#globe valve

Text

#ball valve#check valve#gate valve#globe valve#china valve factory valve#gatevalve#ballvalve#valve#youtube#cantonfair

0 notes

Text

How Electric Actuators Are Transforming Industries

Electric actuators are revolutionizing industries across the globe by providing efficient and precise control of mechanical systems. These devices are used in a wide range of applications, from manufacturing and robotics to aerospace and automotive industries. With their ability to provide accurate and reliable movement, electric actuators are changing the way industries operate and helping businesses improve their productivity and efficiency.

One of the key advantages of electric actuators is their speed and accuracy. Unlike traditional hydraulic or pneumatic actuators, electric actuators can be controlled with high precision, allowing for more consistent and reliable performance. This level of control is especially important in industries where accuracy is critical, such as medical equipment manufacturing or robotics.

Electric actuators are also more energy-efficient than their hydraulic or pneumatic counterparts. By using electricity to power their movement, electric actuators can reduce energy consumption and operating costs. This is particularly beneficial for industries looking to improve their sustainability and reduce their environmental impact.

Furthermore, electric actuators are easier to install and maintain compared to traditional actuators. With fewer moving parts and a simpler design, electric actuators require less maintenance and repairs, saving businesses time and money in the long run. This ease of use also makes electric actuators ideal for industries with limited space or resources for maintenance.

In addition to their efficiency and reliability, electric actuators are also versatile in their applications. These devices can be customized to fit specific industry needs, making them suitable for a wide range of tasks, from simple positioning to complex automation processes. Whether used in industrial robots, medical devices, or aerospace equipment, electric actuators bring precision and efficiency to any industry.

Overall, electric actuators are transforming industries by providing a cost-effective, energy-efficient, and precise solution for mechanical control systems. As businesses continue to adopt these advanced technologies, the benefits of electric actuators will only continue to grow, leading to improved productivity and performance across various industries.

0 notes

Text

globe valve manufacturer in ahmedabad

Flowdo Valves, a renowned globe valve manufacturer in Ahmedabad, is esteemed for its quality products and extensive industry presence, offering reliable solutions for fluid control.

#globe valve#globe valve manufacturer#globe valve supplier#globe valve in india#globe valve manufacturer in ahmedabad#globe valve supplier in all over india

0 notes

Text

API Globe Valve Manufacturer

SVR Global is the leading API globe valve manufacturer in USA and supplies top notch quality valves in various oil and gas industries, chemical industries in Chicago, New York and Houston. API stands for American Petroleum Institute. API Globe valves are operated to control the flow of fluids in the system. They are usually used for throttling the flow apart from controlling as well. These valves have a stem which moves up and down to control the flow of fluids & a disc and seat that is attached to the body of the valve. Globe valves are the best among other valves for controlling and regulating the flow of fluids. These valves are bi-directional which means they can move in either direction inside the valve. The fluid flow in globe valves is highest when its disc is raised. They are operated manually and automatically.

Parts:

•Body: The body of an API globe valve is a shell that houses all the internal parts of the valve.

•Bonnet: The bonnet is a cover that sits on top of the valve body and provides access to the internal parts of the valve. It is usually bolted to the valve body and can be removed for maintenance or repair.

•Disc: The disc, also known as the plug or the disk, is a movable component that regulates the flow of fluid through the valve. It can be moved up or down by the valve stem to open or close the valve.

•Stem: The stem is a threaded rod that connects the valve disc to the valve handwheel or actuator. It is used to control the position of the valve disc and regulate the flow of fluid.

•Seat: The seat is a sealing surface that is in contact with the valve disc to provide a tight shut-off. It is usually made of a resilient material such as rubber, , or metal.

•Packing: The packing is a set of seals that prevent leakage of fluid through the valve stem. It is typically made of graphite or other flexible materials.

•Gland: The gland is a component that compresses the packing material around the valve stem to provide a tight seal. It is usually made of metal.

Industry:

•Electric power industries

•Oil and gas industries

•Petroleum industries

•water and wastewater industries

•Marine Industries

•Construction Industries

•Mining industries

Applications:

•Oil and gas industry - for controlling the flow of fluids, gases, and steam.

•Chemical industry - for resisting corrosive chemicals and high-pressure environments.

•Power plants - for controlling the flow of steam and water in high-pressure and high-temperature.

•Water treatment plants - for regulating water flow and pressure.

•Petrochemical industry - for regulating the flow of petrochemicals and gases.

•Marine industry - for regulating the flow of seawater and fluids.

•Mining industry - for regulating the flow of water and slurries in mining operations.

•Fire protection systems - for controlling the flow of water or other fire suppression agents in case of a fire.

•Aerospace industry - for regulating the flow of fluids, gases, and propellants in aerospace applications.

•Biotechnology industry - for regulating the flow of gases and liquids in bioreactors and fermentation systems.

•Pulp and paper industry - for regulating the flow of chemicals and fluids in pulp and paper production processes.

•Wastewater treatment plants - for regulating the flow and pressure of wastewater and sludge in treatment processes.

Advantages

•Excellent throttling capabilities

•Simple to use and clean the valve

•Can also work as a stop-check valve

•Quick and a safe shutdown

•Durable throughout its life span

•It has a Non-rotating stem

•The seats of these valves are very easy to resurface.

•Safe to use and dependable as well

SVR Global, the API globe valve manufacturer in USA provides top-notch quality valves which are not only durable and strong but also comes at pocket-friendly prices.

Description:

Body material: Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class: 150 – 2500; PN10 – PN 450

Size: DN 10 – DN 1200

Ends: Butt weld, Flanged, threaded, socket weld

Operations: Hand-wheel operated, Pneumatic actuated, Electric actuated, Gear operated

Visit our website for more information- https://svrglobal.net/products/api-globe-valve/

0 notes

Text

youtube

0 notes

Text

Description:

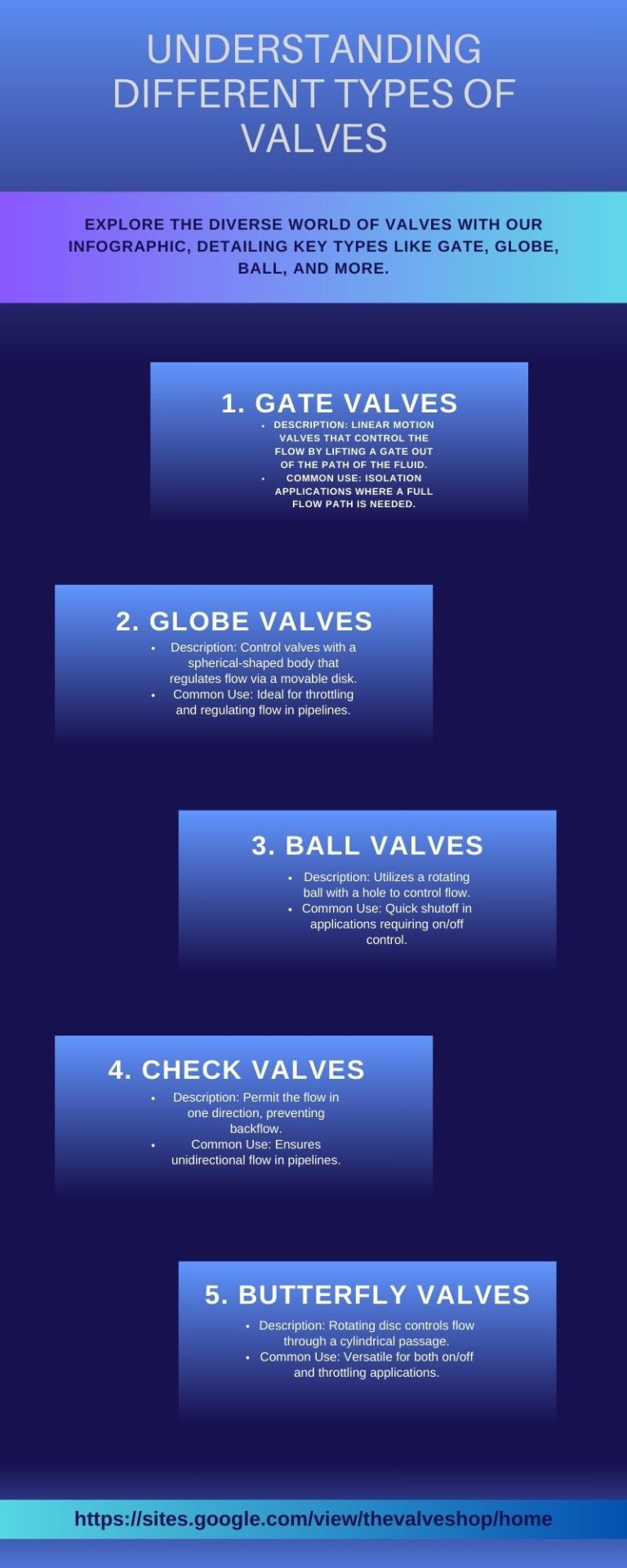

Understanding Different Types of Valves provides a comprehensive overview of key valve varieties crucial in fluid control systems. Gate valves, with linear motion, excel in isolation, while globe valves offer nuanced regulation. Ball valves ensure swift on/off control, check valves maintain unidirectional flow, and butterfly valves offer versatile usage. Each valve type caters to specific needs, from precise throttling to rapid shutoff, impacting industries like oil, water treatment, and manufacturing. This infographic empowers decision-makers to select the right valve for optimal system performance, emphasizing the importance of evaluating specific application requirements. Explore this informative guide to enhance your knowledge of these essential components shaping fluid dynamics across various sectors.

Gate Valves:

Gate valves are essential linear motion devices that manage the flow of fluid by lifting a gate obstructing the path. These valves are particularly valuable in applications where a full and unobstructed flow path is required. The operation of gate valves involves raising the gate to permit flow and lowering it to block the passage of fluid. This on/off functionality makes gate valves suitable for isolation purposes, allowing for efficient control of liquid or gas flow.

Globe Valves:

Globe valves are characterized by their spherical-shaped bodies and a movable disk that regulates the flow. Unlike gate valves, globe valves provide more nuanced control over fluid flow, making them ideal for applications that require throttling and precise regulation. The design of the globe valve allows for fine-tuning the flow rate by adjusting the position of the disk, offering versatility in managing the movement of liquids or gases through a pipeline.

Ball Valves:

Ball valves utilize a rotating ball with a hole to control the flow of fluids. These valves are particularly advantageous for applications requiring quick shutoff or on/off control. The simplicity of their design, consisting of a spherical closure element, ensures a reliable and efficient operation. Ball valves find extensive use in various industries where rapid control and shutoff are critical, providing a durable solution for managing the flow of liquids or gases.

Check Valves:

Check valves, also known as non-return or one-way valves, permit fluid flow in only one direction while preventing backflow. These valves play a crucial role in ensuring unidirectional flow within pipelines. The design of check valves typically includes a mechanism that allows the flow to open the valve while preventing reverse flow. This feature is vital in preventing the contamination of systems and maintaining the desired direction of fluid movement, making check valves essential components in a wide range of piping applications.

Butterfly Valves:

Butterfly valves feature a rotating disc within a cylindrical passage to control the flow of fluids. These valves offer versatility, serving both on/off and throttling applications. The quarter-turn motion of the disc allows for quick and efficient control of the flow, making butterfly valves a popular choice in situations where precise regulation is necessary. Their compact design and ease of operation contribute to their widespread use in various industries, including water treatment, HVAC systems, and chemical processing.

Visit:

0 notes

Text

خرید شیر globe valve

شیر کروی یا globe valve یک نوع شیر برای کنترل جریان مایعات است. این نوع شیرها معمولاً برای کنترل دقیق جریان مورد استفاده قرار میگیرند، و میتوانند توسط یک سیستم سنجش و کنترل عملکرد پروسه را بهبود بخشند.

گلوب ولو ها از نوعی شیرهای متصل به لولهها برای کنترل جریان مایعات یا گازها استفاده میکنند. این شیرها از دو برجکتور اصلی که به نام بادی و بندرنوشته میشوند تشکیل شدهاند که با بالا و پایین حرکت کردن بادی، جریان مایعات را کنترل میکنند. Globe valve ها به دو نوع خطی و زاویهدار تقسیم میشوند.

کاربرد شیر globe valve

شیرهای گلوب معمولاً برای تنظیم جریان سیال در خطوط لوله استفاده می شوند. آنها به ویژه برای کاربردهایی که نیاز به دریچه گاز مکرر و تنظیم جریان دارند مناسب هستند. این شیرها دارای بدنه کروی با بافل داخلی هستند که جریان را هدایت می کند و به کنترل آن کمک می کند. شیرهای گلوب به طور گسترده در صنایعی مانند نفت و گاز، پتروشیمی، تولید برق و تصفیه آب استفاده می شوند.

شیر صنعتی Globe Valve یک نوع شیر است که برای کنترل جریان مایعات در صنایع مختلف از جمله صنایع نفت، گاز، پتروشیمی و آب به کار میرود. این نوع شیر با یک دیسک که به صورت عمودی حرکت میکند، کنترل جریان مایعات را انجام میدهد. از این شیرها بهطور گسترده در سیستمهایی که نیاز به کنترل دقیق جریان دارند استفاده میشود.

در ادامه به برسی خرید globe valve

خرید انواع globe valve

برای خرید globe valve باید از قبل با مدل ها و انواع آنها آشنا بود و همچنین استاندارد خط لوله ای را که میخواهیم از آن استفاده کنیم را نیز در نظر بگیریم تا بتوانیم بهترین مدل را تهیه و خریدارای کنیم. قیمت globe valve با توجه به جنس، نوع، مدل و ... تعیین میشود. برای مطلع شدن از لیست قیمت و خرید globe valve میتوانید به سایت ولو تجهیز مراجعه کنید و از کارشناسان این مجموعه کمک بگیرید.

1 note

·

View note

Text

Globe valve Manufacturer | Globe valve Dealer | Globe valve Stockist | Globe valve Exporter

PECO Valves: World-class Globe Valve Manufacturer, Dealer, Stockist, and Exporter delivering premium quality, durable, and efficient fluid control solutions globally.

#Globe valve Manufacturer#Globe valve Dealer#Globe valve Stockist#Globe valve Exporter#Globe valve#Gate valve Dealer#Gate valve Stockist

0 notes

Text

Industrial Valves and Engineering: The Cornerstones of Fluid Control

In the realm of engineering, precision and control are paramount, and few components play a more critical role in achieving these goals than industrial valves. These seemingly humble devices are the unsung heroes of fluid control, serving as vital components in a wide array of engineering applications. In this article, we delve into the symbiotic relationship between industrial valves and engineering, exploring their significance, types, and the innovative solutions they offer.

The Significance of Industrial Valves in Engineering

Industrial valves are engineering marvels designed to regulate the flow of fluids, be it liquids or gases, in complex systems. Their importance lies in their ability to control the movement and direction of these fluids with incredible precision. Here's why they are indispensable in the field of engineering:

Flow Control: Valves are the gatekeepers of fluid flow, allowing engineers to precisely adjust the rate, direction, and distribution of fluids within a system. This control is essential in various engineering processes.

Safety: Valves serve as safety mechanisms, preventing overflows, leaks, and system failures that could lead to accidents or environmental hazards. They are crucial in ensuring the safety of both equipment and personnel.

Efficiency: In engineering applications, efficiency is paramount. Valves help optimize processes by regulating flow rates, which, in turn, enhances energy efficiency and reduces operational costs.

Flexibility: Valves are versatile components, adaptable to a wide range of engineering processes. Whether in chemical plants, water treatment facilities, or power generation, they are essential for diverse applications.

Types of Industrial Valves in Engineering

Engineers have a wide array of valve types at their disposal, each tailored to specific needs:

Gate Valves: Ideal for applications requiring full flow or shutoff capabilities, gate valves use a sliding gate to control flow. They are commonly used in pipelines.

Ball Valves: Known for their rapid and reliable operation, ball valves employ a spherical disc (the ball) to control fluid flow. They are popular in systems that require frequent on/off cycles.

Butterfly Valves: These valves feature a rotating disc resembling a butterfly, making them compact and lightweight. They are suitable for large-diameter applications.

Check Valves: Check valves allow fluid to flow in one direction only, preventing backflow. They are essential in maintaining system integrity.

Globe Valves: With a globe-shaped body and a movable plug, globe valves are used in applications requiring precise control of flow and pressure.

Engineering Applications of Industrial Valves

Industrial valves are integral to various engineering sectors:

Chemical Engineering: Valves are used to control the flow of chemicals in manufacturing processes, ensuring precise mixing and reactions.

Mechanical Engineering: In HVAC systems and hydraulic machinery, valves play a key role in temperature regulation and fluid movement.

Civil Engineering: Water distribution, sewage management, and irrigation systems rely on valves to control the flow of water and wastewater.

Energy Engineering: Power plants depend on valves to manage steam, cooling water, and other fluids critical for electricity generation.

In the world of engineering, industrial valves are the linchpin of fluid control, enabling precision, safety, and efficiency in a myriad of applications. As engineering continues to advance and innovate, so too will the role of industrial valves, ensuring that the vital processes they regulate are executed with the utmost accuracy and reliability. Their contribution to engineering is not only significant but essential, making them indispensable assets for engineers across the globe.

#industrial valve#freture techno#manufacturers#valve muanufacturers#ball valves#bellowsealvalve#globe valve#gate valve#butterfly valve#ball valve#pipe fittings#instrumentation#accessories#valve automation

1 note

·

View note

Text

OEM Valve: Unleashing Customized Solutions for Industrial Success

In the dynamic world of industrial operations, having tailored solutions that meet specific requirements is crucial. This is where OEM Valve steps in, offering a wide range of customizable valve solutions designed to optimize performance in various industries. Let's explore the key features and advantages of OEM Valve and how it can unlock industrial success through its customized approach.

Customization for Perfect Fit: One of the standout features of OEM Valve is its ability to provide customized solutions that perfectly fit the unique needs of each industry. With a comprehensive range of valve types, materials, sizes, and configurations, OEM Valve offers endless possibilities for customization. Whether it's controlling flow rates, managing pressure, or handling corrosive substances, the OEM Valve team works closely with clients to design valves that align precisely with their operational requirements.

Collaborative Design Process: OEM Valve understands that collaboration is key to delivering exceptional solutions. The OEM Valve team partners with clients to gain an in-depth understanding of their specific challenges and goals. By working closely together, they co-create valve solutions that address unique needs and surpass expectations. This collaborative approach ensures that the final product is not only tailored but also optimized for maximum performance.

Quality and Reliability: When it comes to industrial operations, quality and reliability are non-negotiable. OEM Valve maintains the highest standards throughout the manufacturing process, employing advanced technology and stringent quality control measures. Every valve undergoes rigorous testing to ensure durability, efficiency, and long-term reliability. By choosing OEM Valve, industries can trust in the quality of their valves, knowing they will perform flawlessly even in demanding environments.

Flexibility and Adaptability: Industries evolve, and so do their operational requirements. OEM Valve understands the importance of flexibility and adaptability. Their valves can be easily modified or upgraded to accommodate changing needs, saving time and costs associated with replacing entire systems. With OEM Valve, industries can embrace future advancements without the need for significant overhauls, ensuring seamless integration and operational continuity.

Exceptional Support and Service: OEM Valve goes beyond delivering top-notch valves. They are committed to providing exceptional support and service throughout the entire lifecycle of their products. From initial consultation to installation and maintenance, their team of experts is readily available to address inquiries, offer technical assistance, and ensure customer satisfaction. With OEM Valve, clients can rely on a trusted partner who is dedicated to their success.

Conclusion: OEM Valve stands as a beacon of customized solutions in the industrial valve industry. Through collaborative design, exceptional quality, adaptability, and comprehensive support, OEM Valve empowers industries to achieve optimal performance and success. With their commitment to customization and unwavering focus on client needs, OEM Valve is the go-to choice for industries seeking tailored valve solutions. Embrace the power of customization and unlock your industrial potential with OEM Valve.

0 notes

Photo

Best globe valve in UAE

At Yellowpages.ae, we make it easy to find the right globe valve. We have wide range of suppliers, offering competitive prices and quality services. Search for the best globe valve in UAE and get in touch today.

0 notes

Text

Gate valve,stainless steel gate valve,RTV gate valve,CF8 gate valve,Class150Lb gate valve,API600 gate valve

#ball valve#check valve#gate valve#globe valve#china valve factory valve#gatevalve#valve#youtube#cantonfair#ballvalve

0 notes

Text

Check Valves: The Key to Preventing Backflow

Check valves are a crucial component in any plumbing system, as they play a vital role in preventing backflow. Backflow occurs when water or other liquids flow in the opposite direction than intended, potentially contaminating clean water sources and posing a health hazard. Check valves are designed to allow flow in one direction only, effectively preventing backflow and protecting the integrity of the plumbing system.

Check valves are commonly used in a variety of applications, including residential, commercial, and industrial settings. They are installed in water supply lines, sewage systems, irrigation systems, and more to ensure that water and other liquids flow in the correct direction and do not contaminate clean water sources.

There are several types of check valves available, including swing check valves, lift check valves, and inline check valves. Each type has its own unique design and functionality, but they all serve the same basic purpose of preventing backflow. Swing check valves have a disc or flap that swings open to allow forward flow and closes to prevent backflow. Lift check valves use a piston or ball to lift and allow flow in one direction only. Inline check valves have a spring-loaded disc that opens and closes based on flow direction.

Proper maintenance and installation of check valves are essential to ensure they function effectively and prevent backflow. Check valves should be inspected regularly for any signs of wear or damage and replaced if necessary. It is also important to install check valves in the correct orientation to ensure they operate properly and prevent backflow.

In conclusion, check valves are the key to preventing backflow in plumbing systems. By installing and maintaining check valves properly, you can protect clean water sources and ensure the safety and integrity of your plumbing system. If you are experiencing issues with backflow in your plumbing system, consider installing check valves to prevent future problems.

1 note

·

View note

Text

Top Valve Manufacturers: Leaders in Quality and Innovation

Flowdo Valves stands as the Leading manufacturer of industrial valves in Ahmedabad India, Our comprehensive range includes ball valves, globe valves, gate valves, check valves, butterfly valves and forged steel valves With a commitment to quality. Trust in Flowdo Valves for superior solutions that elevate your industrial operations to new heights.these industry giants set the standard for excellence in valve production.

#Flowdo Valves#Industrial Valve in India#ball valve#globe valve#gate valve#check valve#butterfly valve#forged steel valve

1 note

·

View note

Photo

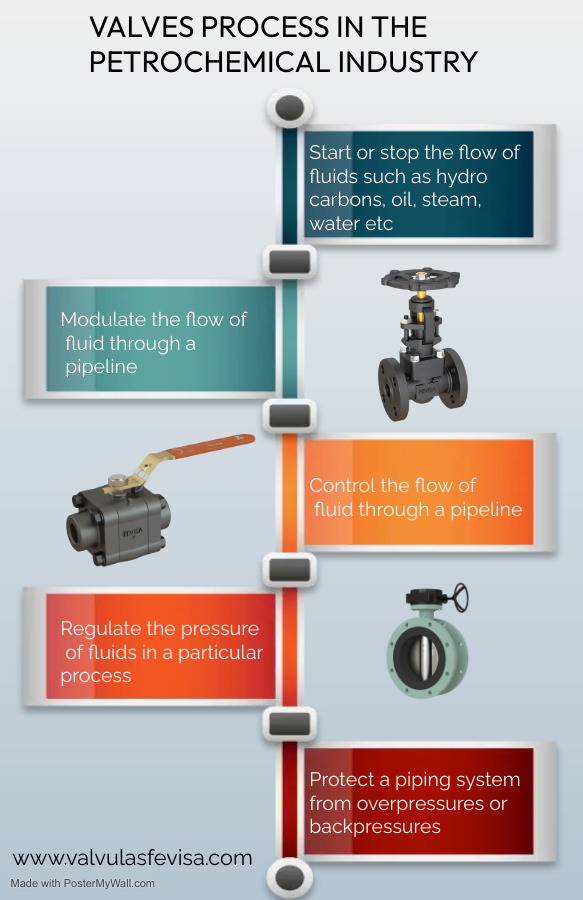

In Petrochemical industry the valves involves in many process, they use different kind of valves like ball valves, butterfly valves, knife gate valve, globe valve, plug valve etc. You should choose the best valve manufacturers and suppliers for buying high standard valves. Valulas Fevisa, being one of the largest valve stockist in USA. Reach us to know more ..

1 note

·

View note

Text

A Complete Guide On Types Of Valves Used In Piping

Summary:

Selecting the perfect valve for your piping may seem difficult. Let us see about some of the most commonly used valves in piping.

There are different types of valves that are used in piping. A valve is a tool that controls, modifies, or manages the run of a liquid by opening, closing, or partly clogging the liquid flow. A valve is an intuitive design that changes the run and coercion of liquid within a system. It manages to flow and pressure. In piping, the following valves are used based on the needs. They are gate valve, globe valve, check valve, plug valve, ball valve, butterfly valve, needle valve, pinch valve, pressure relief valve, etc.

Cast steel gate valve

The gate valve is the topmost standard valve used among process plants. It is a direct motion valve used to initiate or block liquid flow. It is better to use cast steel gate valves than carbon steel gate valves. These gate valves are used in every liquid form, such as air, steam, feedwater, hydrocarbon, lube oil, and more. Gate valves also give better shutoff.

Globe valve and ball valve

A globe valve block initiates or controls the liquid flow. Globe valves are used in processes where fluid flow control and preventing leakage are also required. A ball valve is a quarter-turn spinning movement valve that applies a ball-shaped ring to block or initiate the liquid flow. Most of the ball valves are fast reacting and require a 90-degree turn of the valve handle.

Wafer dual plate check valve

The check valve controls backflow in the piping process. The force of the liquid flowing through a pipe opens the valve, while any backflow will block the valve. This wafer dual plate check valve is productive against back coercion reverse flow and back-siphon age but should be used to separate only unhealthy hazards.

Summing it up

But you are starting with standard features such as design, size, and actuation size of the valves. As a result, you can decide on the perfect valves based on your requirements using these features.

0 notes