#how to design laser cutting files

Text

#laser cutting#laser#laser cutter#laser cutting machine#laser engraving#cutting#laser cut#laser engraver#fiber laser cutting#fiber laser#laser cutting fabric#laser cutting projects#how to design laser cutting files#cutting laser#pagar cutting laser#mesin cutting laser#20w laser cutting#laser cutting 101#tube laser cutting#fast laser cutting#laser cutting metal#metal laser cutting#laser metal cutting#laser cutting vinyl#mesin laser cutting

1 note

·

View note

Note

how did you first get into making this stuff? do you enjoy it?

There's a lot of possible answers here.

For a couple years after college, I worked at a laser engraving and cutting shop. Leather was a material we knew we could cut, but nobody ever asked for it, so I looked up some basic info and put together some masks as demo pieces. Then I got fired for unrelated reasons, but decided to keep going with the masks on my own. A decade later, I’m still going.

I've always enjoyed making things. The focused calm of working a craft, the challenge of finding the problems that need solving, followed by the satisfaction of holding in your hands something that hadn't exited before. It’s hard to beat that feeling. If you haven’t done it for a while, I highly recommend making a habit of it.

Sometime in college I realized that if I kept making things just for myself, I would eventually run out of both space in my closet and money in my bank account. So I took the best photos I could of what I had, and started posting it up on Etsy.

In high school ceramics class, I had an idea to try and make a flexible dragon skin out of little bits of clay, all glazed differently. I had no idea how to do this. A friend of mine was like "Yo it sounds like you want to look up how to make chainmail for that." She was right.

I work in architecture by day, and the decision to do that was unrelated but definitely related to my crafting obsession. Designing a kitchen, a café, a house, takes months or years of work, most of which is tedious details like picking tile patterns or looking up exactly what order to layer different sealant tapes to make sure the walls are watertight. Designing a crafting project gives me a creative outlet that is immediate. I can sit down for an afternoon and take an idea from a sketch on trace paper, to a final mask formed up out of leather. There's an excitement to that. A reminder that, yes, I can make cool stuff quickly, without needing to sink two years into a project.

For a while I worked to teach myself to draw. I managed to get pretty decent at sketching from life, with a moderate understanding of anatomy and perspective. I liked art, so I thought I wanted to make art. But I struggled with it. If I was drawing something from my imagination, no matter how well I managed to put the lines down on the paper, I would ultimately look at it and just be sad that it didn't exist in the real world. So eventually I gave up on the drawing part, and focused on the part I seemed to actually care about.

I can't envision a version of myself that doesn't make things. I think on some fundamental level, I measure my worth as a person based on what I put forth into the world. I don't know what else to do.

When you decide to turn a hobby into a business, it of course takes some of the delight away. It's no longer something you do when you want to relax and have some fun. It becomes an obligation, to make and ship orders on time, to pack up your stuff and bring it to craft fairs, to track your expenses and file your taxes, to stay on top of the constantly changing social media landscape. But it also lights a fire under your ass. You can't just keep making the same thing you made three years ago–you have to keep making new stuff, keep improving your techniques, keep reaching for new ideas that have never been made before. You lose some of the joy, but you gain a lot of satisfaction.

All through my childhood I filled my closet with little handicrafts kits, that I got as gifts or that caught my eye when following my dad to the art store. Calligraphy, wood carving, weaving looms, boondoggles, spirographs, knitting, crochet, fancy nautical knots, sculpey, and more that I can't remember. After all those different things, I’m so glad that I found a couple specific crafts that really grabbed me, that take enough work to develop expertise, that have expansive enough applications and possibilities, that I could devote a decade or more of my time to focusing on them.

I’d been interested in the furry fandom ever since little fantasy reading teenager me tried looking for stories where the dragons were the main characters, and I found people online who were doing just that. There’s a powerful do-it-yourself attitude that’s baked into the core of the fandom: The world isn’t giving us the art that we want, so we’re going to make it ourselves. I keep having ideas for things that I want, that don’t exist yet. If I want them to exist, I have to be the one to make them.

My dad was a photographer, and I spent many childhood afternoons with him in his darkroom in the basement, delightedly washing negatives, turning them gently over in their canisters of chemicals, sitting still in the dark as Dad unspooled the sensitive film, squinting in the red light as the projected images magically re-emerged on the clean white paper. What could be more amazing, more normal, more right, than having your own little space to work such magic for yourself.

In about 2008 or 9 I ordered my first batch of metal scales, with the idea of trying to make a dragon tail in time for Halloween. It took probably a couple weeks to figure out how to make it, and within a week I had thought of how to do it better and disassembled the entire thing. By the 3rd or 4th time I'd rebuilt it, I thought that it was probably good enough that I wouldn't feel embarrassed to post it online and see if someone might want to buy it.

Of course I love working on these things I make. But I don't think that's exactly why I make them.

37 notes

·

View notes

Text

HEY LOOK AT THIS COOL THING I MADE FOR A CLASS PROJECT LAST SEMESTER THAT I KEEP FORGETTING TO UPLOAD PICTURES OF :D

(Long-ass rambles to follow, feel free to skip down to the additional box pics. Short video of the laser cutter working at the bottom!)

This is a laser-cut wooden box! The parts were designed in SolidWorks, then drawings of those works were converted in Autocad to be uploaded to the laser cutter. I had a lot of fun with the designs, as you can tell :] I took inspo from the little heart-embroidered-thing c!Philza has on his shirt in SAD-ist's design because it incorporates what I like to call the "narrow eyes" of the Hardcore heart without the lines ever breaking, making the design possible for a solid object...

...but I couldn't do all the curvy bits because SolidWorks hates me lmao.

The emeralds are for emduo ofc. I thought about doing a crown or pig mask or a sword for Techno, but I was running out of time for the project, mostly because I spent like way too long trying to make the wings curvy and realistic :( In the end, I went with a more geometric design, which I think I like the most. Also, it's more stable overall. The emeralds are on either side of the box btw.

I might come back to this post and add pics of the SolidWorks parts/drawings themselves if I can find the files.

The box's dimensions (LengthxWidthxHeight) in inches are 4.25x2.75x1.75 ignoring the lid. Here is sharpie for reference.

I added the color to the box design by scribbling in color with sharpies on paper, then sticking that paper on the inside of the box behind the designs. I was originally going to paint the box too but uhhhhhh I got lazy. Also I think I like being able to see the imperfections on the wood more anyway.

Oh!! Also the box currently holds my shinies (earrings)!!

You can see the paper lmao.

One last thing I got out of this project: after the wooden designs are cut out, you can fish the bigger scraps out of the machine, so guess what I made? :)

(Colored it with sharpie ofc.)

And uhhh that's it! Vvv fun to make! SolidWorks is awesome once you learn how to use it. I'm hoping to practice more once I have time (and possibly my own computer that won't melt if I try to run SolidWorks on it.)

Okay here's the vid :] It was longer but it had my voice in it so I had to cut it short, but I think it's enough for you to get the idea.

#my art#i guess this qualifies as art lmao#philza#philza fanart#dsmp fanart#emerald duo#emduo#c!philza fanart#solidworks#autocad

100 notes

·

View notes

Text

Proud to be an Aphrodite girl

HELLO! I'm back. So Rick did the Aphrodite cabin dirty and I got inspired by a tiktok post of the Aphrodite cabin pulling up to Capture the flag. Now I introduce you, "Proud to be an Aphrodite girl" A simple fanfiction of Piper learning her siblings can look pretty in pink with swords and daggers.

“HAS ANYONE SEEN MY LIPGLOSS?!”

“DREW! DID YOU TAKE MY PERFUME?!”

“Lacy those boots do not match your shorts.”

“Oh shut it Adrian! Your nail color and that orange don’t go together either.”

“Whoa! What’s going on here?” Piper looked out among the sea of the aphrodite cabin members. It should’ve been obvious what was going on. The aphrodite cabin was getting ready to absolutely demolish the red team at Capture the flag in color coordinated outfits, well would be color coordinated if DANIEL didn’t fuck it up by choosing to wear green sneakers instead of the chosen blue. “Getting ready for Capture the flag.” Valentina said it like it was obvious and Piper had to give it to her, due to the amount of golden armor and brightly customized weapons she should’ve guessed.

“I thought you guys wouldn’t like Capture the flag?” several gasps, mostly from the dramatic ones in the room. Drew spoke up first, sharpening her nails as if they were claws. “It involves fighting and being the best. Why wouldn’t we want to participate.”

“And we get to match! Or we would…” She sneaked a look at Daniel, who rolled his eyes and continued to strap on his neon green sneakers. Looking at it now, everyone else was right it wouldn’t match with their color scheme of blue, gold. Piper didn’t know how they made the bright orange camp shirts work but they did.

Lacy came up to her. Her golden armor went perfectly with those cool colored blue shoes. Her blonde hair in french braids. “Piper! You gotta join us! Penny came up with this really good plan that involves glitter, lipstick and lasers!” the young aphrodite girl rambled before Piper had to cut her off before she lost oxygen. “I’ll join. But what plan involves glitter?” She asked. Of course Piper was going to Join Capture the flag regardless. Penny, the girl who had developed the Aphrodite cabin’s plan, came forward. Piper had seen her hanging around the hephaestus cabin a lot. Red hair always in a ponytail, big round glasses that hid the prettiest brown eyes anyone could have. “I created it with the hephaestus cabin!” She said cheerfully, on her waist was a blue fanny pack that held the thing in her hands. Perfume. A brand of ‘Lovers central’ Piper didn’t know what the perfume could do before Penny had sprayed it in her direction and pink fog clouded her vision. Luckily it had lasted two seconds only before it disappeared. “Penny, you actually did that?”

“The hephaestus cabin helped.” She shrugged, right before placing the perfume back in her fanny pack.

“That’s not all! Valentina show her the lipstick!” Lacy pointed towards her other sister. It didn’t dawn on Piper that the entire cabin had their own designated bags. Valentina had her make up kit, gold to match her armor. Piper remembers Lacey always calling Valentina the makeup girl, how the harpies even requested a full face done from her. She took out the reddest lipstick Piper had ever seen. Quickly passing some on her lips before she rolled it down and aimed it towards the pink pillow on Mitchell’s bed. “HEY!” he shouted. Valentina smiled weakly before putting the lipstick back in her makeup kit.

Piper didn’t know what to say but Drew did. “Guys Capture the flag is gonna start! We gotta go.” Drew quickly put in two beaded hair clips. Piper moved out of the way as the Aphrodite cabin started to file out. In about thirty seconds the entire cabin was empty.

It was no secret that Piper had rejected femininity. She had thought the only way she could’ve gotten accepted was to not be like other girls and to reject the idea of what was accepted for Tristan McClean’s daughter. However, standing in the Aphrodite Cabin after seeing all those cute weapons for Capture the flag and how gorgeous they all made themselves. Maybe being feminine wasn’t so bad.

Drew's words of Capture the flag starting had finally settled in her head. She grabbed her dagger and hurried to where the red and blue team were meeting. After some encouraging and don't die words from Chiron.

The horn sounds. Capture the flag had begun.

46 notes

·

View notes

Photo

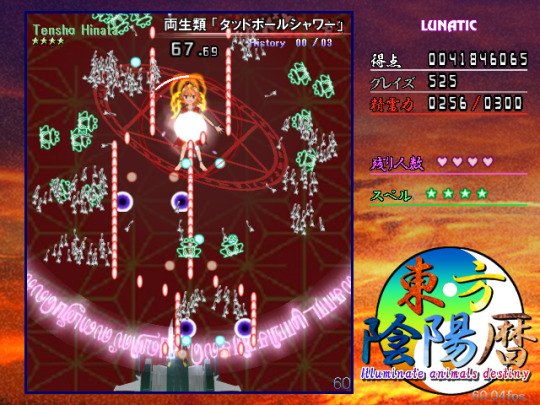

Okay, welp I’m back on tumblr so about time I get back onto the bull I love to pull, talking about Touhou fan games! The past few years have definitely been pretty interesting, though today I want to talk about something... Incredibly curious.

東方陰陽暦 ~ Illuminate animal destiny is probably one of the most interesting danmakufu games of 2022. How so? It uses 0.12m as it’s base... Which for those out of the danmakufu loop, is an engine as old as 2008! Typically people making danmaku Touhou fan games use either Danmakufu ph3, LuaSTG or other independent engines but the main author of this marimo seems pretty dedicated to the engine; as I’ve been told he’s made previous projects on it.

This DOES however make it pretty hard to run the game properly on modern hardware. 0.12m uses DirectX 8 so I’d advise you download a DX8 to DX9 converter in order for the game to run. If you’re already a fan then you might already have these files for the classic era Windows Touhou games but I’ll link them in this post just in case.

Another hurdle for foreign countries though, downloading the game requires you to have your computer to be in Japanese locale otherwise all the files will go corrupt due to not being able to find the right language pack. You can try using locale emulators or other means but I had to download the game this way. After that I could run the game fine on a locale emulator.

Though finally talking about the game this has definitely been an oddity to play. Well first I’ll start off with characters which are sorted into the 5 chinese elements, so think what Patchouli uses:

Wood - Reimu Hakurei

Fire - Flandre Scarlet

Earth - NTR Nilpotent Unit [FAZE] (MJ)

Metal - Youmu Konpaku

Water - Marisa Kirisame

One thing that really sticks out like a sore thumb is who I just call NTR man. I THINK this is suppose to be a self insert of the authour or at least an insert of a friend of his? Some kind of OC? I don’t know the full details, I may have been learning Japanese but I’m currently as fluent as a toddler with sunglasses and who knows if that’ll stay that way.

So the four main Touhou characters primarily use player scripts that were lifted from a Japanese danmakufu wiki. Reimu has homing, Marisa has lasers, Youmu has her IN shot, Flandre has a reticle she fires bubble bullets at which can be set down with focus. All characters are given a shot designated to the element they’re classified under, which said elements are just a copy paste of MarisaB’s different elements from SA. These elements also have abilities associated to them on the C key which is spent by the power you use to gain them.

Reimu has... Nothing from what I could tell

Marisa has auto collect

Youmu cuts the frame rate in half whilst going faster

Flandre literally just clears the screen of bullets

I’m saving NTR man for last because I cannot tell if he’s meant to be a joke or not. He starts out with 6 bombs instead of 3, his unfocused speed is ridiculously fast (practically to meme-like levels) his shot does absurd damage by how rapid they come out and his elemental ability or whatever is borders.

I practically got a Lunatic 1cc easily in this game purely on this guys power alone, nevermind his ludicrously fast speed... If anything on the topic of balance I feel a lot of people might get thrown off by it.

Flan is also pretty broken in the sense her screen clearing ability also clears out bullets you can’t normally clear with bombs... So in a way she can make some spell cards pretty trivial

A lot of the danmaku patterns feel like they were made to be complete noob traps or didn’t have much consideration into how difficult they actually were. Some patterns feel the same across all difficulties or they have something extra to them that either was unnessesary or not well thought out.

And yet there’s also weird moments of neat ideas in here? For example one of the Stage 5 bosses non’s is basically a gimmick from Undertale where you have to shield your heart from Undyne’s spears. I mean it came outta nowhere but to suddenly have that in 0.12m? That’s kinda neat not gonna lie.

The art in the game is surprisingly well done. Granted it’s compressed like heck due to the game having to run at 640x480 but what’s done here, whilst definitely amateur still has some attributes that lead to a pleasent style if very typical of what it is. Granted some of the character names put me through a loop making me feel like it was a Western guy coming up with Japanese names (Nekoko is still kinda painful from my perspective) but no, marimo is Japanese and he made it. Never assume something was made based on superficial things.

The music in the game is not great. I’m unsure who composed these tracks but if anything the musical notation is pretty off in some places and I think the sound mixing gets to the point where you actively hear the crust blaring out due to it trying to go really loud. There is no sound option in the engine itself so you’re going to just have to use system sounds to adjust the overall volume. It’s more or less though a limitation on 0.12m’s part though.

By all accounts the game is not good... But I honestly find it pretty endearing? There’s some nostalgia I gained from this reminding me of the days I use to goof off playing all sorts of scripts in 0.12m and all the different player scripts I’d use to try and 1cc Phantasmagoria Trues back over a decade ago.

Overall if you’re interested the authour has a link available from his twitter. Do remember, download it once you set your computers locale to Japanese and then you should be good if you have a locale emulator. I feel like even talking about this here the game is probably going to get buried in obscurity still on the nature of it being a Touhou fangame made in 0.12m no less.

Still I found some fun in this thrown together treat.

As for what I’ll talk about after, I think I got some ideas but I’m gonna need a good think about what to talk about next.

#touhou#touhou project#東方#東方project#touhou fangame#illuminate animals destiny#reimu hakurei#marisa kirisame#flandre scarlet#youmu konpaku#danmakufu#danmakufu 0.12m

20 notes

·

View notes

Text

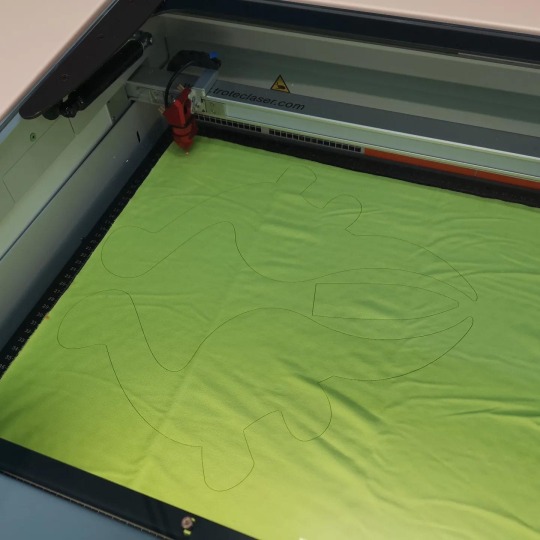

Making Dinosaur Plushies!

Hi, I am Ria and I revived my tumblr. You might have stumbled over the cute dinosaur plushie picture and want to sew one of your own? You can do that! I‘ll tell you how I did mine :)

I found the sewing pattern for our dinosaurs during one of my late night, sleep avoiding pinterest scrolls. It was kindly provided by VirginieLaTeste under the following link:

Now, some of you may know that I work as a media technician at a university makerspace. This means I usually work with machines like laser cutters, 3D printers and embroidery machines. I wanted to find out if I could make a plushie, using the gadgets that I have and share my experience with my students.

So the first thing I did was open the sewing pattern in a vector program. I used Inkscape for this, as its free and open source. I used the path tool to trace the sewing pattern. I also designed some extra spines for the back. Having the images vectorized is necessary for the next step, putting the fabric into a laser cutter. I discovered that laser cutting minky fabric instead of using scissors gives me the advantage of not having to deal with loose hair everywhere, since I only nick the fabric from the back. Plus, since minky is made from polyester, due to the heat the fabric doesn‘t fray. Since my image is now also in vector format, I can scale and resize the sewing pattern to my needs. So what I naturally had to try next was pursuing how big or small can I actually make my dinosaurs? My only limitation in this case was the size of my laser cutter, which is 430x720mm in dimension, for the smallest dino it would only depend on my sewing skills :D

After I cut the fabric, I used an embroidery machine for the litle dinosaur scales. I designed my embroidery file with a program called hatch embroidery designer. This program is not free, but theoretically you could do such an easy design also with an inkscape plugin called inkstitch. For embroidery I used a sandwich technique - embroidery felt on the back of the fabric and wash away embroidery foil on top of the fabric. this makes for cleaner embroidery since the minky hair is pressed flat under the foil and doesn‘t show in the stitches. For the biggest dinosaur I also tried appliqué technique for the scales and eyes, which makes the dino very soft to the touch.

Sewing the dinosaurs wasn‘t easy. I think felt or other fabrics might be favourable for first time projects because minky fabric is really a nightmare to sew with a sewing machine. I needed lots of pin needles because the fabric kept sliding over itself and didn‘t stay in place and sometimes the machine ate my fabric, which is frustrating. But I gained experience and after some getting used to, my dinosaurs were ready. The smallest dinosaur fits just the palm of my hand, I was sewing him by hand, which took about an evening.

I hope you guys have fun making your own!

26 notes

·

View notes

Text

Subject 2022K - The Dark Night

[Subject: Report detailing a series of disturbing dreams experienced during work on the [REDACTED] project.]

It starts the same every time. We finally manage it - extra-solar flight. Not just the few probes and comms we've sent out before, not even the [REDACTED]. Actual, manned, universally-known flight to another solar system. The pilots were glorious, heavenly messengers to the wider universe. We celebrated. We put all our worries behind us. We didn't think how our need for adventure could blind us.

The next ships were made with advanced systems. They were new, sleek, you could barely see the guidance systems. They assured us that the biggest issues from the last flight were taken care of, mostly radiation and comets in the way. As it launched, it unfolded a shield. The pilots were instant celebrities. We loved them, and we knew they loved us.

The third series of ships were even sleeker. They were like sharp spikes pointing into the sky. Angular, with flat panels that would open up. There were warnings that some kind of debris field had floated into the path they were being taken through, so the laser systems were increased, able to blast things out of the way with energy harvested from the black panelling it was covered in. It was a genius design. When it launched, there was a small glitch in the audio feed, but the pilots came back after a moment and they were cheering as they flew. The ship launched a web of carbon tubes before it as it flew, forming a strange, dark star that would absorb the worst of any impacts. The cultural impact reached a fever pitch. We were there, we thought. A truly science fiction world, making our way into deep space. People clamoured to join the next mission, and the next mission came quick.

This time, not just a ship. A small fleet. National budgets turned entirely towards space. We were selling our bodies, our futures, for progress. We forgot the promise that each mission would be feeding back, and the ships were filled up. They did lotteries because they were so popular. These ships were.. strange. More organic seeming, with huge segmented parts like the insides of a shell. They were totally covered in protective surfaces, to the point no communications would leave or enter. They'd said when they were launched they would drop a satellite that could relay messages. We didn't question it. We didn't question it when the people filed in and went silent. When they launched, it was in silence apart from the rockets themselves. The new engines channeled the blast in weird, efficient ways. It sounded like screaming. They were recycling everything. There wasn't any exhaust.

The next few missions passed like that. We stopped celebrating. We stopped seeing the pilots as celebrities and started seeing them like patriots of earth. It wasn't our sense of adventure anymore. It was our sense of duty to the wider universe. The ships kept going out. They kept getting stranger. Long, distorted. Asymmetrical. They were finding new, more advanced shapes. We sold everything we had. We lost all our rights. Nothing mattered more. We didn't look into the night sky in wonder anymore. We didn't look at all. We worked and we worked until we could join the ships. They aren't using pilots anymore. Not... not like they used to. The "pilots" were part of the ship now. And we were part of the crew, even if we weren't aboard yet.

The next ships were black. But not like solar panels. Like they'd been burnt. Like they'd scabbed over some kind of bleeding flesh. They were half-finished, too. From a distance the struts and scaffolds of the ships looked like... I don't know. Like a net, keeping things inside. And they launched silently, like they were being taken by the sky. A black swarm of blades, cutting the atmosphere to ribbons.

Then, we heard from it. The other system. Life. They were broadcasting to everything they could. Pleading with us. Begging us. Stop. Stop. Stop. We're sorry. We're sorry for whatever we did. Stop coming here. Send back your demons.

By the time we saw it, it was too late. We looked up and the sky was black.

[The report ends. [REDACTED] has been transferred to other projects since.]

11 notes

·

View notes

Photo

So this has been a pet project of mine for a while now. I am a big fan of the Stormcrow Omnimech chassis. It's a rock solid 55 ton medium mech that does pretty much everything except ECM. I have used the A, or Alpha, pattern extensively in MechWarrior: Online. So I decided that I wanted to have a proper miniature to use on tabletop. Granted it’s really not necessary to play it on the tabletop but anything worth doing is worth overdoing.

There is currently no actual Alpha miniature in production, although there were apparently some partial update kits for old Ral Partha/Iron Winds miniature from around 1994. So I was going to have to kitbash it into existence, starting with the modern Catalyst plastic Stormcrow miniature.

There’s a guy named David Belsheim who had made a conversion using modern Catalyst plastics so I know it can be done; essentially he removed the original lasers from the arms and grafted on a LRM-20 on one arm, a pair of SSRM-6’s up top, and two pairs of lasers on the other arms. However I wanted to have a design more in line with the MechWarrior: Online design, or as much as feasible. That and on a budget, the new Catalyst Force Packs are pretty affordable but paying upwards of $60 to mutilate three or four miniatures for parts is not really what I consider financially wise right now.

So I decided to look around if anyone was selling spare parts. Turns out Aries Miniatures actually has a section for that with parts from Iron Winds Metals so I was able to sort the missiles from them. Was even able to get an old model Alpha torso and left arm for reference. That left the problem of the torso and the lasers. Which was simple enough to solve. A company named Creative Juggernaut partnered with Catalyst to make the Stormcrow B/TC’s in resin. Some of miniatures produced did not meet standards but they took advantage of this and sold the cast offs as “salvage”. Now that I had everything at had I could begin work.

First off I had to do some clean up on the components, removing the mold lines and what not. Thankfully I found a clean enough resin Torso to use, the plastic torso has an additional laser that I need to remove. The Classic and MW:O Alpha’s have SSRM’s mounted into the body up and above the cockpit. So I took a hobby saw and cut out the “air scoop” portion of the torso to place the SSRM’s. I cleaned up the SSRM’s and filed them so they could set flush together and put them in place. Next I took one of the 6 laser arms from the salvage pack and sawed off the hand and the lower two lasers and then took the LRM pack and pinned it to the arm and placed a spare bit from a Space Marine Hellblaster to add on some surface detail. Next I needed to make my brace of four lasers; problem being that they needed to transferred from the resin right arm onto the plastic left. So using a liberal amount of sawing, sanding, and green stuff I was able to graft it onto a plastic left arm that I had cleaned of it’s own original lasers. Finally it was a relatively simple matter to mount the missiles on the torso, put on the arms, and glue all of that to the plastic legs. BAM.

To finish things off, I decided to paint the Alpha up in Clan Ghost Bear Omega Galaxy colors because I think they’re pretty cool guys. I tried to ramp up my cockpit painting game by adding some blue glow in the dark pigment from Green Stuff World for added effect, so those highlights actually glow in the dark. Even used some water slide decals to complete the look. Overall, I am very pleased with how it turned out. Now I’m looking at the Stormcrow C, Charlie, and it’s relatively low Battle Value and I am sorely tempted to kitbash one of those.

#Kasperls Kraft Korner#Battletech#MechWarrior#Kasperl IRL#MINE#WIP#Stormcrow#Ryoken#Stormcrow A#Alpha#MechWarrior: Online#Clan Ghost Bear#Omega Galaxy

6 notes

·

View notes

Text

How to Use FreeCAD for 3D Printing, CNC, and Laser Cutting

Teaching and learning FreeCAD online can be a rewarding experience for both educators and students alike. With the increasing popularity of online learning platforms and the flexibility they offer, mastering FreeCAD from the comfort of your own home has never been easier. Whether you are an instructor looking to share your knowledge or a student eager to enhance your skills, there are several effective strategies to make the most out of online FreeCAD courses.

One of the key aspects of teaching FreeCAD online is to ensure that the course content is well-structured and engaging. By breaking down complex concepts into digestible modules, instructors can help students grasp the fundamentals of FreeCAD more effectively. Utilizing a combination of video tutorials, interactive exercises, and real-world examples can enhance the learning experience and keep students motivated throughout the course.

For those looking to learn FreeCAD online, it is essential to choose a reputable platform that offers comprehensive courses taught by experienced professionals. Look for courses that cover a wide range of topics, from basic to advanced techniques, to ensure that you receive a well-rounded education in FreeCAD. Additionally, platforms that provide opportunities for hands-on practice and feedback from instructors can greatly accelerate the learning process.

Engaging with the FreeCAD online community is another valuable way to enhance your learning experience. Joining forums, participating in webinars, and collaborating on projects with fellow enthusiasts can provide valuable insights and foster a sense of camaraderie among learners. By sharing knowledge and experiences with others, you can gain new perspectives and stay updated on the latest trends in FreeCAD.

When teaching FreeCAD online, it is important to encourage active participation from students. Incorporating interactive quizzes, group projects, and discussion forums can help students stay engaged and retain information more effectively. Providing timely feedback and guidance is also crucial in helping students overcome challenges and improve their skills in FreeCAD.

To optimize the online learning experience, both educators and students should make effective use of available resources. This includes utilizing FreeCAD's official documentation, exploring online tutorials and guides, and experimenting with different design projects to apply theoretical knowledge in a practical setting. By continuously challenging yourself to learn and grow, you can unlock the full potential of FreeCAD and expand your skill set.

Engaging with FreeCAD for 3D printing, CNC, and laser cutting opens up a world of possibilities for electronic design enthusiasts. By leveraging FreeCAD's versatile tools and features, users can create intricate designs for various electronic components with precision and efficiency. Whether you are designing custom enclosures for electronic devices or prototyping circuit boards, FreeCAD provides the flexibility and functionality needed to bring your ideas to life.

One of the key advantages of using FreeCAD for electronic design is its compatibility with a wide range of file formats commonly used in the industry. This allows users to seamlessly import and export designs between FreeCAD and other software tools, streamlining the design process and ensuring compatibility with manufacturing equipment. Additionally, FreeCAD's parametric modeling capabilities enable users to easily modify designs and iterate on their projects with ease.

Incorporating FreeCAD into your electronic design workflow can also enhance collaboration and communication among team members. By sharing FreeCAD files and designs, team members can provide feedback, make revisions, and work together towards achieving project goals more efficiently. This collaborative approach fosters creativity and innovation, leading to the development of high-quality electronic products that meet industry standards and customer requirements.

In summary, integrating FreeCAD into electronic design processes offers a powerful solution for creating innovative and functional electronic products. By harnessing the capabilities of FreeCAD for 3D printing, CNC, and laser cutting, designers and engineers can bring their electronic designs to fruition with precision and creativity. Embrace the versatility of FreeCAD to elevate your electronic design projects and stay at the forefront of technological advancements in the field.

“Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!”

Read the full article

0 notes

Text

Top Cosmetology Institutes & Training Centres To Craft Your Way Up The Beauty Path

Cosmetology is a multidisciplinary field that integrates various areas of beauty and wellness. It involves not only enhancing a person’s physical appearance but also boosting self-confidence and overall well-being. From getting scar removal treatment, chemical peels, and laser liposuction to getting your hair styled and makeup done, cosmetology encompasses everything. Cosmetology is seen as a medical as well as non-medical discipline. Some colleges and institutes offer a wide range of courses for graduates as well as doctors to explore. You can complete a degree course, a diploma course, a postgraduate diploma course, or a certification course in a subject of your choice and interest.

Which Course Is Best For Cosmetology?

Here are some of the best and most popular courses in cosmetology that you can choose from. Depending on the curriculum these courses have a duration from 2-3 years to a few weeks to a few days.

Hairdressing and Hairstyling- Addressing various scalp and hair issues and mastering the art of hairdressing and styling is vital if you want to focus on hair for your career. Courses offered in this area teach students about the different medical conditions of the hair and scalp along with their treatment, haircutting, hairstyling, and hairdressing. The duration of these courses varies from 1 to 2 years to a few weeks. MBBS, BHMS, BAMS, and BDS graduates are eligible for various scalp and hair treatments like hair transplant, PRP treatment, etc. A minimum high school graduation of 10th +2 is essential for taking up courses in haircutting, styling, and spa treatments.

Skincare and Aesthetics From getting treatments like Botox, thread lifts, microneedling, and chemical peeling to address various skin issues to getting impeccable makeup done to glow on your big day, there are several reasons why you would visit a cosmetologist. There are several courses offered in this branch of cosmetology that teach you the basics of skin care for different skin types, and the various products used for procedures done on your skin. These courses are offered at the basic and advanced levels. The duration of these courses is anywhere between a few days to a month. MBBS, BHMS, BAMS, and BDS graduates are eligible for various skin treatments like microneedling, chemical peeling, microdermabrasion, botox, etc. A minimum high school graduation of 10th +2 is essential for taking up courses in makeup, facial and spa treatments.

Makeup Artistry Makeup artistry is an art form that allows the cosmetologist to bring out the beauty in the client in a nuanced way. Makeup is not just about layering layers of chemicals on your face. Makeup artistry courses include a wide curriculum that teaches students about the basic understanding of skin types, the products used for makeup, their formulation, and the basic and detailed techniques of makeup application. A minimum qualification of 10th or 10th +2 is required to enrol for courses in makeup artistry.

Nail Art and Nail Extensions Nail art has gained incredible popularity in recent years. Gone are the days when ‘getting the nails done’ meant cutting, filing, and getting a coat of colour on your nails. Today nail artists create intricate designs and apply techniques like acrylic nails and gel extensions. Nail artists are in high demand and so are the courses that teach nail art. A minimum qualification of 10th or 10th +2 is required to enrol for courses in nail and nail art extensions.

Salon And Spa Management For those interested in having their set-up of a salon or chain of salons, there are management courses that teach you about how to be a successful entrepreneur in the field of cosmetology. From customer service to financial management to the day-to-day nitty gritty of having your own business, these courses prepare you well. A graduate degree is required for enrolling in management courses.

Starting from certification and diploma courses, students can gain the advanced and highest degrees possible in cosmetology. Associate's, Bachelor's, and Master's degrees are examples of advanced degrees with specialisations in fields like dermatology, trichology, or cosmetic chemistry. These programmes prepare graduates for leadership positions, teaching positions, or entrepreneurship in the beauty business by delving into sophisticated techniques, research methodology, and management strategies.

What Is Diploma In Cosmetology?

A Diploma in Cosmetology is a thorough course that offers extensive instruction in a range of skincare and cosmetics topics. This six- to one-year-long programme gives students the theoretical and practical abilities they need to pursue employment in the beauty business. Numerous subjects are covered in the coursework, such as salon management, skincare procedures, hair styling, cosmetics application, and nail care. Students acquire abilities in product knowledge, client consultation, sanitation procedures, and strategies for improving natural beauty. Graduates can go on to work in salons, spas, or as independent contractors as cosmetologists, hair stylists, makeup artists, salon managers, or skincare specialists.

What Is Cosmetology Course Duration?

Cosmetology training in India typically lasts from six months to a year. These courses offer coaching in a range of beauty and grooming topics, such as skin care, makeup application, hair care, and salon management. Some institutions provide more comprehensive diploma courses that run up to a year, while others may offer shorter certificate programmes that last about six months. The curriculum frequently blends academic knowledge with hands-on training to give students the skills they need to pursue professions in the beauty industry. Furthermore, certain educational institutions could provide specialised programmes that concentrate on particular fields of cosmetology, including hairdressing or bridal makeup.

What Is The Cost Of Cosmetology Courses In Bangalore?

Depending on variables including the institution's standing, the length of the course, and the particular curriculum offered, the price of cosmetology courses in Bangalore might differ significantly. Shorter certificate programmes typically cost between ₹30,000 and ₹1,00,000, whereas six-month to one-year diploma programmes can cost between ₹50,000 and ₹2,50,000. Lengthier, complex programmes, such as degree courses or specialised certificates, can cost up to ₹5,00,000 or more. It is recommended to learn more about and compare various institutions to identify one that both suits your needs academically and your budget.

Which Is The Best Place To Study Cosmetology?

KAAM’s cosmetology and dermatology courses are specially designed for doctors and aestheticians. In the course, we ensure that students are exposed to the practical aspects while learning and will spend most of their time working and learning hands-on on real patients. This will give them the confidence to start practising immediately after the course. At KAAM, we offer various multi-disciplinary cosmetic courses at par with the latest technology and innovation. Our state-of-the-art equipment enables the students to take complete advantage of enhancing their aesthetic skills and flourishing clinical practice. Our faculty is highly qualified and well-trained in various aesthetic procedures and hands-on training is conducted along with theoretical demonstrations during the training programs. The courses offered at our institute help increase the clientele base of the students once they begin their clinical practice. These courses act as add-ons to the already set-up clinical practice. Workshops during these training programs at our institute expose the students to many aesthetic industry veterans, which increases their professional contacts. The training programs have varied durations- short-term, long-term, crash courses, diploma courses, a day's workshop, etc. This benefits students to choose the course that fits their busy schedules. The students who have completed the courses from our institute have emerged to become successful aestheticians and cosmetologists. At KAAM, we also offer professional support to our students in setting up their clinics and increasing their client base. A holistic approach and stringent protocols make KAAM unique, with unmatched credibility with an excellent team of dermatologists and skin therapists.

#Top-Cosmetology-Institutes#Cosmetology-Institutes-&-Training-Centres#Cosmetology-Courses-In-Bangalore#Diploma-In-Cosmetology

0 notes

Text

Digital Printing Solution in Ghana by Sec Print

Sec Print is mindful of the importance of recycling and waste reduction in todayfast-paced business environment, having reliable printing solutions is essential for any company's success. Sec Print, based in Ghana, stands out as a premier provider of digital printing services, offering cutting-edge solutions to meet the diverse needs of its clientele.

Introduction to Sec Print

Sec Print has established itself as a trusted name in the printing industry, known for its commitment to excellence and innovation. With a team of skilled professionals and state-of-the-art equipment, the company delivers top-notch printing solutions tailored to each client's requirements.

Understanding Digital Printing

What is Digital Printing?

Digital printing is a modern printing method that involves transferring digital files directly onto various substrates, such as paper, fabric, or plastic. Unlike traditional printing methods, which require printing plates, digital printing offers greater flexibility and cost-effectiveness.

How Does Digital Printing Work?

Digital printing utilizes advanced technologies, such as inkjet or laser printing, to reproduce digital images with exceptional accuracy and detail. The process involves sending digital files directly to the printing press, eliminating the need for intermediate steps and reducing turnaround time.

Advantages of Digital Printing

Digital printing offers several advantages over traditional printing methods, making it the preferred choice for many businesses.

Cost-effectiveness

One of the primary advantages of digital printing is its cost-effectiveness, especially for small to medium-sized print runs. Since there are no setup costs involved, digital printing allows businesses to print only the quantity they need, reducing waste and saving money.

Quick Turnaround Time

With digital printing, jobs can be completed quickly and efficiently, enabling businesses to meet tight deadlines without compromising on quality. Whether it's urgent marketing materials or last-minute promotional items, digital printing ensures timely delivery.

High-Quality Output

Despite its speed and efficiency, digital printing does not compromise on quality. Advanced printing technologies produce crisp, vibrant images with exceptional clarity and detail, ensuring professional-looking results every time.

Digital Printing Solutions by Sec Print in Ghana

Sec Print offers a comprehensive range of digital printing solutions designed to meet the diverse needs of its clients.

Range of Services Offered

From business cards and brochures to signage and promotional materials, Sec Print provides a wide array of printing services to help businesses stand out in the competitive market. Whether it's offset printing or large format printing, the company delivers top-quality results with precision and efficiency.

Advanced Printing Technology

Sec Print invests in the latest printing technology to ensure superior quality and reliability. With state-of-the-art equipment and skilled technicians, the company stays ahead of the curve, offering innovative solutions that exceed customer expectations.

Customization Options

One of the key strengths of Sec Print is its ability to customise printing solutions to meet each client's unique requirements. Whether it's personalised packaging or branded merchandise, the company provides tailor-made solutions that reflect the client's brand identity and vision.

Quality Assurance and Customer Satisfaction

Sec Print is committed to delivering excellence in every aspect of its operations, with a strong emphasis on quality assurance and customer satisfaction.

Ensuring Print Quality

Quality control is an integral part of Sec Print's workflow, with rigorous checks and inspections at every stage of the printing process. From colour accuracy to finishing touches, every detail is meticulously reviewed to ensure the final product meets the highest standards of quality.

Customer Feedback and Testimonials

Sec Print values feedback from its customers and strives to continuously improve its services based on their input. With a track record of satisfied clients and positive testimonials, the company has built a reputation for reliability and professionalism.

Environmental Sustainability

In addition to delivering exceptional printing solutions, Sec Print is committed to environmental sustainability and eco-friendly practices.

Eco-friendly Printing Practices

Sec Print employs eco-friendly printing practices to minimise its environmental impact. From using recycled paper and soy-based inks to implementing 's world. By using recyclable materials and promoting responsible printing practices, the company aims to contribute to a cleaner, greener planet for future generations.

Clientele and Success Stories

Sec Print has built a loyal clientele across various industries, with a track record of successful collaborations and projects.

Collaborations with Businesses

Sec Print has partnered with businesses of all sizes, from startups to multinational corporations, to deliver impactful printing solutions that drive results. Whether it's branding materials for a new product launch or promotional merchandise for a trade show, the company's expertise and dedication ensure success.

Positive Impact on Clients

Sec Print takes pride in the positive impact its printing solutions have on its clients' businesses. By helping clients enhance their brand visibility and market presence, the company contributes to their growth and success in the competitive marketplace.

Innovation and Future Prospects

Sec Print is committed to innovation and continuous improvement, embracing new technologies and trends to stay ahead of the curve.

Continuous Improvement

Sec Print regularly invests in training and development to keep its team up-to-date with the latest industry trends and best practices. By fostering a culture of innovation and excellence, the company ensures it remains at the forefront of the printing industry.

Embracing New Technologies

From digital enhancements to augmented reality integration, Sec Print explores innovative ways to enhance its printing solutions and deliver added value to its clients. By embracing new technologies and creative approaches, the company drives innovation and sets new standards for excellence in the industry.

Conclusion

Sec Print stands out as a leading provider of digital printing solutions in Ghana, offering a comprehensive range of services tailored to meet the diverse needs of its clientele. With a commitment to excellence, innovation, and sustainability, the company continues to set new benchmarks for quality and customer satisfaction in the printing industry.

0 notes

Text

File: Brightburn

SCP#: AEX

Code Name: Brightburn: Agent of Earth's Destruction.

Object Class: Keter

Special Containment Procedures: SCP-AEX is contained in one of the lower levels of Site-AF. He is locked within an anomalous humanoid coffin reinforced with the same metal of the pod he came to earth on as a baby. Attached to the coffin is a Pygmalion Bio Editor Station designed to feed him, collect his waist through tubes, and collect DNA samples from his body. The machine will also be used to measure his growth through the years so that the coffin can be updated every time he has a growth spurt.

In the event of a growth spurt, SCP-AEX is to be sedated and taken out of the coffin. Foundation technical staff are to weld and alter the coffin so that it can fit his body. This process must be done within 4 hours as no sedative can keep SCP-AEX asleep for any longer. Commander Wells is to be present during this process as she is currently the only Foundation staff member that can stand toe to toe against SCP-AEX. Though as an added precaution Mobile Task Force Epsilon-11 "Nine-Tailed Fox" will also be present with shields and batons made of steel infused with the same metal to help combat against SCP-AEX.

Description: SCP-AEX is a humanoid anomaly that, despite his human appearance, is extraterrestrial in nature. Unfortunately, even after obtaining the technology within SCP-AEX's ship and extensive DNA testing, it is unknown where exactly SCP-AEX hails from. He is much more durable and stronger than the average human able to withstand an attack from steel blades and even the impact of continuous shots from an M134 Minigun. SCP-AEX also has numerous anomalous abilities like being able to manipulate the gravity around his body allowing him to fly without restrictions. His eyes can generate energy and they reflect through the iris of the eyes allowing him to generate concentrated lasers. These lasers are hot enough to burn through steel and vaporize flesh ease.

Surprisingly, SCP-AEX doesn't actually like cutting up with his laser eyes but instead like to ram through them while flying. Because nothing can hurt him, he can tear through metal and flesh easily leaving nothing but splats of blood. SCP-AEX doesn't like over relying on his powers and instead goes for stealth tactics. He doesn't do this out of caution but merely to mock his prey to show them how powerless they are. He normally only uses his laser vision when they have barricaded themselves form him using fortified metal doors and walls.

Though SCP-AEX's psychology seems to be of psychopathic nature, it's also a possibility that SCP-AEX was genetically made to be like this so that he could blend in and conquer the world. SCP-AEX claims his purpose was to "take the world" though for who and why is a question even he seems to have no answer too.

SCP-AEX was discovered in 2018 when a small series of unexplained disappearances and murderers were reported in the small town of [data expunged]. Foundation agents found the clues leading to a farmhouse in [data expunged], unfortunately the agents were spotted by SCP-AEX and slaughtered. The next day SCP-AEX crashed a plain into the farmhouse to coverup the evidence, but the Foundation had already gotten an ID of SCP-AEX from the body cameras on the Agents. After SCP-AEX was taken into local police custody to later be adopted by a local family. Mobile Task Force Alpha-9 "Last Hope" was assigned to his capture. Commander Wells and a few Agents she handpicked were the only ones assigned to the mission, she refused to allow anyone else to participate given how strong SCP-AEX was.

Because of her control over all forms of energy, Commander Wells was able to make SCP-AEX's eyes burn himself and incapacitate him by trapping him in a magnetic bubble. After his ship was found and shown to be able to harm him it was dismantled and used to reinforce the coffin he was later placed in. SCP-AEX's DNA is used to see if it's possible to create genetic mutations or Foundation medication to increase Foundation personal strength and maybe give MTF units his anomalous abilities. Unfortunately, this has been met with zero success; none-the-less, testing on SCP-AEX's DNA has continued to see where his origin is, how exactly his anomalous abilities work, and if they are even considered anomalous where he's form.

.

SCP: Horror Movie Files Hub

#DZtheNerd#SCP: Horror Movie Files#SCP: HMF#SCP Foundation#SCP Fanfiction#SCP AU#SCP#Brightburn#Horror movie#superhero twist#superhero horror#action horror#Mobile Task Force Epsilon-11 “Nine-Tailed Fox”#Mobile Task Force Alpha-9 “Last Hope”#Charlie McGee#Charlie Wells#SCP-AEX#Site-AF#Keter

1 note

·

View note

Text

Some great advancements come from modern machine controllers

Modern metal fabricating machine controllers have significantly impacted various aspects of the manufacturing process, including workflow, speed, efficiency, accuracy, and manageability. Here's how:

Workflow Improvement: Advanced controllers have software that allows for better planning and sequencing of jobs. This integration can streamline the workflow, reducing the time between design and production. Controllers with advanced user interfaces make it easier for operators to input data, understand machine status, and make quick adjustments, leading to a smoother production process. Operators have a number of options for job entry, such as from a CAD file automatically, manual iinput, or scanning from a paper job sheet.

Increased Speed: Modern controllers have greater speed thanks to improved processing power and algorithms. This allows for faster execution of complex tasks and reduces the cycle time for each part. High-speed processing also enables machines to operate at higher speeds without compromising precision—in fact in many cases, precision is increased along with speed.

Enhanced Efficiency: These controllers often include features that optimize energy use and reduce waste. For example, predictive maintenance capabilities can forecast machine failures before they occur, minimizing downtime. The controller’s software can generate a plan to use multiple stations on a part with multiple bends, for example, allowing the setup to happen in one step instead of many. Or, if a laser cutter is cutting metal plate, it plans the job so that a the laser head moves to different cut areas to allow densely-cut areas to cool before the machine cuts nearby again.

Improved Accuracy: The precision of modern metal fabricating machines has significantly increased with the advent of sophisticated controllers. These systems can precisely control the movement of the machine, leading to higher-quality products with tighter tolerances. Advanced sensors and feedback systems ensure that the machine's performance aligns closely with the programmed specifications, reducing errors.

Better Manageability: Modern controllers are often part of larger networked systems that include data collection and analysis capabilities. This allows for better monitoring and management of the production process. Operators can track machine performance, predict maintenance needs, and optimize production schedules based on real-time data. Additionally, integration with other systems (like ERP or shop planning software) allows for better overall plant management and coordination.

Adaptability and Flexibility: Contemporary controllers enable machines to be more adaptable to different types of jobs. Quick setup changes and easy reprogramming allow for shorter runs of custom or specialized parts, making the production process more flexible to meet diverse customer demands. We live in an age of many short run jobs.

Safety Enhancements: Modern controllers also contribute to safer working environments. They can include safety features that prevent operator error and protect against machine malfunctions. Better precision and control also reduce the likelihood of accidents due to machine errors.

Connectivity and Smart Features: With the advent of Industry 4.0, these controllers are increasingly connected and smart. They can be integrated into a wider industrial network, allowing for remote monitoring and control, predictive maintenance, and enhanced data analytics.

Overall, the impact of modern metal fabricating machine controllers on the manufacturing landscape is profound, leading to more efficient, accurate, and flexible production processes. This technological evolution is a key driver in the industry's ongoing efforts to optimize productivity and quality.

#great advancements#modern machine controllers#metal fabricating machine#manufacturing process#including workflow#speed#efficiency#accuracy#manageability#Workflow Improvement#Increased Speed#Enhanced Efficiency#Improved Accuracy#Better Manageability#Adaptability and Flexibility#Safety Enhancements#Connectivity and Smart Features#remote monitoring

0 notes

Text

Laser cutting

Today we were shown how to laser cut the stencils for screen printing. We were told to have images in black and white. This is the photo reference i made with different pictures of my hands while dancing. I turned the image into a silhouette using photo shop.

We used software on the computers to scan the image and turn it into a file the laser cutter can read. I learned that it’s best to either have a digital black and white image or else a picture drawn with a black marker so the computers could pic up the lines correctly.

When we were done this we sent the files to the laser cutter and cut them out, it only took 2 to 3 minutes for each design to be cut. Then we went back and used the stencils to print with. This is how my print came out.

I started off with just yellow then scraped the excess off and used a Burgundy which created a two tone effect. I used black is well as I felt the yellow wasn’t bold enough.

Finally I layered this over one of my prints from yesterday. I found this gave it a lot more energy and made the composition more interesting. Because I used a lighter colour over the green it changed the colour instead of covering it which I really liked. Once i was done printing I managed to pull the stencil off in one piece. It had a really interesting texture to it as i used multiple colours it is also the inverse of the design.

1 note

·

View note

Text

Key Components of a Laser Cutting Machine

Laser cutting is a non-contact process that uses radiation to heat, melt or partially or fully vaporize a localized area of material to create cuts. This allows for more intricate designs than traditional etching and produces metal cuts with reduced distortion.

An XY gantry is a mechanical system for moving laser heads and workpieces around, and comes in three variations: moving material, flying optics, and hybrid.

laser cutting services near me cutting machines are controlled by computers that interpret G-code commands to achieve accurate cutting of materials. G-code converts dimensions and specifications in CAD files into movements for the laser head to follow, providing it with precise cuts through materials.

Depending on the type of laser cutter being used, its power source could either be a CO2 generator or fiber laser. Both utilize a power supply to generate light which is then directed by a resonator and lens into its desired destination.

Lenses refine the beam, so that it focuses on an exact point on the material, enabling laser to vaporize small areas, creating accurate cuts. Furthermore, laser can even bend brittle materials by creating notches in its surface to loosen tension in material - creating living hinges or snap-fit joints.

Motion System

Laser cutting can cut or etch designs into various materials. This technique has many applications in manufacturing industries as it enables engineers to produce smaller parts than would otherwise be achievable with traditional cutting methods.

Laser cutter movement systems refers to any mechanical setup which allows the laser head to be moved around a work area according to its G-code program, known as gantry system, as instructed. Gantry systems help ensure proper focus distance between nozzle and material being processed.

Gantry systems also control the laser's velocity, which can be extremely important during raster operations. A high speed can cause it to burn through thicker materials while low speeds could wear down more rapidly on its components.

Lasers require a cooling system to remove heat from their lenses and other external optics, typically via water cooling systems that help lower power consumption and operating costs.

Servo Motor

Laser cutting machines rely on servo motors to move the laser beam around their work area. These motors receive position signals from their motion control system that tell them how far to move the laser, and use an internal feedback mechanism to maintain desired positioning.

Feedback sensors such as potentiometers or encoders monitor the speed and position of servo motor's output shaft. A digital circuit compares their feedback signals with those from machine's setpoint signal to ensure it's performing as intended.

Servo motors help keep laser beams focused and tight, helping reduce material loss for quality cuts as well as prevent distortion caused by heat. In addition, pulsed servos deliver just the right level of energy into work zones.

Cooling System

In order for laser cutters to function efficiently, they must quickly absorb and dissipate heat. This is especially critical if cutting thicker materials which tend to take longer cut times and generate more heat than thinner ones. Overheating may cause components of your laser cutter to expand too rapidly, leading to vibrations or noise from internal moving parts or even an unpleasant burning smell resulting in overheated parts rubbing against each other causing range noises or vibrations; overheating could even result in physical damage of parts that need adjusting or replacement of parts caused by overheated parts causing expansion causing vibrations or noises when trying to cut thicker materials than expected!

To avoid this from happening, it is necessary to have a cooling system in place - ideally using oil-free compressed air - as any suspended particles or even fractional drops of oil in the air would damage your machine and deflecting mirrors. A Freon chiller will ensure this type of cooling is used; not only can this help lower overall coolant consumption rates but it may even speed up laser movement through material.

1 note

·

View note

Text

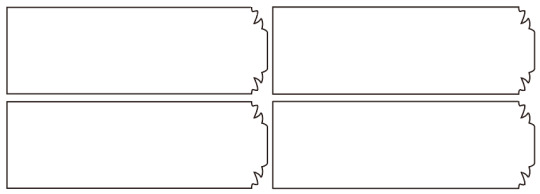

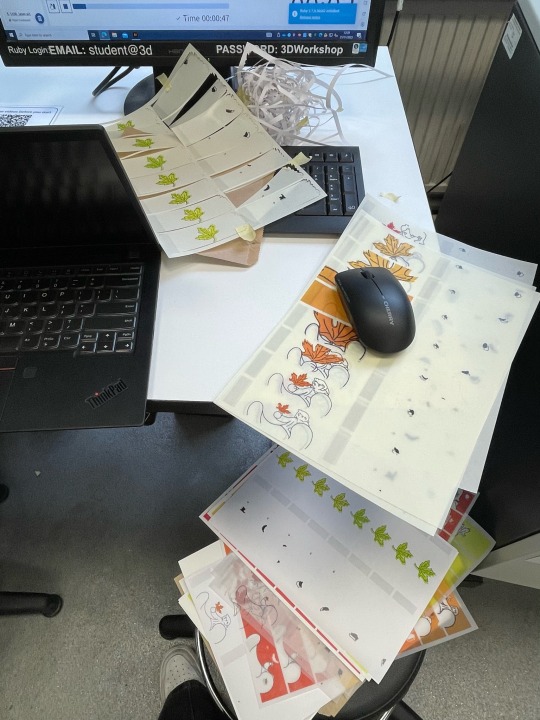

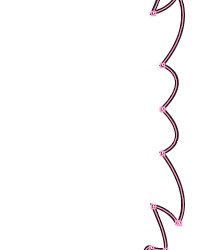

After observing the knowledge of how to arrange the shapes of flipbooks to make every flipping carry more than one page, I did the shape design based on the leaves' edges.

I adjusted it to match the cutting line and the prints through Adobe illustration for the very accurate position and size management.

Scanned images of how the colour shows on different papers

Actually, before printing on the nice and expensive papers, I use the printers near the library to do the test. But it is not so accurate because they print darker than the file and the good one on the workshop block. But I still made some improvements about the position, brightness, and saturability depending on the result I got from it.

________________________

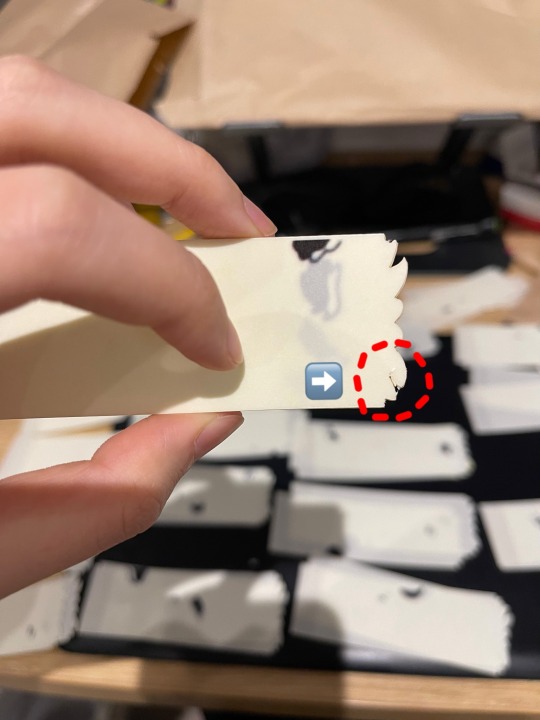

This was the first time I tried to use the laser cutter. It is easier and quicker than I imagined, and the technician there is really nice and patient.

I found the laser cutter is very sensitive to the path, the part that was not fully connected can leave a trace on paper, even if the laser went through so fluently and you won't notice until putting them all together. Moreover, it leaves unpredictable shapes if the path is not well drawn. I assume the cutter may have its settings or programs to make the cutting head move more efficiently. Another thing I learned from this experience is that it is important to manage the order of the pieces as soon as it's been cut. I felt it took me forever to sort all of them out at once that time.

0 notes