#Peeler Manufacturer

Text

Good Quality Peeler Manufacturers

Royal Kitchenware is a leading manufacturer of high-quality peelers that are perfect for every kitchen. We take pride in our commitment to quality and customer satisfaction.

#Peeler Manufacturer#Vegetable Peeler#Fruit Peeler#Kitchen Essentials#Kitchen Gadgets#Kitchen Tools#Food Prep#Cooking Tools#Kitchen Supplies#Kitchen Appliances#Kitchen Equipment#Kitchen Utensils

1 note

·

View note

Text

Cashew Kernels Peeling Machines | Cashew Machines - Efficient and Reliable Solutions

Explore our advanced cashew kernels peeling machines and cashew processing equipment. Increase efficiency and quality with our reliable solutions. Contact us now!

#Cashew Kernels Peeling Machines#Automatic Cashew Peeling Machine Manufacturers#Mechanized Cashew Peeler#Cashew Batch Peeler#Cashew Continuous peeler

0 notes

Text

How Natraj Atta Chakki Commercial Potato Peeler Enhances Food Service Efficiency

In the short-paced international of food carrier, performance is prime. From restaurants to catering groups, streamlining operations now not best saves time however moreover complements the overall dining enjoy for clients. One crucial device that contributes appreciably to this efficiency is the commercial potato peeler. Among the manufacturers in this field, Natraj Atta Chakki sticks out for its commitment to excellent and innovation.

Natraj Atta Chakki, regarded for its excellence in producing flour mills, has ventured into the location of industrial kitchen device with its line of potato peelers. With years of expertise and a deep expertise of the desires of the meals service industry, Natraj Atta Chakki has engineered potato peelers that revolutionize the manner potatoes are prepared, imparting unrivaled performance and convenience.

So, how precisely does the Natraj Atta Chakki industrial potato peeler decorate food provider performance?

Speed and Precision: Natraj's potato peelers are designed to peel a massive quantity of potatoes fast and accurately. Whether it is far for French fries, mashed potatoes, or every different dish, the peeler guarantees constant results in a fraction of the time it did take to peel them manually. This pace no longer only increases productivity but additionally lets in kitchen workforce to recognition on other important responsibilities.

Labor Savings: Manual potato peeling is exertions-enormous and time-consuming. By automating this gadget, Natraj's business potato peeler appreciably reduces the need for guide difficult paintings, releasing up group of workers to attend to exclusive duties. This no longer handiest saves prices related to hard work but moreover minimizes the threat of repetitive pressure accidents among kitchen body of workers.

Consistency in Quality: Uniformity is important in meals carrier, mainly with regards to presentation. Natraj's potato peelers make sure that every potato is peeled to the same popular, resulting in regular quality throughout dishes. This uniformity enhances the overall dining revel in for clients, who can count on the identical degree of top notch with every visit.

Ease of Operation: Natraj Atta Chakki knows that kitchen tool should be intuitive and smooth to use. Their potato peelers feature customer-fine interfaces and easy controls, making them available to kitchen group of workers of all skill tiers. This ease of operation reduces the want for sizeable training and permits for seamless integration into present workflows.

Durable and Reliable: In the traumatic surroundings of an industrial kitchen, sturdiness is non-negotiable. Natraj's potato peelers are built to face up to the trials of everyday use, with strong introduction and first-rate materials. This reliability guarantees uninterrupted operation, minimizing downtime and maximizing productivity.

Hygienic Design: Maintaining hygiene requirements is paramount in food provider. Natraj's potato peelers are designed with hygiene in mind, imparting clean-to-clean surfaces and detachable additives that can be sanitized thoroughly. This reduces the threat of pass-infection and ensures compliance with meals safety regulations.

In cease, Natraj Atta Chakki's business potato peeler is a game-changer for meals carrier establishments seeking to decorate performance and productiveness of their kitchens. With its velocity, precision, tough paintings financial savings, consistency in high-quality, ease of operation, durability, and hygienic design, the peeler is a testimony to Natraj's willpower to excellence. By making a funding in Natraj's potato peeler, agencies can streamline their operations, lessen expenses, and supply exceptional dining reviews to their customers.

0 notes

Video

youtube

egg boiling and shelling processing line

#chicken egg peeler machine#boiled egg peeler machine#egg shell remover#egg manufacturing machine price#egg production machine

0 notes

Text

Commercial potato peeler manufacturer

Are you searching for commercial potato peeler manufacturer in India? Natraj Aatachakki is a reliable service for you. Flora Appliencess Pvt.Ltd is manufacturer of a wide range of products which include potato peeling machine, stainless steel potato peeler machine, ss potato peeler machine and potato peeling machine for food industry. To know more visit my website.

0 notes

Text

About five years ago, for seven dollars, I bought an old citrus juicer at a thrift shop. It was one of those vintage small appliances which seem built to survive gas explosions and hammer attacks. When I turned on the motor with a metal toggle switch, a drive shaft spun a heavy ceramic knob that gouged out the hearts of lemon and orange halves, leaving not a scrap of pulp uncrushed. The thing worked beautifully, almost like new, so I looked up its serial number on the internet to see when the unit was manufactured, guessing it might be almost 40 years old.

Wrong. It dated to the 1940s. It was 70, the stubborn monster, still giving satisfaction with every use.

I can’t say the same about my coffee grinders. I use the plural because I’ve owned a lot of them, all bought in their original packaging and dead within a year. They’re good ones, supposedly, with burrs not blades, but they stop performing before long, ending their long journeys from overseas factories in unmarked graves in my local Montana landfill.

I have a whole ghost kitchen in this landfill, and soon I will need to reserve a bigger plot. For the nifty under-the-counter fridge that has stopped getting cold after three years and no one in the area can fix. For the cool, bagless vacuum cleaner that clogs and chokes when I run it over a rug. For the set of glass measuring cups whose numbers and hash marks are swiftly fading and becoming illegible, much like those on the dials of the washer my wife bought just three years ago. For the remains of the Pyrex casserole that shattered when I removed it from the oven, strewing the floor with blade-like shards, some so tiny I probably won’t find them for another couple of months, and only when they lodge in my bare feet.

Should I go on? I think I will. It’s important to get to the essayistic part, where I ask what it means when the objects in our lives demoralize us in a blizzard of malfunctions that seem to be hastening by the month. But it’s also important—to me, emotionally—to bury the reader in details of the unceasing material disappointments I’ve faced. Disappointments of the sort we will all be facing en masse in a few days. Merry Christmas!

Like the cute yellow mittens my wife picked up at Target which unraveled the second time she wore them. Or the new suitcase which won’t stand upright when it’s full. The laptop computers that have turned to bricks within months of their warranties expiring. And the hybrid sedan with 50,000 miles on it that also turned into a brick while going eighty down the freeway, losing its power steering, its power brakes, its power everything. I survived, by some miracle, issued legal threats, and the car’s manufacturer repaired it, free. Then it bricked again a few weeks later.

It’s the little things too, of course, because they’re constant. The staples that won’t pierce five stacked sheets of paper. The matches that sizzle and smoke but won’t catch fire. The grocery bags split by the corners of the milk cartons whose inadequate seals leak drops. The strangely short power cords on electronics. The two or three new pens I use each week that, because no ink comes out of them (at least not continuously, in lines) aren’t really pens at all, in fact, but tributes to pens. Potemkin pens, mere props.

Baffled by how to measure this decline in the quality of common wares—a decline whose significance I promise to cover once I’ve further gratified my rage—I opened the matter to my Twitter audience and quickly garnered more than 2,000 replies, by far the longest thread I’ve ever triggered. The complaints were specific and formed patterns. One was a loathing for newer washers and dryers because they don’t wash or dry well, and then they break. The clothes that go inside them were disliked, too. (A former top executive of Levi’s chimed in to confirm that jeans aren’t what they used to be.)

My favorite replies were the picky ones. One person noted that the “juice content” of juice is going down. Another observed that the “foaming liquid hand soap” which suddenly is dominating store shelves is really just normal liquid soap, diluted.

Many blamed these problems on the government. They believed it had crippled certain products (major home appliances, especially) with environmental regulations, causing them to function poorly and turn rapidly to landfill fodder—an ecological net loss, perhaps. Some folks blamed our trade agreements with China and the evils of capitalism itself. Weak-link computer chips in items that don’t require them also came in for abuse. One highly philosophical reply spoke of a sinister general trend toward the degradation of everything human. “There’s a war on value that’s going that’s comprised of three parts: war on quality, war on money, war on life.” Lofty rhetoric, but I understood. When my suddenly de-electrified hybrid car became a hurtling giant stone inside which my wife and I were helplessly strapped—all for the crime of trying to save fuel and, ultimately, earth—it was hard not to feel tricked.

Only a couple of my correspondents challenged my premise—and the flood of testimony—that stuff is getting crappier, and acutely so. They made an economic argument. They claimed things are worse because we want them cheaper, but if price is adjusted for inflation, they’re of the same quality as always. These rant-killing sophisticates annoyed me. Our new washing machine with the faded dials and the vanishing enamel on its corners (I forgot to mention that defect) is the costliest model we’ve ever purchased. As for the much of the cheap stuff—those Target mittens, say—they aren’t merely inexpensive, they’re valueless. In fact, they’re of negative value when one considers the waste of materials involved, and the wasted energy of driving to buy them, then driving to return them later—a second trip that, in this case and many others, wasn’t worth making. Instead, we took the loss. And the world took the loss. A small one, but they add up.

In England in the 19th century there arose certain thinkers—John Ruskin, William Morris—who believed that the quality of material objects reflects and affects the quality of society, even of the spirit. “Have nothing in your home,” wrote Morris, the father of the Arts and Crafts movement, which aimed to elevate the lives of the working and middle classes, “that you do not know to be useful or believe to be beautiful.” This would be a tall order nowadays.

Recently, my wife needed a carrot peeler. She needed one rather quickly. Off to Target. The one she bought (the only one on sale) looked handsome enough, and the brand was one she recognized, but it failed in the useful department, miserably. It wasn’t sharp enough to peel a carrot. Like my pens which aren’t pens because pens put ink on paper, her peeler which didn’t peel was a nullity, a simulacrum, a representation of something, not the thing.

The world is going digital, we’re told, and someday there will even be digital real estate inhabited by people in digital clothes drinking digital orange juice extracted with digital juicers. People will play at the lives they once took seriously, lives that had once had heft and weight, and the juice content of juice will fall to zero. I suspect my old physical squeezer will still be working then, but the rest of my kitchen gear won’t. Not much of it. I might not last, either. I fear I won’t. The psychic toll of goods that don’t endure is that one loses faith the future will even come, and then one loses interest in it coming, for little that we own or use or cherish seems likely to be there with us to meet it.

One wonders whose obsolescence is being planned—our products’, our belongings’, or our own?

33 notes

·

View notes

Text

Navigating Challenges in Plywood Manufacturing: Insights from Top Indian Companies

In the intricate process of plywood manufacturing, there are several critical challenges that must be addressed efficiently to ensure quality and durability. Firstly, a major issue is the selection of logs. The right log, known as a peeler, is crucial as it determines the number of layers and ultimately the strength of the plywood. After selection, the logs are transformed into thin layers or veneers. This step is pivotal as the uniform thickness of these layers is essential for the final product's consistency.

Another significant challenge lies in the drying process. Proper dehydration of the veneers is fundamental to avoid future warping or other deformities in the plywood. This step must be meticulously monitored to ensure optimal moisture content.

Gluing, an essential step in plywood manufacturing, also presents challenges. The use of quality adhesives and precise application techniques are necessary to prevent issues such as weak bonding, low wood failure rate, or delamination. Different types of plywood require specific gluing techniques, making this a critical and tailored process in manufacturing.

Baking and pressing the glued plywood sheets at the right temperature and pressure are crucial to ensure strong bonding and durability. Any deviation from the required conditions can lead to significant quality issues in the final product.

Finally, finishing touches are applied to address any defects in the plywood sheets, such as holes, pits, or unfinished edges. This step ensures that the plywood not only meets functional requirements but also aesthetic standards.

To overcome these challenges, manufacturers can adopt innovative technologies and stringent quality control measures. Regular inspection at each step, from log selection to finishing, can significantly reduce defects and improve the overall quality of the plywood. Leveraging advanced machinery and automation can also enhance precision and efficiency in the manufacturing process.

In conclusion, while addressing these pain points can be complex, the solutions lie in meticulous quality control, technological advancements, and adherence to manufacturing best practices. Companies like the top ten plywood companies in India have set benchmarks in efficiently overcoming these challenges, ensuring their products meet global standards of excellence.

0 notes

Text

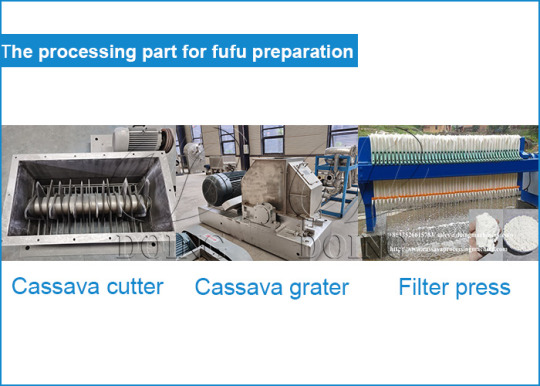

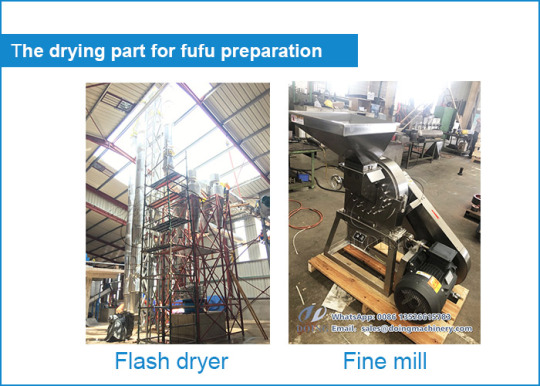

What's the price of fufu flour preparation machine ?

General speaking, the price of fufu flour preparation machine can not provided directly. The price you want to know is decided by many factors, mainly containing the daily capacity requests, The configuration and other objective factors.

The daily capacity of the fufu flour preparation machine:

There is no doubt that the larger of the daily capacity, the more price will be needed. The reason is that more fufu flour preparation machine will be needed for the fufu flour production line. So, the daily capacity should be considered when you prepare your budget and pre-arranged plan of your fufu flour production plant. There are some capacity can be manufactured from Henan Jinrui company as below.

2TPH, 4TPH, 6TPH, 8TPH,12TPH, 20TPH, 30TPH, 40TPH

The configuration of the fufu flour preparation machine:

The complete fufu flour production line should be included tapioca paddle washing machine, tapioca peeler, tapioca cutting machine, rapser, plate-frame filter, hammer crusher, flash dryer and sifter as well as fufu flour packer. If you want to set up one fufu flour processing plant as such configuration, the price you need to pay would be higher than another configuration I will explain to you.

Henan Jinrui company provides machine customizing service for clients. Some clients did not have enough budget or small daily capacity, our managers will provide the clients with a plan as: tapioca peeler, tapioca grater, hydraulic press, flash dryer, fineness miller, vibration sieve and tapioca packer. Although the price of this fufu flour processing line would be cheaper than the complete fufu flour production line, Henan Jinrui company still manufactures good quality and configuration fufu flour preparation machine to clients, ensuring their safe production and stable production. Thus, the configuration is also a important influence factor to the price of fufu flour preparation machine.

The manufacturing material of the fufu flour preparation machine:

As we all know, carbon steel is not good material to manufacture edible food processing machine as fufu flour preparation machine. Therefore, many fufu flour manufacturer of fufu flour preparation machine including Henan Jinrui company prefer to use food grade 304 stainless steel as material to making machines. But, food grade 304 stainless steel's price is more higher than carbon steel. This implied that if many part of the fufu flour preparation machine is made of food grade 304 stainless steel, the price will be high. Thus, the manufacturing material is the third influence factor to the fufu flour preparation machine. For this problem, there is no need to worry. Because Henan Jinrui company can provide you with the reasonable plan according to your practical situation.

At last, if you want to get a fixed cost, you can contact Henan Jinrui company in your spare time. But here Henan Jinrui company will provides you some reference information for you.

http://www.cassavaprocessing.com

WhatsApp/Phone:+86 135 2661 5783

Email:[email protected]

0 notes

Text

Design for the bin: the city of Zurich has its new one

Recycling container partly developed in-house – you can see that.

The bureaucratic design of the city of Zurich's future waste bin is an affront to public space and Swiss design culture.

It's not often that a waste bin writes design history. But the garbage shark made of matt shiny chrome steel has conquered the world from Zurich. The trash can is almost as well known as the peeler or the Landi chair. The bucket designed by Zemp + Partner Design[1] is available to over 4,500 customers from Kilchberg to Vienna to Barcelona.

The manufacturer still advertises with the silhouette of the Limmat[2] city in the background, where it all began in 2002. But the luxury bucket no longer meets Zurich's requirements, although it is also available as a multi-bucket called the “Sortershark”[3] and as the “Solar Pressshark,”[4] which compacts the waste using solar power.

As early as 2018, the city began replacing the waste shark with the “Züri-Kübel 110 liters”[5], which has a larger opening and a flat lid and is cheaper. Unlike its predecessor, its pragmatic design will not make it into the Museum of Design.

Now the requirements have increased again, which is why the Zurich disposal and recycling department ordered a new bucket and partly designed it themselves. As with the “Züri-Kübel”[6] before, there was no design competition. This is an impoverishment for Swiss design culture.

The new “recycling container” – as it is officially called – was developed so that the people of Zurich can dispose of waste more sustainably. There are separate slots for PET bottles, aluminum cans and waste. If necessary, a fourth type of waste can be added, such as glass. This helps the circular economy.

But the bucket's construction is conventional: a generic box made of metal with rounded corners. Environmentally friendly here means above all: little energy was wasted on good design. This energy would be used sustainably: attractive design lasts a long time because it stands the test of time and is popular.

Empirically based design

The bucket is inspired by the SBB multi-bucket, which shows its dirty contents to the outside with pictures. A trash can is there to make things disappear that you don't want to see. The city argues that the design is empirically based. She tested three labels: one with photos of the respective type of waste, one with illustrations and one with questions such as: “Is it really PET?” “The separation quality was best when labelling with photos,” writes the city in a media release.

This may be. But effective environmental protection should also appeal to us aesthetically, especially in public spaces. The eye separates with. The ecological balance is measured in numbers, the quality of design is not. Form follows function – and imagination. Good design can encourage us to do the right thing. But if we are repelled by the design of a trash can, let alone its contents, how is this supposed to increase the recycling rate?

Street furniture is part of the cultural heritage, it is part of the history and identity of a place. Successful everyday design triggers something in us, sometimes it is accompanied by a pinch of humour, for example in Berlin. The orange buckets in the German capital may be impractically small, but their bright colour, round shape and wit when throwing them in brighten up everyday life. There are sentences like: “Give it to me!” Or: “Play me the poop song.” The didactic bureaucratic design of the Zurich bucket, on the other hand, aims to instruct rather than delight, even when it comes to humor: “You hit like a world champion!” says a sign on the side.

In short: functionality reigns, design is neglected. This generally applies to civil engineering in Zurich, where the natural stone was removed from Bahnhofstrasse and Europaallee was asphalted instead of paved. The value of beauty seems outdated.

The economy likes numbers, sustainability likes efficiency, the state likes control. You can see where this reduction to functional aspects leads in Paris: out of fear of terrorist attacks, the buckets in the city were dismantled. Instead, a transparent plastic bag attached to a metal ring flutters in the wind.

New buckets in Basel and New York

Zurich is not alone with the waste design problem. In Basel, the population complains about the solar press bucket nicknamed the “waste monster,” which critics say is disfiguring the city. In the summer, the civil engineering department announced that it would remove 110 of the buckets from the cityscape. The majority of politicians came to the conclusion that the solar press buckets were unworthy of this city.

This year, New York has also been using a new bucket that replaces the iconic buckets made of green metal mesh. Functionality is also the top priority here. The base is made of concrete so that the bucket doesn't fall over. The container is closed to keep rats out. The paint is graffiti-resistant. But unlike Zurich, the design was preceded by a competition. In the New York Times, a passerby calls the bucket “beautiful, gorgeous, amazing.” That may be an American overstatement. The Zurich bucket is a Zwinglian understatement[7].

Source

Andres Herzog: Design für die Tonne: Die Stadt Zürich hat ihren neuen Recycling-Behälter teilweise selbst entwickelt – das sieht man ihm an, in: Neue Zürcher Zeitung, 07.12.2023, https://www.nzz.ch/zuerich/zuerich-recycling-behaelter-statt-abfallhai-ist-ein-affront-aufs-schweizer-design-ld.1769362

[1] https://www.stylepark.com/en/designer/zemp-partner

[2] The Limmat is a river in Switzerland. The river commences at the outfall of Lake Zurich, in the southern part of the city of Zurich. From Zurich it flows in a northwesterly direction, continuing a further 35 km it reaches the river Aare. The confluence is located north of the small town of Brugg and shortly after the mouth of the Reuss.

[3] https://www.archiexpo.com/prod/anta-swiss-ag-abfallhai-191002.html

[4] https://a2-solar.com/en/special-solar-panel-for-littersharks/

[5] Zurich is putting an end to world-famous trash shark Why the design bucket has had its day and the city is now relying on a long-serving design. https://www.tagesanzeiger.ch/zuerich-macht-schluss-mit-weltbekanntem-abfallhai-707140742748

[6] The new Züri Kübel ('bucket') which has been gradually installed since January 2021. https://www.core77.com/posts/116596/Behind-the-Design-of-Zurichs-New-Public-Trash-Can

[7] The theology of Ulrich Zwingli was based on an interpretation of the Bible, taking scripture as the inspired word of God and placing its authority higher than what he saw as human sources such as the ecumenical councils and the church fathers. He also recognised the human element within the inspiration, noting the differences in the canonical gospels.

0 notes

Video

youtube

Management of Wheat Silos(www.immy.cn)Integrated Flour mill EPC services provider: www.immy.cnIn wheat maize barley,millet,durrum etc production, the requirements for moistening time are relatively strict. If the moistening time is too short, the endosperm will not be completely soft, the endosperm structure will be uneven, and the rolling distance will not be easy to adjust during grinding. The grinding will not be thorough and the screening will be difficult. If the wheat moistening time is too long, the moisture on the surface of the wheat will evaporate, causing the moisture on the surface of the wheat to dry out and become easily broken, affecting the milling performance. https://www.immy.cn/blog/management-of-wheat-warehouse-in-flour-mill-1

WUXI HASEN IMPORTAND EXPORT CO.,LTD is a general solution service provider and project system integration service provider with grain and oil equipment technology research and development, engineering design, manufacturing, installation,training and commissioning, project contracting as business main structure. Products including energy saving roller mill,high plansifter, purifier,wheat scourer,wheat peeler,wheat washer,branbrush,bran finish,maize embryo remmoval,degerminator,flow balance,micro feeder(weight in loss feeder,diffrential micro feeder),rotary sifter,vibro sifter,packing machine,double shaft paddle mixer,quantitative weighing scale, paper bag packing machine,impact detacher,hammer mill(water drop pulverizer).suction duct,aspiration separator,moisture controller,single(double)bin control(inspection)sifter,CNC grooving machine,fluting machine,auto stack robot machine,vibro discharger, bran outlet discharger,color sorter,LAB mill,scraper conveyorbucket elevator,air locker,cyclone pipe,PLC control system.dampener, flour dryer.flour refeeder,conveyor feeder.pre cleaning sifter,pulse dust collector,quantitative flow scale,heavy duty combined sifter XMTS,gate, gravity grading destoner(stone removal),rotary screen. ETC flour mill equipment&machine.

We are leading Integrated wheat maize flour mill engineering equipment manufacture EPC turnkey project services provider from 100 to 3000TPD in China, Inquiry us if you need high standard Full Auto Flour Mill Line from 100-5000 tons per a day. Hope to be your valued supplier for life time cooperation. E mail: [email protected] Whatsapp: 008613812016908 www.immy.cn https://lnkd.in/gnYbSr_9

#flourmachine #flourmillmachine #grainmachine #flourmill #wheatflourmillmachine #maizeflourmachine #semolina #Addamaidamachine #nshimamachine #wheatwashingmachine #recycleaspiration #aspirationselector #rollermill #rollerbody #brandischarger #branfinisher #wheatscourer #wheatwasher #wheatcleaner #branbrush #colorsorter #flowbalance #vitaminfeeder #highplansifter #purifier #airlocker #pressurefan #flourconveyor #bucketelevator #steelsilo #degerminator #maizeembryo #destoner #dampener #aspirator #moisturecontroller #PLCsystem #EPCflourmillproject #turnkeyflourmillline #integratedflourmillline #largeflourmillline #dryerwheatflour #dryerwheatban #dryerwheatgerms #productioncapacity #wheatflourmillingmachines #processingplant #flourmillmachine #automaticflour #flourmillplant #millingmachine #flourmillmachine #wheatflourmillmachine #packingmachine #quantitativepacker #spoutpacker #wheatspoutpacker #maizeflourspoutpacker #wheatflourspoutpacker

0 notes

Text

Maximising Freshness: How Processing Machinery Preserves Nutrients in Fruits and Vegetables

Fruits and vegetables are important components in many food products. But they may lose essential nutrients as they go through the processing stage—especially vitamins that dissolve in water. This is why it's crucial for manufacturers to selectfruit processing machinerythat not only prepares the produce but also keeps its nutritional content and freshness intact.

Optimal machinery for nutrient preservation

The right fruit processing machinery does more than just prepare fruits and vegetables; it also helps maintain their nutritional integrity. State-of-the-art industry-grade equipment balances versatility and efficiency, crafted from high-grade materials that ensure durability and reliable performance. This equipment includes specialised machinery like fruit and vegetable washers, food processing elevators, jelly makers, and steel mixing tanks. Additionally, brush rollers and crate washers are also accessible from leading manufacturers.

Understanding how processing impacts nutrients

Various factors (from growth and harvesting to storage and processing) can influence the nutrient content of fruits and vegetables. Elements like high levels of light, oxygen, and heat can also significantly reduce nutrient levels. Even some packaging methods can have an impact.

The good news is that choosing fruit processing machinery with adjustable temperature controls can mitigate the loss of water-soluble vitamins. Equally important is investing in packaging machinery that maintains the quality of the processed items.

Tailored machinery for specific needs

Certain fruits and vegetables require specialised processing. This is why manufacturers offer specific types of fruit processing machinery, such as mango pulp machines, date processing plants, and tomato crushers, among others. Options like pea-peelers, podders, and pineapple processors are also available. Adding a fruit mill or crusher and various types of conveyors can create a comprehensive solution that streamlines the production process.

Customisable features for optimal performance

High-quality fruit processing machinery isn't one-size-fits-all; it's designed for optimal performance tailored to specific operational needs. These machines come with sturdy construction and customisable features to meet unique food processing requirements. Plus, they offer reliable controls to prevent the over-processing of fruits and vegetables, thereby preserving their nutritional value.

Discover the right machinery for your needs.

GEM specialises in an extensive range of food processing solutions, including various types of fruit processing machinery. Contact their team of experts to find out how their machinery can fulfil your specific food processing and budgetary needs.

About the Author:

The article is written by Shashank Garg from Gem Drytech Systems LLP. GEM is an industrial food processing equipment producer and exporter with headquarters in Kolkata. Our wide array of solutions meets the preparation and processing needs of various top food industry business organizations worldwide. We specialize in a wide range of uniquely built, purpose-specific, and multipurpose machinery for our customers as a famous exporter of food processing equipment.

0 notes

Text

Unlocking Efficiency and Sustainability with ISPM15 Custom-Made Pallets

The logistics and supply chain industry functions efficiently mainly due to the presence of custom made pallets from wood and plastic. Companies that manufacture these custom made pallets follow every law and regulation related to their production, and one guideline that they can't afford to skip is ISPM 15. Everything made from wood for overseas transportation has to be manufactured in compliance with the ISPM 15 guidelines. In this blog post, we go through some common questions related to ISPM 15 and what impact these regulations put on custom made pallets.

WHAT IS ISPM 15?

ISPM stands for International Standards For Phytosanitary Measures – Publication Number 15. This publication has guidelines for regulating wood packaging materials in international trade and transportation.

WHY WAS 'ISPM' DEVELOPED?

According to the vendors of pallet bed frames and wholesale timber pallets, ISPM 15 was developed to address the problem of pests transport from one country to another through wooden pallets and other products. These guidelines were intended to regulate the movement of timber packaging and pallets, pallet bed frames, dunnages, wooden boxes and so on in international trade.

WHAT IS INCLUDED IN ISPM 15?

ISPM 15 has all the guidelines related to regulating the movement of wooden packaging products across the globe. It also describes phytosanitary measures to reduce the risks of deadly pests and virus transport in other countries.

WHO DEVELOPED AND ENDORSED ISPM 15

The United Nations Food And Agriculture Organisation played an instrumental role in developing ISPM 15 rules and guidelines. This organisation is responsible for addressing plant current time through the International Plant Protection Convention.

WHAT DOES ISPM 15 APPLY ON?

ISPM 15 applies to every wooden product used for packaging, transporting, and storing goods and products. This means that wooden pallets, wooden crates, custom made pallets, wooden boxes, wooden dunnages, wooden drums, wooden pallet collars etc., all have to comply with ISPM 15 regulations.

Apart from these, several other products also have to comply with ISPM 15, like –

Wood packaging made entirely from thin wood (6 mm or less in thickness)

Wood packaging made wholly of processed wood such as plywood, particle board, oriented strand board or veneer

Veneer peeler core

Barrels for wine and spirit that have been heated

Wooden gift boxes for wine, cigars and other commodities

Sawdust, wood shavings and wood wool

Wood components attached to freight vehicles and containers.

0 notes

Text

Vege cutter

A vegetable cutter, also known as a vegetable chopper or slicer, is a kitchen tool designed to make the process of cutting, chopping, and slicing vegetables more efficient and convenient. These devices come in various shapes, sizes, and designs, but they all serve the same basic purpose: to help you prepare vegetables quickly and with minimal effort. Here are some common types of vegetable cutters:

Manual Vegetable Chopper: This type of cutter usually consists of a container with a grid of sharp blades or attachments. You place the vegetable inside, press down on the lid, and the blades chop or dice the vegetable.

Mandoline Slicer: A mandoline slicer has an adjustable blade and a flat platform with a handguard. You slide the vegetable back and forth across the blade to create thin, even slices.

Food Processor: Food processors come with various attachments, including slicing and shredding discs, that allow you to prepare a wide range of vegetables quickly. Some food processors also have special attachments for julienning or spiralizing.

Electric Vegetable Chopper: These are electrically powered devices that automate the chopping process. You place the vegetables in a container, press a button, and the machine does the chopping for you.

Spiralizer: A spiralizer is used to turn vegetables like zucchini, carrots, and potatoes into noodle-like shapes. It can be used to make vegetable noodles for dishes like zoodles (zucchini noodles.

Julienne Peeler: This is a simple tool that allows you to create thin, uniform strips or julienne cuts of vegetables. It looks like a regular peeler but has a serrated blade.

Conclusion: The choice of a vegetable cutter depends on your specific needs and preferences. Manual choppers and mandolin slicers are good for small-scale chopping and slicing, while food processors and electric choppers are more suitable for larger quantities and a wider range of tasks. Spiralizers and julienne peelers are specialized tools for creating unique vegetable shapes.

When using any type of vegetable cutter, it's essential to follow safety guidelines, especially with sharp blades and moving parts, to prevent accidents and injuries. Always read the manufacturer's instructions and exercise caution while handling these kitchen tools.

#vegetable chopper#piller#spiralizer#electric chopper#julienne#food processor#food processing equipment#the mandolarian#home appliances#kitchen#utensilski#kitchen appliances#kitchen tools#utensils

0 notes

Text

Streamlined Potato Peeling Equipment from Natrajaatachakki

In the world of meals processing, efficiency is prime. Whether you are running a bustling eating place kitchen or managing a huge-scale food production facility, having the right gadget could make all of the difference. When it comes to peeling potatoes, a challenge that can be both time-ingesting and hard work-extensive, having a reliable commercial potato peeler is crucial. That's where Natrajaatachakki, a leading commercial potato peeler manufacturer, comes in.

As a leading producer in the enterprise, Natrajaatachakki has been revolutionizing the way potatoes are peeled with their innovative and streamlined potato peeling equipment. With a commitment to satisfactory, efficiency, and sturdiness, Natrajaatachakki's machines are depended on through cooks, meals producers, and processors worldwide.

So, what units Natrajaatachakki other than different industrial potato peeler manufacturers? Let's take a more in-depth have a look at some key features and advantages of their device:

Cutting-Edge Technology: Natrajaatachakki utilizes modern-day generation in the layout and manufacturing in their potato peeling machines. From advanced peeling mechanisms to shrewd automation structures, their equipment is designed to deliver most excellent performance and reliability.

High Capacity: Whether you're peeling potatoes for a small eating place or a big-scale meals manufacturing facility, Natrajaatachakki offers potato peelers in various capacities to fit your wishes. From compact countertop fashions to commercial-scale machines, they have answers for companies of all sizes.

Time and Labor Savings: With Natrajaatachakki's potato peeling equipment, you may say goodbye to hours of guide peeling. Their machines are designed to peel potatoes speedy and correctly, saving you treasured time and exertions charges.

Consistent Results: Consistency is key in the meals enterprise, and Natrajaatachakki's potato peelers supply steady consequences each time. Whether you are peeling a few potatoes or loads, you can anticipate their equipment to produce uniformly peeled potatoes with minimum waste.

Durability and Reliability: Natrajaatachakki understands that industrial kitchen device desires to withstand the trials of day by day use. That's why their potato peeling machines are built to last, with long lasting creation and extraordinary additives that make certain years of dependable performance.

Easy to Clean and Maintain: Keeping kitchen device clean and nicely-maintained is critical for food safety and hygiene. Natrajaatachakki's potato peelers are designed with clean cleaning and protection in thoughts, making it easy to maintain your equipment in top situation.

In conclusion, in case you're inside the marketplace for a business potato peeler that offers first rate performance, reliability, and efficiency, look no further than Natrajaatachakki. With their revolutionary potato peeling equipment, you may streamline your meals manufacturing technique and take your enterprise to the following stage. Choose Natrajaatachakki and experience the difference excellent makes on your kitchen.

0 notes

Text

So...

Found out the hardest way possible that peelers are hella sharp.

I always thought they used friction more so... 😭

Now I'm involuntary up from pain from (only God knows how I got) the injury, and didn't want take anything for fear it fuck my stomach up.

My catass DID NOT want to go anywhere for a while but probably must go to the damn doctor over peeling mangoes.

Been feeling bad Mojo Jojo lately idk... This accident was strange; it was fast of course but I watched it happen so clearly. The mango was def one them new age (manufactured fruits and vegetables) ones, and this one was extra off.

🙃🤦♀️😩

0 notes

Text

New Gadget Spiral Apple

The electric spiral apple peeler, fruit slicer, and potato peeler is a kitchen gadget that makes peeling and cutting fruits and vegetables a breeze. It is a battery-operated device that automatically peels and spirals apples, potatoes, and other fruits and vegetables.

The device comes with a charger that allows you to recharge the battery when it is empty. This makes it convenient to use without a power outlet. The peeler also has a suction base that ensures it stays on the countertop while in use.

To use the electric spiral apple peeler, fruit slicer, and potato peeler, you simply need to place the fruit or vegetable on the prongs of the device and turn it on. The peeler will then automatically begin to spiral peel and slice the fruit or vegetable. The sliced fruit or vegetable can be used for various dishes or eaten as a snack.

Overall, this device is a useful addition to any kitchen and can save you time and effort when preparing fruits and vegetables. However, it is important to note that some fruits and vegetables may not be suitable for this device and you should always follow the manufacturer's instructions for safe and proper use.

Gadgetentime ❤️ ❤️

Click to get yours today!🥰🥰

1 note

·

View note