#Hevea brasiliensis

Text

(The seed, for reference. Isn't it cool...)

9 notes

·

View notes

Text

I wonder if the reason parts of Luffy turn white in Gear 5 is because, when tapped, natural rubber is white

#preliminary research suggests its milky white#the amount of science research I fall into from one piece#wsd weird brain#one piece#monkey d. luffy#gear 5#gear 5 luffy#gear 5th#gum rubber#natural rubber#one piece musings#hevea brasiliensis#there's others but that is a main one i think

42 notes

·

View notes

Text

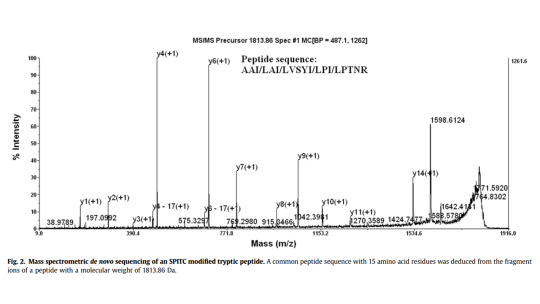

Identification and Subcellular Localization Analysis of Two Rubber Elongation Factor Isoforms on Hevea brasiliensis Rubber Particles

Longjun Dai, Zhiyi Nie, Guijuan Kang, Yu Li, and Rizhong Zeng

Plant Physiology and Biochemistry 111 (2017): 97e106

Download PDF

Rubber elongation factor (REF) is the most abundant protein found on the rubber particles or latex from Hevea brasiliensis (the Para rubber tree) and is considered to play important roles in natural rubber (cispolyisoprene) biosynthesis. 16 BAC…

View On WordPress

0 notes

Photo

Solidago canadensis (Canada goldenrod) and Bombus (bumblebee)

During World War 1, rubber was recognized as a strategic commodity as supplies ran short in the industrial world. The U.S. imported rubber from Southeast Asia and the East Indies. In the 1920′s, Thomas Edison began his search for a home-grown source of rubber.

The rubber tree, Hevea brasiliensis, is not the only source of latex rubber and after testing more than 17,000 plant samples, Edison decided on goldenrod with a yield of about five per cent latex. Edison selected the varieties that seemed to have the most potential, divided the roots, planted them separately, divided them again, and started crossbreeding. It was time-consuming; but a giant goldenrod about fourteen feet tall yielding about twelve per cent latex was ultimately developed.

Henry Ford and Harvey Firestone became interested and put big money into the project. Vast fields of goldenrod were planted, processing factories were built and goldenrod tires were introduced to the market in 1929. Unfortunately, 1929 was not a good year for business in general and the invention of the synthetic rubber Neoprene (made from petroleum byproducts) in 1931, doomed this fledgling industry. During World War 2, German synthetic rubber factories were specifically targeted by Allied bombers.

#flowers#photographers on tumblr#goldenrod#history#botany#fleurs#flores#fiori#blumen#bloemen#Vancouver

79 notes

·

View notes

Note

please do talk about the history of plastic here as well! it sounds very intriguing

We're getting into contemporary history, which is my worst suit but: in the interrogation I specifically mentioned Bachelite, so, it was just a few words about how it was first obtained from a reaction between formaldehyde and fenol, creating a kind of molecular 'map' resembling that of lignina (fenol rings connected by CH2, that sort of thing?) - during a time when most electrical insulating materials were made of lattice, which was plant-produced (by the Hevea Brasiliensis if I'm not mistaken), the fact that Baekeland was able to produce a material which could substain the same temperatures was important for the progress in computers and other electrical circuits.

And to substitute for the ivory used in pool balls, also.

The tricky thing about lattice is that it can't be synthetised easily because the 'rubber' is isoprene, which can have both cis and trans geometrical isomeria, and while in the plant there is an enzime which makes them all cis, so they form the spirals that make rubber elastic and moldable (and then you can make it solid with vulcanisation, which makes double solfur bonds inbetween spirals) - its human synthetisation lacks those enzimes, so we got a mixed bag of the two versions, until the Ziegler-Natta catalysts were made. And Bachelite was a good alternative for thermoelectrical insulation because it was easier to produce than the plant-harvested lattice, although for its more elastic-serving uses we first substituted it with SBR.

#anonymous#[.asks]#infodump tag#This is not a good explanation on my part. I am very tired right now. But I hope it suffices without me going into fenol and alcohols#and all those properties of hydrocarbons that made it so we got to this point

18 notes

·

View notes

Text

Metafloora

[ID: back to the future marty mcfly hey ive seen this one! reaction image. End id]

Welllll i was eating colosal shit so i check my previous and saw hey i ate like shit in the magnolia family last time. Okay. Let me hint. Okay... let me wikia. HEY!!!

A milky latex is a characteristic of the subfamilies Euphorbioideae and Crotonoideae, and the latex of the rubber tree Hevea brasiliensis

Hey but also

The fruit is usually a schizocarp, but sometimes a drupe. A typical schizocarp is the regma,

The what? Its huh??

Anyway someone check on tbe devs maybe

5 notes

·

View notes

Video

youtube

Fantastic Wood Furniture for the Bedroom

Looking for a savvy bedroom set that is stylish and reasonable? Then look at the many arrangements online, the decisions are gigantic and the plans, and prices, just can't be bested. There are many restrictive reaches accessible, you simply have to visit site here establish a point in time to the side to investigate what there is in the present market and recognize the styles and plans, and type of wood you prefer for your home.

Whether you're interested in buying a king-sized bed frame or are sprinkling out and buying everything required for a recently decorated bedroom, from the bed and the twofold closet to the bedside cabinets and chests, then, at that point, the quantity of brands and styles makes certain to put a grin on your face.

Solid wood is a firm number one with home-owners as its notable for its steadfastness and vigor, in the event that you have the financial plan for genuine wood, its worth spending that extra as the quality and craftsmanship with which it has been fabricated ensures a lifetime of purpose.

Bedroom furniture is generally popular created from solid oak, pine, debris, mango, rubberwood, pecan, mango, mahogany and dull wood as well as pine. Single, twofold, king and super king size beds are popular in debris, pine and painted styles while a honey oak and pecan finish have an especially lovely grain detail and the strength of the wood make them ideal for making great furniture.

Look out for companies that arrangement with individual pieces handmade by talented skilled workers who have been in the business for quite a long time, then you know you are getting quality. A few companies likewise offer brands that make their items from harmless to the ecosystem wood which frequently implies that the tree is toward the finish of its life cycle.

Hevea wood, for instance, from the Brasiliensis tree, is a hardwood grown primarily for normal elastic, which it produces for around 30 years. It is an economical wood with new plantings supplanting felled trees proceeding with the life cycle. Recovered Oak is one more green lumber to look out for while buying furniture for your home.

There are a few great children bedroom ranges accessible made with top notch solid woods, made to endure and tolerate a ton of mileage. Things can be requested separately or buy an entire room set in matching wood or colors including chest of drawers, mirrors, shelves, cabinets and cover boxes which are great for keeping toys and games cleaned away.

You can find a few phenomenal reaches created from 100 percent high grade solid oak, flawlessly made with dovetailed drawers, solid oak drawer bases and cabinets backs, all intended to endure forever.

King size beds can be bought with a great 5ft x 6ft 6"" sleeping pad giving a lot of room for a decent night's sleep. Buy them in oak, debris, or pine, or go over the top and get yourself a 4 banner! Coordinate it with a bedside cabinet, closet, and cover box and you'll have a room that is both wonderful and classy.

The bedroom for the majority of us is a spot to take shelter in and be distant from everyone else with our viewpoints, find a few harmony and calm and chill for some time, so we maintain that mitigating quiet colors and stylish practical furniture should help us in accomplishing this. Whatever your style, contemporary, heartfelt or traditional, classic or European, it's not difficult to make a look you've always needed with the expansive choice of bedroom furniture including dressers, chests, and tables accessible.

3 notes

·

View notes

Text

Commercial Rubber Farming Business Guide For Beginners

Commercial or large scale rubber farming is a very old and popular business in many countries around the world. People are using rubber from the ancient time and it's production is profitable.

Rubber is actually an elastic solid material which is retrieved from latex of many tropical trees. It is used for many purposes which may include erasers to tires, tubes and industrial products.

Rubber is also known by many different names, such as natural rubber, India rubber, latex, caucho, caoutchouc, Amazonian rubber etc. Thailand, Malaysia, Indonesia and India are the leading rubber producers.

'Hevea brasiliensis' is the most important and commercially cultivated rubber plant. These plants basically grows up to 30 meter height and begins yielding latex at 6 to 7 years age.

More than 28 million tons of rubber were produced in the year of 2017. And among the production, 47% was natural.

The price of natural rubber is determined, to large extent, by the prevailing global price of crude oil (since the bulk is synthetic, which is derived from petroleum).

Asia was the main source of natural rubber, accounting for about 94 percent of output in the year of 2005. And top 3 largest rubber producers are Thailand, Indonesia and Malaysia (together account for around 72 percent of all natural rubber production).

Natural rubber is not cultivated widely in it's native continent of South America because of the South American leaf blight, and other natural predators available there.

Uses of Rubber

Rubber is used for many different purposes. Uncured rubber is used for cements, insulating, for adhesive and friction tapes. And for crepe, rubber is used in insulating blankets and footwear.

While the vulcanized rubber has many more applications. Resistance toabrasion makes softer kinds of rubber valuable for the trends of rubber valuable for the treads of vehicle tires and conveyor belts.

Around 25 million tonnes of rubber are produced each year globally, of which only 30 percent is natural. The remainder is synthetic rubber derived from petrochemical sources.

The top end of latex production results in latex products such as surgeon's gloves, balloons and relatively high-value products.

Advantages of Rubber Farming Business

Like many other agri business, commercial rubber farming also has numerous advantages or benefits. Here we are trying to describe the top benefits of commercial rubber farming business.

- Commercial rubber farming is relatively a simple and easy business.

- Beginners can also start this business easily. It is just like starting other crop farming business.

- Commercial production of rubber is very easy, and profitable at the same time. So, it can be a great business for making money.

- Beginners can start this business with proper training and support.

- Commercial rubber farming is very profitable and it can be a great employment source for the people (especially for the educated but unemployed people).

- Both demand and value of rubber and all related products are high.

- Many people are already doing rubber farming business commercially for making profits.

- You don't have to worry much about starting this business if you are a beginner. Because many people are already doing this business.

- Marketing rubber products is relatively easy. Because rubber and all the related products have very good demand and value in the market.

- Production costs are relatively high, but the profits are also high and you will get back your invested money soon.

How to Start Rubber Farming

Starting commercial rubber farming business is relatively easy if you follow every steps carefully. You can start this business easily with little practical knowledge.

We recommend starting commercial rubber production after having full training. Here we are trying to describe more information about commercial rubber farming business from planting, caring to harvesting and marketing.

Site Selection

Rubber plants grow well in highly deep weathered soils which consist of laterite and lateritic soils. But the plants grow best in well drained porous soils with moderate acidic in nature.

If there is a good organic matter in the soil, then the rubber plants also thrives in red alluvial soils. pH between 5.0 and 6.0 is best for rubber cultivation.

Prepare the Soil

Remove weeds and make the land clear before planting. Then make pits with dimensions of 120 cm x 45 cm x 60 cm. You will be able to make 200 to 250 pits per hectare land. Add 10 kg organic matter and 150 grams of rock phosphate per pit.

Climate Requirement For Rubber Farming

Commercial rubber production requires heavy and well distributed rainfall of 200 cm to 300 cm, having humidity about 75 percent.

Ideal temperate for proper growth of rubber plants is between 20°C and 35°C. The plants require 5-6 hours of sunlight. Freezing temperatures will halt the growth of rubber plants and strong winds are not suitable for commercial rubber farming.

Propagation

Propagation in rubber farming is generally done through green budding, crown budding and brown budding.

Purchase Plants

Rubber plants are easily available in the nurseries. You can collect plants for planting from any of your nearest nurseries.

Planting

Plant the small plants in the main field where you have made the pits ready earlier. June to July is the best season for rubber plantation.

Caring

Taking good care of the rubber plants will ensure good production. Here we are describing more about the caring process.

Fertilizing

Rubber plants respond very well to organic matter and fertilizers. Apply 10-12 kg of well rotten organic manure and 225 grams of rock phosphate in each pit during land preparation. And this dosage is recommended up to 4th year of planting.

Irrigation

Watering or irrigation should be provided depending upon plant growth.

Controlling Weeds

Weeds consume nutrients from the soil and the rubber plants will suffer. Weeding is generally carried out manually or chemically or through a combination of both.

Intercropping

Intercropping will generate some extra revenue during the first two years of cultivation. Some suitable intercrops in rubber farming are turmeric, ginger, vegetables, tuber crops, banana, pineapple, medicinal or herbal plants etc.

Cover Cropping

Cover cropping is very helpful in sloppy areas for preventing soil erosion. This also helps to enhance the soil fertility and controls the weed growth along with soil temperature.

Intercropping leguminous crops will help in nitrogen fixation in the soil. Calopagonium muconoides, centrosema pubescens, pueraria phaseoloides and desmodium evalifolium are common cover crops in rubber farming.

Pests & Diseases

Mealy but, cockchafer grub, scale insect, white ant and mites are the main pests in rubber cultivation. Abnormal leaf fall, bird's eye spot, secondary leaf fall, powdery mildew, leaf spot, bark cankers, dry rot, pink disease, stump rot, collar rot and brown rot diseases are the main diseases found in rubber farming.

Contact your local agriculture extension office or horticulture department for more information about controlling these pests and diseases.

Yield

Exact amount of yield depends on the method of propagation. But yield usually increases year by year in any method.

Total yield reaches peak after 14 to 15 years of planting. An annual average yield of rubber is about 375 to 400 kg per hectare from seedlings trees. But the average yield is 800-1000 kg per hectare in budded plants.

Marketing

Marketing rubber products is relatively easy. Although, you should determine your marketing strategies before starting this business.

These are the common steps and ways for starting and operating a successful rubber farming business. Hope this guide has helped you! Good luck & may God bless you!

Read the full article

2 notes

·

View notes

Text

I got a lot of stimulating questions for “Fascination of Plants Day”. Here are some questions and my answers.

Q: Here's a simple one, how do plants breath?

A: Through their stomata, the microscopic pores usually found on the undersides of leaves. These tiny mouths can open and close depending on humidity, light stimulus, and chemical signals. The pores allow CO2 to enter the leaf and oxygen to exit as part of photosynthesis. Plants also do aerobic respiration, and in this case they take in oxygen and give off CO2 when releasing energy.

Q: Do plants undergo UV damage too?

A: Yes they do! Excessive UV radiation can damage the DNA in plant tissue just like in human skin cells. Damage to the photosynthesis cellular equipment is a big danger from UV light. Plants have a plethora of other pigments, like anthocyanins, to help absorb excess UV light and keep the correct amount of UV light stimulating photosynthesis but not damaging the cells.

Q: Which plant is historically the most important? Why?

A: One highly important plant in human history that often gets overlooked is the Rubber Tree (Hevea brasiliensis). This South American tree's secretions are the raw material for natural rubber. Indigenous Americans discovered the latex's potential for making rubber sports balls, chewing gum, and works of art but it wasn't until the Industrial Revolution in the Western world that rubber became really important. A lot of Industrial Revolution transportation technology, like automobiles, hoses, tires, modern cooking equipment, and more rely on rubber components. The cultivation of rubber tree plantations also changed the political and economic history of many nations in South America, Southeast Asia, and Africa in the late 19th century.

Q: Which discovery from plant science has had the widest application in other fields through reverse engineering?

A: This is a question with a lot of answers, but one example I like is Barbara McClintock's discovery of transposons or "jumping genes" in Native American multicoloured corn. The mysterious colour patterns of these beautiful corn cobs, which are a popular autumn home decor item in North America, inspired the scientist to look into the biological cause of the colour patterns. Subsequently, these jumping genes were found in all prokaryotes and eukaryotes and help explain the presence of non-coding DNA.

Q: Hello, please tell me what method and fertilizer should be used to enlarge and spread the leaves of flowers and plants. Thank you.

A: Hi there! For encouraging leaf development, I recommend using fertilisers that are high in nitrogen. A natural high nitrogen fertiliser is processed chicken manure. To encourage flower and fruit development, a fertiliser higher in phosphates is better. A natural choice is blood, fish, and bone meal.

Q: Any thoughts on how to get rid of the lily beetle?

A: There are commercial pesticides, but another approach might be to introduce parasitoid wasps into your garden! These are tiny wasps that are harmless to humans but prey upon the Lily Beetles (Lilioceris lilii). The wasps lay their eggs in the beetle larvae bodies, and eat them from the inside out. Gruesome, but a natural and effective way to control the beetle population. There are some native British species of parasitoid wasp shown to be effective against Lily Beetle overpopulation, so maybe these could be introduced into your garden?

#katia plant scientist#plant science#plant scientist#plant biology#plants#plant aesthetic#plantcore#planting#plantlife#fields#garden#biology#botany#gardening tips#greenhouse#biologist#women in science#q&a time#q&a session#plant facts#grow your own food#grow your own#green asthetic#green academia#green aesthetic#green witch#greenery#botanical garden#trees and forests#pests

2 notes

·

View notes

Link

Check out this listing I just added to my Poshmark closet: Cariuma + TOZ Women's Collector's Edition Low Canvas Multicolor Sneakers.

0 notes

Text

A trip to the Rubber Museum,

A trip to the Rubber Museum,

Hidden among the bustling streets of [insert location], lies a treasure trove of history, innovation, and craftsmanship - the Rubber Museum. Tucked away from the everyday hustle and bustle, this museum offers visitors a unique insight into the world of rubber, from its humble beginnings to its diverse applications in our modern lives.

As you step through the museum's entrance, you are greeted by the faint scent of rubber lingering in the air, hinting at the rich history that awaits within. The exhibits are meticulously curated, guiding visitors through the fascinating journey of rubber's discovery and evolution.

The story of rubber begins centuries ago in the heart of the Amazon rainforest, where indigenous tribes first discovered the remarkable properties of the latex sap extracted from the Hevea brasiliensis tree. These early inhabitants used rubber for various purposes, from waterproofing to crafting tools and footwear. Visitors to the museum can learn about the traditional methods of rubber extraction and witness demonstrations of how these ancient techniques are still practiced today in some parts of the world.

As you delve deeper into the museum, you'll encounter exhibits showcasing the pivotal role of rubber in shaping human history. From the rubber boom in the 19th century, which fueled the industrial revolution, to its significance in World War II for military applications such as tires, boots, and aircraft components, the museum vividly illustrates how rubber has been intertwined with major historical events.

But the Rubber Museum isn't just about the past; it's also a celebration of innovation and technology. Modern advancements in rubber processing techniques, material science, and engineering have expanded the applications of rubber beyond imagination. Interactive displays allow visitors to explore the diverse uses of rubber in industries ranging from automotive and aerospace to healthcare and fashion.

0 notes

Text

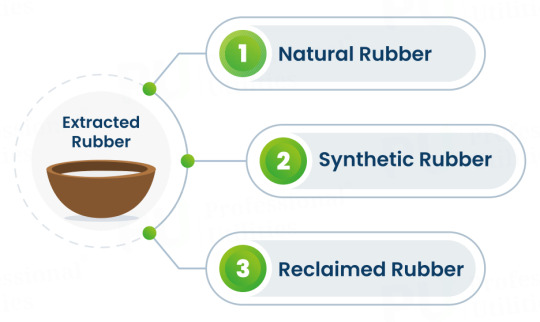

What is the classification of rubber under the rubber board?

The classification of rubber under the rubber board:

Natural rubber: Derived from the sap of rubber trees, primarily Hevea brasiliensis, natural rubber is a versatile polymer utilized in numerous applications. These include manufacturing tires for automobiles, footwear, clothing, and medical devices.

Synthetic rubber: Produced in laboratories using chemicals rather than tree sap, synthetic rubber shares similar properties with natural rubber. However, its production offers control over properties and customization for specific applications, making it prevalent in various industrial uses.

Reclaimed rubber: Also known as recycled rubber, reclaimed rubber is created by grinding and processing scrap rubber and products. Widely employed in industrial manufacturing, it finds applications in products like tires, conveyor belts, and rubber mats.

0 notes

Text

Nestin: Exploring the Latest Innovation In Latex Mattress Technology

Welcome to the future of sleep innovation with Nestin – a brand at the forefront of revolutionizing the mattress industry. The initiators in the natural latex mattress brands in India. In this blog post, we delve into the latest advancements in latex mattress technology, exploring the unique features and benefits that set Nestin apart. Discover how Nestin's commitment to excellence brings you comfort, support, and a restful night's sleep.

Pressure Mapping Technology:

Nestin introduces the latest mattress technology with pressure mapping, via their pure latex mattresses. This innovation ensures optimal support for every inch of your body, reducing pressure points and enhancing overall comfort. Experience a mattress that adapts to your unique shape, providing a personalized and luxurious sleeping experience.

Natural Latex Mattresses for Ultimate Comfort:

Nestin Pure Latex stands as the epitome of innovation in the world of mattresses, presenting a unique and superior single-layer design. Crafted from 100% natural latex, this mattress not only provides exceptional support but also boasts durability and eco-friendliness. The natural latex composition ensures a healthy sleep environment, with an astounding one in every three users reporting a significant reduction in body pain, particularly in the realm of back pain. Nestin Pure Latex understands the importance of targeted support, emphasizing the crucial areas of hips and shoulders to cradle your body in restful comfort. Sourced and refined from the milky sap of the Hevea Brasiliensis tree, this resilient material showcases its eco-friendly roots. Nestin Pure Latex is not just a mattress; it's a testament to a rejuvenating night's sleep, where support, durability, and environmental consciousness seamlessly converge to redefine your sleep experience.Nestin's commitment to excellence extends to hybrid mattresses, combining the best of materials to deliver unparalleled comfort and support. Explore the benefits of a mattress that seamlessly blends natural latex with innovative technology, offering a harmonious sleep surface for the best of both worlds.

Pure Latex Superiority:

Nestin's pure latex pillows and mattresses stand as a testament to excellence. Crafted from 100% natural latex, these mattresses boast a density of 100 kg/cubic meter – a standard 15% above market standards. Higher density translates to superior back support and comfort, making Nestin the top choice for those dealing with body and back pains.

Natural Grid Pattern for Breathability:

The inherent grid pattern of pure latex enhances breathability, promoting a cool and comfortable sleeping environment. Certified as 100% natural latex, Nestin pure latex mattresses feature a premium breathable jacquard knitted fabric on both sides, providing relief, even weight distribution, and improved blood circulation.

Antimicrobial and Resistant to Allergens:

Nestin mattresses are not just about comfort; they prioritize your health too. Certified as naturally antimicrobial and resistant to dust mites, mold, and mildew, Nestin mattresses offer a clean and hygienic sleep environment, ensuring your well-being night after night.

Nestin stands as a beacon of innovation in the realm of latex mattresses, combining cutting-edge technology with unparalleled craftsmanship. From pressure mapping to temperature regulation, Nestin - the best name among the natural latex mattress brands in India, ensures that your sleep experience is elevated to new heights. Explore the superior quality of 100% natural latex, and make Nestin your choice for a mattress that exceeds expectations. Elevate your sleep, embrace comfort, and wake up refreshed with Nestin – your gateway to the future of mattress technology.

#buy mattress online#nestin mattress#online mattress shopping#best mattress online#best mattress in kerala#buy mattress in Kerala

0 notes

Text

Govt raises funding for development of natural rubber sector

Context: The union government has increased the allocation sustainable and inclusive development of the natural rubber sector scheme for the next two financial years (2024-26) by 23 per cent from Rs 576.41 crore to Rs 708.69 crore.

About natural rubber:

It is a polymer of isoprene, an organic compound and obtained from the latex of several tropical trees.

Para Rubber tree (Hevea brasiliensis)…

View On WordPress

0 notes

Text

What is Para wood: Unlocking the Secrets of This Sustainable Powerhouse

Parawood, also known as rubberwood, is a durable and eco-friendly type of wood commonly used in furniture manufacturing. It is obtained from Hevea brasiliensis trees, primarily cultivated for latex production.

Parawood is known for its light color, smooth texture, and resistance to warping, making it an ideal choice for furniture production. Additionally, it is considered environmentally friendly as it comes from sustainable plantations and is often used as an alternative to more expensive hardwoods.

With its strong and versatile characteristics, parawood has become a popular choice in the furniture industry for its affordability and durability.

The Origins Of Parawood

Parawood, also known as rubberwood, is a type of hardwood that comes from the Pará rubber tree, scientifically known as Hevea brasiliensis. This tree is native to Southeast Asia and is primarily grown in countries such as Thailand, Malaysia, Indonesia, and Vietnam. Known for its sustainable harvesting practices and environmental benefits, para wood has gained popularity in the furniture industry. Let's take a closer look at the Southeast Asian origins and sustainable harvesting practices of parawood.

Southeast Asian Origins

Parawood is deeply rooted in the heart of Southeast Asia. The region's tropical climate, abundant rainfall, and rich soil provide the ideal conditions for the growth and cultivation of the Pará rubber tree. Thailand stands out as the leading producer of para wood, renowned for its quality and durability. The climate and geography of Southeast Asia contribute to the exceptional strength and stability of para wood, making it a sought-after material for furniture and other wood-based products.

Sustainable Harvesting Practices

One of the key factors that sets Parawood apart is its sustainable harvesting practices. Unlike other types of hardwood, which are often sourced from deforestation and unsustainable logging practices, para wood is derived from rubber tree plantations. These plantations are grown specifically for the purpose of producing latex, the primary raw material extracted from the trees for rubber production.

When rubber trees reach the end of their latex-producing life cycle, which typically lasts around 25 to 30 years, they are harvested for their wood. This process ensures that no trees are cut down solely for their timber, making parawood an environmentally friendly choice. By utilizing rubberwood as a sustainable resource, the furniture industry can support the conservation of forests and reduce the demand for illegal logging.

Furthermore, the sustainability of parawood extends beyond its origins. It exhibits excellent regenerative properties, as new trees are replanted to replace those that have been harvested. This practice allows for the continuous production of para wood, promoting a renewable and responsible approach to the use of natural resources.

In addition to its eco-friendly characteristics, para wood offers numerous advantages as a material. Its tight grain pattern, straight texture, and light color make it versatile and adaptable to various furniture styles. It is resistant to cracking and warping, ensuring the longevity of furniture crafted from it.

Parawood's sustainable origins and harvesting practices make it a popular choice for environmentally conscious individuals. By opting for para wood furniture, consumers can not only enjoy the beauty and durability of this hardwood but also contribute to the preservation of our planet's forests.

Characteristics Of Parawood

Parawood, also known as rubberwood, is an eco-friendly and sustainable hardwood derived from the rubber tree. It has a dense grain that makes it sturdy and durable, making it an excellent choice for furniture and flooring. With its light color and ability to be easily stained, Parawood is a versatile and cost-effective option for various interior design projects.

Color And Grain Patterns

Parawood, also known as rubberwood, is a beautiful hardwood with distinctive color and grain patterns. Its color can vary from pale cream to light golden brown, creating a warm and inviting appearance in any space.

The grain patterns of Parawood are often straight, though it can also exhibit interlocking or wavy grain patterns. These unique grain patterns add depth and character to furniture pieces made from Parawood.

Durability And Strength

Parawood is highly regarded for its durability and strength, making it an excellent choice for furniture and woodworking projects. Its dense grain structure and high density contribute to its remarkable strength, allowing it to withstand the test of time with minimal wear and tear.

Due to its durability, Parawood is resistant to warping, splitting, and cracking, ensuring that furniture made from it remains structurally sound for years to come. Its strength also enables it to hold up well under heavy use, making it suitable for busy households or commercial settings.

Summary:

- Parawood exhibits a range of colors from pale cream to light golden brown.

- Grain patterns can be straight, interlocking, or wavy, adding visual interest.

- Parawood is highly durable and strong, with a dense grain structure.

- Resistant to warping, splitting, and cracking, ensuring longevity.

- Capable of withstanding heavy use, making it suitable for various settings.

Benefits Of Parawood

Parawood, also known as rubberwood, is a sustainable and versatile option for various applications. Its unique qualities make it a desirable choice for eco-conscious consumers and furniture manufacturers.

Environmental Sustainability

Parawood is an eco-friendly option as it is sourced from rubber trees, which have reached the end of their latex-producing cycle. By utilizing this wood, it reduces the need to cut down valuable rainforest trees, contributing to forest preservation. The cultivation of rubber trees also helps in carbon sequestration, making it a sustainable choice for furniture and flooring materials.

Versatility In Applications

Parawood is incredibly versatile and suitable for a wide range of applications including furniture, flooring, and decorative items. Its consistent grain and natural color make it an ideal material for various aesthetic preferences. It can be stained, painted, or varnished to achieve different looks, providing flexibility in design.

Challenges And Controversies

Parawood, also known as rubberwood, is a versatile and sustainable wood commonly used in furniture manufacturing. However, it is not without its challenges and controversies. In this section, we will explore two key aspects that have sparked discussions within the industry: certification and traceability, as well as market misconceptions.

Certification And Traceability

Ensuring the sustainability of para-wood production is crucial, and that's where certification and traceability come into play. Certifications such as the Forest Stewardship Council (FSC) and Programme for the Endorsement of Forest Certification (PEFC) provide reassurance that the wood used comes from responsibly managed forests.

Traceability is the process of accurately tracking the origin and journey of the wood, from the forest to the end product. It helps validate the credibility of sustainability claims and ensures that the wood has not been harvested illegally or from protected areas. Implementing effective traceability systems can be challenging, especially for complex supply chains and global markets.

Market Misconceptions

Parawood has faced its fair share of misconceptions in the market, which have created controversies and confusion among consumers. It's essential to address and debunk these misconceptions to promote accurate information and facilitate informed buying decisions.

Some common market misconceptions include:

- Low Quality: The misconception that para wood is of inferior quality, perhaps due to its association with rubber tree plantations. However, para wood actually possesses desirable properties such as strength and durability, making it suitable for furniture production.

- Lack of Longevity: Another misconception is that parawood furniture does not last long. This is far from the truth, as proper care and maintenance can ensure the longevity of parawood furniture, just like any other quality wood.

- Environmental Impact: Parawood is often mistakenly believed to contribute to deforestation. In reality, it is a byproduct of the latex industry and gives value to trees that would otherwise be discarded. When sourced responsibly, parawood is an environmentally friendly choice.

Future Outlook For Parawood

Parawood, also known as rubberwood, is a versatile and sustainable material widely used in furniture production. With its durable nature and attractive grain, para wood is gaining popularity in the market and offers a promising future for eco-friendly furniture solutions.

Innovation In Processing Techniques

As the demand for sustainable and eco-friendly materials continues to rise, the future outlook for Parawood looks promising. One key factor contributing to its growth is the innovation in processing techniques. Manufacturers are constantly exploring new ways to maximize the usage of Parawood and minimize waste. They are implementing advanced technologies and equipment to improve the quality and efficiency of processing. By adopting these innovative techniques, Parawood can be transformed into various products with enhanced durability and aesthetics.

Many companies are investing in research and development to find alternative uses for Parawood and create value-added products. The development of engineered Parawood flooring is a great example of this innovation. By combining Parawood with other materials, manufacturers are able to create flooring with improved stability, moisture resistance, and longevity. These advancements in processing techniques not only extend the lifespan of Parawood products but also open up new markets and opportunities for the industry.

Global Awareness And Adoption

Another reason for the bright future outlook for Parawood is the increasing global awareness and adoption of sustainable materials. With growing concerns about deforestation and environmental degradation, consumers are becoming more conscious of the products they purchase. Parawood, being a sustainable and renewable resource, aligns perfectly with this growing demand for eco-friendly alternatives.

Countries across the globe are recognizing the importance of sustainable forestry and are implementing policies to ensure responsible production and consumption of wood products. This has led to an increase in the popularity and availability of Parawood in international markets. As more consumers become aware of the benefits and versatility of Parawood, its demand is expected to grow significantly in the coming years.

The adoption of Parawood as a preferred choice in various industries, including furniture, construction, and interior design, further strengthens its future outlook. Its durability, strength, and attractive grain make it an ideal material for a wide range of applications. From solid wood furniture to decorative panels, Parawood offers endless possibilities for creative designs.

In conclusion, the future outlook for Parawood appears promising due to the innovation in processing techniques and the global awareness and adoption of sustainable materials. With continued advancements, Parawood can play an essential role in reducing the environmental impact of the wood industry while providing high-quality products to meet the evolving needs of consumers worldwide.

Frequently Asked Questions On What Is Parawood

Is Rubberwood Good Quality?

Rubberwood is a good quality material. It is durable, affordable, and eco-friendly. It is commonly used in furniture manufacturing due to its strength and resistance to warping.

What Is Parawood Similar To?

Parawood is similar to teak and oak due to its durability and strength. It shares the qualities of hardwoods.

How Does Parawood Stain?

Parawood stains easily due to its open-grain structure. It absorbs stains effectively and evenly, resulting in a smooth and rich appearance. Its natural color also enhances the stain colors, allowing for a wide range of options. With proper preparation and application, para wood can be stained to achieve various desired finishes.

Is Rubberwood The Same As Parawood?

Rubberwood and Parawood are not the same. Rubberwood comes from rubber trees, while Parawood is derived from the Pará rubber tree.

Conclusion

Parawood offers a sustainable and durable option for furniture and flooring. Its eco-friendly nature makes it an appealing choice for environmentally conscious consumers. With its attractive grain patterns and ability to take on various finishes, parawood provides both aesthetic and practical benefits for your home.

Consider Parawood for your next design project.

Read the full article

0 notes

Text

What is Crude elastic?

Crude elastic is an essential type of elastic removed from plastic, a smooth sap from the elastic tree Hevea brasiliensis, or different sources. This normal substance goes through an interaction where it initially coagulates, as a rule by adding acids to the plastic, making it become strong. After coagulation, the crude elastic is washed and dried to eliminate water and pollutions.

Know more at: https://gummilist.com/ragummi/

0 notes