#cast steel gate valves

Text

A Complete Guide On Types Of Valves Used In Piping

Summary:

Selecting the perfect valve for your piping may seem difficult. Let us see about some of the most commonly used valves in piping.

There are different types of valves that are used in piping. A valve is a tool that controls, modifies, or manages the run of a liquid by opening, closing, or partly clogging the liquid flow. A valve is an intuitive design that changes the run and coercion of liquid within a system. It manages to flow and pressure. In piping, the following valves are used based on the needs. They are gate valve, globe valve, check valve, plug valve, ball valve, butterfly valve, needle valve, pinch valve, pressure relief valve, etc.

Cast steel gate valve

The gate valve is the topmost standard valve used among process plants. It is a direct motion valve used to initiate or block liquid flow. It is better to use cast steel gate valves than carbon steel gate valves. These gate valves are used in every liquid form, such as air, steam, feedwater, hydrocarbon, lube oil, and more. Gate valves also give better shutoff.

Globe valve and ball valve

A globe valve block initiates or controls the liquid flow. Globe valves are used in processes where fluid flow control and preventing leakage are also required. A ball valve is a quarter-turn spinning movement valve that applies a ball-shaped ring to block or initiate the liquid flow. Most of the ball valves are fast reacting and require a 90-degree turn of the valve handle.

Wafer dual plate check valve

The check valve controls backflow in the piping process. The force of the liquid flowing through a pipe opens the valve, while any backflow will block the valve. This wafer dual plate check valve is productive against back coercion reverse flow and back-siphon age but should be used to separate only unhealthy hazards.

Summing it up

But you are starting with standard features such as design, size, and actuation size of the valves. As a result, you can decide on the perfect valves based on your requirements using these features.

0 notes

Text

EWOM is a Chinese Top Valves manufacturer in 2009, exported to 84 countries worldwide They are committed to providing high-quality products Best Stainless Steel ,Metal Seated Ball Valve or Api 600 Gate Valve provider technical support and deliver the best results for our clients through our Quality remarkable valve is designed to provide optimal performance and efficiency for a wide range of Management System.

#gate valve manufacturers china#wafer check valve#cast steel gate valve#check valve china#swing check valve china#gate valve china#api 600 gate valve#forged steel gate valve#cast steel globe valve#forged steel globe valve#piston check valve#Double block and bleed valve#ball valve china#floating ball valve#fully welded ball valve#stainless steel ball valve#metal seated ball valve#flanged ball valve#top entry ball valve#trunnion mounted ball valve

0 notes

Text

Few things you need to know gate valves

Gate valves are also called disconnection valves. Gate valves are very often for their easy accessibility, especially the valves from the Cast steel gate valve manufacturer in China. They are an inexpensive choice among others to cover general services but they are also an option in the aggressive management or corrosive industrial fluids once their operating conditions have been determined.

Features of the gate valve

To know if the valve is closed or open, the position of the handle will show this state. If it is open, the perforation will be aligned with the inlet and outlet of the valve, while when it is closed, it will be perpendicular to the entrance and exit.

The gate valves are usually rectangular or round. It allows fluid to pass through. Its operation does not allow adjustment. So gate valves by the Cast steel gate valve supplier in China are used for an uninterrupted fluid flow.

In addition, if the valve is to be used frequently for opening and closing, its installation is not recommended because the disc that works as a gate may be eroded & suffer wear due to friction.

Check valves have the function of preventing the reflux of fluid into the supply network. In other words, they prevent the water flow in a certain direction. Two types are available on the market: reed valves and spring valves.

Maintenance of gate valves

Gate valves are mainly used to pass a fluid but are not designed to regulate it. It means Cast steel gate valve in China must be completely open or closed so that their interior (seat and wedge) is not prematurely consumed by the fluid & its pressure and thus avoid leakage.

Gate valves are bidirectional, full-pass, and are also called disconnection valves. They can have a fixed or protruding stem depending on the spaces available in the lines for their installation and are also available with threaded, flanged, butt, or glass welded ends.

Gate valves are very often used for their easy accessibility, they are an inexpensive choice among others to cover general services, but they are also an option in the management of aggressive or corrosive industrial fluids once their operating conditions (fluid pressure-temperature) have been determined.

#Gate valves#gate valve China#Cast steel gate valve in China#gate valve supplier in China#gate valve supplier#Cast steel gate valve supplier in China#Cast steel gate valve manufacturer in China

0 notes

Link

We manufacture the cast steel gate valves as per your purchase requirements. Give us your requirements, we make the valves for you! Cast steel gate valve manufacturers, supplier & exporter in India inquiry now.

#cast steel gate valve manufacturers#cast steel gate valves suppliers#cast steel gate valve standard#stainless steel gate valve#Gate valve

0 notes

Text

Gate Valve supplier in Oman

Middleeast valve is one of the best Gate valve supplier in Oman . We supply to cities like Ibri, Sur, Muscat, and Mutrah.

A gate valve is a type of valve used to control the flow of fluids (liquids or gases) by using a gate or wedge-like disc that moves perpendicular to the flow path to either block or allow the passage of the fluid.

The main function of a gate valve is to provide a tight shutoff, effectively stopping the flow of fluid through the pipeline when the valve is fully closed, and allowing unrestricted flow when the valve is fully open. Gate valves are commonly used in applications where the fluid flow needs to be completely shut off, such as in water supply systems, oil and gas pipelines, industrial processes, and more.

Gate valves consist of several main components, including the body, gate (wedge), stem, actuator, and seats. Here's how they work:

Open Position:

In the open position, the gate (wedge) is fully retracted into the valve body, allowing the fluid to flow through the valve with minimal obstruction. The gate moves perpendicular to the direction of the fluid flow. The valve is opened by turning the valve stem (either manually using a handwheel or with an actuator) which is connected to the gate.

Closing Position:

To close the valve, the stem is turned in the opposite direction, causing the gate to move down into the flow path of the fluid. As the gate descends, it gradually restricts the flow until the valve is completely closed. The gate makes contact with the valve seats located at the bottom of the valve body, forming a tight seal that prevents any further flow.

Middleeast valve is the greatest Gate valve supplier in Oman and are known for their ability to provide a tight seal and low pressure drop when fully open. However, they might require more turns to fully open or close compared to other valve types like ball valves. It's important to use gate valves in appropriate applications and avoid using them for flow regulation where frequent adjustments are necessary.

Description:

Available materials: SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel Gate valve, Gear operated Gate valve, Electric actuated Gate valve and Pneumatic Actuated Gate valve

Ends: Flanged(FF,RF,RTJ), Buttweld, Socket weld, Threaded

Standards: API607, DIN, BS, ANSI, AWWA, ASME, API6D

Gate valve types:

Rising Stem Gate Valve

Non Rising Stem Gate Valve

Bellow Seal Gate Valve

Pressure Seal Gate Valve

Cryogenic Gate Valve

Forged Gate Valve

Gate valve advantages :

They have low fluid resistance.

They have superior sealing capability.

They come with a wide application range.

They have dual flow directions.

Gate valve Industries:

Textiles.

Power generation.

Refineries.

Petrochemical plants.

Shipbuilding

Chemical industry.

Paper factories.

Gate valve parts:

Hand wheel.

Stuffing Box.

Bonnet

Gasket

Stem

Flange

Disk

Body seats

Packing

Body

Visit our website: https://www.middleeastvalve.com/product-category/gate-valve/

2 notes

·

View notes

Text

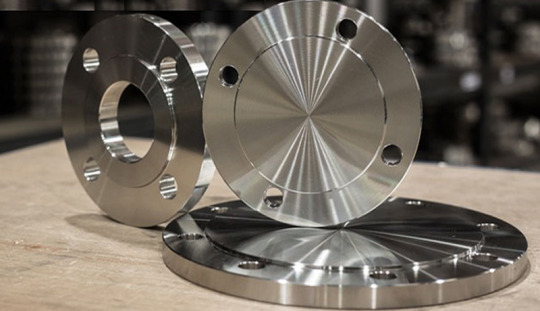

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Thiết bị van cổng - Gate Valves

Gate valve, also known as gate, stop or two-way valve (because it is the typical characteristic of these two types of valves), is a type of valve used to open and close the flow of fluids in pipeline systems, mainly used for liquids with a straight flow. This type of valve is not recommended for flow regulation, except for those specifically designed for that purpose. Depending on the system and environment, we have various options for materials and types of gate valves, such as:

Options for material:

Brass gate valve: limited sizes from DN15 to DN50 with threaded connection.

Cast iron gate valve: large sizes from DN50 and up. Commonly seen in sizes from DN50 to DN300 with a flanged connection. Various connection standards such as DIN, JIS, BS, ANSI, etc. are available.

Stainless steel gate valve: sizes from DN15 to DN300. Connection type can be threaded or flanged.

Steel gate valve: sizes from DN15 to DN300. Connection type is usually welded or flanged.

Options for valve structure:

Rising stem gate valve: a valve with a stem that rises above the valve body as the valve is opened.

Non-rising stem gate valve: a valve with a stem that does not rise above the valve body as the valve is opened.

Wedge-shaped gate valve: a valve with a wedge-shaped gate that moves up and down to open or close the valve. It has a compact design and is suitable for use in high-pressure systems.

Knife gate valve: a valve with a thin, flat gate. It is usually installed between flanges and used for bulk solids and slurries.

Submerged gate valve: a valve with a submerged gate that is hidden inside the body and valve cover. The valve is operated by a handwheel that rotates the gate to open or close the valve. It is compact and saves operating space.

Submerged gate valve with bonnet: similar to a standard submerged gate valve, but with a removable handwheel and a protective cover for the gate. The cover is removed when the valve is operated like a normal submerged gate valve.

Floating gate valve: a valve with a floating gate that rises as the valve is opened. It takes up more operating space than other types of gate valves. It is commonly made of stainless steel, steel, or cast iron.

2 notes

·

View notes

Text

Forged Fittings Vs Wrought Fittings

What is Wrought Fittings?

A Wrought Fittings product is a form of steel made from forged, rolled, ring-rolled, extruded or welded components, while forging refers to one of these forms.

What are uses of Wrought Fittings?

For the construction of buildings, the wrought iron plate girder evolved as a basic device. There were many decorative uses for wrought iron in historical times, including fences, gates, railings, balconies, porches, canopies, roof crestings, lamps, grilles, hardware, nails, cramps, and structural members in tension (I, H, etc.).

What is Forged Fittings?

Forged Fittings is a material produced by alloying iron and carbon under extreme pressure. The surface porosity of forged steel is lower, its grain structure is finer, it has a greater tensile and fatigue strength, and its ductility is significantly higher than steel that has been processed by other means.

What are uses of Forged Fittings?

It is common for forged fitting components to be used in automotive and truck applications, for manufacturing valves, fittings, hand tools and hardware, as well as in manufacturing industrial, heavy construction and mining equipment. The components are made of steel, and these components include the powertrain, axle beams, shafts, wheel spindles and kingpins.

What are the types of forged Fittings?

In order to keep things simple, we divide steel forging into three categories based on the temperature at which it is forged.

Hot forged steel

As the temperature reaches 950°C, the forging process is carried out between 950°C and 1250°C, which is over the temperature of recrystallization. Steel that has been hot forged has good formability and requires a low level of force to shape, which is why it is so popular.

Hardened steel forging

As a general rule, the forging temperature is between 750°C and 950°C. There are limitations in the ductility of this material as well as higher forming forces required than forging at a hot temperature. Besides its great advantages, it can also be considered a middle ground between hot and cold forging, which makes it more versatile than either one alone.

Cold forged steel

This process is carried out under ‘room conditions,’ that is, under temperatures as high as 150 degrees Celsius. The forging process is characterized by the low formability of the material, which demands high forces during the forming process. As a result, it is of great advantage for the conservation of material and for the smoothness of the surface that is achieved with this method.

Here are some comparisons between wrought steel products and forged steel products:

It is important to keep in mind that the major difference between wrought steel and forged steel is their strength. There is no doubt that forged steel is much more durable than wrought steel, since forged steel becomes a casting that is then forged, which adds to its durability even further.

Tap here to read more about:

2 notes

·

View notes

Link

Custom valves get rid of possible leak spots. Thus, the likelihood of contamination is decreased. In contact with surfaces, particles in fluids can adhere. The result could be abrasion, leaking, or other issues. Pneumatic Actuator will use specific valves to stop those contamination-related accidents.

0 notes

Text

Hydraulic door closer hinge, anti pinch and prevent door slams.hydraulic self closing frameless glass hinge pool gate.

Aleader Machinery is a modern and professional manufacturer and exporter dedicated to research, development, production, sales and service of investment castings including construction hardware, auto parts, pump & valve parts, impellers, marine hardware, and some other machinery parts in materials of stainless steel, carbon steel, alloy steel, and brass, etc.

We can supply castings in different conditions including heat-treated, precision-machined, and with some special surface treatments such as spray paint, electric or mirror-polish, satin, vibration grinding, galvanization, and nickel plating, etc. Our products are extensively used in the fields of construction industry, chemical machinery.

0 notes

Text

Knife Edge Gate Valve Supplier in India

Speciality Valve proudly leads as the foremost Knife Edge Gate Valve Supplier in India, with our products reaching global destinations including Canada, France, Australia, and Mexico.

Description:

Available Materials: SS306, SS904, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operation: Hand Wheel, Gear operated, Electric and Pneumatic Actuated

Ends: Flanged, Wafer, Lug

Standards: ASME, API6D, API607, DIN, BS, ANSI, AWWA

Explore our range of Valves on our website: https://www.specialityvalve.com/product-category/unidirectional-knife-gate-valve/

0 notes

Text

What are the advantages of cast steel valves?

Cast steel is a type of carbon steel, usually with a carbon content of between 0.1-0.5percent. It is a commonly used alloy steel known for its good impact resistance. Cast steel is not prone to deformation, breakage, or bending in the face of frequent or sudden impacts.

Cast steel is known for its ability to withstand high stresses and strains. The combination of strength & ductility of steel makes it a staple material in mechanical and structural applications because of its ability to withstand heavy loads. That's why cast steel is one of the most commonly used metals in the world.

Now let's find out about cast steel ball valve by cast steel ball valve manufacturer China.

Cast steel ball value advantages

The opening & closing of the cast steel ball valve is driven by the stem & rotates around the axis of the stem. Cast steel ball valves are mainly used for cutting, connecting media in pipes & for fluid regulation control. Cast steel ball valves have a wide range of applications, ranging in diameter from a few millimetres to a few meters, and can range from high vacuum to high-pressure applications.

Small fluid resistance. When fully opened, the cross-sectional area of the ball channel, valve body channel, and a connecting tube are equal and connected. Straight line. The medium flows through the ball valve. This is the same as flowing through a straight pipe. The fluid resistance of the ball valve is the lowest of all types of valves.

High-speed opening and closing, convenient and high-speed

Simple structure, small size, lightweight: Its height is much lower than that of gate valves & globe valves. Tight and reliable ball valve sealing surfaces are now widely used in plastics and have excellent sealing properties.

Easy maintenance, the simple structure of the ball valve, the seal ring is generally movable, easy to disassemble and replace. Where s it’s hard to maintain in case of forged steel ball valve, explained by forged steel ball valve supplier in China.

W5. When fully opened or completely closed, the sealing surface of the ball and valve seat is isolated from the medium. Even if the medium passes through no corrosion of the valve seal surface occurs.

What are the advantages of cast steel gate valves?

The opening & closing parts of the cast steel gate valve are gate plates. The direction of movement of the gate plate is perpendicular to the direction of the fluid, and the gate valve can only be fully opened and fully closed and cannot be regulated and throttled. The gate has two sealing surfaces, the two sealing surfaces of the commonly used pattern gate valve form a wedge and wedge angle that varies with the valve parameters.

The cast steel gate valve Supplier in China said the major advantages of cast steel gate valves is small fluid resistance, sealing surface subject to medium brushing & erosion is small. Opening and closing are less laborious. The flow direction of the medium is unrestricted, with no spoilage, and no pressure reduction. The structure is simple, the structure length is short, the manufacturing process is good, the high-temperature resistance and high-pressure resistance are optional materials, and the scope of application is wide.

#cast steel ball valve manufacturer China#forged steel ball valve supplier in China#cast steel gate valve Supplier in China

0 notes

Text

Bi directional knife gate valve manufacturer

Bi directional knife gate valve manufacturer

Valvesonly Europe is the largest Bi Directional Knife Gate Valve Manufacturer in Germany A bidirectional knife gate valve is a specialized type of valve used in pipelines to control flow. It features a sharp-edged gate to slice through thick fluids, allowing or blocking the flow, and it can operate in both directions.

The working principle of a bi-directional knife gate valve involves its unique design and functionality:

Gate Mechanism: The valve consists of a sharp-edged gate that moves perpendicular to the flow direction within the pipeline.

Flow Regulation: When the valve is open, the gate retracts, allowing fluid to flow through the passageway. Closing the valve positions the gate across the pipeline, stopping the flow.

Bi-Directional Capability: Its design enables operation in both directions, facilitating flow control regardless of the fluid's movement.

Sealing: The gate creates a tight seal when closed, preventing leakage and maintaining pipeline integrity.

Materials and Design: Often built using durable materials like stainless steel or cast iron, ensuring resilience to abrasive and viscous fluids.

Functions:

Flow Control: Manages the flow of various materials, from liquids to slurries, by opening or closing the gate.

Bi-Directional Operation: Allows flow regulation in both directions, offering flexibility in fluid handling.

Isolation: Provides a tight seal when closed, preventing leakage and maintaining pipeline integrity.

Resilience to Viscous Fluids: Handles thick and abrasive fluids effectively due to its gate design.

Minimal Pressure Drop: Maintains a low pressure drop across the valve, reducing energy consumption.

Benefits:

Efficiency: Ensures smooth flow control, reducing downtime and optimizing operational efficiency.

Reliability: Offers a reliable sealing mechanism, minimizing the risk of leaks or pipeline contamination.

Low Maintenance: Requires minimal maintenance due to its robust design and materials, saving on upkeep costs.

Cost-Effective: Longevity and minimal maintenance translate to cost savings over the valve's lifecycle.

In Germany, manufacturers of Bi Directional Knife Gate Valve incorporate external actuators or handwheels in their design. These components efficiently control the gate's movement, enabling precise fluid flow regulation across diverse industrial applications. The valve's engineering focuses on optimizing flow control and ensuring dependable pipeline isolation, contributing to enhanced operational efficiency in industrial settings.

Available materials: Ductile iron, SS316, WCB, WC6, WCC, LCB, LCC, Cast iron, SS304, Carbon steel

• Class: 150 to 600, PN6 to PN25

• Size: 2''-24''

• Ends: Flanged, Wafer, Lug

Operations:

• Hand wheel

• Pneumatic Actuated

• Electric

• Gear operated

1 note

·

View note

Text

Supplier of Industrial Valves in Pune

Luvana Metal Corporation is a Manufacturer and Supplier of Industrial Valves in Pune, Maharashtra, India.

We are an ISO 9001:2015 certified company, Having extensive experience in the field of all Ferrous & Non-Ferrous metals.

We offer a comprehensive range of stainless steel, carbon steel, nickel alloy, and special alloy products, including pipes, tubes, sheets, plates, rods, pipe fittings, flanges, and more.

Industrial valves are devices used to control the flow of liquids, gases, or slurries within a piping system in various industries.

From ball valves to gate valves, butterfly valves to globe valves.

Understanding the unique functionalities of each valve type is crucial for selecting the most suitable option for your needs.

Selecting the right material for industrial valves is paramount.

Options include stainless steel for strength and cast iron for cost-effectiveness.

And plastic for lightweight suitability in low-pressure and corrosive fluid environments.

Regular maintenance is key to ensuring the continued functionality and longevity of industrial valves.

Industrial valves boast corrosion resistance, high tensile strength, temperature resilience, ease of formability, low-maintenance durability, appealing aesthetics.

Industrial valves find versatile applications in regulating, controlling, and directing the flow of fluids such as water, gas, and oil.

And steam across diverse industries, ensuring efficient operations and optimal performance.

Luvana Metal Corporation is a Manufacturer and Supplier of Industrial Valves in Pune and locations like Chakan, Bhosari, Ranjangaon, Hadapsar, Shirwal, Shikrapur, Amravati, Nashik, Latur, Solapur, Sangli, Kolhapur, Aurangabad, Nagpur, Nanded, Nashik, Sangli, Satara, Vasai-Virar, Wardha, Yavatmal.

For any questions or further information, please contact us.

Read the full article

#AmravatiIndustrialValves#AurangabadValves#ballvalves#BhosariIndustrialSector#butterflyvalves#CarbonSteelValves#CastIronValves#ChakanIndustrialSupplies#CorrosionResistantValves#CustomValveSolutions#DiverseIndustryApplications#EasyFormability#Eco-FriendlyValves#FerrousMetals#FlangeSupplies#FlowControlValves#FluidRegulation#GasControlValves#gatevalves#globevalves#HadapsarIndustries#HighTensileStrengthValves#IndustrialFluidManagement#IndustrialMetalSupplier#IndustrialOperations#IndustrialPipes#IndustrialRods#IndustrialValveApplications#IndustrialValveDurability#IndustrialValves

0 notes

Text

France Industrial Valve Market Size, Share, Types, Products, Trends, Growth, Applications and Forecast 2023 to 2030

France Industrial Valve is Expected to Grow at a Significant Growth Rate, and the Forecast Period is 2023-2030, Considering the Base Year as 2022.

The industrial valve market in France is a vital component of the nation's thriving industrial sector. As an integral part of various industries, including oil and gas, chemical, water and wastewater treatment, and manufacturing, industrial valves play a crucial role in controlling the flow of fluids and gases. The market has witnessed steady growth over the years, driven by technological advancements, increasing demand for energy, and a focus on efficient resource utilization.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the France Industrial Valve Market include:

"ARCA Regler GmbH (Germany), SAMSON Controls SAS (Germany), Bopp & Reuther Messtechnik GmbH (Germany), Velan SAS (Canada), SFC KOENIG SAS (Switzerland), Tecofi SAS (France), Valco Group France SAS (France), LDM Armaturen GmbH (Germany), SLCE Sistemas de Control de liquidos y Electricidad SL (Spain), RITAG Ritterhuder Armaturen GmbH & Co. KG (Germany), Parcol S.p.A. (Italy), Laroche SAS (France), Bray Controls France SAS (Ireland), Gestra France SAS (Germany), CIRCOR International Inc. (France), Gevas GmbH (Germany), Pister Kugelhähne GmbH (Germany), Walworth Valves France S.A.S. (Mexico), VYC Industrial S.A. (Spain), Baelz Automatik GmbH & Co. KG (Germany) and other major players."

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query France Industrial Valve Market Report, Visit:

https://pristineintelligence.com/inquiry/france-industrial-valve-market-99

Segmentation of France Industrial Valve Market:

By Type

Ball

Globe

Gate

Butterfly

Plug

Check

By Material

Steel

Brass

Bronze

Cast Iron

Plastic

By Size

< 1”

1”–6”

6”–25”

25”–50”

50”

By Application

Oil & Gas

Power

Energy

Chemical

Water & Waste Treatment

By Function

On/Off

Control

Isolation

Special Purpose

Key Benefits of France Industrial Valve Market Research:

Research Report covers the Industry drivers, restraints, opportunities and challenges

Competitive landscape & strategies of leading key players

Potential & niche segments and regional analysis exhibiting promising growth covered in the study

Recent industry trends and market developments

Research provides historical, current, and projected market size & share, in terms of value

Market intelligence to enable effective decision making

Growth opportunities and trend analysis

Covid-19 Impact analysis and analysis to France Industrial Valve market

Acquire This Reports: -

https://pristineintelligence.com/buy-now/99

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#France Industrial Valve#France Industrial Valve Market#France Industrial Valve Market Size#France Industrial Valve Market Share#France Industrial Valve Market Growth#France Industrial Valve Market Trend#France Industrial Valve Market segment#France Industrial Valve Market Opportunity#France Industrial Valve Market Analysis 2024

0 notes

Text

UK Industrial Valve Market Outlook for Forecast Period (2023 to 2030)

UK Industrial Valve is Expected to Grow at a Significant Growth Rate, and the Forecast Period is 2023-2030, Considering the Base Year as 2022.

The UK industrial valve market serves as a vital component within the broader industrial machinery sector. Industrial valves are crucial for controlling the flow of liquids, gases, and slurries in various industrial processes, including oil and gas, water and wastewater treatment, power generation, chemical processing, and manufacturing. The market encompasses a wide range of valve types, including gate valves, ball valves, butterfly valves, globe valves, and check valves, catering to diverse industrial applications. Key factors driving the market include infrastructure development projects, technological advancements, increasing focus on efficiency and safety, and stringent regulatory standards governing industrial operations.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

The latest research on the UK Industrial Valve market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global UK Industrial Valve industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the UK Industrial Valve market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

Leading players involved in the UK Industrial Valve Market include:

"Spirax-Sarco Engineering PLC (UK), IMI PLC (UK), Weir Group PLC (UK), Rotork PLC (UK), AVK UK Limited (Denmark), Watson Valve Services Ltd (UK), Tyco Valves & Controls UK Ltd (Ireland), KOSO Kent Introl Limited (UK), Pentair Valves & Controls UK Ltd (US), Hobbs Valve (UK), Oliver Valves Ltd (UK), T-T Flow (formerly T-T Pumps) (UK), Flotite Valves & Controls (US), Frese Limited (Denmark), Heaton Valves Africa (UK) Ltd (UK), Oliver Twinsafe Valves Ltd (UK), ARI-Armaturen UK Ltd (Germany), Kitz UK Ltd (Japan), R&M Bearings International Ltd (RMB) (UK), Bifold Fluidpower Ltd (UK) and other major players."

If You Have Any Query UK Industrial Valve Market Report, Visit:

https://pristineintelligence.com/inquiry/uk-industrial-valve-market-103

Segmentation of UK Industrial Valve Market:

By Type

Ball

Globe

Gate

Butterfly

Plug

Check

By Material

Steel

Brass

Bronze

Cast Iron

Plastic

By Size

< 1”

1”–6”

6”–25”

25”–50”

50”

By Application

Oil & Gas

Power

Energy

Chemical

Water & Waste Treatment

By Function

On/Off

Control

Isolation

Special Purpose

Reasons for Acquiring this Report:

1. Strategic Decision-Making for Government Leaders and Politicians:

Gain insights into the global UK Industrial Valve Market Growth 2023-2030 market revenues at global, regional, and national levels until 2030.

Assess and strategize market share based on comprehensive analysis, enabling informed decision-making.

Identify potential markets for exploration and expansion.

2. Informed Decision-Making for Professionals and Product Developers:

Access a detailed breakdown of the UK Industrial Valve Market Growth 2023-2030 market worldwide, including product variations, use cases, technologies, and final consumers.

Allocate resources effectively by anticipating demand patterns for emerging products.

Stay ahead in product development by understanding market dynamics and consumer preferences.

3. Strategic Planning for Sales Managers and Market Stakeholders:

Utilize market breakdowns to target specific segments, optimizing sales strategies.

Address challenges and capitalize on expansion opportunities highlighted in the report.

Mitigate threats effectively with a comprehensive understanding of market risks.

4. Comprehensive Understanding for Executives:

Analyze primary drivers, challenges, restrictions, and opportunities in the global Laboratory Clothes market.

Develop effective strategies by gaining insights into market dynamics.

Allocate resources based on a thorough understanding of market conditions.

5. Competitive Intelligence:

Obtain a detailed analysis of competitors and their key tactics in the UK Industrial Valve Market Growth 2023-2030.

Plan market positioning based on a comprehensive understanding of the competitive landscape.

Stay ahead by learning from competitors’ strengths and weaknesses.

6. Accurate Business Forecasting:

Evaluate the accuracy of global UK Industrial Valve Market Growth 2023-2030 business forecasts across regions, major countries, and top enterprises.

Make data-driven decisions with confidence, minimizing risks associated with inaccurate forecasts.

Stay ahead of industry trends by aligning business strategies with reliable forecasts.

Acquire This Reports: -

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96367

Email: [email protected]

#UK Industrial Valve#UK Industrial Valve Market#UK Industrial Valve Market Size#UK Industrial Valve Market Share#UK Industrial Valve Market Growth#UK Industrial Valve Market Trend#UK Industrial Valve Market segment#UK Industrial Valve Market Opportunity#UK Industrial Valve Market Analysis 2024

0 notes