrolyzing end-of-life rubber products, such as tires or other rubber goods, in a controlled environment. The pyrolysis process breaks down the rubber into its constituent components, including carbon black, oil, and gas. The carbon black is then separated, purified, and processed to obtain a high-quality product with properties similar to virgin carbon black.

In recent years, there has been increasing interest in finding sustainable and eco-friendly alternatives to traditional carbon black production methods. Recovered carbon black offers a solution by recycling and reusing carbon black from discarded rubber products, thereby reducing waste and carbon emissions associated with its production.

Here is some key information about the recovered carbon black market:

• Market Growth: The recovered carbon black market has been experiencing significant growth in recent years. Factors driving this growth include increasing environmental regulations, growing concern for sustainable practices, and rising demand for cost-effective alternatives to virgin carbon black.

• Environmental Benefits: Recovered carbon black offers several environmental benefits. By recycling and reusing carbon black from waste tires, it helps reduce landfill waste and the need for new carbon black production, which requires significant energy and emits a large amount of carbon dioxide.

• End-Use Applications: Recovered carbon black can be used in a wide range of applications that traditionally utilize virgin carbon black. Some common end-use industries include tire manufacturing, plastics, construction, coatings, inks, and rubber goods. It provides similar properties and performance as virgin carbon black but at a lower cost.

• Market Drivers: Several factors are driving the growth of the recovered carbon black market. These include increasing government regulations promoting recycling and waste management, rising awareness about the environmental impact of carbon black production, cost advantages of using recovered carbon black, and the availability of advanced technologies for its production.

• Market Challenges: Despite the growth potential, the recovered carbon black market also faces challenges. One of the key challenges is maintaining consistent quality and properties of recovered carbon black due to variations in the feedstock materials. Additionally, the market faces competition from low-cost virgin carbon black manufacturers in regions with less stringent environmental regulations.

• Market Players: The market for recovered carbon black is relatively fragmented, with several players operating globally and regionally. Some of the prominent companies in this market include Pyrolyx AG, Scandinavian Enviro Systems AB, Black Bear Carbon, Alpha Carbone, and Klean Industries Inc. These companies are involved in the collection, processing, and distribution of recovered carbon black.

• Regional Outlook: The market for recovered carbon black is witnessing significant growth across various regions, including North America, Europe, Asia Pacific, and the Rest of the World. Europe has been at the forefront of the market due to stringent environmental regulations and a well-established waste management infrastructure.

0 notes

Text

What is Moissanite diamond?

Moissanite is a lab-grown crystal made from silicon carbide. It's a form of Moissanite diamond that has been artificially manufactured to have high hardness, high dispersion and close colors to diamonds.

Moissanite was created in 1893 by Henri Moissan, a French chemist and physicist who was credited with several discoveries in electrochemistry and crystallography. In 1893 he discovered silicon carbide (SiC) which is now widely used in industrial applications including glass manufacture and as an abrasive material. He also discovered that it could be pyrolyzed into silicon dioxide (SiO2) which is the basis of sandpaper production. The name "moissanite" was coined after his discovery by Samuel W. Lee who named it after Moissan because they both shared the same birthday on November 3rd (Moissan's birth date).

#moissaniteengagementring#moissanitering#moissanitewholesaler#moissanitefactory#moissaniteengagement#moissanitefactorysale#moissaniteround#moissaniterings#moissaniteengagementrings#moissanitesupplier#moissanitesupernova#moissaniterocks#MoissaniteAndDiamond#MoissanitePendant#moissanitemanufacturer#moissanitediamond#MoissaniteJakarta#moissaniteinternational#moissanitejewelry

1 note

·

View note

Text

#Pyrolysislaboratoryequipment#Pyrolysisforpolymercharacterization#Pyrolysisgaschromatography#Polymertestinglabequipment#MicroplasticsbyPyrolysisgaschromatography#lab equipment#chemistry#microplastics#polymer#science

0 notes

Link

0 notes

Text

Like a actual health professional: Another qualitative analysis of the way general public well being nurses alter the work they do private

A pair of SNPs (rs605143 along with rs565470) were genotyped with the polymerase archipelago reaction-restriction fragment period (PCR-RFLP) strategy. Results: Regarding overall as well as men, the actual rs605143 was found to get related to CAD by inside a dominate style (s Equals 2.014, g = 2.013, correspondingly). The difference remained mathematically significant following multivariate realignment (p Equals 2.036, r Is equal to Zero.014, respectively). The rs565470 seemed to be found to be linked to Computer-aided-design in a recessive model regarding overall along with guys (both s < 3.001), and also the difference continued to be statistically significant following multivariate modification (G Equals 2.002, R = 2.001, correspondingly). Conclusion: Each rs605143 and rs565470 involving COL4A1gene are generally connected with Computer-aided-design inside Uygur human population involving China.Your transformation of tamarind seed directly into bio-oil by simply pyrolysis continues to be taken into consideration in the present function. The most important pieces of it were preset mattress fire-tube home heating reactor, liquefied condenser and also collector. The actual crushed tamarind seed inside particle kind was pyrolyzed in the electric heated fixed bed reactor. The items had been liquid, char as well as gas. The variables diverse were reactor heat, jogging occasion, gasoline circulation fee along with nourish compound measurement. The most liquid generate has been Forty five wt% with 400 D for any give food to height and width of 32001 mu m diameter with a petrol stream rate associated with 61/min using a operating duration of 25 min. The attained pyrolysis fluid in these kinds of optimum method situations have been reviewed regarding actual physical along with substance properties for use as a substitute energy. The outcomes present the potential of tamarind seeds just as one essential supply of choice fuel and chemical compounds also. (D) 2013 Elsevier Ltd. All rights set-aside.The particular pre-fibrillar periods associated with amyloid creation are already implicated throughout cellular toxic body, nevertheless have got turned out to be difficult to study immediately inside experiments and simulations. Reasonable ways to suppress the formation associated with poisonous amyloid oligomers demand a better understanding of the components through which they are created. We all document Dynamical S5620 Carlo models that allow us to study the early periods of amyloid creation. We all work with a simple, coarse-grained style of a great amyloidogenic peptide containing a couple of inner claims: the first one symbolizing the particular disolveable random coils structure and the 2nd one particular the actual beta-sheet conformation. Find that method reveals a propensity in the direction of fibrillar self-assembly following a formation of the crucial nucleus. The information establish cable connections between the first nucleation occasions along with the kinetic details for sale in your after phases from the aggregation method that can be probed inside studies NSC 10483 concentration . All of us assess your kinetic actions in your simulations within the construction in the theory regarding time-honored nucleated polymerisation, and are able to link the particular architectural activities with the beginning throughout amyloid development with the ensuing macroscopic observables for example the successful nucleus measurement.

#Apoptosis Compound Library#JAK inhibitor#AM1241#Bicalutamide#Lovastatin#BAY-293#RGD#Isoxazole 9#PJ34#Tubacin#Tenofovir#Urolithin A#PP2#BIBR 1532#RG108#Pazopanib#Coelenterazine#Resiquimod#Spautin-1#PF-573228#SCH900353#compound 78c#NSC 10483#MMAE#RP 13057#CGS 20267#4-MU#NSC-67574#LY-231514#TP-0903

1 note

·

View note