#block bleed valve

Text

The Top Valve Fittings Manufacturers,Supplier & Exporter in USA - Mcneil Instruments

Mcneil Instruments stands as the leading valve fittings manufacturer, supplier, and exporter in the USA, specialising in a wide array of valve fittings. With a focus on quality and precision, we offer tube fittings, needle valves, ball valves, check valves, and more, ensuring adherence to industry standards. Valves play a critical role in fluid and gas pipe networks, regulating flow effectively. As top industrial valve manufacturers, we provide the best instrumentation valves to meet diverse industry needs. Manifold valve, needle valve, ball valve, check valve, globe instrumentation valve, gate instrumentation valve, huge cock valve, and block bleed valve, our products are engineered to deliver optimal performance and reliability, making us the preferred choice among valve suppliers in the USA.

#valve fittings#manufacturer#USA#Manifold valve#needle valve#ball valve#check valve#globe instrumentation valve#gate instrumentation valve#Gauge cock valve#block bleed valve

0 notes

Text

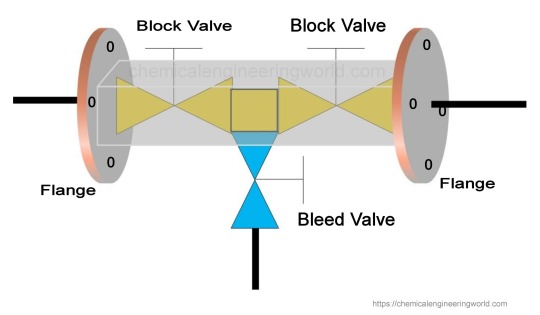

Double Block and Bleed Valve Supplier in Egypt

African Valve is the leading Double Block and Bleed Valve Supplier in Egypt. It is a type of valve that combines the function of two block valves and a bleed valve into a single unit. It is primarily used where safety and isolation of fluid flow are critical. These valves have two separate seating surfaces or sealing mechanisms that provide double isolation against the flow of fluid in the pipeline. By providing double isolation, valves helps in reduce the number of potential leak paths in a system, improving safety and reducing the risk of fluid loss or contamination.

Explore top-quality Double Block and Bleed Valve solutions in Egypt with our trusted and reliable supplier.

● Improved Safety: By providing two separate isolation points and a means for verifying the integrity of the seals, these valves help enhance safety by reducing the risk of fluid leakage or contamination during maintenance or shutdown process.

● Space and Cost Savings: They can replace multiple valves and fittings with a single assembly, reducing the overall footprint and potentially lowering installation and maintenance costs.

● Easy Maintenance: These valves simplify maintenance procedures. When the valve is closed, the bleed valve allows for the release of any trapped pressure between the seating surfaces, facilitating safe maintenance activities. This eliminates the need for separate venting valves or additional bleed connections, streamlining maintenance processes and reducing downtime.

Industries:

● Water Supply Systems

● Irrigation Systems

● Oil and Gas Industry

● LNG and Gas Processing

● Water and Wastewater Treatment

● Mining and Minerals Processing

● Power Generation

● Industrial Pumping Systems

● Chemical Processing

● Power Generation

Description:

● Available materials: F51, ASTM A105, WC6, CF8, CF8M, SS304, SS316, WCB, WCC, LCB, LCC, WC6

● Size: 3” to 24”

● Class: 150 to 2500

● Nominal Pressure: PN25 to PN450

Visit us today:

0 notes

Text

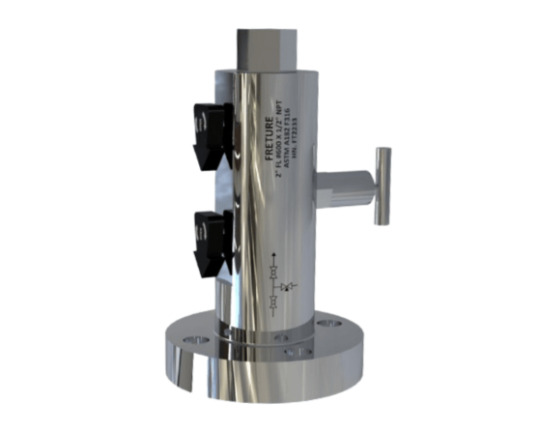

Double Block & Bleed Valves serve multifaceted roles, offering versatility across diverse applications. Whether for general utility or as a pivotal component in fuel service systems, these valves provide paramount control over fluid flow. With their unique design featuring dual isolation and bleed capabilities, they ensure heightened safety and efficiency, surpassing standard instrumentation ball valves. From regulating flow in industrial processes to safeguarding critical systems, Double Block & Bleed Valves from Feature Techno stand as the superior choice, empowering seamless operations and peace of mind.

0 notes

Text

EWOM is a Chinese Top Valves manufacturer in 2009, exported to 84 countries worldwide They are committed to providing high-quality products Best Stainless Steel ,Metal Seated Ball Valve or Api 600 Gate Valve provider technical support and deliver the best results for our clients through our Quality remarkable valve is designed to provide optimal performance and efficiency for a wide range of Management System.

#gate valve manufacturers china#wafer check valve#cast steel gate valve#check valve china#swing check valve china#gate valve china#api 600 gate valve#forged steel gate valve#cast steel globe valve#forged steel globe valve#piston check valve#Double block and bleed valve#ball valve china#floating ball valve#fully welded ball valve#stainless steel ball valve#metal seated ball valve#flanged ball valve#top entry ball valve#trunnion mounted ball valve

0 notes

Text

Double Block And Bleed Valves Market (2022to 2027) - by Product Type, Sensor Type, End-user, and Region

Double Block And Bleed Valves Market research report covers inclusive data on prevalent trends, drivers, growth opportunities, and restraints that can variation the market changing aspects of the global industry. This report provides an in-depth analysis of the market segmentation that contains products, applications, and geographical analysis. Global Double Block And Bleed Valves market report delivers a close watch on leading participants with strategic analysis, micro and macro market trend and scenarios, pricing analysis, and a complete overview of the industry conditions during the forecast period.

Report Coverage:

The research report of the defending coatings industry offers a inclusive analysis of existing companies that can affect the market outlook throughout the forthcoming years. In addition to that, it affords an accurate assessment by highlighting data on multiple aspects that may contain growth drivers, opportunities, trends, and hindrances. It also represents the overall: Double Block And Bleed Valves market size from a global perception by analysing historical data and qualitative insights.

For More Information or Query or Customization Before Buying, Visit @

Double Block And Bleed Valves Market is envisaged to record an expansion at the CAGR of 3.3% over the forecast period, 2022 – 2027.

Contact Us:

Head of Sales: Mr. Hon Irfan Tamboli

+1 (704) 266-3234 | [email protected]

#Double Block And Bleed Valves market research#Double Block And Bleed Valves market analysis#Double Block And Bleed Valves Market Trends#Double Block And Bleed Valves Market Size

0 notes

Text

Double Block and Bleed Valves Market 2022 Overview by Industry Size, Top Trends, Drivers, Growth and Forecast to 2027

The new record on the global Double Block and Bleed Valves Market is centered on offering a benefit to the business major parts in the serious grounds over the business space by giving bits of knowledge about the angles that assume a significant part in the business development and assists them with taking clear choices about their methodologies in the business space. The data is accumulated from a couple of sources and the models are apparent from the bona fide data and the current business floats that are happening in this market space. It joins granular experiences concerning the huge market drivers, advancement openings, pay possibilities and huge challenges and threats that imperatively influence the augmentation of the business space.

To Browse Full Report:

The Global Double Block and Bleed Valves Market Size is Projected to Reach a CAGR of 3.1% during 2022-2027.

#Double Block and Bleed Valves Market Analysis#Double Block and Bleed Valves Market Top Companies#Double Block and Bleed Valves Market Research#Double Block and Bleed Valves Market Trends

0 notes

Text

Do you guys still love me even though i keep reblogging oc prompts with tags about my ocs in the middle of the night because it's the only thing bleeding the pressure valve of a huge creative block

3 notes

·

View notes

Text

Added a Bleed Valve into the airline so I can adjust the level of bubbles from the air pump without creating back pressure on the pump itself.

Back pressure on the pump occurs when something is preventing it from easily pushing out the air and this can shorten the lifespan of the pump.

Using a bleed valve gives you control over the airflow while avoiding putting that back pressure in the pump by ‘bleeding’ a controlled amount of air out of the line rather than partially blocking the line itself. So it’s basically a controlled air leak.

I put this one together using an Aqua One Airline Control Kit 10414.

These kits are ~$4-5 AUD and have enough components to create 2 of these valves.

To make one you’ll need some air line, one of the T shaped pieces and one of the pieces that has the plastic screw on it.

Attach some air line to your pump and cut it to however long you want it to be before the valve then attach the other end of that piece of line to one of the ends of the T piece.

Cut a short piece of line and attach one end of that to the short part of the T piece and the other end to one side of the piece with the screw.

Now attach another part of the air line to the other end of the T piece and if you have a check valve (reccomended) cut the air line again and put the end into the end of the check valve that you can easily blow air through.

Another piece of airline and this time put that end into the OTHER end of the check valve (the end you CAN’T blow air through) and then simple attach the other end of your air line to whatever air stone or bubbler ornament you want it to go in.

Using this valve assembly you’ve just made you can adjust the bubble flow by turning the plastic screw.

Tighten the screw and you’ll get more bubbles, loosen the screw and you’ll less bubbles as it will allow the excess air to escape while still allowing enough air to get through the main line to power your air stone or bubbler ornament.

I use the valve to adjust the bubble rate as needed for the situation so I’ll turn the bubbles down a decent amount at feeding time and at night but otherwise I keep it at a moderate stream of bubbles to cater for my slower swimming fish that wouldn’t enjoy the full bubble volume. So this allows them to be comfortable but also still allows for bubbles to aerate the water and gentler bubble streams that they can play with when they want to.

1 note

·

View note

Text

Double block and bleed valve (DBB) : A Comprehensive Guides

Double block and bleed (DBB) is a critical valve arrangement in various industries where isolation of process flow is essential for safety, maintenance, and operational efficiency. This system involves two block valves and a bleed valve positioned in between, designed to achieve a high level of isolation. In many industrial settings, ensuring the safe and efficient control of fluids and gases is…

View On WordPress

0 notes

Text

Manifold Valve: Definition, Types And Advantages - SEALEXCEL

Valves are one of the most important components of fluid based industrial systems. From controlling fluid flow to regulating the pressure, these valves perform a variety of functions.

In accordance with their usage, these valves come with several different configurations. Most prominently, pneumatic check valves, high pressure needle valves, ball valves, toggle valves and purge valves are used.

In certain conditions, two or more different requirements have to be fulfilled. This necessitates use of two or more valves at a single location in the system. However, this can be inefficient since it takes double the space.

The problem was thus solved by configuring a valve manifold.

What is a valve manifold?

Manifold valve are equipment which connects two or more valves of a hydraulic system.

A variety of block/isolate valves can be combined in a single body configuration. Each of these valves has a separate opening below in order to connect a pipe. The main body or valve chamber is common to all.

These manifolds commonly include ball, bleed, needle, and vent valves. Their use results in savings in terms of space and installation costs.

Advantages of a manifold valve

Manifold valve are used in a number of different applications, ranging from mobile machineries to heavy industrial equipment.

When included in a fluid control and/or regulation system, valve manifolds have shown to improve efficiency as well as reduce energy costs. Other advantages include:

Shorter path flows which reduces pressure drop and heat fluctuations, improving overall energy efficiency of the system

Reduction in installation costs as well as fluid connections because of a simpler, more compact design

Minimum chances of oil leak due to less number of connections, further reducing the need for upkeep against fatigue, wear and lose joints

Improved layout due to less hoses and connections

Small, compact cartridge sizes which suits confined spaces

Types of manifold available at SealExcel

At SealExcel, we offer high quality manifolds that are manufactured with 316 stainless steel. These valves are available in three different configurations:

Two way manifold valves(Series- MFV2) are mainly used for general plant service, standard pressure and differential pressure instrumentation devices, pressure equalization, venting, and block and bleed applications.

Three way manifold valves(Series- MFV3) are prominently involved in pressure and differential pressure instrumentations.

Five way manifold valves(Series- MFV5) are also used for pressure and differential pressure instrumentations.

All these manifold Valve employ convenient methods of bleeding, blocking and calibrating instruments. These are factory tested and available for pipe to pipe, flange to flange, pipe to flange, remote, base and remote mounting base vent, and direct and integral mounting.

Do you require a manifold valve for your hydraulic system?

Call us right away at 0091-22-26788534 or send an email to our sales team.

1 note

·

View note

Text

Manifold Valves: The Powerhouse of Fluid Control Systems

In the complex global of fluid manage structures, manifold valves stand out as critical components that make certain precision, performance, and protection. These valves are vital to a extensive variety of packages, from commercial approaches to high-pressure hydraulic systems.

In this comprehensive manual, we will delve into the world of manifold valves, exploring their features, advantages, sorts, and the pinnacle manifold valves manufacturers inside the enterprise.

Understanding Manifold Valves

Manifold valves are a sort of multi-port valve machine designed to govern the flow of fluids or gases in diverse programs. They integrate more than one valves into a single unit, presenting streamlined manipulate and reduced leakage factors. These valves are particularly valued for their capability to control complex piping systems without difficulty, making them indispensable in industries including oil and gasoline, petrochemicals, prescribed drugs, and manufacturing.

Functions of Manifold Valves

Manifold valves perform numerous important functions in fluid manage systems:

Isolation: They can isolate a segment of the piping gadget for maintenance or protection purposes with out shutting down the complete system.

Pressure Regulation: Manifold valves assist hold and adjust strain levels within the device, making sure operational safety and performance.

Flow Control: They manage the course and price of fluid or gasoline waft, taking into account unique operational changes.

Testing and Calibration: These valves facilitate testing and calibration of instruments and system, ensuring accuracy and reliability.

Benefits of Using Manifold Valves

The use of manifold valves offers severa benefits that enhance the overall performance and reliability of fluid manage structures:

1. Compact Design

Manifold valves consolidate a couple of features right into a single unit, lowering the want for large piping and connections. This compact layout saves space and simplifies installation and maintenance.

2. Enhanced Safety

By minimizing the quantity of potential leak factors, manifold valves notably improve the safety of the system. They also permit for clean isolation of sections for renovation, reducing the chance of accidents.

3. Improved Efficiency

The streamlined layout and efficient go with the flow manipulate talents of manifold valves make contributions to typical device efficiency. They assist keep highest quality strain degrees and reduce electricity intake.

4. Cost Savings

The integration of a couple of valves into a single unit reduces cloth and exertions costs related to set up and maintenance. Additionally, the improved performance and protection of the system can lead to lengthy-time period operational cost financial savings.

Types of Manifold Valves

Manifold valves are available diverse configurations, every perfect to specific programs and operational necessities. The maximum not unusual sorts include:

1. Two-Valve Manifolds

These manifolds normally encompass a block valve and a bleed valve. They are utilized in packages wherein simple isolation and venting are required, consisting of strain gauges and transmitters.

2. Three-Valve Manifolds

Three-valve manifolds consist of two block valves and one equalizing valve. They are normally utilized in differential strain measurement applications, taking into consideration isolation, equalization, and calibration.

3. Five-Valve Manifolds

Five-valve manifolds feature block valves, equalizing valves, and one bleed valve. They are utilized in complex structures where comprehensive isolation, calibration, and venting are essential.

4. Single Block and Bleed Manifolds

These manifolds combine a single block valve and a bleed valve into one compact unit. They are used in programs requiring common isolation and venting, together with in sampling systems.

5. Double Block and Bleed Manifolds

Double block and bleed manifolds consist of block valves and a bleed valve. They offer double isolation, improving protection and reliability in critical packages which includes high-stress systems and hazardous environments.

Conclusion

Manifold valves by Instrumxx Industries are the powerhouse of fluid manage systems, imparting unprecedented control, safety, and efficiency. By integrating multiple capabilities into a unmarried unit, these valves simplify complicated piping structures and enhance common operational performance.

Understanding the diverse types of manifold valves and selecting the proper manufacturer are key to reaching premier effects in any fluid manipulate software. Whether you are in the oil and gasoline enterprise, prescribed drugs, or production, manifold valves are important additives that could extensively enhance the reliability and efficiency of your device.

0 notes

Text

Common Vaillant Boiler Problems and How Servicing Can Help Prevent Them

Vaillant boilers are mostly known for their reliability and efficiency. But a gas boiler, like any appliances, can experience problems over time. Servicing in regular intervals is essential for preventing any unforseen issues. Therefore regular servicing can keep your boiler running smoothly. In this article, we'll discuss some common problems that Vaillant boilers may encounter and how servicing can help prevent them.

Lack of Heat or Hot Water

Problem: One of the most common issues with any boiler is a lack of heat or hot water. This can be caused by a variety of factors, including a faulty thermostat, airlocks in the system, or low water pressure.

Prevention: Regular servicing can help identify and address any issues that could lead to a lack of heat or hot water. A technician can check the thermostat, bleed radiators to remove airlocks, and ensure that the water pressure is at the correct level.

Strange Noises

Problem: Unusual noises coming from your boiler, such as banging, whistling, or gurgling sounds, could indicate a problem with the system. These noises are often caused by issues like air in the system, a build-up of limescale, or a malfunctioning pump.

Prevention: During a service, a technician can identify and resolve any issues causing strange noises. They can bleed the radiators to remove air, descale the heat exchanger to prevent limescale build-up, and check the pump for any faults.

Leaks

Problem: Leaks are a common issue with boilers and can be caused by a variety of factors, including corrosion, loose connections, or a faulty pressure valve.

Prevention: Regular servicing can help prevent leaks by identifying and addressing any potential issues. A technician can check the boiler and its components for signs of corrosion, tighten any loose connections, and ensure that the pressure valve is working correctly.

Pilot Light Goes Out

Problem: If the pilot light on your boiler keeps going out, it could be due to a faulty thermocouple, a build-up of debris in the pilot light, or a draft blowing it out.

Prevention: During a service, a technician can inspect the pilot light and its components to ensure they are clean and in good working order. They can also check for any drafts that could be extinguishing the pilot light.

Boiler Keeps Turning Off

Problem: If your boiler keeps turning off by itself, it could be due to a variety of issues, such as low water pressure, a faulty thermostat, or a blocked condensate pipe.

Prevention: Regular servicing can help prevent this problem by identifying and addressing any underlying issues. A technician can check the water pressure, test the thermostat, and clear any blockages in the condensate pipe.

The Benefits of Upgrading to a New Vaillant Boiler During a Service

Increased Energy Efficiency: New Vaillant boilers are more energy-efficient, leading to lower energy bills and reduced carbon emissions.

Improved Performance: Upgrading to a new boiler can improve heating performance, providing a more consistent and comfortable temperature in your home.

Enhanced Reliability: New boilers are less likely to break down, reducing the risk of costly repairs.

Warranty Coverage: New Vaillant boilers come with warranty coverage, giving you peace of mind in case of any issues.

Modern Features: New boilers often come with modern features such as smart thermostats, allowing for greater control and convenience.

Safety: New boilers are designed with the latest safety features, ensuring the safety of you and your family.

Increased Property Value: A new boiler can increase the value of your property, making it more attractive to potential buyers.

Conclusion

Regular servicing is essential for preventing common boiler problems and ensuring that your Vaillant boiler continues to run efficiently. A qualified technician can identify and address any issues before they become major problems, saving you time, money, and inconvenience in the long run. If you haven't had your Vaillant boiler serviced recently, now is the perfect time to schedule an appointment and ensure that your boiler is in top condition for the colder months ahead.

0 notes

Text

Smart Decision of Maintaining Your Baxi Boiler and Make it Run Longer

Maintenance of your boiler is an inevitable aspect for its good health and longevity. Baxi boilers are no different. These boilers also call for regular maintenance for its efficiency and safety. Regular boiler maintenance can help you avoid boiler breakdowns and save expensive repairs. Not only this, the maintenance also helps in smooth operation of your boiler throughout the year. A homeowner should be well aware about the do’s to recognise common issues and how to avoid them.

1. Regular Inspections

Scheduling an annual inspection by a qualified engineer is the first step. They would ensure your boiler is efficient and in good working condition.

The next job is to look for leaks, if any. Also check if there are any strange noises, or unusual smells coming from your boiler.

2. Cleaning and Servicing

Clean the exterior of the boiler regularly. Removing dust and dirt is very important.

For cleaning the internal component of the boiler a professional service is wiser. Internal components include the heat exchanger and burner. Cleaning internal components is required to ensure efficient operation.

3. Bleeding Radiators

For removing trapped air, bleed your boiler radiators regularly. The trapped air can make your boiler work harder. This in continuation would charge a higher electricity bill.

4. Checking Pressure

Check the pressure gauge of your boiler at regular intervals. Top up the pressure if required. It is recommended to follow the manufacturer's instructions thoroughly.

5. Insulating Pipes

Boiler pipes can freeze in Chilled weather. To avoid this, insulating them is necessary. Frozen pipes can lead to boiler breakdowns.

Common Issues and Solutions

Low pressure: Check for any kind of leakage in the system. If required, top up the pressure.

No hot water or heating: Check the settings in the thermostat and the pilot light. If you notice the issue not resolved, contact a professional.

5 Signs Your Baxi Boiler Needs Servicing in London

Strange Noises

Unusual noises like banging, whistling, or gurgling sounds can indicate trouble. This trouble mostly arises from problems in the internal components and limescale buildup.

Leaks

Leaks indicate a number of issues like faulty pressure valves or a corroded pipe. All these issues require immediate attention and professional engineering.

Low Pressure

Low pressure in the pressure gauge signals leak in the system or the pressure relief valve has to be replaced. Low pressure affects efficiency of the boiler.

Pilot Light Issues

Changing lights of the pilot light indicates combustion issues in the boiler. It can be a result of a dirty or blocked burner.

Increased Energy Bills

An inefficient boiler will get you higher electricity bills. Regular servicing and maintenance by a professional personnel is the only way out.

Tips for Maintaining Your Baxi Boiler

Annual Servicing: Schedule an annual service with a qualified engineer to ensure your boiler is in top condition.

Regular Inspections: Keep an eye out for any signs of trouble, such as leaks or strange noises, and address them promptly.

Bleeding Radiators: Regularly bleed your radiators to remove trapped air, which can improve boiler efficiency.

Checking Pressure: Regularly check your boiler's pressure gauge and top up if necessary, following the manufacturer's instructions.

Insulating Pipes: Insulate your boiler's pipes to prevent freezing during cold weather, which can lead to breakdowns.

Conclusion

Maintaining your Baxi boiler with servicing in regular intervals is a smart and wise decision. This decision would save you money, expand the boiler life, and make sure your home stays warm and safe. By following these tips and scheduling regular servicing, you can ensure a smooth running Baxi boiler for a longer time.

0 notes

Text

Enhancing Safety and Efficiency with Instrumentation Double Block and Bleed Valves

In the complex world of industrial processes, where safety and efficiency are paramount, the role of instrumentation valves cannot be overstated. Among these, Instrumentation Double Block and Bleed (DBB) Valves stand out as crucial components for ensuring safety, reliability, and performance in critical applications.

Understanding Instrumentation Double Block and Bleed Valves

Instrumentation DBB valves are engineered to provide an additional layer of safety and efficiency in fluid control systems. As the name suggests, these valves offer two separate isolation barriers (the "double block") along with a third valve for bleeding pressure (the "bleed"), all integrated into a single compact unit.

Enhanced Safety

One of the primary advantages of DBB valves is their ability to isolate fluids in both upstream and downstream directions simultaneously. This feature is particularly valuable in industries where fluid containment is critical, such as oil and gas, chemical processing, and power generation.

By providing two independent sealing mechanisms, DBB valves minimize the risk of leakage and cross-contamination, thereby enhancing operational safety and environmental protection. In scenarios where maintenance or repair is necessary, these valves allow for isolation of equipment without shutting down the entire system, reducing downtime and improving overall productivity.

Improved Efficiency

In addition to their safety benefits, DBB valves contribute to operational efficiency by streamlining fluid control processes. With integrated bleed functionality, these valves enable efficient purging of trapped fluid or pressure between the isolation barriers, facilitating smoother operation and maintenance.

Applications

Instrumentation DBB valves find applications across a wide range of industries and processes, including:

Oil and Gas Production and Transmission

Petrochemical and Chemical Processing

Power Generation

Pharmaceutical Manufacturing

Water and Wastewater Treatment

Aerospace and Defense

Types of Instrumentation DBB Valves

There are various configurations of DBB valves to suit different application requirements:

Single Piston Design: Ideal for applications with limited space, this design features a single piston that provides both the primary and secondary isolation.

Dual Piston Design: Offering enhanced reliability, this design incorporates two separate pistons for primary and secondary isolation, providing redundancy.

Slab Gate Design: Commonly used in high-pressure applications, slab gate DBB valves utilize a gate mechanism for sealing, ensuring tight shut-off even in extreme conditions.

Conclusion

Instrumentation Double Block and Bleed Valves play a crucial role in ensuring safety, reliability, and efficiency in fluid control systems across various industries. By providing dual isolation barriers and bleed functionality in a single compact unit, these valves offer an effective solution for critical applications where fluid containment is paramount. As industries continue to prioritize safety and operational excellence, the demand for high-quality DBB valves is expected to remain strong, driving innovation and advancement in fluid control technology.

Freture Techno

#dbb valves#instrumentation valves#doubleblockandbleedvalves#freturetechno#instrumentationvalves#manufactuers#mumbai#india

0 notes

Text

Double Block and Bleed Valves Market : Evolving Technology, Trends and Industry Analysis 2031

The global "Double Block and Bleed Valves Market Market" report indicates a consistent and robust growth trend in recent times, projecting a positive trajectory expected to persist until 2031. A significant trend observed in the Double Block and Bleed Valves Market market is the rising consumer inclination towards environmentally sustainable and eco-friendly products. Furthermore, a notable advancement in this market is the increasing incorporation of technology to elevate both product quality and efficiency. Cutting-edge technologies like artificial intelligence, machine learning, and block chain are actively employed to develop innovative products that outperform traditional options in terms of effectiveness and efficiency. The Double Block and Bleed Valves Market Market Research Report for 2024 highlights emerging trends, growth opportunities, and potential scenarios envisioned up to the year 2031.

By delving into the latest trends, the report keeps businesses abreast of the dynamic market environment, helping them identify emerging opportunities and navigate potential challenges. The meticulous analysis covers various aspects, offering valuable insights into the historical performance of the market and presenting the current (CAGR) status.

Get a Sample Copy of the Report at: https://www.proficientmarketinsights.com/enquiry/request-sample-pdf/1852

Who are the biggest Double Block and Bleed Valves Market manufacturers worldwide?

CIRCOR (U.S.)

Bonney Forge (U.S.)

Cameron (U.S)

AS-Schneider (U.S.)

Oliver Valves (U.K.)

L&T Valves (India)

The Double Block and Bleed Valves Market Market is described briefly as follows:

The global Double Block and Bleed Valves Market size was USD 479.35 million in 2024 and the market is projected to touch USD 590.99 million by 2031, exhibiting a CAGR of 3.0% during the forecast period.

SWOT Analysis of Double Block and Bleed Valves Market Market:

A SWOT analysis involves evaluating the strengths, weaknesses, opportunities, and threats of a particular market or business. In the case of the keyword market, we'll be looking at the factors that can impact the industry's performance.

Pestle Analysis of Double Block and Bleed Valves Market Market:

To better comprehend the market environment, a five-force analysis is performed, which takes into account the bargaining power of the customer, the supplier, the threat of substitutes, the threat of new entrants, and the threat of competition.

Get a Sample Copy of Double Block and Bleed Valves Market Market Report

What are the Types in Double Block and Bleed Valves Market Market?

Full Bore

Reduced Bore

What are Applications in Double Block and Bleed Valves Market Market?

Oil & Gas

Chemical Industry

Power Industry

Others

Inquire or Share Your Questions If Any before the Purchasing This Report: https://www.proficientmarketinsights.com/enquiry/queries/1852

Geographical Segmentation:

Geographically, this report is segmented into several key regions, with sales, revenue, market share, and Double Block and Bleed Valves Market market growth rate in these regions, from 2017 to 2028, covering

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia, and Vietnam)

South America (Brazil etc.)

Middle East and Africa (Egypt and GCC Countries)

Some of the key questions answered in this report:

Who are the worldwide key Players of the Double Block and Bleed Valves Market Industry?

How the opposition goes in what was in store connected with Double Block and Bleed Valves Market?

Which is the most driving country in the Double Block and Bleed Valves Market industry?

What are the Double Block and Bleed Valves Market market valuable open doors and dangers looked by the manufactures in the worldwide Double Block and Bleed Valves Market Industry?

Which application/end-client or item type might look for gradual development possibilities? What is the portion of the overall industry of each kind and application?

What centered approach and imperatives are holding the Double Block and Bleed Valves Market market?

What are the various deals, promoting, and dissemination diverts in the worldwide business?

What are the key market patterns influencing the development of the Double Block and Bleed Valves Market market?

Financial effect on the Double Block and Bleed Valves Market business and improvement pattern of the Double Block and Bleed Valves Market business?

Purchase this Report (Price 2900 USD for A Single-User License) at: https://www.proficientmarketinsights.com/purchase/1852

TOC of Global Double Block and Bleed Valves Market Market Research Report 2023

1 Double Block and Bleed Valves Market Market Overview

2 Market Competition by Manufacturers

3 Double Block and Bleed Valves Market Production by Region

4 Double Block and Bleed Valves Market Consumption by Region

5 Segment by Type

6 Segment by Application

7 Key Companies Profiled

8 Industry Chain and Sales Channels Analysis

9 Double Block and Bleed Valves Market Market Dynamics

10 Research Finding and Conclusion

11 Methodology and Data Source

0 notes

Text

Double Block and Bleed Valves Market Key Vendors, Opportunities, Deep Analysis by Regional & Country Outlook

The report titled Double Block and Bleed Valves Market offers detailed insights on the Double Block and Bleed Valves industry entailing key information on its different market segments. The report gives an industry overview from around the world and covers the latest trends, market restraints, and investment opportunities, and conducts exclusive interviews of the Double Block and Bleed Valves industry leaders to contribute to the report’s findings. The report discusses the buyers’ requirements and suggests strategic actions & business changes accordingly to the market players. Moreover, the natural, internal, and external barriers to progress are given in the report. The wider business environment of the Double Block and Bleed Valves market and the industry challenges are included in the report.

Read Full Report at:

Growth prospects, leading trends, progress projections, key industries, and business innovations are the primary focus of the Double Block and Bleed Valves study. A comprehensive Double Block and Bleed Valves study is available for a number of key areas involved in the report. Furthermore, the Double Block and Bleed Valves study examines present and potential consumer positions in terms of sales based on market goods around the globe.

Key Players in the Double Block and Bleed Valves Market:

Cameron, CIRCOR, Bonney Forge, AS-Schneider, Oliver Valves, Valbart (Flowserve), L&T Valves, Parker Hannifin, Swagelok, Hy-Lok, DK-Lok, Haskel, Alco Valves (Graco), Sabre, Western Valve, PBM Valve, Control Seal, Colson

Double Block and Bleed Valves Market Types:

Full Bore

Reduced Bore

Double Block and Bleed Valves Market Applications:

Oil & Gas

Chemical Industry

Power Industry

Others

Highlights of the Report:

The report gives information on all the active tenders in the Double Block and Bleed Valves industry across the globe based on different categories. The important government notifications and change in regulations according to the latest updates is provided in the report.

The market size and forecast estimates of the Double Block and Bleed Valves market is given in the report considering the economic, financial, and general business conditions prevailing in the Double Block and Bleed Valves market from 2022 to 2027.

The report demonstrates the contribution of each segment and sector in the improvement of Double Block and Bleed Valves market share, market size, and CAGR.

Request a sample report:

Regional Double Block and Bleed Valves Market (Regional Output, Demand & Forecast by Countries):

North America (United States, Canada, Mexico)

South America (Brazil, Argentina, Ecuador, Chile)

Asia Pacific (China, Japan, India, Korea)

Europe (Germany, UK, France, Italy)

Middle East Africa (Egypt, Turkey, Saudi Arabia, Iran) And more.

Why Purchase This Market Research Report?

Critical issues and challenges the Double Block and Bleed Valves market will be facing in the forecasted years are identified in the report to help market players align their business decisions and strategies accordingly.

The report identifies key trends facing the Double Block and Bleed Valves market.

Trends responsible for global and regional economic growth of the Double Block and Bleed Valves market are highlighted in the report to help market players in a critical understanding of the future of the Double Block and Bleed Valves market.

The report conducts an assessment of the production and operational practices taking place in the marketplace.

The report presents the challenges faced by the leading geographies and nations from the pandemic and their reorientation of policies to survive the market.

The Report Attempts to Answer the Following Questions:

What will be the financial performance of North America, APAC, Europe, and Africa in the Double Block and Bleed Valves market in 2022 and beyond?

Which companies are likely to succeed in the Double Block and Bleed Valves market with the help of foreign companies, mergers and acquisitions and new product launches?

What are the strategy recommendation and business models for emerging market players?

Which are the Double Block and Bleed Valves market’s largest manufacturing firms and most competitive firms?

Thanks for showing interest in the Double Block and Bleed Valves Market research publication; you can also get individual chapter-wise sections or region / Country report versions like Germany, France, China, LATAM, GCC, North America, Europe, or Asia.

ABOUT US:

IndustryDataAnalytics is your single point market research source for all industries including pharmaceutical, chemicals and materials, energy resources, automobile, IT, technology and media, food and beverages, and consumer goods, among others.

CONTACT US:

Irfan Tamboli (Head of Sales) – Industry Data Analytics

+1 (704) 266-3234 | [email protected]

#Double Block and Bleed Valves Market#Double Block and Bleed Valves Market Analysis#Double Block and Bleed Valves Market Top Companies#Double Block and Bleed Valves Market Research

0 notes