#Silica Sand Mining

Text

Arrow Smith and VRX Silica: Pioneering Sustainable Silica Sand Mining

Arrow Smith and VRX Silica have emerged as industry leaders in the field of sustainable silica sand mining. With a strong commitment to environmental responsibility and innovative practices, they are revolutionizing the way mining operations impact the ecosystem. In this article, we explore the accomplishments and milestones of Arrow Smith and VRX Silica's Arrowsmith North Silica Sand Project, shedding light on their sustainable initiatives and the path they are paving for the future.

Environmental Review Document Approval: A Turning Point for Arrowsmith North Project

DWER's approval of the Environmental Review Document (ERD) marks a significant milestone for Arrow Smith and VRX Silica.

The commencement of the Public Environmental Review (PER) period reflects their commitment to transparency and environmental responsibilities.

VRX Silica's proposed unique rehabilitation method for the mined area showcases their dedication to native vegetation regeneration.

Milestones in the Approvals Process: Demonstrating Dedication and Compliance

VRX Silica's previous confirmation from the Commonwealth Department of Climate Change, Energy, the Environment, and Water highlights their commitment to meeting regulatory standards.

The Environmental Protection Authority's assessment and approval of the Environmental Scoping Document (ESD) indicate the project's progress.

The introduction of the Vegetation Direct Transfer (VDT) rehabilitation methodology underscores VRX Silica's innovative approach to site restoration.

Moving Forward: Public Environmental Review and Response

The completion of the four-week PER period initiates the collection and review of public submissions by the Department of Water and Environmental Regulation.

VRX Silica's diligent response to the submissions demonstrates their commitment to engaging with stakeholders and addressing concerns.

The compilation of an assessment report by the Environmental Protection Authority, containing recommendations for the Western Australian Environment Minister's decision, represents a crucial milestone.

Investor Outlook: Transparent and Responsible Development

VRX Silica's achievements in the approvals process for the Arrowsmith North Silica Sand Project reinforce their dedication to responsible development.

The significant increase in VRX Silica's share price and its market capitalization exemplify investor confidence in the company's sustainable practices.

VRX Silica's focus on four Western Australian silica sand projects, including the Arrowsmith North and Arrowsmith Central projects, highlights their commitment to long-term growth and positive environmental impact.

Conclusion:

Arrow Smith and VRX Silica are leading the charge in sustainable silica sand mining, setting new industry standards through their commitment to environmental responsibility. With their innovative practices, engagement with regulators, and dedication to stakeholder satisfaction, they are reshaping the future of mining. As the Arrowsmith North Silica Sand Project progresses, their achievements serve as a testament to the transformative power of sustainability in the resource extraction sector.

#Arrow Smith#VRX Silica#Arrowsmith North Silica Sand Project#Environmental Review Document#Public Environmental Review#Sustainable Mining#Silica Sand Mining#Rehabilitation Methodology#Environmental Responsibility#Environmental Protection Authority#Department of Water and Environmental Regulation#Mining Approvals Process#Native Vegetation Regeneration#Environmental Scoping Document#Vegetation Direct Transfer#Stakeholder Engagement#Investor Outlook#Resource Extraction#Sustainability#Market Capitalization#Share Price#Western Australia#Ecosystem Impact#Innovative Practices

0 notes

Photo

Explain Industrial Sand VS Construction Sand Mining

Sand mining in Rajasthan has been taking place for more than 100 years now, but the petroleum industry's growth has given the high demand for sand. Industrial sand refers to the high-purity silica sand, where the size of the grain is also an important feature. Construction sand has fine particles that make the construction process very easy. Here we are sharing detailed information about Industrial sand and Construction sand in Jaipur.

#high-purity silica sand#construction sand in Jaipur#sand suppliers in Jaipur#mining plant in Jaipur#sand supplier in Rajasthan

0 notes

Text

𝓱𝓾𝓷𝓰𝓮𝓻 𝓪𝓷𝓭 𝓱𝓮𝓪𝓻𝓽 𓈒 ˖ ࣪ 𝜗𝜚

boothill x f!reader . unspecified relationship ノ unspoken confessions (?) ノ reader is implied to be his engineer ノ he calls you poppet ノ something short and hopefully sweet for our dashing ranger (〃ω〃) ꒱ྀི 912 wc

“you know, i’m most jealous of people who have houses to live in.”

your muscles tense upon hearing boothill’s words and the crack to his voice as he speaks them. he sounds more human than ever.

the metal plates of his chest are turned open, outwards, baring all his inner workings for you to inspect for errors. tangled wire and frayed heart. a cold, lorn ancestor pumping blue blood.

“why?”

“i mean, it’d sure be nice to have a place to come back to at the end of the day. kick my feet up ‘nd pop open a bottle of bart 17 years… strum some tunes ‘nd sing to the moon. fudge, having a bed to lay down in don’t sound so bad, either.” he scoffs, takes a swig of the malt juice sitting next to him on the lab bench. sets it back down, smiles at the floor— a wistful smile at that, you notice. one that doesn’t near reach his bionic eyes, one that crackles and decays at the edges of his lips like oxidising iron.

the grip on the soldering gun in your hands slackens the slightest of bits, your smile mirroring his own. “that sounds rather lovely.”

“y’know what else would be rather lovely? a pretty little lady to make that house a home.”

there’s a hitch to your breath when you realise how boothill has leaned in to invade your space, broad shadow looming over you and diesel oil laying thickly on the membrane of your nostrils. some feeling bordering the line between trepidation and earnest expectation fills your gut as you sense his gaze on you, and you do your best to avoid it, fighting the urge to hold the man you’ve grown so terribly fond of to your chest, as tender as your own heart.

(you would let him live there, in your heart, if he so desired. you would wish for it, even.)

“perhaps she’d be an engineer of sorts— patch me up when my missions go awry, put all of my broken pieces back together again…”

“oh… yeah?” your voice wavers, yet your hands remain as steady as ever, welding two wires together.

“mhm,” boothill drawls, leaning into you further. the space between the tip of his nose and your forehead feels infinitesimal. “i’d have her back, just as she’d have mine. i’d take care of her, just as she does me… kiss her ‘nd love on her, make her the happiest woman in all the galaxy.”

his voice melts into something nectary and bedroom-soft the more he speaks of this woman, so cloyingly sweet that it gives your lungs and limbs a warm ache, warmer than silica from the sweetest of sands. you find your sinews loosening at the feeling, heart slowing— his shoulder looks to be an enticing spot to rest your head.

you yearn to share this warmth with him.

so, finally, you allow yourself to meet the ranger’s eyes, blinking in surprise when you realise just how close he’d gotten over the past minutes. close enough to be able to make out the yawn of craters and mountains decorating his slate irises, the near faded freckles over pale meat that you long to brush your thumbs over. boothill, too, seems to startle as you look up at him, the little smirk once etched on his lips falling into a small pout of awe.

“and… and she’d have these eyes, the most darlin’ dewy eyes that’d just— gosh— they may as well have gone and knocked my heart straight outta whack.”

these eyes, your eyes, chocolate sweet eyes that are teeming with about the same paradoxical innocence and percipience as a doe’s— boothill doesn’t think he’ll ever get used to them. how looking into them rouses his mechanical heart like no other, seizes his entire being with such a voracity that he thinks he just may blow a fuse.

the cyborg nearly remembers what it feels like to be hungry.

and born from the longing that chokes you is a generosity wherein you’re ready to offer anything, everything to him; you’d let him indulge in that hunger and have you without question.

there’s no hesitation in your response as you whisper, near inaudibly— he’s sure he wouldn’t have picked up on your mousy voice if it weren’t for prior enhancements you’ve made to his neuro chip. “maybe you should try asking her if she’ll join you. maybe… she’ll say yes.”

you finish your soldering job on his wires and seal shut the metal plates of his chest, letting your gloved hands linger there momentarily before bringing them up to cradle his face.

an odd sensation works its way under his flesh at the contact, sweet little tingles beneath his cheek, like cinnamon powder dusting over frothy milk. he’s quick to find a place of rest within your palms, the respite you give him with a tender smile, and boothill realises that this is more than enough.

he doesn’t need a house, when he’s already found a home in you.

“well, then,” huffing out a quiet laugh, he gently takes you by the waist with chromium fingers, soft lips finding the crown of your head. his body is of both hard and soft parts; metal and meat. “what say you, poppet?”

his hunger, too, has both hard and soft parts. head and heart, an immortal soul and human happiness.

“would’ja ride with this lone ranger ’til the end of the line?”

#𝓭𝓸𝓵𝓵𝓯𝓸𝓵𝓭𝓮𝓻 ⑅˚˖ ݁ ˓ ෆ#boothill x reader#hsr x reader#honkai star rail x reader#losing myself to delirium waah this was mostly just catharsis for me so im sorry if it sucks butt to you ! ! 。゚(゚´ω`゚)゚。

369 notes

·

View notes

Text

🔥 Fire Safety Tips — For Witches 🌞

I just want to share some of my tips, as someone who has been practicing witchcraft for almost 20 years, for working with fire (as it relates to safety):

🔥 Buy a cauldron : I use mine for burning herbs, incense, candles, paper, fabric etc. I have one with just salt in it that I use to burn my small tapered candles and incense. It’s one of the most useful tools in my practice.

“Can Salt Burn? No, salt does not burn. It can melt at an extremely high temperature (800°C/1472°F), but this is unlikely to happen in everyday surroundings. Salt is made up of sodium and chloride, which come together to form a highly reactive bond.”

🔥 Don’t burn candles for more than 4 hours : Even if you’re in the room the entire time, it’s recommended that you don’t burn a candle for longer than 4 hours.

“If you burn your candle for more than 4 hours at a time, carbon will collect on the wick, and your wick will begin to "mushroom." This can cause the wick to become unstable, the flame to get too large, your candle to smoke, and soot to be released into the air and around your candle container.”

🔥 When burning things like paper, in your cauldron, fill the bottom with sand first : I’ve found that it helps avoid any flames from getting too high or out of control.

“Because its primary constituent is silica (SiO2), which is already oxidized, sand cannot burn. This is why it works as an effective firefighting method, which can extinguish fires by cutting off the oxygen supply and absorbing flammable liquids.”

🔥 Make sure that you triple check that nothing in the immediate area of any open flame is combustible or flammable : This means don’t burn something on a plate that’s sitting on an alter cloth lol. Or don’t spray anything into the air (like perfume or air freshener) around an open flame.

Be safe witches :)

3K notes

·

View notes

Text

Two former Progressive Conservative cabinet ministers say their own government tried to push through a controversial silica sand mining project in Manitoba just days before the new NDP government was officially sworn in.

In the aftermath of the provincial election, former PC cabinet minister Kevin Klein says he got a phone call on Oct. 12 from his colleague Jeff Wharton – then minister of economic development, investment and trade.

Klein, who was the minister of environment and climate at the time, said Wharton asked him to sign a directive which would allow a license to be approved for Sio Silica.

"I immediately said no, I was not going to do that. In fact, I was quite disappointed and angry that I would even be asked to do something like that," Klein told CTV News.

Continue Reading

Tagging @politicsofcanada

#cdnpoli#canada#canadian politics#canadian news#progressive conservative party of canada#environmental justice#manitoba#mining#environmental protection

57 notes

·

View notes

Note

hello excellent dirt person. do you know anything about kaolin? i am curious if so, what the Dirt Person view on it would be

So the long and short of it is I have no view on it because kaolin is just, a thing that exists. I have no view on steel or grapes. They exist. There's a lot of commercial grade uses for rock and soil that lay people wouldn't anticipate but are entirely common within certain industries, from gravel and sand mining, to the mining of rocks and soils bearing certain clay minerals or rich in certain elements. Kaolin in particular has uses valuable to ceramics and the paper industry but I know very little about either of those.

However, I do know things about the clay mineral that is actually what's extracted from kaolinite and what an excellent opportunity to talk about phyllosilicates, aka, clays and micas!

I am, more technically speaking, an environmental soil chemist, and though I lean on the last one of those titles the least, here we're going to have to take a quick detour onto chemical bond angles and crystals. This is a very brief oversimplification but deeply relevant.

Atoms bind together in order to be more stable, but the bonds themselves are charged, and therefore repel each other. Imagine an atom as an orb with things sticking out of it:

If you have two bonds, as far apart on a circle means 360/2, so the bond angle will be 180, and they'll be on opposite ends (examples: CO2)

If you have three, 360/3 means 120, and so you get something that looks like a triangle.

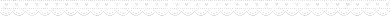

If you have four, then things get fun, because the previous two have been two dimensional shapes, and what you actually get instead is a three dimensional tetrahedron with an average bond angle of ~109. And when you get into silicates, tetrahedrons are your basic building block

If you have six, then your average bond angle is 90 degrees; imagine four in a square plane and two at the 'poles'. Remember these for later!

Silicates dominate our world. If carbon forms everything living, then silicon forms everything non-living. Over 90 percent of the earth's crust is formed by silicate minerals, which are as astounding diverse and varied as big brother carbon's molecules. This diversity comes in spite of the fact that silicon is near-exclusively bound in the form of the silica tetrahedron seen above.

Where we move from bond angles to crystals is the fact that each oxygen in a silica tetrahedron has two charges, meaning oxygen can be bound to two different silicon atoms, which creates a crystal lattice structure of repeating units of silica tetrahedra. Depending on how silca tetrahedra are linked together, you get the following structures:

(Fun fact! Quartz and Zeolites are some of the most chemically and mechanically stable minerals on earth, and the Tectosilicate arrangement is the exact same crystalline pattern that makes up diamonds. Anyways!)

Focusing down on phyllosilicates, the structures that form are vast molecule thin sheets of repeated chained circles of silica, which is just one of the many ways math that may seem abstract emerges in the natural world, as what forms as a result is a tesselation. Now although silicates are dominated by silica, they are not exclusively silica tetrahedra for the simple fact that the real world conditions in which these form are messy, but secondly, the tetrahedral shape means that in a sheet crystal, silica has leftover oxygens that it could share with other ions. And so what you get in nature is that phyllosilicates are not just sheets of silica tetrahedra, but are two to three layers of repeating tetrahedra/octahedral units bound to a silica backbone.

(src paper; good resource for those who want to know more)

Now these phyllosilicates, literally "sheet-silicates", are very strong and chemically resistant molecule thin layers. But the thing about being so strongly attached to itself means that the actual attraction between layers is governed by an entirely different form of chemical bond (IMFs, which we won't get into), and ranges from no real binding to tightly bound to weakly bound.

And finally, it's time to talk about kaolinite!

Kaolinite is the clay mineral named for kaolin, the rocks/sediment that bears a lot of it. Kaolinite, pictured above, has very uniform physical properties, is very chemically stable, is quite cheap, and has abundant material use.

But, time for a shock and a swerve, I spent all this time talking about clay minerals to talk about smectite instead! You fool!

Smectitic clays differ from kaolinite substantially in ways we won't get into, but the short answer of it is that bonds form between sheet layers, but weak bonds. Strong bonds will basically not really come apart and aren't an issue. No bonds aren't an issue. Weak bonds are an issue.

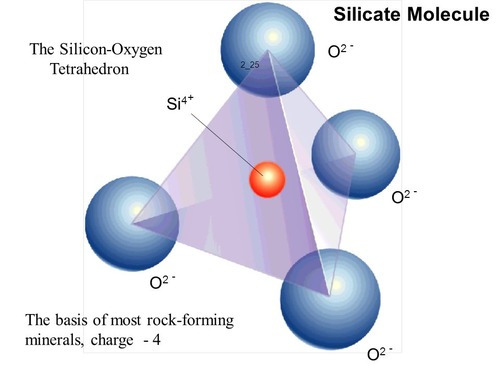

What weak bonds between layers leads to is a shrinking and swelling of clay layers over time, as water enters clay layers in the fall through spring, then leaves in the summer, causing the entire soil to shrink and swell with moisture, like thermal expansion joints on bridges but much more pronounced. This also leads to a lot of interesting soil properties, so much so there's an entire soil order named for soils with smectitic clays, the Vertisols.

What's shown here with the slickensides are literal smooth surfaces that form as large units of soil shrink-swell and rub against each other. Very strange stuff!

On the human scale, soils with vertic characteristics cause a lot of headaches in the places I grew up, meaning a lot of people in North to Central Texas spend time watering their lawns in deep summer heat to avoid foundations cracking. I've seen new homeowners in Texas who didn't know about it have their entire fence come down because of soil cracks, especially wood fences that catch the wind.

And that's how clay will ruin your foundation.

(PS: Clay mineralogy is foundational to soil chemistry but we'll get into that at a later date. To simplify: clay mineralogy is variable by geology and essentially serves as the most chemically active site in soils, but you kind of have to get real in the weeds on it and I do not have time to get into ion substitution and why every mineral's chemical formula looks like a fucking math equation just so I can talk about cation exchange capacity right now.)

15 notes

·

View notes

Text

Loch Aline to Puilladobhrain

Saturday 2nd September 2023

Off early past the silica sand mines and out into the South of Mull to catch the tide south. The promise of another lovely day... Headed over to Dunstaffnage marina just north of Oban but decided only to pause for lunch and take on water before heading out again. Easier said than done - we were blown off coming in and blown on getting out! An interesting spot with extremely interesting tides and eddies! We then enjoyed another lovely cruise down the Sound of Kerrera dodging the ferries in and out of Oban and in to Puilladobhrain anchorage (pronounced Puldohran!) on the northern tip of Seil. Very peaceful despite the other 10 boats in the anchorage!

2 notes

·

View notes

Text

Industrial Garnet Market Analysis: Key Players and Growth Prospects

Origin and Properties of Industrial Garnet

Garnet is a group of silicate minerals that forms through metamorphic processes deep within the earth. Their chemical composition makes them extremely hard and abrasion resistant. The garnet group includes almandine, spessartine, pyrope, grossular and uvarovite. Among these, almandine garnet which is an iron aluminium silicate mineral, is most commonly used for industrial applications due to its high hardness rating of 6.5–7.5 on Mohs scale. Other desirable properties of industrial garnet include chemical inertness, thermal stability and angular crystalline structure which allows it to perform well as an abrasive.

Applications in Abrasive Blasting and Waterjet Cutting

Garnet's hardness and angular crystalline shape make it ideally suited for abrasive blasting applications. Finely ground garnet is used as the abrasive media in various blasting processes like grit blasting, sand blasting and micro blasting. It is used to clean metal surfaces, degrease parts and prepares surfaces for painting or other coatings. In waterjet cutting, high pressure jets of water mixed with garnet abrasive are used to cut through even the hardest of metals like steel and titanium with extreme precision. Garnet isPreferred over other abrasives like silica and aluminum oxide for waterjet cutting as it is non-toxic and pose no health hazards.

Role in Abrasive Powder and Paper Products

Finely crushed garnet finds use in the manufacture of abrasive powders in varied grain sizes for uses like grinding, honing and polishing metal and stone surfaces. It is a key ingredient in manufacturing coated abrasives like sandpaper, grinding discs and belts etc. The angular structure and hardness of garnet particles provides the abrasiveness for removing material when used with coated abrasives. Garnet powder is also used as a filler in the manufacture of grinding wheels, cut-off wheels, grinding stones and honing sticks where it enhances their abrasiveness and performance.

Use in Cleaning and Blast Finishing

Due to their hardness and durability, garnet particles effectively remove dirt, stains, rust, coatings and even smooth rough surfaces. They are thus widely used in blast finishing of surfaces to achieve varied grades of roughness for applications like preparing metal surfaces for painting. Garnet particles are also used in cleaners for domestic and industrial applications to remove scale, stains and other dirt from surfaces like tiles, sanitary ware, glass, vehicle bodies etc. Their safety for the environment makes garnet an attractive alternative to other harmful abrasives for a host of cleaning purposes.

Key Global Producer and Exporter - India

India holds significant garnet reserves globally and is one of the leading producers and exporters of industrial garnet to markets across the world. Major garnet deposits are found in the states of Andhra Pradesh and Rajasthan which are mine to extract almandine-pyrope hybrid garnet variety. Stringent mining norms and emergence of organized players has ensured quality supply. India exports over 80% of its total refined garnet, primarily to the USA and Europe where it finds application in abrasives, waterjet cutting, drilling and surface preparation industries. With their unique abilities, garnet from India is poised to continue supporting key modern industries globally.

0 notes

Text

The Versatility and Benefits of Crushed Glass Media

Crushed glass media has emerged as a revolutionary material across various industries due to its versatility and eco-friendliness. From sandblasting to water filtration, this recycled material is not only cost-effective but also sustainable, making it a preferred choice for many applications. In this blog post, we'll delve into the multiple uses of crushed glass media, its advantages, and how it stands out compared to traditional materials.

The Multifaceted Applications of Crushed Glass Media

Crushed glass media is widely used in abrasive blasting, where it serves as an effective substitute for traditional sandblasting materials like silica sand and coal slag. Its angular particles make it ideal for surface preparation, providing a cleaner and smoother finish. Unlike silica sand, which poses health risks such as silicosis, crushed glass is non-toxic and safe for operators, enhancing workplace safety.

Another notable application of crushed glass media is in the construction industry. It is used as an aggregate in concrete and asphalt, contributing to the strength and durability of the final product. The reflective properties of glass particles also improve the aesthetic appeal of concrete surfaces, making them a popular choice for decorative concrete applications. Moreover, using recycled glass in construction helps reduce the environmental impact by diverting glass waste from landfills.

Environmental Benefits of Using Crushed Glass Media

One of the most significant advantages of crushed glass media is its positive impact on the environment. This material is made from recycled glass, which means that it helps reduce the amount of glass waste that would otherwise end up in landfills. By repurposing glass into useful products, we can minimize the need for new raw materials and decrease the energy consumption associated with glass manufacturing.

The production of crushed glass media also generates fewer carbon emissions compared to traditional sandblasting materials. The process of crushing and recycling glass requires less energy than mining and processing virgin materials. This reduction in energy consumption translates to a smaller carbon footprint, making crushed glass media a more sustainable choice.

Cost-Effectiveness and Performance Advantages

In addition to its environmental benefits, crushed glass media offers significant cost savings. Its durability and efficiency mean that it can be reused multiple times before needing replacement. This longevity reduces the frequency of media replacement, lowering overall operational costs. For instance, in abrasive blasting, the high recyclability of crushed glass media ensures that fewer resources are needed over time, providing substantial economic advantages.

Conclusion

Crushed glass media stands out as a versatile, eco-friendly, and cost-effective material with numerous applications across different industries. Its use in abrasive blasting, water filtration, and construction highlights its multifunctional nature and the benefits it brings in terms of performance, safety, and sustainability. By choosing crushed glass media, industries can not only enhance their operational efficiency but also contribute to environmental conservation.

0 notes

Text

Arrowsmith North Silica Sand Project: A Milestone in Environmental Approvals

VRX Silica Limited (ASX: VRX) has reached a significant milestone in its Arrowsmith North Silica Sand Project as the Department of Water and Environmental Regulation (DWER) approved the publication of the Environmental Review Document (ERD). This approval marks the beginning of a four-week Public Environmental Review (PER) period, showcasing VRX Silica's dedication to transparency and environmental responsibility.

Starting on June 19th, 2023, the public environmental review process allows stakeholders to provide their comments and feedback, which VRX Silica is obligated to address. Following the PER, the Environmental Protection Authority of Western Australia (EPA) will prepare an assessment report with recommendations for the Western Australian Environment Minister's review and consideration for project approval.

Managing Director Bruce Maluish expressed his delight, stating, "We are delighted that the environmental approvals process has moved to this next important stage. This is a significant milestone for the process." Maluish further highlighted VRX Silica's unique rehabilitation method for the mined area, emphasizing the potential economic contribution to the Irwin Shire and Western Australia as a whole.

With over 40 years of involvement in the mining industry, Bruce Maluish brings a wealth of experience and expertise to VRX Silica. Holding a bachelor's degree in Applied Science in Surveying from the Western Australian Institute of Technology, Maluish has held vital positions in esteemed organizations throughout his career. His extensive knowledge and experience in resource sectors make him a valuable asset to VRX Silica.

The Arrowsmith North Silica Sand Project's approvals process has witnessed several milestones. VRX Silica previously obtained confirmation from the Commonwealth Department of Climate Change, Energy, the Environment, and Water for an accredited assessment. The company has conducted extensive environmental studies since 2017, demonstrating its commitment to meeting regulatory standards.

The project was referred to the EPA for assessment under the Environmental Protection Act 1986 (WA) Act, which determined that a Public Environmental Review was necessary. VRX Silica's Environmental Scoping Document (ESD) received approval from the EPA in March 2022, signifying progress in the project's assessment.

An essential feature of VRX Silica's proposal is the unique Vegetation Direct Transfer (VDT) rehabilitation methodology for site restoration in the Arrowsmith North Silica Sand Project. Throughout the approval process, VRX Silica has actively addressed information requests from DWER, culminating in the acceptance of the final ERD on June 8th, 2023.

Moving forward, the Department of Water and Environmental Regulation will collect and review public submissions during the four-week PER period, and VRX Silica will diligently respond to these submissions. The Environmental Protection Authority will then compile an assessment report with recommendations for the Western Australian Environment Minister's decision on the Proposal's approval. The issuance of a Ministerial Statement upon successful approval will signify a crucial milestone for the project.

Investors have shown confidence in VRX Silica, reflected in the 31.818% jump in the company's share price during a single trading session on June 9th, 2023. As of that date, VRX Silica's market capitalization stood at AUD 61.64 million, with a share price range of AUD 0.093 to AUD 0.190.

VRX Silica, listed on the ASX, is a leading pure-play silica sand company focused on advancing its portfolio of four Western Australian silica sand projects. In addition to the Arrowsmith North Silica Sand Project, the company is also developing the Arrowsmith Central Silica Sand Project, the Muchea Silica Sand Project, and the Boyatup Silica Sand Project.

For the latest updates and details on VRX Silica and its projects, visit the official website at https://vrxsilica.com.au/. With its commitment to responsible and transparent development, VRX Silica is poised for continued success in the silica sand industry.

#Arrowsmith North Silica Sand Project#VRX Silica Limited#environmental approvals#Environmental Review Document#public environmental review#Bruce Maluish#rehabilitation methodology#Western Australian Environment Minister#Environmental Protection Authority#mining industry#resource sectors#sustainability#transparency#responsible development.

0 notes

Link

Silica sand, also known as industrial sand, comprises Silicon Dioxide. The Silica sand's physical appearance distinguishes it from other regular sand. Silica sand is found in a wide range of shades, unlike the brown color sand used for concrete applications.

Read Post: https://bit.ly/3fcD6pv

0 notes

Text

Colloidal Silicon Dioxide Prices Trend, Database, Chart, Index, Forecast

Colloidal Silicon Dioxide Prices, a versatile and indispensable compound, plays a significant role across various industries, ranging from pharmaceuticals to food and beverage, cosmetics, and beyond. As its demand continues to surge, the market dynamics governing its prices have become increasingly intricate. The pricing of colloidal silicon dioxide is subject to multifaceted influences, including raw material costs, manufacturing processes, supply chain disruptions, and market demand fluctuations.

Raw material costs form the bedrock of colloidal silicon dioxide pricing. Silicon dioxide, the primary ingredient, derives from silica, which can be obtained from various sources such as sand, quartz, and rice husk ash. Fluctuations in the prices of these raw materials, driven by factors like mining regulations, environmental policies, and global supply-demand imbalances, directly impact the cost of colloidal silicon dioxide production. Consequently, any disruptions or fluctuations in the supply of silica can ripple through the pricing structure, affecting end-users and manufacturers alike.

Manufacturing processes also exert a significant influence on colloidal silicon dioxide prices. The production of colloidal silicon dioxide involves intricate chemical processes, including hydrolysis and condensation of silicates, followed by purification and stabilization. These processes require precise control of parameters such as temperature, pressure, and reactant concentrations, all of which contribute to the overall production costs. Moreover, advancements in manufacturing technologies and process efficiencies can either mitigate or exacerbate cost pressures, thus influencing pricing trends in the market.

Get Real Time Prices of Colloidal Silicon Dioxide: https://www.chemanalyst.com/Pricing-data/colloidal-silicon-dioxide-1246

Supply chain dynamics further shape colloidal silicon dioxide prices. Given its widespread use across industries, any disruptions in the supply chain, whether due to transportation bottlenecks, geopolitical tensions, or natural disasters, can lead to supply shortages or delays. Such disruptions often trigger price spikes as manufacturers scramble to secure adequate supply or explore alternative sources. Additionally, the consolidation of suppliers or the emergence of new market players can introduce competitive pressures, thereby influencing pricing dynamics in the long run.

Market demand serves as the ultimate arbiter of colloidal silicon dioxide prices. As industries evolve and consumer preferences shift, the demand for colloidal silicon dioxide fluctuates accordingly. For instance, the pharmaceutical industry's increasing emphasis on drug formulation and delivery systems that incorporate colloidal silicon dioxide as a key excipient has driven up demand in recent years. Similarly, the growing popularity of functional foods and dietary supplements has spurred demand from the food and beverage sector. These demand-side dynamics not only influence current prices but also shape future pricing expectations, driving investment decisions and market strategies.

In addition to these fundamental factors, external macroeconomic conditions can also impact colloidal silicon dioxide prices. Currency fluctuations, inflationary pressures, and regulatory changes can introduce volatility and uncertainty into the market, influencing pricing decisions across the value chain. Moreover, global megatrends such as sustainability and carbon neutrality are increasingly influencing consumer preferences and corporate strategies, thereby reshaping the competitive landscape and pricing dynamics of colloidal silicon dioxide and related products.

Navigating the complex landscape of colloidal silicon dioxide pricing requires a nuanced understanding of these interconnected factors. Manufacturers, distributors, and end-users alike must remain vigilant, monitoring market trends, supply chain risks, and regulatory developments to make informed decisions and mitigate pricing volatility. Collaboration across the value chain, from raw material suppliers to end-consumers, can foster resilience and agility, enabling stakeholders to adapt to changing market conditions and sustain long-term competitiveness.

In conclusion, colloidal silicon dioxide prices are shaped by a myriad of factors, including raw material costs, manufacturing processes, supply chain dynamics, market demand, and macroeconomic conditions. Navigating these complexities requires a holistic approach that integrates market insights, risk management strategies, and collaborative partnerships. By staying attuned to these dynamics and embracing innovation, stakeholders can navigate the evolving landscape of colloidal silicon dioxide pricing and unlock new opportunities for growth and value creation.

Get Real Time Prices of Colloidal Silicon Dioxide: https://www.chemanalyst.com/Pricing-data/colloidal-silicon-dioxide-1246

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Practical Uses and Benefits of Food-Grade Diatomaceous Earth

Food Grade Diatomaceous Earth from Seema Minerals & Metals stands out as a versatile, natural product. Seema Minerals & Metals is a renowned name in the mining and processing of various industrial minerals. The company ensures high-quality DE by adhering to stringent quality control measures and using advanced processing techniques. Known for reliable and consistent product quality, it is a trusted supplier in the industry.

Introduction to Diatomaceous Earth

Diatomaceous Earth (DE) is a naturally occurring, soft sedimentary rock that is easily crumbled into a fine white to off-white powder. Mainly composed of silica, which is a common component in sand and quartz. Food-grade DE typically contains 85-90% amorphous silica. There are two main types of DE: food-grade and industrial-grade. Food-grade DE is safe for human and animal consumption.

Benefits of DE Food Grade

Health Supplement:

Acts as a detoxifying agent, absorbing toxins, heavy metals, and parasites. It promotes a healthy digestive system by cleansing the digestive tract. Provides a natural source of silica, essential for healthy hair, skin, nails, and bones.

Pest Control:

Effective against a variety of pests, including fleas, ticks, bed bugs, and ants. Works by dehydrating and killing insects without the use of harmful chemicals. Non-toxic to humans and pets when used properly, making it a preferred choice for organic pest control.

Animal Health:

Acts as a natural dewormer for pets and livestock. It enhances the overall health of animals by improving digestion and nutrient absorption.

Household Uses:

Absorbs odours in trash cans, refrigerators, and pet areas. Mild abrasive properties make it an excellent cleaner for sinks, tiles, and other surfaces. Helps to control moisture in the home, preventing mold and mildew growth.

Applications of DE Food Grade

In Agriculture:

Improves soil structure and promotes healthy plant growth by increasing aeration and water retention. Used as a natural pesticide in organic farming, protecting crops from pests without harmful residues.

In Food Industry:

Used as an anti-caking agent in food products to prevent clumping. Effective in filtering impurities from beverages, including wine, beer, and juices.

In Cosmetics:

Used in facial scrubs and toothpaste for its gentle abrasive properties. Common in makeup and deodorants for its absorbent qualities.

In Pharmaceuticals:

Acts as an inert carrier for drugs and supplements. Used in the formulation of pills and capsules for its absorbent properties.

Environmental Benefits

The DE Food Grade provided by Seema Minerals & Metals benefits the environment in various ways:

Eco-Friendly:

DE is a natural and sustainable resource, causing minimal environmental impact during extraction and processing.

Biodegradable:

Fully biodegradable and does not contribute to pollution.

Inhalation Risk:

While food-grade DE is safe for consumption, inhalation of fine DE dust can cause respiratory issues. Proper protective equipment like masks should be used during handling.

Storage:

Should be stored in a cool, dry place to maintain its efficacy and prevent clumping.

Purchasing and Availability

Packaging Options:

Available in various sizes, from small consumer packages to bulk industrial quantities.

Distribution:

Widely distributed through various channels, including online platforms and physical stores.

Conclusion

DE Food Grade from Seema Minerals & Metals stands out as a versatile, natural product with numerous applications across health, agriculture, and household maintenance. Its effectiveness, combined with the company’s commitment to quality, makes it a valuable addition to any home or business focused on natural and eco-friendly solutions.

Experience the remarkable benefits of Food Grade Diatomaceous Earth in your health, home, and garden today. Discover how this versatile and natural product can transform your life with its multitude of applications. Whether you’re looking to improve your digestive health, tackle pest problems, or enhance your agricultural practices, our high-quality Food Grade Diatomaceous Earth is the perfect solution. Contact us now for your needs!

0 notes

Text

The Rise of AAC Block Factories in India: Paving the Way for Sustainable Construction

In the realm of construction, the push towards sustainable and eco-friendly building materials has led to the adoption of Autoclaved Aerated Concrete (AAC) blocks. In India, a country experiencing massive growth in infrastructure and housing development, AAC blocks have emerged as a popular choice. This is due to their lightweight, thermal insulation, fire resistance, and energy efficiency. The rise of AAC block factories in India not only aligns with the global trend of environmentally conscious construction but also presents unique opportunities and challenges in the Indian context.

Overview of AAC Blocks

AAC blocks are manufactured from natural ingredients including sand, lime, cement, water, and an aerating agent, typically aluminum powder. These components undergo a high-temperature autoclave process which results in the creation of air pockets within the blocks, giving them their lightweight and insulative properties. The final product is a building material that is about one-fifth the weight of traditional concrete, making it easier to handle and transport, while still providing significant structural integrity.

Growth of AAC Block Factories in India

The proliferation of AAC block factories in India can be attributed to several factors. Firstly, the Indian government’s initiatives to promote sustainable development have encouraged the construction industry to adopt greener practices. AAC blocks contribute significantly to this by reducing the overall carbon footprint of buildings. They require less energy to manufacture compared to traditional bricks and their lightweight nature reduces emissions related to transportation.

Secondly, the increasing cost of traditional building materials like clay bricks, coupled with environmental regulations restricting clay mining, has made AAC blocks an attractive alternative. Moreover, AAC blocks offer better earthquake resistance, which is crucial in a seismically active country like India.

Manufacturing Process in Indian Context

The manufacturing process in an Indian AAC block factory typically involves several key stages:

Raw Material Preparation: Silica-rich materials and lime are finely ground to produce a homogeneous mixture. Cement acts as a binder while gypsum helps in adjusting the setting time of the concrete.

Batching and Mixing: Ingredients are then batched and mixed with water and an aluminum powder paste which acts as the aerating agent. This mixture forms a slurry that is poured into molds.

Cutting and Curing: Once the slurry sets slightly, it is cut into blocks or panels using wire cuts or saws. These are then cured under heat and pressure in autoclaves for up to 12 hours, which significantly enhances their mechanical properties.

Packaging and Distribution: The finished blocks are packaged and stored in moisture-free conditions before being distributed.

Challenges Facing AAC Block Factories in India

Despite their benefits, AAC block factories in India face several challenges:

Initial Investment: Setting up an AAC block factory requires substantial initial investment, particularly in machinery and technology. This can be a barrier for small to medium enterprises.

Awareness and Adoption: There is still a significant portion of the construction industry in India that relies on traditional materials due to lack of awareness about the benefits of AAC blocks.

Distribution and Logistics: Given their bulk, even though lighter than traditional blocks, AAC blocks require efficient logistics solutions to minimize damage during transport and to reach remote construction sites effectively.

Market Potential and Future Outlook

The market for AAC blocks in India is projected to grow significantly. Urbanization is a key driver of this growth, with cities expanding and new urban centers emerging. The demand for residential and commercial spaces that adhere to newer, stricter building codes favoring energy efficiency and environmental sustainability is expected to rise.

In addition, the Indian government’s focus on affordable housing projects under schemes like the Pradhan Mantri Awas Yojana (PMAY) provides a significant opportunity for the expansion of AAC usage. The factory-made quality of AAC blocks ensures consistent performance, which is essential for such large-scale housing projects.

Technological Innovations and Skilled Workforce Development

As AAC block factories grow in number across India, technological advancements play a crucial role in optimizing production efficiency and product quality. Modern AAC factories are increasingly incorporating automation and robotics to streamline various stages of the manufacturing process, from raw material handling to final packaging. This not only increases production capacity but also enhances the consistency of the blocks produced, a critical factor in large-scale construction projects.

Furthermore, the growth of this industry has spurred the need for a skilled workforce capable of operating sophisticated machinery and managing the technical aspects of AAC production. Training programs and partnerships with educational institutions are vital for developing the necessary human resources. Initiatives to train workers not only support the AAC industry but also contribute to job creation, uplifting the socio-economic status of communities around manufacturing sites, thereby fostering a more skilled and economically active population.

Conclusion

AAC block factories in India represent a pivotal shift in the construction landscape, embodying the move towards more sustainable, efficient, and innovative building practices. While challenges remain, the potential for growth and the benefits of adopting AAC blocks are clear. As more stakeholders in the construction industry recognize these benefits, AAC block factories are set to play a crucial role in India’s construction boom, aligning economic growth with environmental sustainability. The future of construction in India, with AAC blocks at the forefront, looks not only promising but also greener and more sustainable.

0 notes

Text

Ilmenite Market: Sustainable Solutions with Titanium Dioxide Photocatalysts

Decoding Ilmenite Industry: Exploring the economic and Environmental Impact

Formation and Properties

Ilmenite is a widespread titanium-iron oxide mineral with the chemical formula FeTiO3. It forms as a natural material from magmatic or hydrothermal processes. When lava or magma cools slowly, it will crystallizes and solidifies. Contact metamorphism of suitable rocks under mountain building processes can also result in new formation.

It has a hexagonal crystal structure and usually forms black to steel-gray crystals. However, it can also appear in massive forms without distinct crystal shapes. It has a Mohs hardness of 5.5-6.5 and specific gravity in the range of 4.7-5. Its luster is typically submetallic. It is quite common in igneous and metamorphic rocks worldwide. Some of the notable ilmenite deposits are found in Australia, South Africa, Canada, Ukraine and India.

Uses and Demand

It is one of the most industrially useful ores as it is the chief ore of titanium. Around 60% of the global ilmenite production is utilized to manufacture titanium dioxide pigment. Titanium dioxide pigment has premium qualities like brightness, opacity and durability. It finds extensive applications in paints, plastics, paper, textiles, rubber and other industries.

A major portion of the remaining ilmenite is processed to obtain titanium metal and titanium alloys. Titanium and its alloys have outstanding corrosion resistance and high strength to weight ratio. They are extensively used in aerospace, military, medical and other specialized applications. It is also a rich source of iron units that can be recovered as by-products during titanium processing.

With rising global consumption of titanium dioxide pigment and increasing demand from high-tech industries, the market for ilmenite is steadily growing. Ilmenite production in most years over the last decade has been pegged at 6-7 million tonnes annually. Australia with its mineral sands deposits is the leading producer followed by South Africa and Canada. Countries like India, Ukraine, and Vietnam are also emerging as important players.

Beneficiation and Processing

Raw ilmenite as mined contains other associated mineral impurities like silica, rutile, zircon, monazite apart from iron. Hence, it needs to be upgraded through various beneficiation methods before utilization. Commonly used beneficiation techniques include washing, magnetic separation, electrostatic separation, gravity separation etc.

This upstream processing liberates the valuable residue from gangue minerals and improves its iron and titanium content. Washing deslimes and removes most of the silica impurities. Electrostatic separation exploits the difference in electrical conductivity between ilmenite and other minerals. Magnetic separation works on its magnetic properties to concentrate it.

The next stage involves metallurgical processing to recover titanium, iron units and produce value added products. Rotary kiln processes roasted concentrates at 1000-1200 °C to form synthetic rutile or titanium slag as intermediate products. These are then subject to chlorination or sulphate processes to yield pure titanium tetrachloride which upon hydrolysis produces titanium dioxide. Additional processing produces titanium metal, sponge and alloys.

Environmental Concerns and Regulations

Major environmental issues relate to land disturbance, dust generation, sedimentation of rivers during beneficiation plant operations. Toxic tailings and slag from processing plants require scientific disposal and management.

Stringent regulations are in place worldwide to control emissions, effluents, dumping/storage of wastes from titanium industries. Environmental Impact Assessments and Cleaner Production plans are mandatory. Mining leases specify strict compliance on pollution control, site reclamation and biodiversity conservation measures. In many countries, public consultation is part of approval process for new projects.

With growing environmental consciousness, the titanium sector emphasises on judicious resource utilisation, recycling, greener technologies and sustainability. Adoption of international standards on safety, health and environment protection will enable responsible mining and value addition of this important mineral resource for the long term.

So in summary, ilmenite is a key industrial mineral with major applications in pigment and metal industries. Its deposits are widely distributed but selective countries dominate production. Beneficiation and metallurgical processing upgrades it into various economically valuable titanium compounds and alloys. Like all mining activities, this industry too needs to factor in environmental management for sustainable development.

0 notes

Text

Unlocking the Potential of High Purity Quartz: Market Analysis and Forecast

The Expanding High Purity Quartz Market is Trending due to Increasing Demand for Optoelectronic Devices

The high purity quartz market is a multibillion-dollar industry primarily attributed to the increasing demand for optoelectronic and semiconductor devices across diverse sectors. High purity quartz or HPQ, commonly known as fused silica, is an engineered product manufactured by melting the highest purity quartz sand and reforming it into a glass with long-range order and superior mechanical and optical properties than ordinary fused silica. It finds widespread application in industries such as semiconductors, lighting, solar, fiber optics, displays, aerospace and optics due to attributes such as high purity levels exceeding 99.996%, low coefficient of thermal expansion, and excellent transmission in the vacuum ultraviolet region. The Global High Purity Quartz Market is estimated to be valued at US$ 948.2 Mn in 2024 and is expected to exhibit a CAGR of 10% over the forecast period 2024 to 2031.

Key Takeaways

Key players operating in the high purity quartz market are Unimin Corp./Sibelco, The Quartz Corp., Russian Quartz LLC, Kyshtym Mining, Sumitomo, Jiangsu Pacific Quartz Co., Nordic Mining, and High Purity Quartz Pty Ltd. These players account for over 50% of the global production.

The growing demand for semiconductor wafers as well as LED and solar products is fueling the consumption of high purity quartz significantly. The rapidly expanding optoelectronics and semiconductor industries are relying more on high purity quartz for various applications ranging from optics to diffusion barriers.

The high purity quartz market is witnessing increasing focus on global expansion strategies by the key players. Companies are enhancing production capacities as well as building purifying plants in different geographical locations to gain wider access and better serve the rapidly growing and geographically distributed end-use markets.

Market Key Trends

The increasing miniaturization of optoelectronic chips and devices requiring higher purity levels is one of the major trends in the high purity quartz market. The purity levels demanded by various applications such as optics, displays and semiconductors are constantly rising with advancements in technology. This is presenting growth opportunities for specialized players who can offer quartz glass achieving the exacting purity specifications of 99.999% and beyond. The high purity quartz market is also benefiting from the burgeoning demand for 5G infrastructure and increased focus on renewable energy sources, with the solar sector relying heavily on HPQ for critical applications in solar panels, furnace tubes and crucibles.

Porter’s Analysis

Threat of new entrants: New entrants need significant investment to set up mines and processing facilities.

Bargaining power of buyers: Buyers have moderate bargaining power due to availability of substitutes.

Bargaining power of suppliers: Few suppliers operate mines and control resources.

Threat of new substitutes: Substitutes like fused silica, silicon, and boron threaten market.

Competitive rivalry: Intense competition exists among existing players to gain market share.

Geographical Regions

North America accounts for the largest share in terms of value due to presence of established electronics and semiconductor industries. Countries like the US and Canada are major consumers.

Asia Pacific exhibits the fastest growth rate owing to rapid infrastructural development and increasing number of wafer fabrication units in China, South Korea, and other developing nations. Countries like China, Japan, and South Korea are at the forefront of adopting innovative technologies and drive regional market growth.

0 notes