#compression tooling

Text

What is Bulk Molding Compound Used For?

Bulk Molding Compound (BMC) is a versatile and widely used composite material in various industries. Its unique properties make it suitable for a broad range of applications, from automotive parts to electrical components. In this article, we will delve into the details of what BMC is, its properties, and its diverse applications across different sectors.

Understanding Bulk Molding Compound

Bulk Molding Compound is a type of thermosetting polymer composite material. It is composed of various ingredients, including:

Resin: Usually polyester or vinyl ester resin, which acts as the matrix binding the composite together.

Reinforcement Fibers: Typically glass fibers, which provide strength and rigidity.

Fillers: Such as calcium carbonate, to improve properties and reduce cost.

Additives: These can include pigments, catalysts, stabilizers, and release agents to enhance specific characteristics of the compound.

Key Properties of Bulk Molding Compound

Several properties make BMC an attractive material for manufacturing:

High Strength and Stiffness: The inclusion of glass fibers significantly enhances the strength and stiffness of BMC, making it suitable for structural applications.

Dimensional Stability: BMC maintains its shape and size even under varying temperatures and environmental conditions, which is critical for precision parts.

Heat Resistance: BMC can withstand high temperatures, making it ideal for applications that involve exposure to heat.

Electrical Insulation: Its excellent electrical insulating properties make BMC perfect for electrical and electronic components.

Corrosion Resistance: BMC is resistant to many chemicals and environmental factors, ensuring longevity and durability.

Ease of Molding: BMC can be easily molded into complex shapes, which is beneficial for producing intricate components.

Applications of Bulk Molding Compound

The unique properties of BMC have led to its adoption in numerous industries. Here are some notable applications:

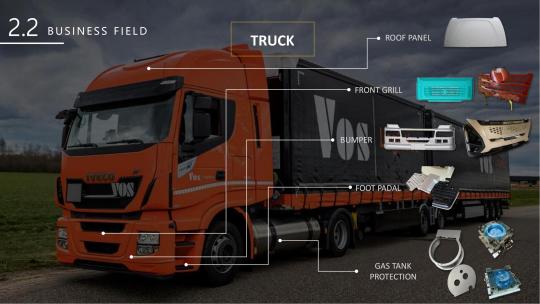

Automotive Industry

In the automotive sector, BMC is used for a variety of components due to its high strength-to-weight ratio and resistance to heat and chemicals. Common applications include:

Engine Covers: BMC is used for engine covers due to its ability to withstand high temperatures and its durability.

Headlamp Reflectors: Its excellent dimensional stability and heat resistance make BMC suitable for headlamp reflectors.

Transmission Components: BMC's mechanical strength and stability are ideal for various transmission parts.

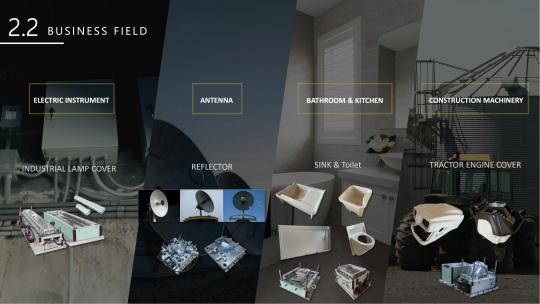

Electrical and Electronics

BMC's excellent electrical insulating properties make it a preferred material for electrical and electronic applications. Examples include:

Switchgear Components: BMC is used in the production of switchgear and other electrical insulation parts.

Connectors and Sockets: Its insulating properties ensure safety and performance in connectors and sockets.

Motor Housings: BMC provides the necessary heat resistance and dimensional stability for motor housings.

Consumer Goods

BMC is also used in the production of various consumer goods due to its aesthetic appeal and durability. Applications include:

Household Appliances: Parts for appliances like washing machines, dryers, and dishwashers often use BMC due to its resistance to heat and moisture.

Power Tools: BMC's strength and durability make it suitable for components in power tools.

Construction

In the construction industry, BMC is used for applications that require high strength and resistance to environmental factors. Examples include:

Panels and Cladding: BMC panels and cladding are used for their strength and weather resistance.

Plumbing Fixtures: Components like sinks and bathtubs benefit from BMC's durability and ease of molding.

Aerospace

The aerospace industry also benefits from BMC's properties. Its high strength-to-weight ratio and resistance to heat make it suitable for:

Interior Components: BMC is used in aircraft interiors for panels, seating components, and other structural parts.

Engine Components: Some engine parts utilize BMC for its heat resistance and stability.

Conclusion

Bulk Molding Compound is a highly versatile material that has found applications across various industries due to its excellent mechanical properties, dimensional stability, heat resistance, and electrical insulation capabilities. From automotive parts to electrical components, consumer goods, and aerospace applications, BMC continues to play a crucial role in modern manufacturing. Its ability to be easily molded into complex shapes further enhances its appeal, making it an indispensable material in today's industrial landscape.

0 notes

Text

talkin bout friends and pals

#ive been having fun with animation but GOD it takes forever#at least in aseprite. which is my animation tool of choice#also the compression on this gif is kinda shitty and i hate it but whatevs#hilda's art landfill#madotsuki#yume nikki#poniko#the batter off#zacharie off#off game#space funeral#phillip space funeral#leg horse space funeral#leg horse#rpg maker#animation#lots of tags im sorry

388 notes

·

View notes

Text

Swen Vincke from the BG3 dev team did an interview with Dropped Frames on Twitch and here are some of the things he mentioned:

The game will be released 10 am pacific but it is subject to change

He doesn’t know if pre-load is a thing, but it seems like a no

He also mentions that because of the compression, having EA installed will not save you from having to download part of the full game as only a few bytes are the same. (Therefore it’s probably best to do a clean install of the game at release)

No rolling for stats due to production reasons

They’re working on Linux support

There will be modding support after release but not right away

Swen recommends playing as a custom Tav for your first playthrough rather than playing as one of the Origins (including the Dark Urge)

The team is working on optimising the game for steam deck

more info on this reddit post

#baldur's gate#bg3#.thoughts#he also said something about the compression that i don't remember#but it seems like it might make it more difficult for the mod tool devs to update their tools for full release which rip

101 notes

·

View notes

Text

drew my fursona as some fangamer shirts i got recently :)

timelapse under the read-more!

#fursona#furry#furry art#anthro#sfw furry#original#transparent#timelapse#oc: fursona#ALRIGHT this is actually the first of my recent batch of drawings#ft. my discovery of the shapes tool and mesh transformations fhjgfj#the timelapse is a lil compressed bcus i forgot to crop the fucking. 2kx2k canvas so i had to zoom it in in post fhgjf#anyway yayayay i love my new shirts <3#there is so much swag in my closet by now ill b unstoppable

177 notes

·

View notes

Text

"Dean has no time for fruitless quests to find God. He's got people to protect" | 1.03 "Dead In The Water

Quote is tags from @ilarual ♥️

#i couldn't think of what to caption this one then thought of those tags! hope it's okay :O#i know this part has been giffed a million times#but I wanted to try another bash scripted set#and this interaction fascinates me.#The way Sam has zero plan zero leads and he just wants Dean to fix it. But Dean already got their first two leads in 1.01 and 1.02!#1.03#the one who cares#good gifs with free tools challenge#second set with pure ffmpeg#had to compress these a good bit#but I think they still turned out nice!#deans moral compass#sams moral compass#projecting displaced aggression and scapegoating in spn#youre such a control freak

90 notes

·

View notes

Text

i got new bandages 💜 theyre actual compression bandages for sports injuries but they fix my hands so awesomely

#text#my mom wa spushing for compression gloves but as much as theyd be nice my pain often goes from my wrist up to my elbow#so. not long enough#And with these i can decide how compressed i need to be super easily!!!#Yayyyy pain management tools 💜

2 notes

·

View notes

Text

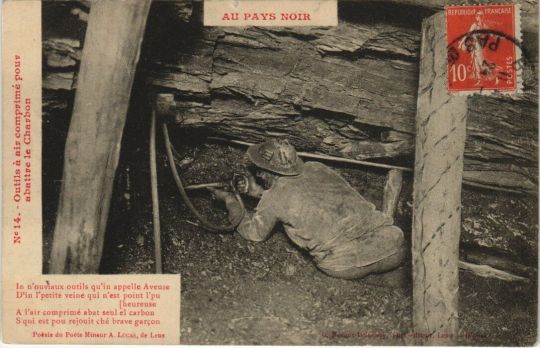

Compressed air tools in coal mining, French Hainaut region of northern France

French vintage postcard, mailed in 1911

#vintage#photography#compressed#postkarte#french#carte postale#mining#air#postal#region#briefkaart#tools#france#postcard#old#photo#coal#ansichtskarte#sepia#1911#postkaart#ephemera#mailed#tarjeta#hainaut#northern#historic

7 notes

·

View notes

Text

im doing so many studies rn, im gonna level up so hard with my art (<- said through gritted teeth and a forced grin)

#skull and hand and general body anatomy proportions so far#I feel my brain expanding (/silly)#I've just noticed i keep drawing ppl way too compressed/condensed so all the limbs end up too short sjdjdkl#so I have to go back to basics to figure out where I've gone wrong#and the skull studies are bc i cannot for the life of me figure out how to place the nose and mouth and chin lately#i seem to end up with too low of noses and mouths and not enough chin djdksl and its esp noticeable on side profiles#and the hand studies... well. we all know how hands are tools of the devil and therefore cannot be drawn easily SBSBDHDHJSL#GRRRR IM GONNA GET THIS ALL FIGURED OUT THOUGH IM MAKING GOOD PROGRESS#I'm working on body proportions rn dhdksl giving me a lot of trouble though bc ppl are not all built the same#dandy.cmd

5 notes

·

View notes

Text

Advancements in Tablet Compression Tooling: Revolutionizing Pharmaceutical Manufacturing

In the realm of pharmaceutical manufacturing, precision and efficiency are paramount. Among the many tools instrumental in this process, tablet compression tooling stands out as a linchpin in ensuring the production of high-quality tablets. Recent advancements in this field have not only enhanced the quality and consistency of tablet production but have also streamlined manufacturing processes, significantly impacting the pharmaceutical industry. Let's delve into the latest innovations and their implications.

The Evolution of Tablet Compression Tooling:

Traditionally, tablet compression tooling consisted of sets of dies and punches designed to compress powders into tablets of specific shapes and sizes. While this method proved effective, it was limited in terms of flexibility, precision, and speed. However, recent technological advancements have led to the development of sophisticated tablet compression tooling systems that offer unparalleled control and efficiency.

Key Technological Advancements:

Advanced Materials: Modern tablet compression tooling utilizes high-quality materials such as hardened tool steel or carbide, ensuring durability and resistance to wear and corrosion. These materials are essential for maintaining the integrity of the tablet's shape and surface finish over prolonged use.

Precision Engineering: Cutting-edge manufacturing techniques, including computer numerical control (CNC) machining and laser technology, enable the creation of intricate tooling designs with micron-level precision. This precision is crucial for producing tablets with uniform weight, thickness, and hardness, meeting stringent regulatory requirements.

Innovative Coatings: Specialized coatings, such as diamond-like carbon (DLC) and ceramic, are applied to tablet compression tooling surfaces to minimize friction, prevent sticking, and prolong tool life. These coatings not only enhance tablet quality but also reduce maintenance downtime and costs.

Automation and Robotics: Integration of automation and robotics into tablet compression systems has revolutionized manufacturing processes, allowing for continuous operation, real-time monitoring, and adaptive adjustments. Automated tool inspection and cleaning further ensure product consistency and compliance with quality standards.

Data Analytics and Connectivity: Incorporation of sensors and data analytics software enables comprehensive monitoring of tablet compression parameters, including compression force, ejection force, and tablet thickness. Real-time data analysis facilitates predictive maintenance, process optimization, and quality control, driving operational efficiency and product quality.

Implications for Pharmaceutical Manufacturing:

Enhanced Product Quality: The advanced features of modern tablet compression tooling contribute to the production of tablets with superior quality attributes, including uniformity, hardness, and dissolution profile. Consistent tablet quality minimizes variability in drug performance and ensures patient safety and efficacy.

Increased Production Efficiency: Automation and robotics streamline manufacturing processes, reducing cycle times and increasing production throughput. Furthermore, predictive maintenance algorithms prevent unexpected equipment failures, minimizing downtime and maximizing operational uptime.

Compliance and Regulatory Assurance: The precision and control offered by advanced tablet compression tooling facilitate compliance with stringent regulatory requirements, such as those outlined by the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). Accurate documentation of process parameters and real-time monitoring capabilities ensure audit readiness and regulatory compliance.

Cost Reduction and Resource Optimization: Improved tool longevity, reduced maintenance requirements, and minimized scrap rates translate to cost savings for pharmaceutical manufacturers. Additionally, increased production efficiency allows for optimal utilization of resources, lowering overall manufacturing costs and enhancing competitiveness.

Future Directions and Challenges:

While recent advancements in tablet compression tooling have propelled pharmaceutical manufacturing to new heights, the industry continues to explore innovative solutions to address emerging challenges. Future developments may focus on:

Integration of artificial intelligence (AI) and machine learning algorithms for predictive process optimization and quality prediction.

Exploration of novel materials and coatings to further enhance tool performance and durability.

Advancement of additive manufacturing (3D printing) techniques for rapid prototyping and customization of tablet compression tooling.

However, challenges such as ensuring compatibility with diverse drug formulations, minimizing environmental impact, and addressing regulatory complexities remain areas of active research and development.

Conclusion:

In conclusion, tablet compression tooling has undergone a remarkable transformation, driven by technological innovation and a relentless pursuit of excellence in pharmaceutical manufacturing. The latest advancements offer unprecedented levels of precision, efficiency, and quality control, revolutionizing the production of tablets and ensuring the delivery of safe and effective medications to patients worldwide. As the industry continues to evolve, collaboration between manufacturers, technology providers, and regulatory agencies will be essential in shaping the future of tablet compression technology and its impact on healthcare.

0 notes

Text

thinking about how maul never got to find out what the surprise from kilindi and daleen was. i like to think it was some sort of escape plan. they're both smart and well aware of how strong sidious is and how afraid maul is of him. they wanted to run away together. they could have been safe had they just left without maul.

#⸢ headcanon ⤑ maul ⸥ always remember.#maul said he didn't want to know anymore.#BUT DID HE THINK OF ME?? I WANT TO KNOW.#and thinking about the amount of grief he would have felt when kilindi tried to smile.#when she didn't fight back even tho she could have.#thinking about maul looking at her for the last time.#before steeling himself and compressing all the feelings into rage.#and from then on the denial begins.#he doesn't need anyone or anything.#he is a tool that serves him master.#and that is his only purpose.#FEELING BAD AT 2AM.

8 notes

·

View notes

Text

Socket Plug connectors, Receptacle Housing, cable connectors

DT Series Contact Size 16 3 Way Gray Receptacle Housing

#TE Connectivity#DT04-3P#Connectors#Tooling and Accessories#Cable compression tool#SAN#cable crimper#Tin Plated Contacts#f connector#Socket Plug connectors#Receptacle Housing#cable#Crimp Contact Socket#Ethernet crimping

2 notes

·

View notes

Text

#CNC spoilboard cutter#cnc insert router tooling#cnc insert v groove bit#cnc helical planing cutter#solid carbide router bit for wood#ball nose solid carbide bit#compression solid carbide bit#upcut solid carbide bit#down cut solid carbide bit#solid carbide router bit for plastics#dowel drill bits#v point drill bits for wood#hinge drill bits#solid carbide dowel bit#solid carbide through point bit#panel saw blade

2 notes

·

View notes

Text

Don’t mind me just fucking around with mobile gif making in 1) Adobe Express 2) Tumblr gif maker 3) ezgif.com

#they do have nice captions I’ll give em that!#just paywalling the stupidest things that you can just do in your photo app#and garbage compression settings#force you to make the gifs tiny#good gifs with free tools challenge

11 notes

·

View notes

Text

#cookie.txt#txt#one good thing came out of our jackbox blog but otherwise#running it was such a mistake#our motivation - my motivation - was generosity#because we LIKE data mining!#and we LIKE sharing what we find!#some people made some very generous tools to make it easy to pull apart old YDKJ games#and the party packs? their audio isn't even compressed into anything! it's all right there! you don't need fancy tools!#but i keep seeing this trend of#people just wanting more and more and going out of their way to fish for archives of that blog#and. guys. if you want it so bad. you can look up how to do it. WE looked up how to do it.#you lost your rights to having us do it for you when you all decided to be weird and uncomfortable and constantly violate our boundaries!#ugh!#it frustrates me that most of the other fans of our special interest - at least the ones we keep encountering - are children#or are otherwise not very bright!!!!!!#and it makes me feel mean to say that but it's true and i'm frustrated about it#prolly delete later. whatever.

6 notes

·

View notes

Text

Lion Brand Stress Relief Gloves for Knitters, Hit or Miss?

Lion Brand Stress Relief Gloves brings a new option for wrist comfort for many crafters, it’s slightly compressing made with Nylon and Spandex so it doesn’t have that cotton thick feel these gloves are both breathable and lightweight. As someone who lives in compression garments, I would estimate these gloves are only about 5mmhg to 10mmhg of compression. While the glove part of the gloves are a single ply on either side there are two seams that do press into the hand with use, so they do leave temporary marks; something to keep in mind if you crochet before an important or photographic event. The wrist part however is two ply going around which does provide a little extra wrist support like a level 1 wrist support depending on size of glove to hand.

As a former violinist I do already suffer from angry wrist syndrome (tendinitis - mild) plus crocheting a king size blanket in a month which completely pulled me from crocheting for almost 6-8 months. That being my prior history hopefully helps the understanding of where I’m coming from for this review. I wear a size small, though extra small would be better but atlast they only have small and medium at least that I can quickly find on the joann’s website which is kind of disappointing that they don’t have larger sizes. These gloves are initally tight going on and I would make sure any hand/wrist jewelry is taken off prior to putting it on because the fingers cut outs don’t have a seam to keep them from unraveling, though mine as survived one round in the dryer so far. I own two pairs of these, the first part I wore for about 72 hours over a few days and they did stretch out so they weren’t as compressing which was pretty annoying because that compression let me sit for hours without feeling any sort of wrist pain (always make sure to stretch your hands and take breaks) after throwing them in the dryer they did shrink back down a little bit but they still weren’t as compressive as when I originally put them on.

Usefulness ⅘

I have definitely noticed a change in my normal crocheting with these gloves, I can definitely crochet longer and faster (yet to know if this is a good thing or not, need longer time to determine) but they do seem to helpful while I’m wearing them; the spandex/nylon mix does keep my hands warmer and seems to help the blood circulation in my hands and it doesn’t seem over slippery at least with how I hold my hook (violin bow like). While I do complain about the lack of protection seams about the finger holes they have held up in the dryer at least once, I think I might have twice; they don’t have any loose threads or signs of the holes expanding. While I do have smaller hands I can not speak about larger hands stretching them out if it cause the seams to come undone or not. I do wish they came in more colors but I do like that they are bright blue so when I put them down I can easily see them so I will add that as a bonus because I do tend to misplace things.

Price Point ⅗

These gloves retail for $16.99 prior to any discounts, for the first pair to weaken after the first few days was really disappointing, this score may change after I wear the second pair more to see if they hold up better and for longer. Joanns does current offer three gloves, the gloves in this review, then Thergonomic Hand Aids (comes in large and made with the same material and the same price) but also have Dritz Crafters Comfort Gloves - Cloth like and longer finger coverage which are $19.99; I would say that this Lion Brand Stress Relief Glove is a little more expensive than it needs to be because there is no finger coverage, no protect seams in the finger or thumb holes.

These are just my first impressions after having them for about 2-3ish weeks. I do have another pair by Sparthos Wrist Support Compression gloves coming so I will definitely be comparing the two after they arrive. I am a true Sparthos fan with their compression socks. I'm excited to see if their gloves hold up.

Final thoughts; as someone who does have extra small hands fitting into size small I would say you aren’t going to get as much support as if you have the correct size, and if you are prone to edema and swelling I wouldn’t recommend them myself just in case of the lack of protection seams and it would suck if they broke after a few uses. If you have ‘normal’ hands, I would suggest trying them to see if they help, their as comfortable as they can be for light compression

#crochet love#hand crocheted#crochet aesthetic#crochet community#crochet cosplay#real reviews#product reviews#reviews#compression#crochet accessories#crochet tools#crochet gloves#crochet lover#crochet enthusiastic#hand knitted#knittersofinstagram#crochetersofinstagram#crochetersoftiktok#crochetblr#crochet tumblr#knitterslife#crochet life#joanns#crafting#crafters of tumblr#arts and crafts#crochet crafts#crafter community#lion brand yarn#lion brand

3 notes

·

View notes

Text

Tablet Compression Machine manufacturer and exporter

IRM Enterprises is a Tablet Compression Machines, Capsule Filling Machines, Granulation line, Tablet Tooling machine manufacturer and exporter.

Tablet Compression Machine is a critical process in pharmaceutical manufacturing where powders or granules are compressed into tablets. Tablets are a popular dosage form for medication due to their convenience, stability, and ease of administration. Tablet Compression Machine is a complex but essential process in pharmaceutical manufacturing, requiring a thorough understanding of material properties, process parameters, and quality control measures to produce effective and reliable medication.

Our all Pharma Machinery Solutions products

Tablet Compression Machines,

Capsule Filling Machines,

Granulation line,

Tablet Tooling,

Granulation Machine,

Tablet Tooling

Kalweka Multi-Purpose Equipment’s

For More Details

Click here : https://www.karnavatiengineering.com/

#Tablet Compression Machines#Capsule Filling Machines#Granulation line#Tablet Tooling#Granulation Machine

0 notes