#Structural Safety Inspection Engineer

Text

Parking Structure Inspection

RAS Engineering is a reputable provider of parking structure inspection services in Pennsylvania (PA). Our experienced team uses advanced techniques and tools to assess the condition and safety of parking structures. Contact us at (888) 343-0713 for more details.

#Parking Structure Inspection#Energy Audit San Francisco#Exterior Wall Inspector New York#Structural Inspection New Jersey#Building Structural Recertification#Structural Safety Inspection Engineer#Structural Integrity Reserve Study

0 notes

Text

youtube

#youtube#militarytraining#Bridge renovation#Bridge collapse#Bridge safety#Civil engineering#Bridge inspection#Bridge demolition#Structural engineering#Bridge repair#Bridge maintenance#Bridge design#Infrastructure#Heavy machinery#Bridge replacement#Destruction#Precision cutting#Construction technology#Engineering marvel#Bridge construction#Bridge destruction.#Demolition techniques#Bridge engineering

0 notes

Text

Expert Structural Engineering and Building Safety Inspections in West Palm Beach and Broward County

In the dynamic landscapes of West Palm Beach and Broward County, the demand for reliable Structural Engineering and building safety inspections has never been more critical. Universal Engineering stands at the forefront of this essential service, ensuring that structures not only meet but exceed the rigorous standards set forth by local regulations.

Structural Engineering Excellence in West Palm Beach

West Palm Beach, with its vibrant communities and expanding infrastructure, requires a nuanced approach to structural engineering. At Universal Engineering, our team of expert structural engineers brings a wealth of knowledge and experience to every project. We specialize in designing resilient structures that withstand Florida's unique environmental challenges, from hurricanes to humidity. Our commitment to excellence ensures that each building is not just a structure but a safe, enduring part of the community.

Building Safety Inspections in Broward County

In Broward County, where safety and compliance are paramount, Universal Engineering provides comprehensive building safety inspections. Our meticulous approach covers everything from foundational assessments to electrical and plumbing systems, ensuring that every aspect of your building is scrutinized for safety and compliance. Our inspections are thorough, transparent, and aimed at identifying potential issues before they become problems, thereby safeguarding the inhabitants and the investment made in the property.

Commitment to Community and Safety

At Universal Engineering, our mission extends beyond mere compliance. We are dedicated to the safety, well-being, and peace of mind of the communities we serve in West Palm Beach and Broward County. Our structural engineers and inspectors work diligently to ensure that every building project and inspection adheres to the highest standards of safety and quality.

In conclusion, whether you're embarking on a new construction project in West Palm Beach or require a building safety inspection in Broward County, Universal Engineering is your trusted partner. Our commitment to structural integrity, safety, and community well-being makes us the go-to choice for all your engineering needs. Trust us to bring our expertise, diligence, and passion for engineering to your next project, ensuring that your structures stand the test of time and nature.

0 notes

Text

Exploring Brooklyn's Icons: A Guide to Empire Stores Dumbo and the Brooklyn Bridge

Brooklyn, New York, is a treasure trove of iconic landmarks and historical sites. Among these, Empire Stores Dumbo and the Brooklyn Bridge stand out as must-visit destinations. Whether you're a local or a tourist, here's everything you need to know about getting to these attractions, navigating the Brooklyn Bridge, and discovering the rich history that surrounds it.

How to get to Empire Stores Dumbo?

Empire Stores, located at 55 Water Street, Brooklyn, NY 11201, is easily accessible by various modes of transportation. If you're using public transit, take the subway to the High Street-Brooklyn Bridge station (A, C trains) and enjoy a picturesque stroll toward the East River. Alternatively, several buses serve the Dumbo area, providing convenient options. If you prefer driving, parking facilities are available in the vicinity.

Are there any restrictions for cyclists on the Brooklyn Bridge?

Cyclists are welcome on the Brooklyn Bridge, and there's a dedicated lane for them. However, it's important to be aware of any restrictions during special events or maintenance periods. Adhering to traffic rules and being mindful of pedestrian traffic ensures a safe and enjoyable ride across this historic bridge.

How many lanes does the Brooklyn Bridge have for vehicular traffic?

The Brooklyn Bridge boasts six lanes for vehicular traffic, with three lanes in each direction. The outer lanes accommodate regular traffic, while the inner lanes are reversible, changing direction based on the time of day to optimize traffic flow.

What is the current condition of the Brooklyn Bridge?

As of the latest available information, the Brooklyn Bridge is generally in good condition. Regular inspections and maintenance work are conducted to preserve its structural integrity. For the most up-to-date information, it's advisable to check with local authorities or official sources.

Are there any interesting events or stories related to the construction of the Brooklyn Bridge?

The construction of the Brooklyn Bridge, spanning from 1869 to 1883, is a tale of engineering marvels and human determination. Notably, Washington Roebling, the chief engineer, faced decompression sickness during construction. His wife, Emily Warren Roebling, played a pivotal role in overseeing the completion of the bridge, a testament to her resilience and dedication.

How many years did it take to build the Brooklyn Bridge?

The Brooklyn Bridge took a total of 14 years to build, showcasing the dedication and perseverance of the individuals involved in this historic project.

Has the Brooklyn Bridge ever undergone significant renovations?

Over the years, the Brooklyn Bridge has undergone significant renovations to ensure its longevity. Preservation efforts focus on maintaining its historic elements while incorporating modern engineering standards to meet safety requirements.

Are there any guided tours available for the Brooklyn Bridge?

Immerse yourself in the history and architecture of the Brooklyn Bridge by taking a guided tour. Several local operators offer insightful tours, providing a deeper understanding of the bridge's significance. Check with local tour providers or visitor centers for the latest information on available tours.

Can you see the Statue of Liberty from the Brooklyn Bridge?

While the Brooklyn Bridge offers breathtaking views of the Manhattan skyline, keen observers can catch glimpses of the Statue of Liberty from certain points along the bridge. The panoramic vista makes the bridge a unique vantage point for appreciating this iconic symbol.

Are there any special events or celebrations held on the Brooklyn Bridge?

The Brooklyn Bridge occasionally hosts special events, celebrations, and festivals. Fireworks displays, cultural events, and charity walks are just a few examples of the diverse activities that take place on or around the bridge. Stay updated on local event listings for information on upcoming activities.

In conclusion, exploring Empire Stores Dumbo and the Brooklyn Bridge is a journey through history and modernity. Whether you're fascinated by the engineering prowess of the bridge or captivated by the events surrounding its construction, Brooklyn's iconic landmarks promise an enriching experience for every visitor.

#Brooklyn Bridge#Bridge#new york city#new-york#new york#newyork#nyc#ny#manhattan#urban#city#usa#United States#buildings#travel#journey#outdoors#street#architecture#visit-new-york.tumblr.com

759 notes

·

View notes

Note

Hiya! Would you be willing to explain why keeping captive right whales is completely nonviable, as you mentioned? I’m fascinated, but the adhd simply will not let me parse scientific papers.

That's a fantastic question! While it would be wonderful if captive breeding were a viable option for this critically endangered species, it just isn't possible under any realistic conditions.

For starters, their size. Orcas are the largest mammals successfully held in captivity, and we all know how difficult (and controversial) that is, with only a very small handful of facilities ever pulling it off with any semblance of success. Tilikum, the largest captive orca (although I believe that record has since been overtaken by a male in China), was 22.5 feet (6.9 meters) long and weighed 12,500 pounds (5,700 kg). Most other orcas in human care, particularly the females, are considerably smaller. Compare that to a northern right whale. Even the smallest adults are over 40 feet long—double Tilikum's length—and weigh 88,000 pounds (40,000 kg)—seven times his weight—while the biggest specimens on record reached up to 61 feet (18.5 m) and an incredible 234,000 pounds (106,000 kg).

A tank for an animal that size would be far beyond anything we have the ability to engineer and maintain. Think of how deep it would have to be for the whale to even turn around! The water pressure would be astronomical, wreaking havoc on the building materials even if it were possible to build the structure. And remember—someone has to dive to clean it! Our theoretical right whale habitat would have to be a sea pen, but even the 100-acre facilities proposed with orcas in mind are nowhere near deep enough. While right whales are considered to inhabit "coastal" waters, they do not live right up by the shoreline, like certain orca ecotypes and other small delphinids. They are a pelagic species, designed to live out in the open water column, as are all baleen whales. So, the pen would have to be a floating habitat miles out into the open water (think of an offshore oil rig), with netting sturdy enough to not be destroyed by a 50 ton whale and long enough to extend hundreds of feet to the ocean floor. We're talking probably thousands of square miles of netting, that would have to be routinely inspected for safety and upkeep. So, you would probably need a submersible, since no human can dive that deep. On top of that, it would be difficult to find such a larger stretch of ocean in their habitat without shipping lanes, underwater noise, or pollution. And let's just forget about the logistics of staffing that place—or worse, funding.

Additionally, we wouldn't be able to feed them by tossing fish into their mouth like with dolphins. Northern right whales feed on tiny crustaceans and zooplankton, cruising along and filtering the creatures from the water with their baleen. Assuming our right whale keepers were somehow able to acquire the insane amount of food the whale requires (potentially over 5000 pounds of zooplankton a day), it would need to be scattered throughout the massive habitat to facilitate feeding. I imagine this would probably look something like the way Georgia Aquarium feeds their whale sharks from a little boat, although on a much larger scale. And since the food obviously can't be kept alive, we would need to develop someway of delivering the daily vitamins that are lost in the freezing process—and to keep hundreds of tons of krill frozen on a floating kitchen in the middle of the ocean.

Of course, the ultimate goal of this project would be to breed northern right whales... that means we need to take everything we just talked about and double it, at a bare minimum. For the breeding program to be successful, it would need a whole lot more than just two whales. And unfortunately, even if we lived in world with magical floating thousand-acre sea pens, unlimited krill, and endless money... we still don't know if it would even work. Right whale breeding habits are poorly understood, with the whales mating in cold northern waters before migrating 1,000 miles south to calve. Despite our best theoretical efforts, these migratory patterns could very well be necessary for successful reproduction.

Thank you again for the ask! This was actually a lot of fun to think about! If you want to read about JJ, the only baleen whale ever successfully housed in (temporary) human care, you can find an article and pictures here.

#still working through my inbox#the frequency at which I answer will slow down now that I'm back on clinics#northern right whale#baleen whales#cetaceans#marine mammals#conservation#answered asks#funlovingfuzzball

46 notes

·

View notes

Text

I-35 Bridge- Ethical Obligation

I-35 Bridge Ethical Case Study

Abstract

This case study is about a bridge in Minnesota that collapsed and resulted in the death of thirteen individuals and one hundred and forty-five more individuals were admitted to the hospital for injuries from the same incident. The incident took place on August 1st, 2007. The overcapacity due to the heavy traffic on the bridge during the time of collapse is considered the main cause of the collapse (NTSB). However, the investigators stated inattentive inspection and design error to be some of the other causes of the collapse. One of the gussets plates of the bridge had an uneven thickness which went unnoticed by officials during inspection; however, the accident could have been prevented if there had been more cooperation between the state of Minnesota and the engineering firm in coming up with a better design procedure and review which was noted by the investigation to be improper. The recommendation is that officials conduct a comprehensive inspection regularly, and the detected errors should be rectified by the officials immediately. The recommendation is referred to the Minnesota Department of Transportation (MnDOT). Adherence to comprehensive analysis and action to problems will help prevent similar future accidents. Moreover, this paper will detail means of preventing ethical failures related to decisions and emphasize the need to prioritize the wellbeing of citizens to the high maintenance cost to ensure at most safety in engineering structures. Therefore, improving the manual book and inspection course is important to maintain engineering structures.

Problem statement

The I-E35W Bridge collapsed under the pressure of heavy traffic in 2007, resulting in many injuries and deaths. Bridges are considered one of the best architectural accomplishments of the past century; bridges have become a fundamental part of society, especially when people are required to cross a place where it would be almost impossible without the bridge. Therefore, the collapse disaster of a bridge is a very critical issue for society. The collapse of the I-E35W was attributed to a lack of maintenance and structural deficiencies (NTSB). Despite the federal government marking the bridge as structurally deficient, the government still delayed its replacement until 2020. The ethical violation of bridge inspection can be attributed to the cause of the disaster.

Moreover, despite the risks of leaving the bridge operational, the bridge was not closed for public use due to underestimating the outcomes. Therefore the failures associated with this disaster should serve as a lesson to prevent future related disasters. Comprehensive inspection and correction of faults detected should always be adhered to to avoid such disasters.

Background

The I-35W Bridge, since its construction, has served as critical infrastructure for the people of Minneapolis. The bridge was developed as a link between Marcy-Holmes and the Downtown East neighborhoods of Minneapolis. The I-35 became one of the busiest bridges in Minnesota, with an average of over 140000 cars using the bridge daily (Bickal, Jim, and Sara). The bride accommodated the interstate highway 35W across the Mississippi River. According to witnesses and news stations, the bridge is reported to have collapsed during a rush hour in the evening, which resulted in 145 people being injured and 13 fatalities on August 1st, 2007 (Bickal, Jim and Sara). Moreover, the tragedy victims included car owners and construction workers who reportedly drowned; over 100 vehicles were also destroyed.

According to the investigation of The Federal Highway Administration, the Sverdrup & Parcel, an engineering construction company, constructed the I-35W Bridge in the early 1960s. The bridge construction under this case will be regarded in Division 1 of the Standard Specification for Highway Bridges (AASHO) (Holt& Hartman 05). After the completion of bridge construction in 1967, the firm was again taken by Jacob's Engineering Group in the ear 1999; the new management was then responsible for the inspection through the preparation of design documents and performing calculations for the bridge design. The main design for the bridge is a deck truss. This design adopts the truss located underneath the roadway to support the main infrastructure and the traffic. The I-35W Bridge had a center span that tied the two ends forming an expansion of up to 458 feet of steel arch. The little second foundation of the bridge was due to the river traffic below. To compensate for the little secondary foundation, the bridge was fortified with a continuous truss to equilibrate and balance the whole structure; this technique was applied due to its need for fewer parts. However, due to little redundancy, the bridge was categorized under the fracture critical bridge category; this implies that a failure of one part would incapacitate the whole structure (Wald). Despite the risks associated with the structure, it was still adopted due to its cheaper cost and lightweight. The NTSB attributed the cheaper cost of the bridge to incorporating only the necessary parts, which resulted in a cheap and efficient structure.

Engineering Failure

Investigations were performed after the incident to uncover and identify the cause of the tragic collapse. The lead investigators for the tragedy were the Federal Highway Administration (FHWA) and NTSB (Holt and Hartman 04). During the investigation, there was numerous hypothesis and speculations about the reason for the collapse. The investigators did a comprehensive review of the bridge since its construction in 1967. During the investigation, the investigation noted an unusual condition of the bridge due to MnDOT inspection. The bridge was recorded to function properly for seven years from 1983. However, at the start of the 1990s, the piece of architecture received a structurally deficient rating by MnDOT. The rating was contributed by bridge-bearing corrosion. The report from NTSB indicated a significant amount of corrosion and wearing down of the bridge, which increased the amount of the bridge collapsing by a significant margin.

Moreover, there was a prior inspection before the incident, which was carried out by URS Corporation- a contract-based construction, design, and engineering firm. The firm's duty was to document the design of the bridge; the form reported a compromised specification concerning the effectiveness of the bridge. Moreover, the firm recommended a number of retrofit projects for the bridge. However, most of the recommendations and judgments of the firm were declined. The engineer responsible for the bridge, Dorgan, argued that since the bearings of the bridge could not be replaced by engineers without incurring high costs as the whole bridge had to be elevated, and because the bearings were not reported to be sliding, therefore, he commented that the corrosion and URS corporation's report was a minor issue (Bickal, Jim and Sara).

Moreover, the cracks detected by MnDOT in 1997 were patched up by officials without appropriate maintenance and investigation (Kimball and Williamson). A department formed by the University of Michigan Civil Engineering was contracted to perform further investigations regarding the design and efficiency of the bridge. The investigations revealed the deck truss to have been overburdened. However, even after the investigation, engineers concluded that the government would not replace the bridge since the deck truss had no signs of cracking. Moreover, the FHWA did a review concerning the bridge in 2005. The review rated the bridge's structural stability as 50% effective. Despite a clear need for replacement noted by the state, the bridge was still considered operational, and officials took no action to close or warn against its use by the public (Bickal, Jim, and Sara).

Being among the state departments with jurisdictions to investigate and review the bridge's original design, the FHWA was able to perform an investigation that uncovered errors in the design of the gusset plate, specifically the U10 node. The investigation revealed that Sverdrup & Parcel and Associates failed to ensure correct quality control procedures and calculations of the gusset plate (NTSB). The investigation revealed that the U10 gusset plate's thickness was only a half-inch. Using other gusset plates for comparison, the report showed that other locations had a massive difference in thickness compared to the gusset plate. Moreover, there wasn't a credible reason for the thin gusset plate design, as the plate recommended thickness was not achieved in relation to the load it was supposed to carry (Holt and Hartman 08). The FHWA conducted more experiments; the tests involved measurement of efficiency design; the report noted that the design requirements for the U10 node were not required to support the bridge.

Moreover, a (D/C) capacity ratio was also the appropriate requirement for the U10 node. To the Federal Highway Administration, if the (D/C) ratio was found to be less than one, the design is termed conservative. However, if the same ratio was noted to be more than one, the design is considered liberal and would consequently need safety regulations. The investigation found the ratio of the U10 node to be more than one (Holt and Hartman 06). This revelation showed the fault in the calculations of the respective firm in measuring and calculating the correct load capacity. However, the NTSB report showed that inadequate design was just one of the causes that resulted in the bridge's collapse. Another factor noted as a result of the analysis was the poor state of the peak section of the structure. The NTSB reported that officials incorrectly assessed the bridge's weight. Being the duty of State Highway and Transportation, it failed to assess the bridge weight capacity accurately.

Moreover, the investigation noted a lack of gusset plate application in two instances- the National Highway Institute (a training course for bridge inspection) and the Reference Manual of the Bridge Inspector. It resulted in an incorrect assessment concerning capacity calculations of the bridge plates. Additionally, it failed to offer appropriate attention to distortions, including bowing the gusset plates during the bridge's inspections (NTSB). After reviewing the incident, both the FHWA and NTSB agreed that the main cause of the tragedy was a creaking gusset plate in the deck truss upper section. The gusset plates connected other trusses (Davey and Wald).

The collapse was attributed to the snapping of some of the plates held together with the gusset plate, which were overloaded by traffic and construction materials. Moreover, the collapse was also attributed to the bridge design's previous addition and renovation activities, which increased the weight of the bridge span (Wilber and Laris). The NTSB's report showed that the construction work on the bridge on the day of the catastrophe added dead weight to the bridge. Moreover, the bridge was filled with vehicles which were about 140000 passing over the bridge at the time of the incident. The heavy traffic and construction materials specifically located close to the south-side section at U10 nodes resulted in the snapping of the main gusset (NTSB, 2008).

Ethical Analysis

The best ethical framework that is applicable and able to analyze actions of MnDOT in relation to ethical lapse is Kantian ethics. This part will analyze how the Minnesota transport department is responsible for an ethical lapse through the analysis of the involved group's actions. The deontological framework focuses on the accepted moral actions based on certain defined moral rules ( Poel and Lamber). Immanuel Kant makes an argument in relation to deontology, insisting that the best framework is the categorical imperative that uses deontology principles. He further states that it is divided into two parts. The two parts are the reciprocity principle and the universality principle.

The universality principle focuses on the action which ought to evolve into a universal law based on a maxim; a maxim can be defined as a practical-based principle that dictates an action (Poel and Lamber). Applying this principle to this case study, it becomes evident that, being in charge of the structure, the MnDOT was unable to properly assess the structure's condition properly. The report conducted after the incident showed that they knew of the deck truss fatigue signs and cracks present in the bridge. Moreover, the report shows that despite knowing the condition of the bridge, they did not take any action to rectify the situation or warn the public. They assumed the problem. Based on this case, the maxim can be categorized as "Failing to follow small problems safety policy is acceptable." Based on this maxim, it is clear that it violates and contradicts the principle of universality.

Moreover, another violation of the categorical imperative by the MnDOT association is the reciprocity principle; this principle focuses on treating someone else in a moral and equal manner (Poel and Lamber). The reciprocity principle is of the argument that everyone should place it as their duty to respect the personal autonomy of other people by valuing everyone through the treatment of a person as an end instead of treating them as a means. Relating to this case, the MnDOT failed to provide further information to those who crossed the bridge. They purposefully engaged in acts of preventing the condition of the bridge from being known by the public. Consequently, they failed to provide a free option of choice to the bridge users on whether to use or not use the bridge. The reason for failing to provide knowledge of the bridge's condition to the public was to save on refinement costs. Based on the reciprocity principle, their actions are irresponsible and unethical because they risked the lives of many citizens.

Recommendation

Numerous means can be applied to prevent a similar incident to the one that happened to the I-35W Bridge. To assure maximum safety to other bridge structures, comprehensive inspections and immediate action to problems detected should always be performed. Moreover, personnel and officials in charge of such architectural structures as the I-35W Bridge should always ensure that they perform their duties diligently and critically analyze the conditions of the bridges they are in charge of to ensure that they can foresee disastrous situations. Therefore, they should make a critical and comprehensive analysis of the deck truss of their bridges. They should also not underestimate small problems such as loss of useless parts, a small crack, or even truss fatigue. Moreover, they should make it their moral duty to inform citizens of the bridge's condition. This is a reciprocity principle in relation to ethics.

In addition, the gusset plates of different bridges should be investigated to determine their efficiency as this was the main reason for the tragedy of the bridge, report revealed that overcapacity led to snapping of the plates. Moreover, the state should create a team to provide knowledge on inspector training and manual book. Creating such a program will help the inspectors remove any doubts and gain more knowledge on the observation of every element.

Conclusion

Numerous reports from news indicate that the bridge's collapse was among the most horrendous incidents in the United States due to the number of casualties and losses incurred as a result of the collapse. The accident resulted from assumptions and disregard for the standard maintenance procedures by the transportation officials and engineers. Furthermore, there was also a lack of enough training on the officials' manual book and course use. Regarding the problem, the officials and construction companies ought to be more responsible and cautious in adhering to ethical means of performing their tasks. Moreover, the officials should also be accorded proper education on manual book use and structural designs of bridges to ensure accurate assessments. Adhering to these guidelines will ensure that similar future tragedies are prevented.

References

Bickal, Jim, and Sara Porter. "Reporting, Memories From the I-35W Bridge Collapse." Minnesota Public Radio, 2017.

Davey, Monica, and Wald, Matthew L. "Potential Flaw is Found in Design of Fallen Bride." The New York Times, August 8th 2007, www.nytimes.com/2007/08/08/us/09cnd-bridge.html?

Holt, Reggie, and Hartmann, Joseph. "Adequacy of the U10 & L11 Gusset Plate Designs for the Minnesota Bridge No. 9340." (n.d.): n. pag. Web Archive. Federal Highway Administration, 2008.

Kimball, Joe, and Elizabeth Williamson. "Interstate Bridge Collapses Into Mississippi River in Minneapolis." Washington Post, August 2nd 2007,www.washingtonpost.com/wpdyn/content/article/2007/08/01/AR2007080102072.html.

National Transportation Safety Board, Highway Accident Report, 2008.

Poel, V. I., & Royakkers, L. Ethics, Technology, and Engineering: An Introduction (1st ed.). Wiley-Blackwell 2011.

Saulny, Susan, and Libby Sander. "Bridge Collapse in Minneapolis Kills at Least 7." The New York Times. 2007, www.nytimes.com/2007/08/02/us/02bridge.html?_r=0. Wald, Matthew L. Faulty Design Led to Minnesota Bridge Collapse, Inquiry Finds. 2008, www.nytimes.com/2008/01/15/Washington/15bridge.HTML?_r=0%5D.

26 notes

·

View notes

Text

The Role of MS Plate in Modern Structural Engineering

Utilising high-quality materials is essential for the safety and longevity of buildings, bridges, and infrastructure projects in the dynamic world of contemporary structural engineering. Plates made of Mild Steel (MS) serve an important role in structural engineering. MS plates for numerous construction applications are in high demand in Vadodara, Gujarat, and their significance cannot be overstated. This blog will examine the role of MS plates in modern structural engineering, with a concentration on the availability of MS plates from suppliers and distributors in Vadodara, Gujarat.

MS Plates' Evolving Form:

Structural engineering has made great strides with plates of mild steel. Initially, iron plates were employed, but they lacked the required strength and durability. As a result of metallurgical advancements, MS plates have become the material of choice for a variety of structural applications. MS plates are fabricated from low carbon steel, making them ideal for welding, bending, and forming without sacrificing structural integrity.

In structural engineering, the function of MS plates:

MS plates offer remarkable strength and durability, making them an excellent option for supporting the load-bearing components of structures. The durability of the structure is ensured by the ability of these plates to withstand large loads and adverse weather conditions.

MS plates are extremely versatile and can be used in a wide variety of structural applications, such as building foundations, bridges, and industrial structures. They are an indispensable component of modern engineering due to their adaptability.

MS plates are renowned for their excellent weldability, enabling for the creation of strong joints and connections. This characteristic is indispensable in structural engineering, where precise welding is frequently required.

MS Plates in Vadodara, Gujarat:

When sourcing high-quality MS plates in Vadodara, Gujarat, it's crucial to work with dependable suppliers and distributors who can provide the appropriate materials for your projects. Tube Trading Co. is a reputable provider and distributor of MS plates in Vadodara, Gujarat, and their dedication to quality and customer satisfaction sets them apart.

MS Plates Supplier in Gujarat's Vadodara

In Vadodara, Gujarat, Tube Trading Co. takes pride in being a dependable supplier of MS plates. To meet the diverse requirements of the construction industry, they provide a vast selection of MS plates. Whether you need MS plates for a residential project or a large-scale industrial undertaking, they have the knowledge and inventory to meet your needs.

MS Plates Distributor Vadodara, Gujarat

As a dedicated distributor of MS plates in Vadodara, Gujarat, Tube Trading Company ensures that you have convenient access to high-quality MS plates whenever you require them. Their efficient distribution network and on-time delivery services make them the preferred supplier for contractors and engineers in Vadodara and beyond.

Why Buy MS Plates from Tube Trading Co. in Vadodara, Gujarat?

Tube Trading Co. is dedicated to delivering MS plates of the highest quality, meeting or exceeding industry standards. Their products undergo stringent quality inspections to ensure their dependability.

They offer competitive pricing, which makes the use of MS plates cost-effective for projects of any size.

Expert Guidance: Their seasoned team can offer valuable guidance and recommendations to assist you in selecting the ideal MS plates for your specific project requirements.

Final Thought

MS plates are indispensable in contemporary structural engineering because of their strength, durability, versatility, and weldability. If you are in Vadodara, Gujarat and in need of high-quality MS plates, Tube Trading Co. is your reliable source as an MS plates supplier and distributor. Their commitment to quality and customer satisfaction ensures that your structural engineering projects will have access to the finest materials on the market. To ensure the success of your upcoming endeavour in Vadodara, Gujarat, select MS plates from Tube Trading Co. It is impossible to overstate the significance of MS plates in contemporary structural engineering. Their strength, sturdiness, weldability, and adaptability make them indispensable in the construction of safe, dependable, and lasting structures. Tube Trading Co. is your trusted partner when it comes to procuring premium MS plates in Vadodara, Gujarat, ensuring structural consistency and adaptability in your projects. Choose Tube Trading Co. as your MS plates supplier and distributor to enhance your construction projects and reinforce structural integrity in Vadodara and the surrounding areas. MS plates from Tube Trading Co. are the best option for your construction project's success.

#MS plates supplier in Vadodara#MS plates supplier in Gujarat#MS plates distributor in Vadodara#MS plates distributor in Gujarat#MS plates in Vadodara#MS plates in Gujarat#Jindal Pipes#Tube Trading Co.#Gujarat#Vadodara#business

6 notes

·

View notes

Text

a maintenance worker surveys a problematic pipe in the basements of hangar 7. // 3200

I love lowercase letters. dont go sending emails to random people now! mild horror, no explicit stuff. for the sake of your sanity and tumblr scrolling, why not just read it on my blog or on a PC? it really is long.

FWD: ATTN : PIPE INSPECTION REQUIRED IN BASEMENT LEVEL 3

From : RED BULL GMBH ENGINEERING DEPARTMENT, Mathias Mischa <[email protected]>,<[email protected]>

to: me <[email protected]>

date : 16:34 , August 3 2023

Technician required in Hangar-7 Basement 3. Routine inspection of pipes from July 30.

Valeri

same pipes as July 30, just a check on whether they are working. You can grab a guy if you want. piping maps are the same, but attached in PDF below as usual. you can report directly to my office or send an email whichever is easier for you in three days…….. sorry, next shift is also preoccupied with another section. :-(

Regards,

Mathias

—---

MATHIAS MISCHA |TEAMMASTER 02, RED BULL GMBH ENGINEERING DEPT.

// 16:35 ------------------------

The soft ding from the laptop spooked the poor technician who was riveted to the article on his browser tab. A few moments passed before he grumbled audibly. That is the third time in the last few weeks I have to go down there… We already have to do a routine inspection. What the fuck? He was starting to wonder if the Michelin Star Restaurant in that building was starting to cook and present some forest monster from Schwarzenberg nearby.

And alone? That went against every single safety precaution known to man. Mathias, you’ve worked for Red Bull for twenty years, but you don’t even care about that huh.

He fucking hated that tunnel, and he didn’t feel like waiting, might as just get it over and done with.

It took him another three seconds to realise that the email was sent an hour before he was scheduled to clock out of his shift. Pretty rude of them to send an email so close to the end of the work hour too…bastards. Can’t let a man read his horror stories in peace!

Thankfully, past him had the diligence of putting away his tools neatly. He scooped up the navy and red duffel bag from the corner of his office and made his way easily down to the great glass building 2 streets away…would be what he would’ve said, if not for the absolute rainstorm right outside. He scrambled back in, cursing and swearing under his breath as he ran back up to his office room to grab his big umbrella and company jacket. Gotta thank them for making a solid jacket, but still, fuck them for making him do this. He looked up at the gloomy sky before starting his brisk walk to the eye-catching glass architecture of Hangar-7.

.

.

.

The underworkings of Hangar-7 was the very least, really odd, and at worst, a kind of maze. Maybe it was in his imagination but in his fifteen years of working as a technician for structural stuff all over the country, he hadn’t seen one as weird as the glass building belonging to Mateschitz. Then again, anything made or promoted by him or his, y’know, entire company, was weird. Who thought that sticking a Formula 1 car on the side of a cliff was a good idea? Or an entire bungee jumping competition? Aerobatics? What’s a drink got to do with Aerobatics? He was never in it for any of the F1 fame and frankly, having watched a race in person, he didn’t feel it was worth the price. The questions asking him whether he ever got to see the racers never ended though.

.

.

.

// 16: 55 ------------------------

He flashed his pass to the old security guy, and after a tense few seconds, was waved through and allowed to the maintenance hallways. He could feel the guard staring at the back of his head even after he closed the door behind him. This wasn’t the guard that was there the last time, but he sure gave the exact same vibe as the previous two - total distrust. Must be part of the job, he wondered.

tink tink tink….the hurried patter of rain on the glass.

The first basement floor of the maintenance areas were pretty well lit and actually really neat, thanks to the combination of,well, lights, and glass letting the outside in. He could still see the rain from here. He had to say, pretty cool and forward thinking engineering. Basement 1 was where most of the important stuff was located, and really, that’s usually where all the work would be. Not today however.

The soft patter of rain was completely shut out when Valeri reached the end of the corridor tunnel and headed to the door with stairs leading directly down to the third basement. Man, he thought. I hate this part. The atmosphere completely contrasted with the modern look of Basement 1 – rusty and creaky were the words that came to his mind as he made his way slowly down the dimly lit, steep but wide stairwell. His colleague had also remarked on the condition of the place the last two times they were here. It was weird, and even he had his fair share of traversing janky dubious tunnels in his career around Austria.

BASEMENT 3. AUTHORISED STAFF ONLY -

Well, that was the door alright. Text spray painted with a stencil.

Last he came here, he had notified the management of the poor lighting of the tunnel, and had almost tripped over whatever that was going down here. They had acknowledged it, and promised to work on it as soon as possible. Valeri wasn’t going to take any chances this time and took out his stronger torchlight, clicking it on. He turned on his helmet light as well, before pushing down on the bar that served as the hinge.

As expected, the tunnel was, well, not well lit. In fact, it seemed darker than the last two times before, and oddly, feeling worse. Was it always this way? Maybe they had scheduled the lighting personnel to come at a later date and this pipe decided it was a good time to screw things up. Either situation, still dark. So that is a fantastic development, especially that he was alone.

He walked deeper into the tunnels, the stale air and humidity stinking up the place. He made sure he could see the painted numbers and signs on the wall, and referencing it to the slightly sad and soggy printout of the map from the email. Valeri was impressed with how quickly the ink had smudged just from a bit of rain - some of the numbers were barely visible at that point, pink ink mixed with cyan and whatever. The circle he drew with a red pen, too, was slowly cascading down the paper with every moment that passed. Valeri, of course, was not pleased.

Thankfully he navigated the route cleanly enough, and managed to find the same thin pipe that was the source of all the problems, at the farthest ends of Basement 3’s tunnels, which was a squalid dead end, horribly darker than the rest. Whatever lamps that were being used here felt more like a mockery than actual help. Brushing his gloved hand along the pipe, he found the troublemaker kink that was supposed to be fixed a couple of weeks ago.

Valeri visibly frowned on realising that the fixes that were done hadn’t worked. He didn’t have the full tools as before obviously - just here to check if they functioned. He quickly made a note of it on the back of his printed map as a precaution ---

- ‘leaking again bolt area - joints - may require heavy maintennce - close rstrnt?

Alright, that was more than enough. Remembering the details was easier anyway when you weren’t being distracted by the strange sickly-sweet iron stench of this not-really sewer.. A cursory glance at the other pipes revealed nothing else of note, aside from typical grime and the leaking orange substance --

Hold on. Orange? Valeri jerked his head up to look at the pipe again. This was a brand new development and he was already dreading the report he had to write. He obviously couldn’t feel it through his padded gloves, but it was slimy, and prone to gelling, and the source of the new alarming smell. It couldn’t be sludge or whatever sewer stuff and he hurriedly pocketed the pen and paper, hoping that he wouldn’t have to stay around any longer for any longer, grabbing his duffel and making a blind beeline right for what he felt was exit as he whispered the zone where the exit was located ; “B3-Z6, B3-Z6, B3-Z6…”walking right into another dead end, and Valeri was staring right into a wall where the pipes ended. Checking the map, he felt his temples throb a bit at his own stupidity.

There was no B3-Z6; the ink had simply smeared down connecting the 5 into a 6, and Z5 was in another end of the Basement. Fuck.

He held his breath, trying not to yell, only letting out a long sigh through his gritted teeth over how blind he was. He leaned against one of the pipes in the corner, letting himself take a good look at his surroundings in the dim light.

And then the pipe moved in a little.

The speed at which Valeri moved away from the wall in fear was understated, and he traced the offending pipe that moved, before having his fear turn into confusion.

The entire section of the wall that he had leaned in was not a wall - rather, it was an extremely well concealed door with thin yellow pipes that had no function. Gently handling them had no effect - it did not budge, but when he pushed it down, the door groaned and swung in, revealing a terrifyingly steep metal staircase down with no lighting, save for a small light winking erratically in the dark. Shining his light down felt pointless - the inky darkness just absorbed it.

Nothing and no one had any mention of this door. He had been working for the Red Bull company for a good three and a half years, and all the maps to the various places around the city were well documented and labelled. This was not one of them and the map had nothing of note about this section.

To anyone else, they would simply be bolting out of the area at that very moment. Unfortunately, Valeri found himself very rational and massively intrigued by this entire complex. Gingerly, he stepped a foot at a time to test its structural integrity, and upon finding that it was safe, descended down, but not before dumping his duffel to make sure the door did not close, and only carrying his torch with him.

.

.

.

// 17:27 ------------------------

“Valeri! Whaddup!”

A man by the name of Jann walked into the office with his drink, fully prepared for his shift. This simple routine was broken by the obvious lack of his co-worker’s reply, or presence for that matter, alongside the general state of affairs of his table. A remnant of a sandwich wrapper was hastily left, and the man snorted. Is he still around? Not like him to stay til it was truly the end of his shift.

Jann stole a glance at Valeri’s PC, being the nebby person he was. That one busted pipe again and …an Austrian tabloid site about weird unsolved cases. ‘...human remains found in highly unusual places in and around the three Germanic-speaking Countries…not really human parts…’ Since when was he into this shit?

Whatever. I need my shit for later. The thought of his colleague was promptly put to the back of his mind as he went back out to his own locker for his own tools.

.

.

.

The logical assumption was that he was in the sewer tunnels of Salzburg at this point. But the air was not the overwhelming stench of grease and waste he knew of; to his curiosity, but rather…of clinics. Unless there was a clinic that he hadn’t known of that had terribly bad disposal practices, this all pointed to “a bad idea”. But they were on the extreme outskirts, and the medical bay wasn’t even close to being near Hangar 7. And yet he was following that smell because frankly, there weren’t any other routes down here.

The technician had no idea how far down he was at this point. He had long left the stairwell into an equally badly lit metal stairway. It was notable to him that everything down here felt ‘neat’. He had looked at his gloves and the odd cleanliness confirmed it, getting him to wonder how long - or recently - this place had been built. The pipes were dead silent, a stark contrast to the constant drone of gas and liquids of Basement 3. He hated that he could almost hear the ringing in his ears.

.

.

.

‘Disposal’ . Now that room was going to bode well for him certainly. He considered leaving it knowing it would be locked like the others, but the little squeaks of the door hinge said otherwise, baffling him.

Still somewhere, at least.

The apparent smallness of the room was obvious the moment he stepped in and was greeted by a shelf four steps away. The stains on the floor lit by his torch was enough to inform him it was clearly trash water stains.

And then Valeri looked past the first shelf directly into the eyes of a head smiling right at him.

Or the lack of its eyes, in this case.

Valeri screamed, sending his torch clattering to the floor. The beam’s frantic movement did not help as he properly perceived the unknown shelved objects lit up by the beam – forearms, feet, torsos, heads, hair, red lines – He scrambled backwards and right out of the door, and into the hallway–

Nononononopenopenopenopenope—

He had run to the opposite end of the corridor steps. He wanted away, wherever the fuck. The voids were clear in his mind’s eye and he wanted it gone.

Direction did not matter, and when he finally gained his wits, he realised he was not in the vicinity of Disposal,, but the set of stairs on the other end of the corridor.

All his lights were off. He didn’t remember when. But he would be thankful for it, when he heard the clanking of footsteps from above and chose to hide in the darkness with the safety of his dark hoodie. Praying wasn’t enough, as Valeri held his breath and shut his eyes so tightly it hurt.

Tnk….tnk….tnk….

.

.

.

‘Hold it properly, I’m gonna open the door.’ The sound of the hinge hunking and opening, and a pause.

‘……//what the hell, why is it a mess? fucking Stein...’

Valeri opened one eye. As his muddy vision solved itself, he made out two figures in weird medical suits in front the room he had just run out of. One of them carried what was unmistakably a body, but without its head.

He stifled a choke of disgust, unsure whether it was from the scene, or the overwhelming medical stench.

In a beat, the one outside carrying the headless body threw it in. There was no care whatsoever, no regard, until he heard the barely perceptible conversation become clearer as they headed closer back to the stairs they came back from.

“How… cking bodies did they make? ”

“After that Seb guy retired. Had to remove everything. Burn, trash, whatever. ‘No more Vessels’. ”

“Which Seb, there are like, four...five.”

“Vettel. Some program years ago, but just started to take out the trash after that big old guy died.” A pause. “Fuck that other old man too, creepy-ass one eye. Said they still kept one though…”

He waited a minute more, hearing the last garbled words of “...not even having a wiki pic”. making sure of complete silence before leaving the safety of his space and bolted his way back from where he came. It made no sense whatsoever, sounded fucking wrong, but he had enough of it, and he had enough of parts, he’d enough about weird shit, he just wanted to not fix that fucking pipe anymore.

Back up the steel rusty staircase.

Up the tunnels.

Up the stairwell, until he saw the duffel bag that loyally kept the cursed door open. Valeri grabbed it, and hightailed it back the right way this time. B3-Z3, Z2, Z1, and he tanked the door open, almost falling over with the full force of his body just trying to get the fuck away from Basement 3, up, up , up to Basement 1 and his face right into the of the guard from earlier.

“What took you so long? Isn’t it just an inspection?”

The guard was not amused at the sight of the technician, who looked right out from a sewer. Valeri wanted to tell him about everything below, but it sounded utterly stupid and would get him dragged out the premises and his job permanently.

“.......i just tried running up the stairs." oof.

“............That’s what I thought. You techies barely do jack anyway. This section is going to be off limits, closing time and all. Hurry along.” The guard walked off, leaving Valeri to be alone.

It was for the best really. But he had noticed something when he said it. It didn’t feel like that guy’s first time, either.

.

.

.

// 18:00 ------------------------

“Jesus Christ, Valeri. You really haven't – You look like shit?”

The sopping-wet technician stood in the doorway of his office, while Jann peered from behind his PC.

“...Yeah, pretty shit day overall. Also, they told me to check the pipe.”

“Oh?”

“It’s fucked again. Can’t believe it. Needa write a report.” Walking over to his table, he started stuffing his things into his usual work bag, trying hard to hide his tremors. That weird fucking face kept flashing in his mind and he knew it was going to have a bad night tonight.

Just keep with the report. That’s it. That’s all.

.

.

.

// August 5, 10:22 ------------------------

Doo-doot.

The Teams application lit up, and the weary Valeri looked at the message from his Teammaster with furrowed brows.

“forget about the second day”

“Second day?”

“fully read your report…..yeah forget about the second day inspection. We’ll let an external team do it. out of our scope really”

(thumbs up react)

Good. As long as it wasn’t him, he didn’t care. He navigated to his fave tabloid site and was ready to gorge on stupid funny articles again for the rest of the day, until he scrolled to the sports section.

“Vettel Possibly Back To F1? New F1 Boss Inbound!” said the heading. But that didn’t catch his eye – rather, the image used was his Championship win in 2010. Kind of hard to believe that this little babyface won one of the most prestigious titles in the sporting world,yet with a demeanour so loved by everyone until his last curtain call. And yet...

Babyface?

He stared at the picture for a good minute. No mistaking it, that was the same face he saw in the cesspit 2 days ago. The same body type they tossed into the disposal. And he didn’t feel too good. He tabbed out, pressing his palms to his eyes to rid of the sight in his mind again. But the same fucking grin kept appearing in his mind.

It’s just a stupid fucking sport about cars. What do you need for all that?

--------------------------------

that was ass. Thanks for reading it. 3200 i think…i edited it in the post either way.

It used to be that before the page got updated, his wiki page was…really scant (go wayback machine his jan ‘22. Like the picture used for him was literally a drawing.) weirdo.

I just watched too much wendigoon, nexpo and lemmino, fnaf stuff the past week. Safe to say i wasnt really sleeping well.

Lol. https://www.redbull.com/gb-en/f1-wrc-f3-motorsports⠀⠀⠀

I like to think the vessels are made from the same stuff as gemjam’s reset @ ao3. Great oneshot and has lead to perma rb-drivers-are-experiments brainworms.

#writing#long post#like extremely long post#i can shut the voices in my head now. here's your dumb story#consider putting dot flow's ost on play because that was my brain the whole time.

3 notes

·

View notes

Text

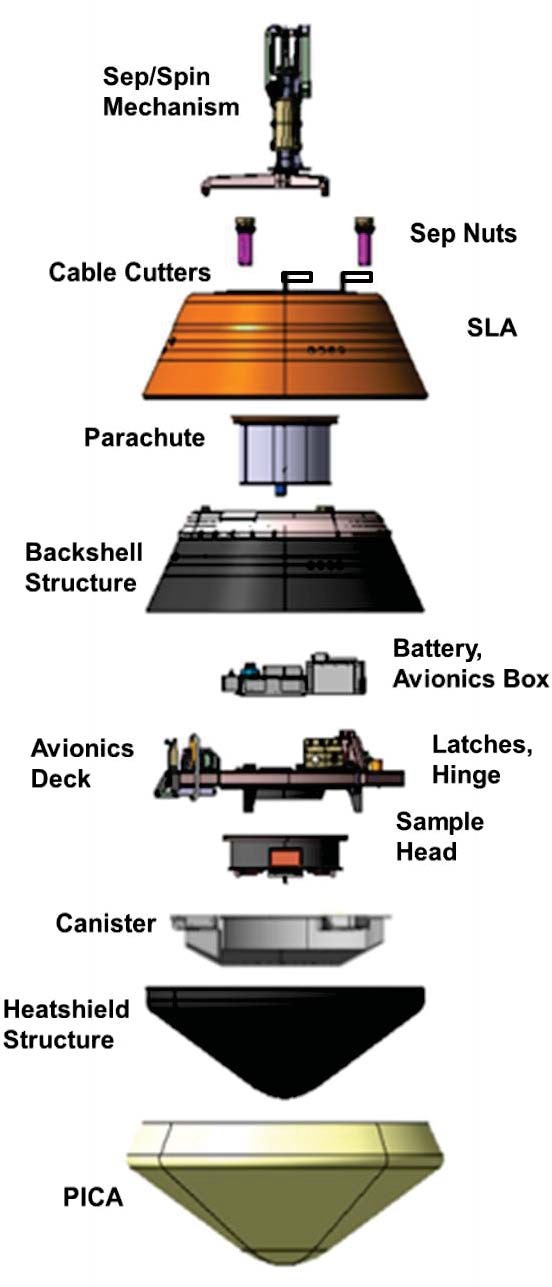

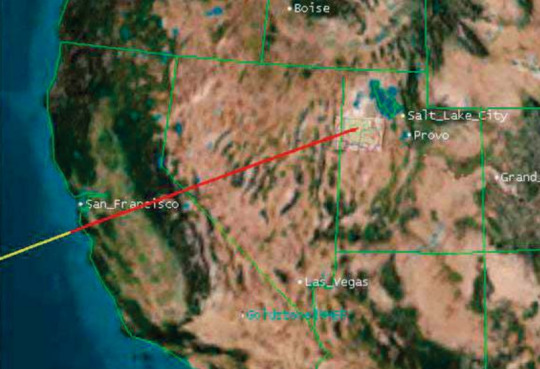

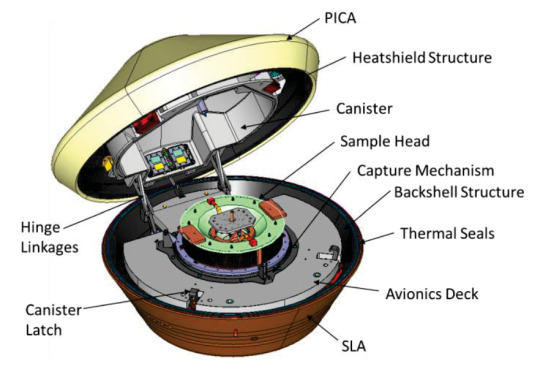

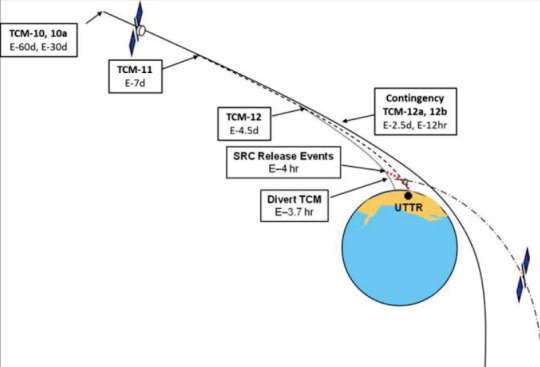

The Sample Return Capsule (SRC) will land today in the Utah Test and Training Range, south west of Utah City.

The OSIRIS Rex (Origins, Spectral Interpretation, Resource Identification, Security, Regolith Explorer) will release the SRC capsule at 11:42 BST (the spacecraft itself will then fire its engine to avoid Earth at 12:02 BST to fly-by at a distance of 485mi so it can continue on another mission). The SRC capsule will enter the Earths atmosphere at 15:42 BST at 12km/sec (feature than an Apollo/Orion reentry from the Moon) and will experience a deceleration of some 32g.

11:42BST (04:42MDT) E-04:00:00 SRC release

12:02 (05:02) E-03:07:00 OSIRIS Rex divert TCM burn (flyby 485mi)

15:00 (08:00) LANDING COVERAGE NASA TV

15:42 (08:42) 14:38:28UT E-0 Entry Interface

E+00:00:51 Maximum heating

E+00:00:61 Maximum G (31.8G)

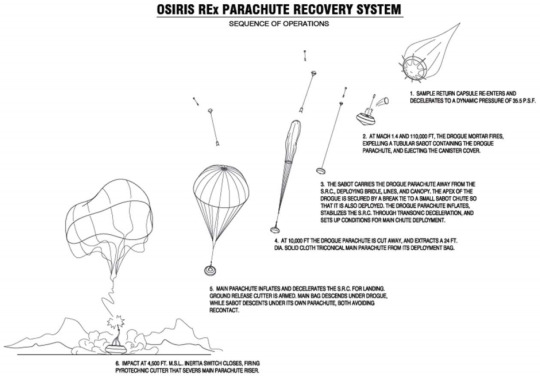

* At 110,000ft and mach 1.4 drogue chute mortor fires. ejecting the canister cover and expelling a tubular sabot containing the drogue chute.

* Sabot chute deploys pulling out bridle, lines and canopy of drogue chute

E+00:02:25 Drogue Chute Deploy

* Drogue chute inflates, sabot and its chute detach via break tie

* 10,000ft drogue chute detach pulling out 24ft diameter main parachute from its deployment bag

E+00:07:06 Main Chute Deploy

* Main chute inflatesE+00:13:05 Touchdown

Pyrotechnic cutter severs main parachute riser

The recovery team will arrive in four helicopters, first a Lockheed Martin safety engineer will approach the capsule and measure the capsules temperature remotely to ascertain if it is safe to approach, next the atmosphere will be sampled and the area around the capsule will be inspected for any potential hazards.

Them a team from the University of Arizona lead by Principle Investigator Dante Lauretta will cordoned off the area around the Sample Return Capsule (SRC) with flags to denote a keep-out zone and then conduct environmental sampling in that area to build up a library of anything, air, soil, organic matter etc, which could possibly have contaminate the asteroid samples during the landing and recovery.

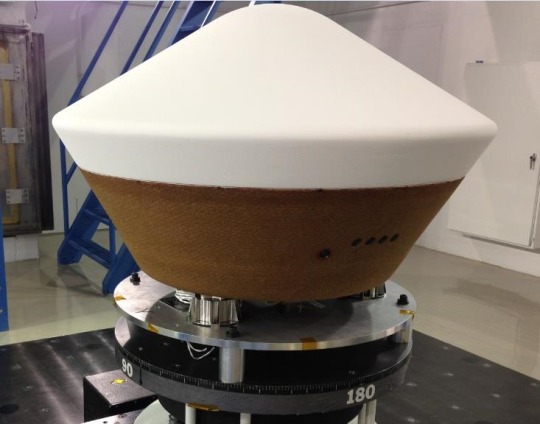

Once the capsule, weighing 45kg (100 lb), is ready for transport it will be lifted by two people into a metal transport crate and wrapped in multiple layers of Teflon and a tarpaulin. Next the wrapped crate will be fitted with a cargo harness and secured to a lift cable.

This will be attached to a hired Bell Jet Ranger helicopter (in rehearsal's anyway), as a slung load and flown to a hanger at Hill Air Force Base (the range HQ) equipped with a clean room (tent like structure in this case).

There the capsule will be opened and the sample canister will be extracted. The day after both the sample canister and the capsule will be flown to NASA’s Johnson Spaceflight Centre in Houston for storage and from there the sample will be divided and distributed to science investigator teams around the world.

Coverage on NASA TV from 3pm BST (10:00am EDT)... (the picture of the capsule under a parachute is from the recovery rehearsal conducted on 23 August 2023 which was dropped from a helicopter fro the rehearsal)

2 notes

·

View notes

Text

Facade Inspection San Francisco

RAS Engineering, PA specializes in facade inspection services in San Francisco. Our team of experts ensures the safety and reliability of your building's exterior. Contact us today at (888) 343-0713 for a thorough and professional inspection.

#Local Law 11 Inspection#Facade Inspection San Francisco#Milestone Inspection Florida#Structural Integrity Reserve Study#Energy Audit San Francisco#Building Recertification Florida#Facade Inspection Jersey City#SB 4-d Milestone Inspection#Energy Audit New York#Structural Recertification#Structural Safety Inspection Engineer#Exterior Wall Inspector New York#Facade Inspection Engineering#Building Structural Recertification#Facade Inspection New York#Exterior Walls And Enclosures Inspection Chicago#Parking Structure Inspection#Structural Inspection New Jersey

0 notes

Note

Spoiler!

“This is why you never build on top of a sinkhole,” Lefty spoke, “I would love to speak to the building engineers and know how much Fazbear Entertainment paid them to break several construction laws.”

“Several?” Gregory asked.

“First law they’ve broken, they most certainly did not contact the appropriate department to make sure the ground was stable enough to build a structure this large. Normally when building a large structure, you have to get an inspector from the environment department and they run some tests then they have declared it safe for construction to begin. The larger building puts weight on the already weak soil and it further compromises it, which is why I know this wasn’t tested, an inspector would have declared it unsafe,” Lefty froze then jumped across to the next beam he could see.

Freddy followed, Lefty then spoke again, “Second, they have certainly violated the mandatory reporting of any ground collapse, if a sinkhole occurs, it must be reported to the local department of public health and safety, not to mention OSHA, sinkholes are uncontrollable and they keep growing larger, this building would be closed down as a result. Lastly the building itself was definitely never inspected, a building this big? It’s mandatory for an inspector to come out and survey the structure approximately every six months, they have to check any damages on walls, plumbing pipes, steam pipes, flooring, anything of the sort.”

“How are you so knowledgeable?” Gregory asked.

“Helpy reads law books when he’s bored. When he finds interesting laws he’ll read them to me.”

“Helpy must be boring.”

“Gregory!” Freddy said in a disapproving way.

“Well kids find law boring, don’t fault him for that, Helpy’s actually more the type who likes to tie balloons to himself to make himself fly, it takes twenty helium balloons to lift him off the ground for the record.”

11 notes

·

View notes

Text

ABL stands out in creating sustainable Parks & ABC Water Design, promoting eco-friendly solutions. They prioritize safety through Periodic Façade and Structural Inspections, ensuring building integrity. With extensive experience in Structural and Geotechnical Design, they tackle complex engineering challenges. Their expertise includes Temporary Works and Geotechnical Engineering, delivering robust and innovative solutions.

2 notes

·

View notes

Text

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

Has the Brooklyn Bridge ever undergone significant renovations?

The Brooklyn Bridge, an iconic symbol of New York City, stands as a testament to engineering brilliance and architectural marvel. Since its completion in 1883, the bridge has played a crucial role in connecting the boroughs of Manhattan and Brooklyn, witnessing the evolution of the cityscape over the decades. In its long and storied history, the Brooklyn Bridge has indeed undergone significant renovations to ensure its structural integrity and adapt to the changing needs of a bustling metropolis.

Initial Construction:

Designed by renowned engineer John A. Roebling and completed by his son Washington Roebling, the Brooklyn Bridge was a groundbreaking feat of engineering in its time. However, even with its sturdy construction, the bridge needed to adapt to the increasing demands of a rapidly growing city.

Early Renovations:

In the early 20th century, several renovations were undertaken to enhance the bridge's stability and accommodate the ever-increasing vehicular and pedestrian traffic. The original wooden walkway was replaced with a more durable concrete surface, and the bridge's cables and support structures were reinforced to meet modern safety standards.

Mid-20th Century Upgrades:

As the mid-20th century dawned, the Brooklyn Bridge faced another wave of renovations. The emergence of automobiles as a dominant mode of transportation prompted the need for wider lanes and reinforced roadways. The bridge's signature Gothic towers underwent meticulous restoration to preserve their historic charm while ensuring they could withstand the test of time.

1980s Rehabilitation:

In the 1980s, the Brooklyn Bridge underwent a comprehensive rehabilitation project to address the effects of wear and tear from decades of heavy use and exposure to the elements. The project included the replacement of deteriorating stones, repainting of the bridge's steel components, and the installation of modern lighting to enhance visibility and safety.

Post-9/11 Precautions:

In the aftermath of the tragic events of September 11, 2001, the Brooklyn Bridge, like many other landmarks, became a focus of heightened security measures. The city implemented additional safety features, including surveillance systems and increased police presence, to safeguard this critical piece of infrastructure.

Contemporary Maintenance:

Even in the 21st century, ongoing maintenance is crucial to preserving the Brooklyn Bridge for future generations. Regular inspections, repairs, and technological upgrades ensure that the bridge continues to serve as a vital transportation link while retaining its iconic status.

Conclusion:

The Brooklyn Bridge stands not only as a physical link between boroughs but also as a symbol of resilience and adaptability. Over the years, the bridge has undergone significant renovations to keep pace with the evolving needs of a dynamic city. From its initial construction in the 19th century to the comprehensive rehabilitation efforts of the 1980s and the ongoing maintenance in the present day, the Brooklyn Bridge remains a testament to the commitment of New Yorkers to preserve their heritage and ensure the safety of this architectural masterpiece.

#new york city#new-york#new york#newyork#nyc#ny#manhattan#urban#city#usa#United States#buildings#travel#journey#outdoors#street#architecture#visit-new-york.tumblr.com#Bridge#Brooklyn Bridge

272 notes

·

View notes

Note

Idea 3: Pizzaplex is an engineering disaster waiting to happen.

An idea that I don't see brought up at all, is the idea that the Pizzaplex is not constructed well.

Remember in FNAF 6 when the tutorial unit said this?

"There may be times when you purchase something of questionable quality, and we don't blame you. Cutting corners is just good business."

Keep this statement in mind while I bring up my next point. As someone who's taken an engineering class, when you are constructing a building, there are a VERY large number of codes (rules) that you need to follow for every conceivable part of it.

Fazbear Entertainment would probably find it a lot cheaper just to pay off the people inspecting the plex than to actually put money into making sure everything is up to code.

They would also try to construct the building as cheaply as possible, trying to "cut corners" wherever they could. They use substandard materials and contractors that don't double-check their work. They built the mall itself over the subterranean remains of their old restaurant, despite this making the ground very unstable.

This all works in my mind because Fazbear Entertainment has been proven to follow the "be as cheap as possible" and "maximize profits by any means necessary" approaches many times in the past.

Here is just one example of a code being violated, according to Section 1006.2.1.1 of Utah Building Codes, "Three exits or exit access doorways shall be provided from any space with an occupant load of 501 to 1,000. Four exits or exit access doorways shall be provided from any space with an occupant load greater than 1,000." We only see 2 public exits in the game, and the Pizzaplex likely holds well over a thousand people at any one time. What's worse is that one of the exits, the only one designated for emergencies, requires a VIP pass in order to be used.

If Fazbear Entertainment is willing to do this to cut costs, who knows what else they have done?

It's why, in my mind, I don't have Gregory live at the pizzaplex after the 3-star ending. Freddy would calculate that it is statistically safer for Gregory to live in his box than at the plex. He instead lives with Vanessa, creating opportunities for them to grow closer.

BTW This has happened in real life, even down to the shoddy construction and profit maximization. It was the Sampoong Department store collapse. Informative Link

Oh interesting!

But yeah it's canon that the Plex is a disaster. The track in Roxy's Raceway won't lay properly because the ground is unstable, the walls are thin enough for an assisted go-kart that probably can't reach the speeds necessary to do this, can break through walls and the only durable parts of this place seem to be where the animatronics are not allowed to go.

That being said, they did just put a big stop sign over a picture of Monty on chain link fences to keep him out and look how well that worked.

Also, generators in soft play structures? In a daycare? Cool game idea! Not great life idea!

But yeah this is something I've brought up as side points in some AUs and stuff of mine. The place is built on what seems like mines and caverns that are being filled with the waste from the Plex in order to probably cut costs on waste disposal. This place is a fucking health and safety nightmare.

8 notes

·

View notes

Text

Most men are not aware of what and how a Temperature pressure relief valve is or does

The water heater, a home inspection life safety issueHome inspection in Gravenhurst, Bracebridge and Orillia can be very interesting due to the wide variety of structures and home styles. I inspect Log homes to ultra modern concrete and glass homes and everything in between.

When it comes to inspecting cottages throughout Muskoka they run the gamut from 200 sq ft thrown up basic shelters to very large multi structure estate homes. While the basic premise behind home inspections is providing the client with peace of mind in the decision making process with information on any material defects in the home there are safety issues that come up as well. Most safety issues , like the rest of the report are confidential to the client. It is the client’s home inspection, they pay for the report and only they have the right to its contents. On occasion a life safety issue emerges during the inspection and that type of issue I inform my clients I would report to the sellers Real Estate agent or have the clients agent report it to them.

One such safety issue I come across all too often in my home and cottage inspections is the incorrect installation of the hot water heater.Most homeowners and handy men are not aware of what and how a Temperature pressure relief valve is or does. I must confess that despite having installed many electric hot water heaters myself according to manufactures directions ( yep I am apparently one of the few guys who reads them all. ) I too was unaware of the deadly potential these items have in the home. Until I undertook my home inspection training through Carson Dunlop Engineering Home Inspection Program I viewed hot water heaters as a simple device pretty much anyone could install safely. That viewpoint changed as I came to understand the relationship between the sudden release of steam energy, and the role the Temperature Pressure Release Valve on the hot water heater plays in preventing the buildup of steam energy in the first place. Wholesale Solenoid Valve Here I am going to do something unusual for a blog articleThis is a site I would like you to visit before going on, it is a video from the television series Mythbusters and it illustrates the explosive power of the hot water tank.

In the video they have removed the safety mechanisms to force the result for the show but failure of the secondary safety or a lack of it could and has produced the same result in homes. After you visit and view the video come back and I will tell you about the safety mechanisms and what I find that is a life safety issue when inspecting homes and cottages.

2 notes

·

View notes