#manufacturingprocess

Photo

Robotics System Toolbox helps to design, simulate, and test manipulators, mobile robots, and humanoid robots in a single integrated design environment. #roboticautomation #robots #armrobots #automation #automationsystems #enstein_project #manufacturingindustry #productdesign #prototyping #fabrication #innovation #technology #enstein #industry40 #industrial_automation #industrialdesign #robotics #manufacturingprocess #roboticsengineering (at Enstein-Robots & Automations Pvt Ltd.) https://www.instagram.com/p/CpUW5ujLD0i/?igshid=NGJjMDIxMWI=

#roboticautomation#robots#armrobots#automation#automationsystems#enstein_project#manufacturingindustry#productdesign#prototyping#fabrication#innovation#technology#enstein#industry40#industrial_automation#industrialdesign#robotics#manufacturingprocess#roboticsengineering

2 notes

·

View notes

Text

#PPWovenBags#SugarPackaging#PackagingIndustry#ProductProtection#Transportation#ShelfLife#ManufacturingProcess#CustomizationOptions#BrandIdentity#Sustainability#Innovation

0 notes

Text

"Turning metal sheets into works of industrial art, one punch at a time - that's how we roll at Omnific Solution's Sheet Metal Department in MIDC Koper Khairne, Navi Mumbai!"

Address: Plot No.A- 814, Khairane Village, TTC Industrial Area, MIDC Industrial Area, Kopar Khairane, Navi Mumbai, Maharashtra 400705

Hours:

Phone: 087670 77801

@omnificsolution

#MetalPunching#SheetMetalFabrication#PrecisionPunching#ManufacturingProcess#OmnificSolution#MIDCIndustrialZone#KoperKhairne#NaviMumbaiManufacturing#Metalworking#industrialengineering

0 notes

Text

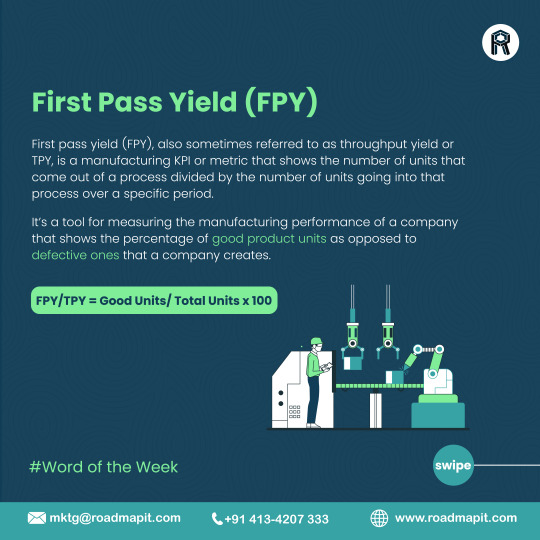

First Pass Yield

ERP systems integrated with production lines can be used to obtain first pass yield (FPY) data in real time. Using automated systems like quality management software (QMS) can also eliminate the need for manual data entry, resulting in more reliable FPY metrics.

Businesses seek to achieve a high FPY score reflecting the way they produce many high-quality, error-free goods. Having a high FPY score enables companies to spend money efficiently and fulfill consumer demand quickly. By analyzing this metric over time, companies can track their progress toward their goals and identify areas for improvement, such as reducing waste and increasing efficiency.

#firstpassyield#FPY#throughputyield#industrialmaintenance#qualitymanagementsystem#manufacturingprocess#roadmaperp#wordoftheweek#erpsoftware#erpsoftwareinchennai#erpsoftwareinbangalore#dairyindustry#roadmapitsolutions

0 notes

Text

#ADITYAELECTRODES#weldingelectrodes#weldingrods#arcwelding#WeldingElectrodes#WeldingRods#ArcWelding#MetalJoining#WeldingConsumables#WeldingProcess#ManufacturingProcess#RawMaterials#ElectrodeCoating#WeldingProfessionals#IndustrialWelding#WeldingSupplies

1 note

·

View note

Link

#collectingbaseballcards #errorcards #valuablecards #uniqueopportunity #manufacturingprocess #rarefinds #highvalue #printingmistakes #historiccards #1972Topps #1974Topps #1975Topps #1991Bowman #1992Donruss #1996Pinnacle #1998SPAuthentic #2000ToppsChrome #2010Topps #2014ToppsUpdate

#collectingbaseballcards#errorcards#valuablecards#uniqueopportunity#manufacturing processes#manufacturingprocess#rarefinds#highvalue#high value men#printingmistakes#historiccards

0 notes

Text

𝐓𝐡𝐞 𝐂𝐨𝐦𝐩𝐥𝐞𝐭𝐞 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲 𝐁𝐨𝐨𝐤 𝐨𝐧 𝐇𝐞𝐫𝐛𝐚𝐥 𝐁𝐞𝐚𝐮𝐭𝐲 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐬 - 𝟐𝐧𝐝 𝐄𝐝𝐢𝐭𝐢𝐨𝐧 | 𝐍𝐈𝐈𝐑 𝐏𝐑𝐎𝐉𝐄𝐂𝐓 𝐂𝐎𝐍𝐒𝐔𝐋𝐓𝐀𝐍𝐂𝐘 𝐒𝐄𝐑𝐕𝐈𝐂𝐄𝐒

The ultimate guide to herbal beauty product manufacturing! The Complete Technology Book on Herbal Beauty Products (Cosmetic Industry) offers in-depth insights into formulation, manufacturing process, machinery equipment details, and plant layout. Unleash your creativity in the cosmetic industry with 𝐍𝐈𝐈𝐑 𝐏𝐑𝐎𝐉𝐄𝐂𝐓 𝐂𝐎𝐍𝐒𝐔𝐋𝐓𝐀𝐍𝐂𝐘 𝐒𝐄𝐑𝐕𝐈𝐂𝐄𝐒 as your trustworthy partner. Learn from the experts and create products that enhance natural beauty. Grab your copy of this essential resource now!

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬 𝐟𝐨𝐫 𝐚 𝐜𝐨𝐧𝐬𝐮𝐥𝐭𝐚𝐭𝐢𝐨𝐧 𝐭𝐨𝐝𝐚𝐲!

☎ Call : +91-9097075054, +91-8800733955

📨 Email: [email protected]

📍 Address: 106-E, Kamla Nagar, Opposite Spark Mall, New Delhi-110007, India.

#HerbalBeautyProducts#CosmeticIndustry#TechnologyBook#ManufacturingProcess#MachineryEquipmentDetails#PlantLayout#BeautyIndustry#BeautyBook#HerbalCosmetics#BeautyFormulations

0 notes

Text

🎨 A little dab will do ya! Witness the mesmerizing color transformation of EPDM as the binder blends in. In this high-color blend, 85% of it is vibrant blue. The PLC system ensures a perfect mix. In a 3,000-pound mold, around 180 pounds of binder add strength and aesthetics. It's not just functional; it's eye-catching! Explore more at US Rubber. #sportsflooring #rubbergymflooring 🏋️♂️

#RubberFlooring#GymFlooring#EPDMColorBlends#ManufacturingProcess#SportFlooring#FitnessArea#ColorTransformation#EPDMBinder#AestheticImpact#USRubber

0 notes

Text

Translation Company in Dubai.

Are you looking for professional translation services in Dubai? That too for Manufacturing Company Our expert team provides accurate and reliable translation solutions for businesses and individuals. Contact us today for quality translation in Dubai.

#additivemanufacturing#apparelmanufacturing#garmentmanufacturing#leanmanufacturing#ukmanufacturing#clothingmanufacturing#manufacturingindustry#manufacturingengineering#manufacturingjobs#manufacturingprocess#americanmanufacturing#manufacturinguk#britishmanufacturing#foodmanufacturing#custommanufacturing#australianmanufacturing#contractmanufacturing#manufacturingcompany#manufacturingservices#manufacturingjeweller#digitalmanufacturing

1 note

·

View note

Text

Casting Session

Department of Mechanical Engineering organized a "Session on Casting"on 24th May,2023, for First year students of Dronacharya College of Engineering, Gurugram.The session was aimed at teaching experiments on heat and mass transfer and enable participants to conduct the experiments on their own.

The event was supervised under the supervision of Prof. Neha Chauhan. The session was attended by the students of Mechanical Engineering.

The objective of the event was to provide a valuable insight of manufacturing process particularly on Metal Casting.

#session#castingsession#experiments#heat#masstransfer#metalcasting#manufacturingprocess#mechanicalengineering#students#btechstudents#iic#aicte#engineeringcollege#topprivateengineeringcollegeingurugram#DronacharyaCollegeOfEngineering#cbseboard2023#JEE2023#BestEngineeringCollege#BestEngineeringCollegeinDelhiNCR#InstitutionInnovationCouncil#multipleplacement#Gurgaon#haryana

0 notes

Text

Silico Manganese Manufacturing Process and Its Different Stages - Sarda Metals

Silico manganese, a crucial alloy in the steel industry, plays a significant role in enhancing the quality and properties of steel products. Understanding the manufacturing process and the different stages involved in producing silico manganese is vital for anyone in the metallurgical field. In this article, we will delve into the intricate process of silico manganese production, exploring its various stages and their significance.

Table of Contents

Introduction

Raw Materials

2.1. Manganese Ore

2.2. Silicon

2.3. Carbon

Smelting Process

3.1. Preheating

3.2. Charging

3.3. Reduction

Refining Process

4.1. Desiliconization

4.2. Deoxidation

Alloying

5.1. Carbon Addition

5.2. Alloying Elements

Casting and Solidification

Crushing and Screening

Quality Control

Packaging and Distribution

Environmental Considerations

Importance in Steel Production

Advantages of Silico Manganese

Challenges in Manufacturing

Future Trends

Conclusion

Introduction

Silico manganese, often referred to as SiMn, is a ferroalloy composed primarily of manganese (Mn), silicon (Si), and carbon (C). It is used extensively in the steel industry to improve the mechanical and chemical properties of steel. The manufacturing process of silico manganese is a complex procedure that involves several stages, each contributing to the final product's quality.

Raw Materials

2.1. Manganese Ore

The primary raw material for silico manganese production is manganese ore. Manganese ore is mined from various sources, and its quality and composition significantly impact the final alloy's characteristics.

2.2. Silicon

Silicon, another essential component, is added to the mix to enhance the alloy's strength and heat resistance.

2.3. Carbon

Carbon serves as a reducing agent in the smelting process and contributes to controlling the carbon content in the final alloy.

Smelting Process

3.1. Preheating

The first step in manufacturing silico manganese is preheating the raw materials in a furnace. This preheating process reduces the energy required for smelting.

3.2. Charging

Once preheated, the raw materials are charged into the smelting furnace. This stage involves careful measurement and blending of the materials to achieve the desired composition.

3.3. Reduction

In the smelting furnace, the reduction process takes place, where manganese oxide is reduced to manganese metal. Silicon and carbon are crucial in this reduction, as they react with manganese oxide to produce silico manganese.

Refining Process

4.1. Desiliconization

To attain the desired silicon content, a refining process follows smelting. This stage removes excess silicon from the alloy.

4.2. Deoxidation

Deoxidation is carried out to eliminate any residual oxygen, ensuring the alloy's purity and quality.

Alloying

5.1. Carbon Addition

The carbon content is adjusted during the alloying stage to meet the specific requirements of different steel grades.

5.2. Alloying Elements

Additional alloying elements may be introduced to customize the properties of the silico manganese alloy for specific applications.

Casting and Solidification

Once the alloy is refined and alloyed to the desired composition, it is cast into molds to form various shapes and sizes. The alloy then solidifies, ready for further processing.

Crushing and Screening

After solidification, the silico manganese alloy is crushed and screened to obtain the desired particle sizes for different steelmaking processes.

Quality Control

Stringent quality control measures are implemented throughout the manufacturing process to ensure that the final product meets industry standards and customer requirements.

Packaging and Distribution

The processed silico manganese is packaged appropriately and distributed to steel manufacturers and other end-users.

Environmental Considerations

Silico manganese manufacturing, like many industrial processes, has environmental implications. Proper waste management and emissions control are essential to minimize its environmental footprint.

Importance in Steel Production

Silico manganese is indispensable in the steel industry, as it imparts desirable characteristics to steel, including increased strength, corrosion resistance, and high-temperature stability.

Advantages of Silico Manganese

Enhances steel quality

Improves mechanical properties

Increases heat resistance

Facilitates deoxidation

Customizable for various steel grades

Challenges in Manufacturing

Silico manganese production involves intricate processes and can be energy-intensive. Managing raw material quality and minimizing environmental impact are ongoing challenges.

Future Trends

Continuous research and development are expected to lead to more efficient and sustainable silico manganese production methods in the future.

Conclusion

Silico manganese is a vital alloy in the steel industry, contributing to the production of high-quality steel products. Understanding its manufacturing process and the different stages involved is crucial for anyone involved in metallurgy and steel production.

FAQs

What is silico manganese used for?

Silico manganese is used to enhance the quality and properties of steel, making it stronger and more corrosion-resistant.

Where is manganese ore sourced from?

Manganese ore is mined from various locations globally, including countries like South Africa, Australia, and Brazil.

How does silico manganese improve heat resistance in steel?

Silico manganese increases steel's heat resistance by reducing the carbon content and adding silicon, which enhances its ability to withstand high temperatures.

Are there any environmental concerns associated with silico manganese production?

Yes, silico manganese production can have environmental implications, but measures are taken to minimize its impact, such as proper waste management and emissions control.

What are the future prospects for silico manganese manufacturing?

Research and development efforts are focused on making the production process more efficient and environmentally friendly, ensuring a sustainable future for silico manganese manufacturing.

In conclusion, silico manganese is a critical component in the steel industry, and understanding its manufacturing process is essential for those in the metallurgical field. It not only improves the quality of steel but also contributes to its versatility in various applications, making it a valuable asset in the world of metallurgy. For those seeking a reliable metals manufacturer in India, exploring the intricate process of silico manganese production can shed light on the capabilities of such manufacturers and their contributions to the steel industry.

#SilicoManganese#SteelAlloy#Metallurgy#ManufacturingProcess#SardaMetals#SteelIndustry#QualitySteel#MetalsManufacturer#MetallurgicalField#IndianMetals

0 notes

Photo

Robot Operating System, a framework for building robot applications, allows developers to assemble a complex system by connecting existing solutions for small problems. ROS provides functionality for hardware abstraction, device drivers, communication between processes over multiple machines, tools for testing and visualization, and much more. #roboticautomation #robots #armrobots #automation #automationsystems #enstein_project #ros #manufacturingindustry #productdesign #prototyping #fabrication #innovation #technology #enstein #industry40 #industrial_automation #industrialdesign #robotics #manufacturingprocess #roboticsengineering (at Enstein-Robots & Automations Pvt Ltd.) https://www.instagram.com/p/CoB2P6BLo8s/?igshid=NGJjMDIxMWI=

#roboticautomation#robots#armrobots#automation#automationsystems#enstein_project#ros#manufacturingindustry#productdesign#prototyping#fabrication#innovation#technology#enstein#industry40#industrial_automation#industrialdesign#robotics#manufacturingprocess#roboticsengineering

2 notes

·

View notes

Text

Behind the Scenes: Manufacturing PP Woven Bags for Sugar Packaging

Introduction

PP woven sugar bags, crafted from polypropylene (PP) material, are indispensable in the packaging realm for their robustness and adaptability. Engineered through meticulous weaving, these bags offer unparalleled strength, ideal for safeguarding sugar and other commodities during storage and transit. Their moisture resistance properties ensure sugar freshness by preventing clumping and spoilage, while their breathability extends shelf life. Beyond the sugar sector, PP woven bags serve diverse industries, including agriculture and chemicals, as reliable packaging solutions. As a versatile and economical choice, PP woven sugar bags continue to drive efficient and sustainable packaging practices.

Importance of Packaging in Sugar Industry

In the dynamic landscape of the sugar industry, packaging plays an indispensable role, serving as the cornerstone of product integrity, brand reputation, and consumer satisfaction. Understanding the pivotal significance of packaging is crucial for sugar producers and distributors alike, as it directly impacts various facets of the supply chain, from product protection to transportation and shelf life.

1. Product Protection:

One of the primary functions of packaging in the sugar industry is to safeguard the product from external elements that could compromise its quality and purity. The robust barrier provided by packaging materials prevents contamination, moisture ingress, and exposure to light, preserving the freshness and flavor of the sugar from production facility to end-consumer.

2. Transportation:

Efficient transportation is essential for the seamless distribution of sugar products across vast distances, from manufacturing facilities to retail outlets and beyond. Packaging serves as a protective shield during transit, shielding the sugar from physical damage, vibration, and temperature fluctuations that may occur during handling and shipping processes.

3. Shelf Life:

The longevity of sugar products on store shelves is directly influenced by the quality and integrity of their packaging. Properly designed and sealed packaging solutions extend the shelf life of sugar by preventing exposure to air, moisture, and microbial contaminants, thereby minimizing the risk of spoilage and ensuring consumer satisfaction upon purchase.

In conclusion, the importance of packaging in the sugar industry cannot be overstated. From product protection to transportation and shelf life, packaging serves as a linchpin in the supply chain, safeguarding the quality and integrity of sugar products while enhancing brand trust and loyalty.

Materials Used in PP Woven Sugar Bags:

Let’s understand the manufacturing process behind our PP woven sugar bags:

Polypropylene (PP) Fiber

UV Stabilizers

Lamination

Customized Printing

Stitching and Sealing

Manufacturing Process

Raw Material Preparation

Extrusion and Weaving

Printing

Cutting and Stitching

Recycled Materials

Quality Control

Packaging and Shipping

Customization Options for PP Woven Sugar Bags

When it comes to packaging sugar, Formosa Synthetics Pvt. Ltd., a leading manufacturer of PP woven bags, offers a wide range of customization options to meet the unique needs of its clients in the sugar industry.

1. Size Options:

Formosa Synthetics Pvt. Ltd. provides flexibility in bag sizes, catering to various quantities of sugar, whether it’s for retail packaging or bulk storage. From small 5 kg bags to large 50 kg bags, there’s a size option to suit every requirement.

2. Color Selection:

With a diverse selection of colors available, Formosa Synthetics Pvt. Ltd. allows clients to choose the perfect hue to complement their brand or product. Whether it’s vibrant colors to attract attention on store shelves or muted tones for a more sophisticated look, there’s a color option to match every brand aesthetic.

3. Printing Designs:

Formosa Synthetics Pvt. Ltd. offers high-quality printing services to customize PP woven bags with logos, product information, and eye-catching designs. Utilizing advanced printing technology, intricate designs and vibrant colors can be reproduced with precision, ensuring brand visibility and recognition.

4. Branding Options:

In addition to printing designs, Formosa Synthetics Pvt. Ltd. provides branding options tailored to the sugar industry. Clients can incorporate their company logo, slogan, and other branding elements to create bags that reflect their brand identity and enhance brand awareness among consumers.

By partnering with Formosa Synthetics Pvt. Ltd., for customized PP woven sugar bags, clients can elevate their packaging strategy while ensuring product integrity and brand consistency.

Advantages of PP Woven Bags for Sugar Packaging:

Strength

Moisture Resistance

Durability

Conclusion

The utilization of PP woven bags for sugar packaging represents a sophisticated interplay of innovation, quality, and sustainability. With their robust construction, moisture resistance, and durability, PP woven bags ensure the safe and secure containment of sugar products throughout the supply chain. Formosa Synthetics Pvt. Ltd. exemplifies excellence in manufacturing, offering customizable solutions tailored to the unique needs of the sugar industry. From the meticulous selection of materials to the implementation of advanced printing techniques and quality control measures, Formosa Synthetics Pvt. Ltd. maintains unwavering commitment to delivering premium-quality PP woven bags that meet the highest standards of performance and reliability. As we look towards the future, the industry can anticipate further advancements in materials, sustainable technology, and eco-friendly practices, propelled by the collective efforts of companies like Formosa Synthetics Pvt. Ltd. to innovate and elevate packaging standards.

Read More

#PPWovenBags#SugarPackaging#PackagingIndustry#ProductProtection#Transportation#ShelfLife#ManufacturingProcess#CustomizationOptions#BrandIdentity#Sustainability#Innovation#formosasynthetics

0 notes

Text

" How to Properly Maintain and Inspect Flanges "...READ MORE: https://bit.ly/44MJB6s

#maintain#inspect#flange#failure#safety#precautions#causes#prevention#machining#manufacturing#manufacturingprocess#americaninstitute#americansociety#internationalorgnization#nationalboard#regulationofindustries#humble#forging#industrial#system#pipe#piping#steel#stainlesssteel#alloysteel#carbonsteel#valves#equipment#temperature "

0 notes

Text

From Assembly to Shipping: The Ultimate Factory Conveyor Belt

In the world of modern manufacturing, efficiency is paramount. One of the unsung heroes behind this efficiency is the factory conveyor belt. These unassuming systems play a vital role in seamlessly transporting products through various stages of production, all the way from assembly to shipping. At Conveyors Joint, we delve into the incredible journey of the factory conveyor belt and its indispensable role in today's manufacturing landscape.

Assembly Line Prowess:

The journey begins on the assembly line. Here, raw materials and components come together to form the final product. The factory conveyor belt takes center stage, shuttling parts from one workstation to another. This continuous movement ensures a steady workflow, reducing the chances of bottlenecks and delays. The precision and speed of the conveyor belt guarantee that each station receives the necessary components right on time, allowing for a seamless assembly process.

Quality Control & Inspection:

Before a product can move on to the next phase, it undergoes rigorous quality control checks. The conveyor belt facilitates this process as well. Products move past specialized sensors, cameras, and inspectors who meticulously examine them for defects or irregularities. Any faulty products can be easily identified and removed from the line, ensuring that only the highest quality items proceed further.

Automation Advantages:

Modern factory conveyor belts are often integrated with automation systems. This integration allows for even greater efficiency gains. Automation can include everything from product tracking using RFID tags to automated adjustments based on real-time data. The marriage of conveyor belts and automation reduces human error, increases production speed, and provides valuable insights into the manufacturing process.

Packaging and Shipping Preparation:

Once the products are assembled and thoroughly inspected, they are ready for packaging and shipping. Conveyor belts continue to play a pivotal role in this phase. They transport the products to packaging stations, where they are carefully boxed, labeled, and prepared for shipping. This last leg of the journey ensures that products are neatly organized and ready to be dispatched to their final destinations.

Environmental Considerations:

The modern factory conveyor belt isn't just about efficiency; it's also about sustainability. Many manufacturers are now investing in eco-friendly conveyor belt systems. These systems are designed to be energy-efficient, reducing both operational costs and environmental impact. Additionally, conveyor belts are often made from recyclable materials, contributing to the circular economy.

0 notes

Text

Unveiling the Art of ACP Sheet Manufacturing:

The ACP sheet manufacturing process involves precision engineering and adheres to strict quality standards, making it a popular choice for a wide range of architectural and construction applications due to its lightweight, durability, and aesthetic appeal.

Here is an overview of the ACP (Aluminum Composite Panel) sheet manufacturing process:

Learn more

https://www.aludecor.com/manufacturing-unit

#ACPManufacturing#AluminumCompositePanel#BuildingMaterials#ManufacturingProcess#ConstructionMaterials#AluminumCoils#InnovativeMaterials

0 notes