#Valve manufacturer USA

Text

API Globe Valve Manufacturer

SVR Global is the leading API globe valve manufacturer in USA and supplies top notch quality valves in various oil and gas industries, chemical industries in Chicago, New York and Houston. API stands for American Petroleum Institute. API Globe valves are operated to control the flow of fluids in the system. They are usually used for throttling the flow apart from controlling as well. These valves have a stem which moves up and down to control the flow of fluids & a disc and seat that is attached to the body of the valve. Globe valves are the best among other valves for controlling and regulating the flow of fluids. These valves are bi-directional which means they can move in either direction inside the valve. The fluid flow in globe valves is highest when its disc is raised. They are operated manually and automatically.

Parts:

•Body: The body of an API globe valve is a shell that houses all the internal parts of the valve.

•Bonnet: The bonnet is a cover that sits on top of the valve body and provides access to the internal parts of the valve. It is usually bolted to the valve body and can be removed for maintenance or repair.

•Disc: The disc, also known as the plug or the disk, is a movable component that regulates the flow of fluid through the valve. It can be moved up or down by the valve stem to open or close the valve.

•Stem: The stem is a threaded rod that connects the valve disc to the valve handwheel or actuator. It is used to control the position of the valve disc and regulate the flow of fluid.

•Seat: The seat is a sealing surface that is in contact with the valve disc to provide a tight shut-off. It is usually made of a resilient material such as rubber, , or metal.

•Packing: The packing is a set of seals that prevent leakage of fluid through the valve stem. It is typically made of graphite or other flexible materials.

•Gland: The gland is a component that compresses the packing material around the valve stem to provide a tight seal. It is usually made of metal.

Industry:

•Electric power industries

•Oil and gas industries

•Petroleum industries

•water and wastewater industries

•Marine Industries

•Construction Industries

•Mining industries

Applications:

•Oil and gas industry - for controlling the flow of fluids, gases, and steam.

•Chemical industry - for resisting corrosive chemicals and high-pressure environments.

•Power plants - for controlling the flow of steam and water in high-pressure and high-temperature.

•Water treatment plants - for regulating water flow and pressure.

•Petrochemical industry - for regulating the flow of petrochemicals and gases.

•Marine industry - for regulating the flow of seawater and fluids.

•Mining industry - for regulating the flow of water and slurries in mining operations.

•Fire protection systems - for controlling the flow of water or other fire suppression agents in case of a fire.

•Aerospace industry - for regulating the flow of fluids, gases, and propellants in aerospace applications.

•Biotechnology industry - for regulating the flow of gases and liquids in bioreactors and fermentation systems.

•Pulp and paper industry - for regulating the flow of chemicals and fluids in pulp and paper production processes.

•Wastewater treatment plants - for regulating the flow and pressure of wastewater and sludge in treatment processes.

Advantages

•Excellent throttling capabilities

•Simple to use and clean the valve

•Can also work as a stop-check valve

•Quick and a safe shutdown

•Durable throughout its life span

•It has a Non-rotating stem

•The seats of these valves are very easy to resurface.

•Safe to use and dependable as well

SVR Global, the API globe valve manufacturer in USA provides top-notch quality valves which are not only durable and strong but also comes at pocket-friendly prices.

Description:

Body material: Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class: 150 – 2500; PN10 – PN 450

Size: DN 10 – DN 1200

Ends: Butt weld, Flanged, threaded, socket weld

Operations: Hand-wheel operated, Pneumatic actuated, Electric actuated, Gear operated

Visit our website for more information- https://svrglobal.net/products/api-globe-valve/

0 notes

Text

# 1 Control Valve Gearbox Manufacturer & Supplier in the USA

Viral Industries is a renowned control valve gearbox manufacturer, supplier, and exporter in the USA, Europe, and Canada. We offer gearboxes that provide smooth operation and accurate management. Contact us today to get top-notch valve gearboxes at the most competitive prices.

For more information

Call us: +91 8238089658

Reach us: https://www.viralindustriesindia.com/control-valve-gearbox-manufacturer/

0 notes

Text

Diaphragm Valve Manufacturers

Valvesonly are reputed Diaphragm Valve Manufacturers in USA. A diaphragm valve is a type of control valve that uses a flexible diaphragm, typically made of rubber or synthetic material, to regulate the flow of fluids within a pipeline.

Description:

Available materials: Cast Iron, Ductile Iron, Alloy 20, WCB, WC6, WCC, LCB, LCC , SS304, SS316, CF8, CF8M

Sizes: ½” to 12”

Class: 150 to 600

Nominal Pressure: PN10 to PN100

Operation: Hand wheel, Pneumatic, Electric

Ends: Flanged, Threaded

Visit us: https://valvesonly.com/product-category/diaphragm-valve/

1 note

·

View note

Text

The Top Valve Fittings Manufacturers,Supplier & Exporter in USA - Mcneil Instruments

Mcneil Instruments stands as the leading valve fittings manufacturer, supplier, and exporter in the USA, specialising in a wide array of valve fittings. With a focus on quality and precision, we offer tube fittings, needle valves, ball valves, check valves, and more, ensuring adherence to industry standards. Valves play a critical role in fluid and gas pipe networks, regulating flow effectively. As top industrial valve manufacturers, we provide the best instrumentation valves to meet diverse industry needs. Manifold valve, needle valve, ball valve, check valve, globe instrumentation valve, gate instrumentation valve, huge cock valve, and block bleed valve, our products are engineered to deliver optimal performance and reliability, making us the preferred choice among valve suppliers in the USA.

#valve fittings#manufacturer#USA#Manifold valve#needle valve#ball valve#check valve#globe instrumentation valve#gate instrumentation valve#Gauge cock valve#block bleed valve

0 notes

Text

Glass Valves | Goel Scientific | Canada

We Manufacturer Best Variety of Glass valve Borosilicate Glass bodies & PTEF plug-in QVF & SCHOTT & Supply in Bulk to OEMs in Canada, USA, BC, Ontario, Alberta Quebec

#Top#Manufacturer Best Variety of Glass valve Borosilicate Glass bodies & PTEF plug-in QVF & SCHOTT & Supply in Bulk to OEMs in Canada#USA#BC

0 notes

Text

Plug Valve Manufacturer in USA

Valvesonly is a leading Plug Valve Manufacturer in USA. A plug valve is a type of industrial valve designed for controlling the flow of fluids in a pipeline. It is characterized by a cylindrical or tapered plug with a through-hole, known as the port that can be rotated within the valve body to either allow or block the flow of the fluid. Plug valves are commonly used in various industries such as oil and gas, petrochemical, water treatment, and power generation due to their simple design and reliable performance.

In the open position, the plug aligns with the ports in the valve body, allowing the fluid to flow through the valve with minimal obstruction. The rotation of the plug is controlled by the stem, which is manipulated by the actuator. To stop the flow, the plug is rotated to a position where it blocks the ports completely, preventing the passage of fluid. This is achieved by turning the stem, which is connected to the plug. Plug valves can also be positioned partially open or closed to regulate the flow of fluid. The degree of opening or closing is controlled by adjusting the rotation of the plug using the actuator.

The appearance of a plug valve can vary based on its size, design, and the materials used in its construction. However, some common features include a cylindrical or tapered body with inlet and outlet ports, a stem extending from the top, and an actuator (manual lever, gear, or motor) attached to the stem. The material of construction depends on the type of fluid and the environmental conditions in which the valve will operate, with options ranging from carbon steel to stainless steel and other alloys. The size of plug valves can range from small sizes suitable for residential applications to large industrial valves used in heavy-duty processes.

Parts:

Body

Plug

Ports

Stem

Actuator

Bonnet

Packing

Gland

Backseat

Body Bolts and Nuts

What are the advantages of a plug valve?

Plug valves have a relatively simple design, consisting of few components, which makes them easy to manufacture, install, and maintain. Their simplicity contributes to their reliability and longevity.

They can be opened or closed rapidly, making them suitable for applications where swift isolation or regulation of fluid flow is required. This quick operation can be crucial in emergency shutdown situations.

Due to their uncomplicated design and fewer moving parts, plug valves generally require less maintenance compared to more complex valve types. This results in lower maintenance costs and reduced downtime for industrial processes.

These valves are often designed to allow flow in either direction, offering flexibility in installation and operation. This characteristic is advantageous in applications where the direction of fluid flow may change.

They can handle a wide range of fluids, including corrosive and abrasive materials. The choice of materials for the plug and valve body allows customization to suit specific applications, making them versatile in various industries.

These valves provide excellent sealing capabilities, ensuring a tight shut-off when in the closed position. This feature is particularly valuable in applications where leakage prevention is critical, such as in chemical processing or hazardous fluid handling.

They are often more compact than other valve types with similar flow control capabilities. This makes them suitable for applications with limited space or where a more streamlined piping system is desirable.

The simplicity of the design, ease of manufacturing, and low maintenance requirements contribute to the cost-effectiveness of plug valves. They are often a more economical choice for certain applications compared to more complex valve types.

Plug valves are capable of handling high-pressure and high-temperature applications, making them suitable for use in challenging industrial environments such as oil and gas processing.

Types of plug valve:

Lubricated Plug Valve

Non-lubricated Plug Valve

Jacketed Plug Valve

Twin Seal Plug valve

Lift Plug valve

Orbit Plug valve

Eccentric Plug valve

Expanding Plug Valve

Industries:

Oil and Gas

Petrochemical

Chemical

Water Treatment

Power Generation

Pulp and Paper

Mining

Marine

Aerospace

Textile

Municipal Water and Wastewater

Construction

Automotive

Environmental Engineering

Fire Protection Systems

Description:

Body material: Cast Carbon steel (WCC, WCB, WC6), Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F31L, F91], Duplex Steel and Super duplex Steel (F51, F53, F55), Cast iron, Ductile Iron.

Class: 150-2500; PN 10 – PN 450

Size: 1/2”- 48”.

Operations: Lever, electric actuated, pneumatic actuated, gear

Ends: Flanged, butt weld, socket weld, threaded

Our Website: https://valvesonly.com/product-category/plug-valve/

0 notes

Text

Top Quality Valve Manufacturers in USA - Pipingprojects.us

Piping Projects is one of the leading Valve Manufacturers in USA. We manufacture our Valves using top-quality raw materials. We supply variety of Valves such as 3 way ball valve, 2-way ball valve, Needle Valve, Nimonic Valves, etc. Valves may be defined as mechanical apparatuses that facilitate the regulation of flow and pressure within a designated system. Pipingprojects.us is a top Valve Supplier in USA. Various types of valves are obtainable, each possessing different attributes and capabilities.

Valves are mechanical appliances specifically engineered to regulate the flow and pressure of fluids within a system. We are a top-notch Valve Manufacturers USA. Their importance stems from their capacity to efficiently control the flow of gases or liquids through pipes and other related applications. Valves are typically constructed from materials such as Stainless Steel, which provides them with durability to corrosion. These Valve Supplier are considered indispensable components, facilitating efficient and secure fluid flow management. They are available in various types and grades, each designed to serve specific purposes and offering unique features to cater to diverse applications as per requirements. We are also a leading Steel Pipe Manufacturers in USA.

Product: Valve Manufacturers

Website: pipingprojects.us

0 notes

Text

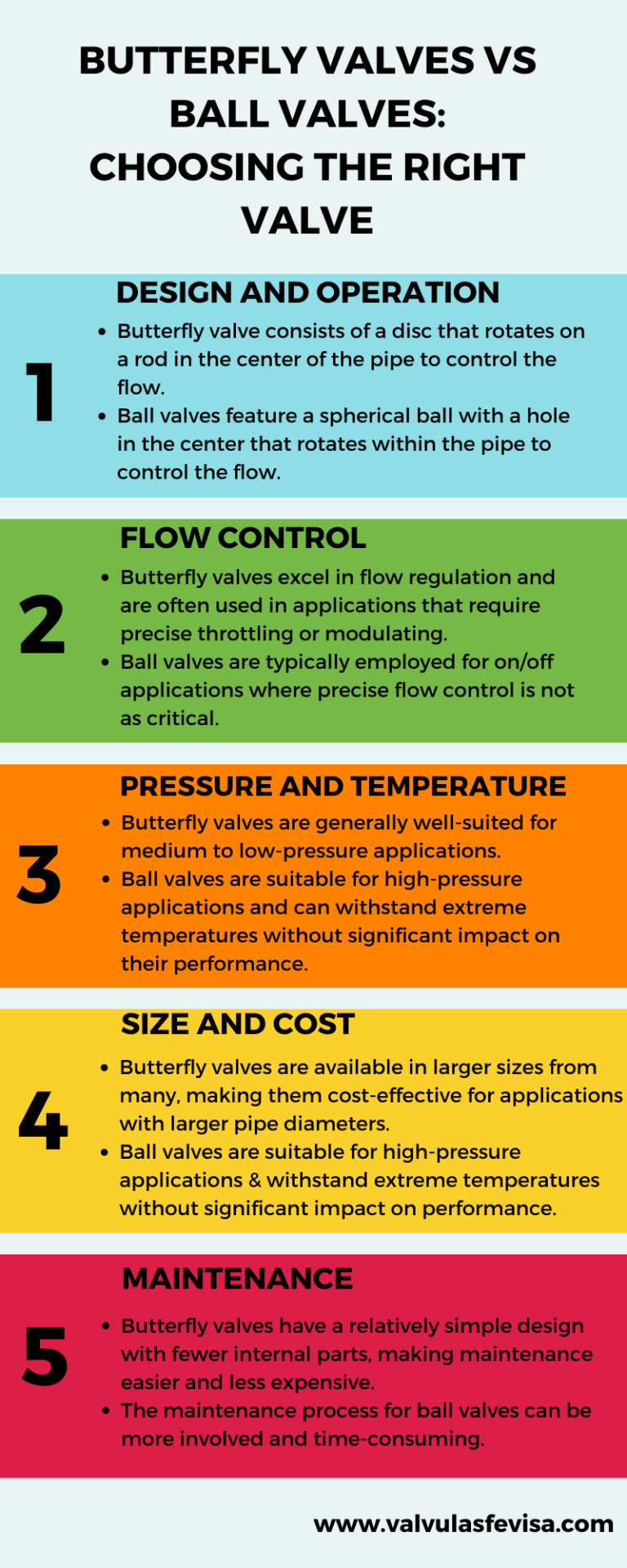

Both butterfly valves and ball valves are commonly considered. Each type has its own advantages and considerations, it is important to know several factors to determine the most suitable option for your specific needs. Consulting with valve specialists or an experienced Valve Stockist can provide valuable insights and guidance in choosing the most suitable valve for your application. We fevisa is the leading Valve Manufacturers and Valve Stockist in USA, you can contact us anytime we are always available to provide assistance.

#valve suppliers#valve manufacturers#butterflyvalves vs ballvalves#valve stockist in USA#Ball valves supplier#Butterfly valve supplier

0 notes

Text

Dual Plate Check Valve Manufacturer in USA

SVR Global is the most reputed and leading dual plate check valve manufacturer in USA. A dual plate check valve is a type of check valve that consists of two plates or discs that are hinged together in the center. The plates are designed to open in response to fluid flow, allowing fluid to pass through the valve, and then close to prevent backflow. This design allows for a more compact valve than traditional swing check valves and provides for a faster response to changes in fluid flow.

The dual plate check valve operates by utilizing the kinetic energy of the fluid to push the plates open against the force of gravity and any springs or weights that may be used to assist in closure. When the fluid flow stops or reverses direction, the plates close under the influence of gravity and any spring or weight.

Dual plate check valves are commonly used in a variety of industries including water treatment, oil and gas, chemical, and petrochemical. They are typically used in applications where a reliable and fast-acting valve is required to prevent backflow or protect pumps and other equipment from damage.

Parts of a Dual Plate Check Valve:

Body: The main body of the valve, which contains the two plates and the hinge mechanism.

Plates: Two plates or discs that are hinged together in the center.

Hinge: A mechanism that connects the two plates and allows them to pivot.

Spring: A spring mechanism that helps to close the plates and maintain a seal.

Seals: A set of sealing elements that prevent leakage when the plates are closed.

Types of Dual Plate Check Valves:

Wafer Type: Wafer type dual plate check valves are designed to be installed between flanges and are held in place by bolts or other fasteners. They are generally less expensive and more compact than other types of check valves.

Lug Type: Lug type dual plate check valves are similar to wafer type valves, but they have threaded inserts or lugs that allow them to be bolted directly to a pipeline without the need for separate flanges.

Flanged Type: Flanged type dual plate check valves are designed to be installed between flanges and have a raised face to provide a seal against the flange faces. They are generally more expensive and larger in size than wafer or lug type valves.

INDUSTRIES

Chemical Industry

Pulp and paper Industry

Marine Industry

Mining Industry

Power Generation Industry

Oil and Gas Industry

Nuclear Industry

Petrochemical Industry

APPLICATIONS

Pump protection in water treatment plants and pumping stations.

Preventing backflow in oil and gas pipelines and refineries.

Protection of compressors and turbines in chemical and petrochemical plants.

Protection of fire protection systems and sprinklers.

Protection of industrial boilers and heat exchangers.

In marine applications such as ballast water systems and cooling water systems.

ADVANTAGES

Pump protection in water treatment plants and pumping stations.

Preventing backflow in oil and gas pipelines and refineries.

Protection of compressors and turbines in chemical and petrochemical plants.

Protection of fire protection systems and sprinklers.

Protection of industrial boilers and heat exchangers.

In marine applications such as ballast water systems and cooling water systems.

SVR Global is the Dual plate check valve manufacturer in USA has the following body material, size, class, ends-

Body Material: cast iron check valve, cast steel check valve (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), ductile iron check valve, stainless steel check valve [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), duplex and super duplex STEEL [ F51, F53,F55 ] forged steel A105, A105N, F11, F22, F304, F316, F91] , alloy20, Hastelloy ALBR.

Size: ½” – 80”

Class:150 – 2500; PN10 – PN-450

Ends: wafer, lug, flanged

Visit our site for more information

0 notes

Text

Transport Airbags Dunnage Bags - PLASTIX USA

used to secure cargo while it is being transported, whether by truck, rail, container, or sea. After being installed between the shipment, the flat dunnage bag is filled with compressed air. prevents handling and movement connected to many types of intermodal transportation.

#Transport Airbags Dunnage Bags#Dunnage Bag Valve#Dunnage Bags Manufacturer#Dunnage Air Bags Manufacturer#Dunnage Bags Usa

0 notes

Text

Choosing the Right Control Valve Gearbox

Choosing the correct control valve gearbox is critical for many industrial applications. It guarantees that operations are efficient, consistent, and safe. The gearbox is important for maintaining the valve position according to requirements. Here in this blog, we have mentioned some top reasons to choose the right control valve gearbox.

0 notes

Text

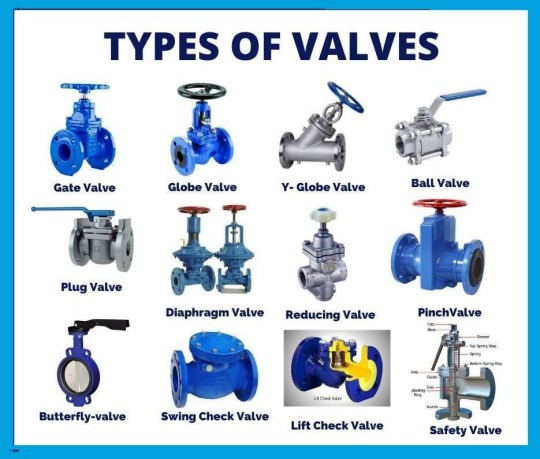

Different Types Of Valves

What are Valves?

Valves made from this metal have exceptionally high oxidation and corrosion resistance and extreme durability, making a product that lasts a long time. Stainless steel valves do not rust, even if placed in areas of high moisture or directly in water.

Dalmine Flanges is a well-known Gate Valves Manufacturer, Forged Steel Valves Manufacturer in India, Globe Valves Manufacturer and Ball Valves Manufacturer.

Types Of Valves:

Globe Valves

Globe Valves is a type of valve used for regulating flow in a pipeline, consisting of a movable plug or disc element and a stationary ring seat in a generally spherical body.Globe valves are named for their spherical body shape with the two halves of the body being separated by an internal baffle. Dalmine Flanges is a prominent Globe Valves Manufacturer.

Gate Valves

A gate valve is generally used to completely shut off fluid flow or, in the fully open position, provide full flow in a pipeline. Thus it is used either in the fully closed or fully open positions. A gate valve consists of a valve body, seat and disc, a spindle, gland, and a wheel for operating the valve. Dalmine Flanges is one of the biggest Gate Valves Manufacturer.

Forged Steel Valves

Forged Steel Valves are used for Starting or stopping flow based on the valve state. Regulating flow and pressure within a piping system. Controlling the direction of flow within a piping system. Throttling flow rates within a piping system. Dalmine Flanges is a leading Forged Steel Valves Manufacturer, using high precision using top quality material.

Ball Valves

Ball valves are used to control the flow and pressure of corrosive fluids, slurries, normal liquids, and gases, as well as to shut them off. They're used in the oil and gas industry, but they're also used in a variety of other industries, including manufacturing, chemical storage, and even residential applications. Which regulates the low flow rate. A major Ball Valves Manufacturer producing the finest products is Dalmine Flanges.

Gate Valves Manufacturer in Other Country

Dalmine Flanges is also a famous Gate Valve Manufacturer in USA, and is a prominent Gate Valve Manufacturer in Dubai, Gate Valve Manufacturer in Saudi Arabia and a well known Gate Valve Manufacturer in Europe, whose clients include those in construction, power industries, agriculture industries and many more.

The Leaders in Manufacturing High Quality Valves in India.

Dalmine Flanges is a well-known Gate Valves Manufacturer. One of our most popular items is Gate Valves. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide. We are one of the largest Forged Steel Valves Manufacturer in India.

Dalmine Flanges manufactures all products following international standards. We are also known as one of the finest Globe Valves Manufacturer and Ball Valves Manufacturer .

We are also top class Slip On Flanges Manufacturer in India, Blind Flanges Manufacturer in India.

#Gate Valves Manufacturer#gate valves manufacturer in india#Forged Steel Valves Manufacturer in India#Globe Valves Manufacturer#Ball Valves Manufacturer#Forged Steel Valves Manufacturer#Gate Valve Manufacturer in USA#Gate Valve Manufacturer in Dubai#Gate Valve Manufacturer in Saudi Arabia#Gate Valve Manufacturer in Europe

0 notes

Text

Non Rising Stem Gate Valve Manufacturer in USA

1 note

·

View note

Text

Glass Valves | Goel Scientific | Canada

We Manufacturer Best Variety of Glass valve Borosilicate Glass bodies & PTEF plug-in QVF & SCHOTT & Supply in Bulk to OEMs in Canada, USA, BC, Ontario, Alberta Quebec

#Top#Manufacturer Best Variety of Glass valve Borosilicate Glass bodies & PTEF plug-in QVF & SCHOTT & Supply in Bulk to OEMs in Canada#USA#BC#Ontario#Alberta Quebec

0 notes

Text

Globe Valve Manufacturer in USA

SVR Global is a trust-worthy Globe Valve Manufacturer in USA that provides a vast selection of globe valves that are specifically built to meet industrial standards. Our designs are specifically made to provide the highest standards in the entire production process, a high degree of dependability, sustainability and durability.

Definition of a Globe Valve:

A globe valve gets its name from the shape of its body. An internal baffle divides the body of a globe valve's two parts. It consists of a stem that swings up and down to control fluid flow and a disc (ball or composition or plug) attached to it. The flow line is either parallel to or inclined in the direction of the seats. By sliding the disc against the flow stream, it ceases the flow of fluid.

Since a globe valve is bi-directional, fluid can flow through it in either direction. It can be utilized automatically or manually.

The most frequent application of a globe valve is to open, close, or throttle flow in systems.

Applications of a Globe Valve:

SVR Global is a trust-worthy Globe Valve Manufacturer in USA that has applications such as-

Applications for steam.

Extraction drains and condensing air extraction systems.

Feedwater, condenser air, chemical feed.

Fuel oil system.

Piping in small sizes.

Plumbing sector.

Provide flow control.

Provide leak tightness.

Pumps and compressors.

Used as an emergency shutdown valve.

Used in low-point drains and high-point vents.

Used in systems that require frequent stroking, vacuum or a wide variety of temperature extremes.

Used in systems where pressure drop is not an issue.

Water-cooling systems.

Advantages of a Globe Valve:

Bubble tight shut-off.

Can be utilized as a stop-check valve by altering the design.

Controlled precision.

Easy to maintain.

Excellent sealing ability.

Fast-acting.

Fast operation due to shorter stroke length.

No fear of wear of seat and disc; hence good for frequent operation.

Great and precise throttling ability.

Has excellent closure ability.

Repair work is easy to repair as the seat and disc can be accessed from the valve top.

Seats are easy to machine and resurface

Suitable for high-pressure systems.

Used for corrosive or highly viscous fluids.

Disadvantages of a Globe Valve:

Can be installed only in one direction.

Complex design.

Create noise during operation.

Expensive.

Heavier.

High head loss from two or more right-angle turns of flowing fluid. through the valve body.

High pressure drops due to numerous directional shifts.

High torque.

Huge power is required to open.

Internal trim parts can be damaged by pulsations and shocks.

Large disc assembly opening.

Longer operating time.

Low-flow coefficients.

Not recommended to use in pipes with big diameter.

Not suitable for sterile or clean applications.

Susceptible to Cavitation and flow-induced vibrations.

The disc is mounted on the stem in a cantilevered position.

More power is required to seat the valve.

Throttling flow under the seat and shutoff flow over the seat.

Industries where Globe Valves are operated:

Marine

Oil and Gas

Power generation

Pulp and Paper

Refinery

Types of a Globe Valve:

API Globe Valve

The two sides of a globe valve are unscrewed to open and close the valve. It is most commonly used in systems to open, close, or throttle flow. A globe valve has a stem that swings up and down to control flow, as well as a disc (ball, composition, or plug) and a seat that are both linked to the valve body. The flow line is either parallel to or inclined towards the seats. A globe valve is bi-directional, meaning the fluid can flow in either direction within the valve. It allows you to control the flow and pressure as well as full cut off the flow. It can be used both manually as well as automatically.

Bellow Seal Globe Valve

A Bellow Seal Globe Valve is a control valve with a compact structure that uses bellow to seal the valve stem components. The bellow valve has a bellow within, and the stainless-steel bellows' lower end is welded to the stem to keep the system fluid from eroding it. To produce a permanent seal, the other end is positioned between the body of the valve and the cover of the valve. This double seal construction prevents leakage, as the stem packaging will prevent additional leakage even if the bellows collapse. The bellows are welded to the valve stem to guarantee consistent working efficiency and to avoid valve stem vibration caused by valve insert movement.

Forged Steel Globe Valve

Forged steel is a material created by fusing iron and carbon under extreme pressure. Forged steel has lower surface porosity, a finer grain structure, stronger tensile and fatigue strength, and more ductility than other treated steels. Steel becomes ductile and malleable when heated to forging temperature, allowing it to be shaped into the required shape with force and pressure.

Forged valves are created using a process known as forging, which involves shaping metals & alloys while they are still solid. Forged valves are known for their strength, making them excellent for high-pressure and high-temperature applications.

According to body type-

Angle type

Y type or Wye Type

Z type or Tee Type

According to body bonnet type-

Bolted Bonnet

Pressure Sealed Bonnet

Screwed Bonnet

Welded Bonnet

Description of a Globe Valve:

SVR Global is a trust-worthy Globe Valve Manufacturer in USA providing an extensive range of valves, in numerous sizes, styles and designs.

Body Material: Cast Iron, Cast steel [LCB, LCC, WCB, WCC, WC6, WC9], Ductile Iron, Stainless Steel [CF8, CF8M, F3, F304, F316, F31L, F51, F55, F91, SS304, SS316, SS316L, SS904L]

Class: 150 to 2500; PN 10 to PN 450

Ends: Buttweld, Flanged, Socketweld, Threaded

Operations: Gear-operated globe valve, Hand-wheel operated globe valve, Pneumatic actuated globe valve, Electric actuated globe valve

Size: DN 10 to DN 1200

Know more about various globe valves provided by SVR Global - https://svrglobal.net/products/globe-valve/

0 notes