#industrialrobots

Text

youtube

How to choose the right loading equipment

#Leapion#LeapionLaser#LeapionCNC#LaserCutting#ManufacturingTechnology#MaterialHandling#AutomationSystems#LoadingEquipment#C-shapedautomaticloadingmechanism#Columnrobotloadingequipment#Four-axiscolumnrobot#Guiderailrobot#LaserCutter#EquipmentSelection#FactoryOperations#ManufacturingProcesses#IndustrialRobots#EngineeringTechnology#IndustrialAutomation#AdvancedManufacturing#ProductivityEnhancement#MachineOperations#ToolSelection#Youtube

0 notes

Link

#actuatorsinrobotics#AdvancedRoboticGrippers#AdvancedRoboticsEngineering#AutomationTechnology#collaborativerobots#CustomRoboticSolutions#EndEffectors#FlexibleRobotSystems#Grippertechnology#industrialrobots#KinematicsinRobotics#ManipulatorDynamics#MechanicalEngineering#MotionControl#PrecisionRobotics#ProgrammableManipulators#RobotManipulators#RoboticArmDesign#RoboticArms#RoboticAssemblyAutomation#RoboticAutomationSystems#RoboticControlSystems#RoboticEfficiencyEnhancement#RoboticManipulationTechniques#RoboticSystemIntegration

0 notes

Text

Revolutionizing Tech | 4 HUMANOID ROBOTS THAT WILL LAUNCH IN 2024

youtube

In this exciting video, They delve into the future of technology by showcasing four incredible humanoid robots set to launch in 2024. Get ready to be amazed by the cutting-edge advancements in robotics that are revolutionizing their world. From AI-powered companions to versatile industrial assistants, these robots are set to change the way we live and work. Join and explore the fascinating world of robotics and the incredible potential it holds.

#TechRevolution#HumanoidRobots#2024Tech#RoboticsInnovation#AICompanions#FutureTech#IndustrialRobots#RoboticsRevolution#Innovation2024#AIAdvancements#Youtube

0 notes

Text

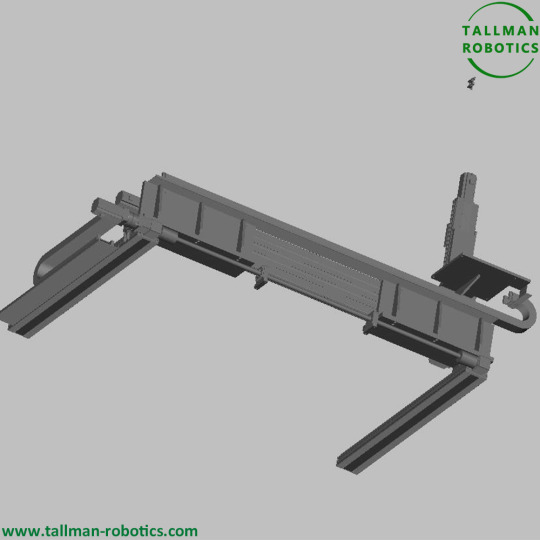

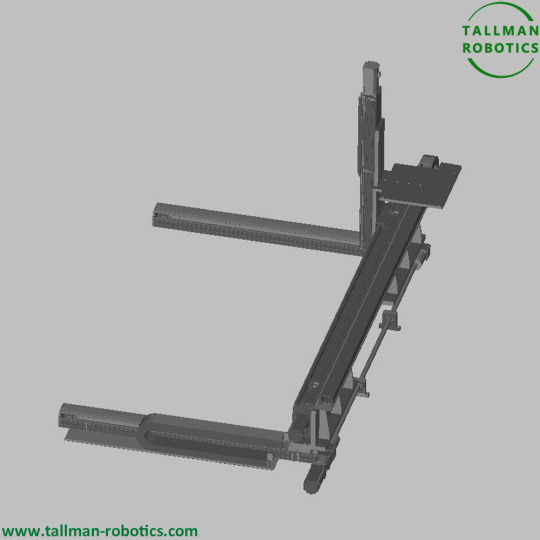

XYZ Cartesian Robots Will Be Ready for Delivery to Germany

XYZ Cartesian Robots from Tallman Robotics Limited will be delivered to Germany.

XYZ Cartesian Robots are automated machines that are used in industry to carry out repetitive tasks.

XYZ have three axes of movement and can be programmed to carry out precise, repetitive motions. They are widely used in production, assembly and packaging in many industries.

XYZ Gantry Robots,which are motorized robots used for industrial automation and material handling applications. They are usually mounted on a linear rail system and can move, lift, and manipulate loads in a three-dimensional space. Gantry Robots are especially well-suited to applications that require high payloads and repeatable accuracy.

You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data.

Read the full article

#Cartesianrobotsystem#CartesianRobotSystems#Cartesianrobots#GantryStages#GantrySystems#IndustrialRobots#ModularCartesianRobotsSystems#MultiAxisCartesianRobots#XYGantryStages#XY-ZCartesianRobots#XYZGantry

0 notes

Text

FANUC R-2000iC Robot

The FANUC R-2000ic robot is a smart robot based on the long experience of FANUC and renowned technical advantages.With high efficiency and high reliability, this intelligent robot serves your needs in a range of applications such as spot welding, material handling, and assembly.

Here are a few of its key Features:

Mechanical and lightweight robot weight reduction.

The solid but lightweight arm and advanced motion control technologies enhance motion efficiency dramatically, allowing increased productivity.

Comprehensive solutions, including the spot welding solution arm, are available for different processes.

With its energy regeneration option and lightweight cabinets, the R-30iB and R-30iB Plus robot controller saves energy and floor space.

Offered with various smart functions, such as the learning robot, bin collection, strength sensing, and visual line tracking.

Here are a few Models of FANUC’s top of the line R-series that are made for every thought of task at hand. You may find these Robots in our inventory at a very substantial and fair price.

Fanuc R-2000iC/165R Robot

Rack mount all-rounder

The Fanuc R-2000iC/165R rack mounting robot is suitable for increasing the efficiency of rack systems, such as presses, CNC, and other tendering applications for robotic machines. Its large work pack also ensures that robotic loading and unloading operations are as versatile as possible. In addition to adding flexibility to your robot, you save precious floor space by mounting the rack.

Fanuc R-2000iC/210R Robot

Rack mounted all-rounder

The Fanuc rack-mounted robot saves room. Thanks to its large work surface of 3095 mm, it provides massive versatility. It is the ideal solution for a multitude of high-paid robotic automation applications with high quality and excellent payload capabilities. It also allows a very powerful spot welding robot fitted with a lightweight kit.

Fanuc R-2000iC/210F Robot

Heavy handling at any angle

The Fanuc R-2000iC/210F is suitable for almost any robotic automation program, with its massive 210 kg payload and a wide range of heavy handling tasks. It provides an excellent spot welding robot with various mounting options to allow efficient use of the space and to generate an optimal envelope. Food processing automation or wet environments can be supplied in additional choices.

Fanuc R-2000iC/125L Robot

Long arm all-rounder

This world-beating robot series provides an extra-wide scope for high performance and payload capabilities. With 6 axles for maximum flexibility, it can handle heavy loads precisely within a generous working envelope. This makes it the right option for applications with high loads that require outstanding repetitiveness.

Fanuc R-2000iC/165F Robot

The nimble all-rounder

The all-round model of the R-series, this version, sets new standards in almost every sector due to the versatility of the six-axis high payload model. Equipped with an outstanding turnaround time and a thin forearm, it is a spotlight welding robot for industrial applications and related robotics. It is also designed to optimize space use and to allow robots to work nearby.

2 notes

·

View notes

Text

Industrial Robotics Market Business Summation, Industry Examination, Standpoint 2024 to 2030

The qualitative report published by Exactitude Consultancy research on the “Industrial Robotics Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Industrial Robotics market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Industrial Robotics Market from a Global and Regional perspective.

The global industrial robotics market was valued at 15.8 billion in 2022, and is projected to reach USD 40.22 billion by 2029, growing at a CAGR of 14.3% from 2022 to 2029.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/17446/industrial-robotics-market/

#IndustrialRobotics#RoboticsTechnology#FactoryAutomation#ManufacturingAutomation#RoboticAutomation#IndustrialAutomation#RoboticsIndustry#Industry40#AutomationTechnology#RoboticSystems#SmartManufacturing#RoboticsEngineering#RoboticsInnovation#RoboticSolutions#AutomationEngineering#RoboticManufacturing#RoboticsDevelopment#RoboticAssembly#RoboticArm#RoboticsResearch

0 notes

Text

Ever thought your security guard could use an upgrade? 🤖💡

Athena - the surveillance robot who’s never caught napping on the job (because, well, it doesn’t sleep).

Forget old-school security; let’s get a bit of robotic flair in the security game with endless energy! 😉

#SurveillanceRobot#SecurityRobot#RoboticSolution#Innovation#Future#Robot#Technology#MallSecurity#AiRobot#AdvanceRobot#AiPoweredRobot#IntelligentRobot#artificialintelligence#Ahmedabad#IndianRobot#IndustrialRobot#DefenceRobot#militaryrobotics#MakeInIndia#machinelearning#KodyRobots#KodyTechnolab

0 notes

Text

Revolutionizing Industrial Robotics with Deep Reinforcement Learning

In the realm of industrial automation, robots are taking center stage, but mastering complex tasks like object grasping and assembly has been a hurdle. However, a recent breakthrough by researchers at Qingdao University of Technology is poised to change that narrative. Unlocking the Potential of Autonomous Robotics Semi-autonomous and autonomous robots are making waves across various industries, from manufacturing to logistics. Their ability to assist human workers and streamline processes is undeniable. But what if they could do more than just assist? What if they could learn and adapt on their own? The Challenge of Industrial Automation Industrial robots have […]

#MACHINELEARNINGAI#ROBOTICS#Automation#DeepReinforcementLearning#IndustrialRobotics#RoboticsResearch#TechnologyInnovation

0 notes

Video

youtube

Fun facts about Industrial robots #ai #airobots #robots #industrialrobot...

#youtube#ai robots industrialrobots airobots video industry artificialintelligence foryou fyp viral usa trending scienceonline science_online I

0 notes

Text

youtube

Join us as we delve into the Customized Dual-Axis Manipulator Robot Welding Machine. This tutorial offers a comprehensive guide on program parameters setup for optimal performance.

#Leapion#LeapionLaser#LeapionCNC#CustomRobotWelding#DualAxisManipulator#WeldingMachineTutorial#ProgramParameterSetup#ManufacturingAutomation#IndustrialRobotics#CustomizedMachinery#AdvancedManufacturing#RoboticWeldingTechnology#PrecisionManufacturing#WeldingProcessOptimization#MachineProgramming#RoboticsTutorial#CustomerizationService#LaserRobotWeldingMachine#DetailedTutorial#ProgramParameterSetupTutorial#LaserWelders#Customizes#Youtube

0 notes

Text

#FoodRobotics#ChangingFoodIndustry#RoboticRevolution#FutureofFood#AutomationInFood#TechInFood#FoodTech#RoboticsInnovation#SustainableFood#EfficiencyInFood#FoodIndustryTrends#SmartFoodSystems#FoodTechRevolution#RoboticsAdvancements#FoodPreparation#FoodServing#FoodPackaging#FoodWasteReduction#NextGenFood#IndustrialRobotics

0 notes

Text

0 notes

Text

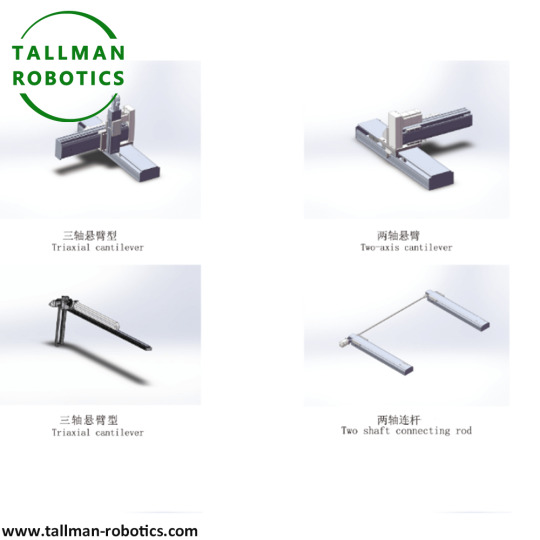

Multi Axis Robots

Multi Axis Robots in our ranges refere to XYZ Three-axis Cantilever Manipulator or Multi axis robotic arm.You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects.

The Y-axis base is fixed, the Z-axis body is fixed, and the slider moves up and down. The XYZ axis moves with the Y-axis slider to achieve XYZ space movement, in this case, it can be understood as Multi axis robotic arm or Multi Axis Robots.

The most commonly used combination structure is suitable for the handling, taking and placing, positioning and other functions of workpieces.

Transmission mode: standard type: ball screw transmission (synchronous belt transmission is optional)

Maximum load: according to the actual model selection/customized specifications.

The most commonly used combination structure is suitable for the handling, taking and placing, positioning and other functions of light loaded workpieces.

The cross sliding platform module is a combination of two groups of directly selected sliding platforms in the X and Y directions, which is usually called a right angle robot, a coordinate axis sliding platform, and an XY axis sliding platform. In industry, the X axis is often represented in the horizontal direction, and the other axis is the Y axis. When the midpoint of the X axis coincides with the Y axis, it looks like the Chinese character "cross" in appearance, and the name of the cross slide is derived from this.

The working principle of the cross sliding platform module is to fix one group of linear sliding platforms on the sliding blocks of another group of sliding platforms. For example, fix the X axis on the sliding table of the Y axis, so that the slider on the X axis is the moving object, and the Y axis can control the Y direction movement of the slider.

Read the full article

#AutomatedGantries#Cartesianmulti-axissystems#CartesianRobot/OrthogonalRobot#Industrialrobots#LinearRobotics#MultiAxesApplicationRobots#Multi-Axis-IndustrialAutomatedRoboticArm#Multi-AxisSystems#RoboticAutomationSolutions

0 notes

Text

APTRON Solution Noida is a leading provider of Industrial Automation Training Institute in Noida, India. The institute offers a comprehensive range of courses designed to meet the needs of students of all levels, from beginners to experienced professionals. APTRON Solution Noida's industrial automation training courses are taught by experienced and qualified instructors who use state-of-the-art equipment and facilities to provide students with the hands-on experience they need to succeed in their careers.

#industrialautomation#industrialsolutions#industrialnetworking#industrialrobotics#Noida#APTRON#career#training#job

0 notes

Link

◆◆CONTACT US◆◆

972-352-3552

972-488-1200

universalroboticinc.com

#new#newproduct#automation#industrialrobot#industrial#robotics#robots#offlineprogramming#fanucrobotics#FANUC#FANUCTurkey#ROBOCUT#WireCutting#WireEDM

2 notes

·

View notes

Text

OILES Corporation is a manufacturer of Self-lubricating bearings. These bearings can be fitted to many more applications from machine tooling to aerospace or marine industry. The multi-layer bearings are composed of sliding surfaces made of sintered material and steel back metals.

Industrial robots use different types of self-lubricating bearings for more smooth functioning. Oiles Drymet LF is made of steel back metal with dry lubrication. It showcases performances during temperatures ranging between -200 to ~ +280. It provides superior dimensional stability, mechanical strength, and thermal conductivity.

SEIMITSU factory Automation Pvt Ltd is an authorized distributor of OILES Corporation in India. With the fastest delivery feature, we can be your best solution partner. Please visit our website at https://www.seimitsu.in/OILES-bearing-products.html for detailed information on OILES products. You can write us at [email protected] for personal assistance.

#oiles#oilesbearings#selflubricatingbearings#industrialrobot#drymetlf#oiles2000#metalicbearings#multilayerbearings#bearings#oilesdistributor#oilessupplier#oilesindia#seimitsu#seimitsufactoryautomation

0 notes