#Durable Woodworking Machines

Text

Dellatecnica - Best Woodworking and Panel Processing Machines

DELLATECNICA provides best variety of Woodworking and Panel Processing Machines. We offer top quality woodworking equipments of Holzmac and Promac Brand having machines like Panel saw, Beam Saw, Curvilinear Edge Bander, Automatic Throughfeed edge banding Machine, CNC Nesting Machine and many more.

#Corner Rounding Machine#Dust Collectors#CNC Machines#High tech CNC Machines#Best Woodworking Machine Brands#Woodworking tools#Panel Processing Woodworking Machinery#Durable Woodworking Machines#Woodworking machine manufacturer#Woodworking machines in India#panel Processing Machine#woodworking Machine

1 note

·

View note

Text

Unlocking the World of RR Tools and Machinery

In the fast-paced world of machining and metalworking, the choice of tools plays a pivotal role in determining the efficiency and precision of operations. Among the myriad of options available, RR Tools stand out as a beacon of quality and reliability. In this article, we delve into the intricate world of RR Tools, exploring their product range, the esteemed RR brand, and specific tools like the revolving center MT4 and ER collets.

Brief Overview of RR Tools

RR Tools, synonymous with quality and precision, have been catering to the needs of industries worldwide. With a diverse product range and a commitment to excellence, they have become a go-to choice for machinists and manufacturers.

Importance of Quality Tools in Various Industries

In industries where precision is paramount, the quality of tools used directly impacts the outcome. RR Tools, with their commitment to delivering top-notch products, contribute significantly to the success of various sectors.

Exploring RR Toolstore

Diverse Product Range

One of the key strengths of RR Tools is their extensive product range. From ER collets to revolving centers, drill chucks to clamping kits, the toolstore is a one-stop solution for machinists' needs.

User-Friendly Interface

Navigating the RR Toolstore is a breeze, thanks to its intuitive design. Machinists can easily find the tools they need, with detailed product descriptions and specifications aiding in informed decision-making.

Unveiling RR Brand

Legacy and Reputation

The RR brand boasts a rich legacy in the industry. Years of expertise and a commitment to quality have earned them a stellar reputation among machinists and manufacturers alike.

Signature Products

Certain products under the RR brand have become synonymous with excellence. These signature tools not only meet industry standards but often surpass them, setting a benchmark for quality.

Understanding Revolving Center MT4

Key Features

The revolving center MT4 is a cornerstone in precision machining. Its key features, such as high rotational accuracy and durability, make it an indispensable tool for machinists.

Applications in Machining

From metalworking to woodworking, the MT4 revolving center finds applications across various industries. Its versatility and reliability make it an asset in achieving precise and intricate designs.

Dive into ER Collets

ER32, ER40, ER25, ER20, and ER16

ER collets, available in different sizes, cater to the diverse needs of machinists. Understanding the variations in ER32, ER40, ER25, ER20, and ER16 collets is crucial for optimal tool usage.

Sizes and Applications

Each ER collet size has specific applications. Machinists must choose the right size based on their requirements, considering factors like tool shank diameter and workpiece material.

Decoding Drill Sleeve Size Chart

Significance in Precision Machining

Drill sleeve size charts act as a guide for machinists, ensuring the correct pairing of drills and sleeves for optimal performance. Precision in sizing is paramount for efficient machining.

Choosing the Right Size

The drill sleeve size chart aids machinists in selecting the right combination for drilling operations. Choosing the correct size ensures stability, reducing the risk of tool breakage and enhancing overall efficiency.

Morse Taper: An Essential Tool

Different Taper Sizes

Morse tapers come in various sizes, each serving a specific purpose. Understanding the Morse taper size chart is vital for selecting the right tool for tasks like drilling and reaming.

Applications in Metalworking

Metalworking operations often require the use of Morse tapers. Whether it's drilling, turning, or milling, having the right taper size ensures seamless and accurate machining.

RR Tools Store: A Closer Look

Overview of Product Categories

The RR Tools store categorizes products meticulously. From cutting tools to measuring instruments, machinists can easily explore and find the tools they need for their specific applications.

Customer Reviews and Testimonials

Real-world experiences shared by customers provide valuable insights into the performance and reliability of RR Tools. Positive reviews highlight the trust and satisfaction machinists derive from these tools.

Clamping Kit for VMC

Importance in Vertical Machining Centers

Clamping kits play a crucial role in securing workpieces in vertical machining centers. RR Tools offers specialized clamping kits designed to enhance stability and precision in VMC operations.

RR Tools' Specialized Kits

The clamping kits from RR Tools are engineered to perfection, offering a secure grip on workpieces. Machinists can trust these kits to withstand the rigors of VMC operations.

MT4 Revolving Centre Dimensions

Specifications and Variations

MT4 revolving centers come in different dimensions and specifications. Understanding these variations is essential for machinists to ensure compatibility with their machinery.

Compatibility with Machinery

Before purchasing an MT4 revolving center, machinists must verify its compatibility with their machines. Ensuring the right fit guarantees optimal performance and longevity of the tool.

Quick Change Drill Chuck

Efficiency in Changing Tools

Quick change drill chucks expedite the tool-changing process, saving valuable time during machining operations. Machinists benefit from increased efficiency and reduced downtime.

Advantages in Machining Processes

The quick change feature allows machinists to adapt swiftly to different drilling

T-Nut Dimensions and Applications

Understanding T-Nuts

T-nuts are essential components in various machining setups. Understanding their dimensions and applications is crucial for ensuring a secure and stable connection between workpieces and the machine's table.

Compatibility in Different Machining Setups

Machinists encounter different T-nut sizes and designs in their operations. Choosing the right T-nut ensures proper alignment and prevents any undesirable movement during machining, contributing to overall safety and precision.

VMC Clamping Kit: Ensuring Stability

Features of VMC Clamps

VMC clamping kits from RR Tools are equipped with features designed to ensure stability during vertical machining center operations. Exploring these features is vital for machinists aiming for high precision.

Enhancing Precision in Machining

Stability is synonymous with precision in machining. RR Tools' VMC clamping kits provide machinists with the confidence to undertake intricate tasks, knowing that their workpieces are securely held in place.

14. Exploring Jacobs Taper Chart

Jacobs Taper Overview

The Jacobs taper, a standardized tool holder, finds widespread use in drill chucks. Understanding its design and applications, as outlined in the Jacobs taper chart, aids machinists in selecting the right tool for drilling tasks.

Applications in Drill Chucks

Jacobs tapers are a fundamental part of drill chucks, facilitating the secure attachment of drills. This ensures a precise and stable drilling process, making it an indispensable tool in machining operations.

Conclusion

Summarizing the Importance of RR Tools

In conclusion, RR Tools have established themselves as a reliable and reputable choice for machinists and manufacturers seeking quality tools. From the diverse product range available at the RR Toolstore to the legacy and signature products of the RR brand, the article has shed light on the crucial aspects that make RR Tools stand out in the competitive market.

2 notes

·

View notes

Text

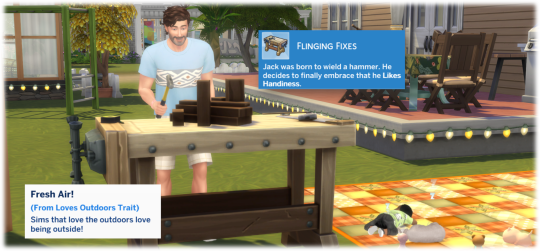

NSB (Straud Legacy) Gen 8 Ep. 149: Idyllic Summer Days

Jack was also very aware of his upcoming final life stage, but unlike Peachy, that knowledge just encouraged him to live each day to its fullest.

With no plans to return to the office, he was having a blast staying at home all day with baby Luigi. They spent long hours out in the sun together, going on walks or working in the yard. He even took up woodworking and enjoyed hand crafting durable goods from scrap lumber.

---------------------------------------------

Of course, in Brindleton Bay the weather was often rainy, forcing papa and baby back inside.

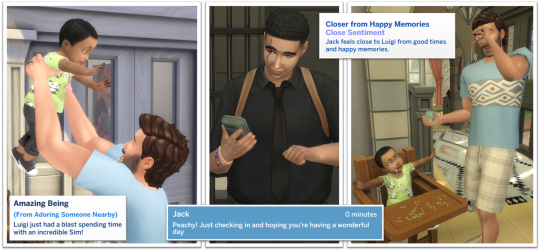

Now that Luigi could sit up on his own Jack had brought Steven and Spencer’s old dollhouse down from the attic for the two of them. On rainy days he’d pull from the vast treasure trove of stories he’d collected during his time in law enforcement to entertain his boy as they played with his dollies.

---------------------------------------------

As he grew it became obvious that Luigi’s love of his little musical mobile was only the tip of his musically inclined iceberg.

He seemed to be entranced with anything that could make noise, from the jingle of the dangling beads on his playmat to the rattle of his stuffed bunny.

Maybe funniest of all to Jack was when he would turn on his favorite jazz station and watch his little man start bopping along to the music. Seeing his tiny dance machine boogie up and down the floor from only a foot high never got old for the doting Papa.

---------------------------------------------

Just because he couldn’t get enough of his tiny son didn’t mean that Jack forgot about his husband. Being at home gave him plenty of free time to check in regularly, not to mention blowing up social media with all the funny and adorable things Luigi got up to during their time together.

Peachy could only smile and shake his head when his phone would ding, yet again, with another cute update from Jack. His partners excitement to become a father had left him little doubt that Jack would enjoy parenthood, but it was still impressive how quickly and completely he’d taken to the job.

---------------------------------------------

Jack made sure to reserve time for their shared hobbies as well, whenever the hard working Peachy was able to be with them. It might only be the three of them around the homestead’s table these days, but neither man saw that as any reason not to make each homecooked meal an event.

Luigi was often ready for a nap shortly after Peachy arrived home from work, giving the boys a window to chat man to man in the kitchen as they whipped up that night’s family dinner.

---------------------------------------------

Maybe best of all Jack was finally able to conquer the fear of failure that being twice pushed out of law enforcement had planted in his heart.

One night, after showing Peachy the solid oak planter he’d just finished, his husbands praise for both his handicraft and the fantastic job he was doing raising their boy helped him to an emotional revelation.

As Peachy went on to thank him for making all his promotions at work possible, first by mentoring him originally, and now by supporting his focus on these final rungs of their shared career and calling, Jack finally realized that he was far from a failure. In fact, to the people who mattered most in his life he was a raging success, and that brought him more joy than any “exceeds expectations” performance review at the office ever had.

---------------------------------------------

For his part, Peachy enjoyed listening to Jack’s delighted stories about the amazing time he was having during those long, languid summer days at home.

They were planning a joint birthday celebration with Tori and Toni for their three infants, who would all too soon be aging up into “big kids”. Jack could hardly believe that summer was almost over, and little Luigi and his cousins would all soon be official toddlers.

He fully intended to continue making the most of every moment, creating memories with his husband and son that he hoped would last forever.

-----------------------------------------

Want To See More? View The Full Story of My Not So Berry Challenge Here

#sims 4#sims 4 challenge#sims 4 legacy#sims 4 nsb#sims 4 not so berry#sims4#sims4nsbstraud#sims 4 let's play#sims 4 gameplay#sims 4 lets play

3 notes

·

View notes

Text

Powermatic

Powermatic is a well-known brand of woodworking machinery that has been producing high-quality tools and machines since 1921. The company is known for its wide range of products, including table saws, bandsaws, jointers, planers, lathes, and dust collection systems. Woodworking professionals and enthusiasts around the world trust Powermatic machines due to their precision and accuracy.

One of the key features that sets Powermatic machinery apart from others is the use of cast iron in their construction. This material provides stability and durability to their machines, making them reliable and long-lasting.

Powermatic machinery is designed with safety in mind. They incorporate various safety features in their machines such as blade guards and safety switches to prevent accidents in the workshop.

Overall, Powermatic is a reputable brand that offers high-quality woodworking machinery. Their precision, durability, and safety features make them a popular choice for both professional woodworkers and hobbyists alike.

Powermatic product line

Powermatic is a renowned brand that specializes in crafting top-quality woodworking machinery and tools. The brand offers a diverse product line that caters to the varying needs of woodworkers, from novice hobbyists to seasoned professionals.

Table Saws - Powermatic's table saws are engineered for precision, power, and durability. The brand offers cabinet saws designed for heavy-duty use, featuring large table surfaces and robust motors. Contractor saws are more portable and suitable for job site use, while hybrid saws combine features of both cabinet and contractor saws.

Bandsaws - Powermatic's bandsaws are designed to make accurate cuts in wood and other materials. They come in different sizes, from benchtop models suitable for small jobs to floor models capable of handling larger wood pieces. Powermatic's bandsaws are renowned for their precision, ease of use, and smooth operation.

Planers - Powermatic's planers are designed to smooth rough lumber and make it usable for woodworking projects. The brand offers a variety of sizes, with larger models capable of handling wide boards and thick wood pieces. Powermatic's planers are known for their precision and user-friendliness.

Jointers - Powermatic's jointers are used to straighten and flatten wood surfaces. They come in benchtop and floor models, with larger ones capable of handling wider wood pieces. Powermatic's jointers are known for their accuracy and ease of use.

Sanders - Powermatic's sanders include both belt and drum sanders, designed to make sanding jobs quick and straightforward. They come in different sizes, with larger models capable of handling more substantial wood pieces. Powermatic's sanders are renowned for their accuracy, speed, and ease of use.

Dust Collectors - Powermatic's dust collectors are designed to ensure workspace cleanliness and safety by removing dust and debris from the air. They come in different sizes, with larger models capable of handling multiple machines at once. Powermatic's dust collectors are known for their efficiency and reliability.

Lathes - Powermatic's lathes are used for turning wood and other materials. They come in benchtop and floor models, with larger ones capable of handling more significant wood pieces. Powermatic lathes are known for their precision and ease of use.

Mortisers - Powermatic mortises are used to make precise mortises in wood. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's mortises are renowned for their accuracy and user-friendliness.

Drill Presses - Powermatic's drill presses are used to drill accurate holes in wood and metal. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's drill presses are known for their precision and ease of use.

CNC Machines - Powermatic's CNC machines are used for computer-controlled manufacturing processes. They come in different sizes, with larger ones capable of handling larger wood and other materials. Powermatic's CNC machines are known for their precision and efficiency.

In conclusion, Powermatic's product line is designed to cater to the needs of woodworkers at all levels, offering high-quality woodworking machinery and tools that are durable, efficient, and user-friendly.

#powermatic#CNC Machines#Drill Presses#Mortisers#Lathes#Dust Collectors#Sanders#Jointers#Planers#Bandsaws#Table Saws

2 notes

·

View notes

Text

How To Choose The Best Cutting Tools For PCD?

You might be wondering which is the most suitable PCD cutting tool for you. Keep reading to find out the basic characteristics of PCD cutting tools and their applications. The next step is to begin cutting edge preparation. You'll eventually get the results that you want. These are the top aspects to take into consideration when choosing sundi tools. Your job's results depend on it.

Picking the appropriate pcd-cutting tools

While PCD tools are more expensive than other carbide materials in terms of price but they are more precise and longer tool lifespan as compared to carbide cutters. Although PCD tools can improve the performance of carbide tools in some situations, they're not always the best. It is important to consider the cost-benefit ratio with respect to the process of machining. To reduce the chance of errors and increase efficiency, it is essential to understand the nuances of the products and the process of manufacturing.

As compared to carbide and various materials, PCDs are able to handle a wider variety of applications. Aluminum-based parts, such as ones used in the automotive industry are becoming increasingly sought-after. pcd drilling tools could be used to connect the components. However, you shouldn't use them for ferrous materials. If you're looking for a specific requirement, TOMMASIN UTENSILI offers customized PCD tools. These cutting tools are used on complex, intricate parts.

Characteristics

There are numerous benefits to using PCD cutting tools. They are durable, good surface roughness and high dimensional precision. Non-metallic woodworking materials, as well as ceramic materials are the primary processing tools. Additionally, the polycrystalline diamond tool can be used to process many fiber-reinforced composite materials as well as a variety of metallic alloys. PCD cutting tools come in three types that include piston series cutters inserts and hub cutters.

We conducted several experiments to investigate the wear properties in PCD tools. By using two different grinding methods that we developed three-dimensional PCD devices and tested them in high-speed titanium alloy cutting. This research was intended to analyze the cutting forces as well as the geometry, worn morphology, and wear mechanisms of PCD tools. The findings of this study will enable us to improve the design of PCD cutting tools.

Applications

When creating a product that requires precision and high productivity, a company must use the appropriate PCD cutting tools. The engineering and design process of PCD cutting equipment is extremely precise. They are designed and built with high-quality in mind. This means that the tool will last longer in life, greater throughput and lower costs for ownership. A good PCD cutter tool will lower the cost of your final product without sacrificing quality and productivity.

When selecting the right PCD cutting tools, be certain to think about the kind of material you'll have to cut. Tools made of carbide, for instance will wear out quickly and require more frequent modifications. Non-ferrous materials , like fiberglass and copper, however require PCD tooling. Furthermore, they maintain sharp cutting edges longer, making them perfect for a wide range of uses. PCD inserts are a great option if you require a tool that can endure high temperatures.

Edge preparation

When selecting PCD cutting tools it is essential to understand the role that the edge preparation play. Edge preparation is vital to successful manufacturing and for cutting tools to perform at their optimal levels. Edge preparation is an integral part of every manufacturing procedure pcd reamer cutting speed. But how can you determine the best tools for your needs? For more details take a look! Let's begin by explaining what edge preparation is.

Carbide drills are not easy to prep. It may require t-landing and grinding. PCD is a fan of edge preps and well-designed hones. These can be expensive and may differ in size based on the type of tool. PCD is generally run "up sharp." This is contingent on the manufacturer. Some suppliers run PCD instruments 10,000 times before being considered to be no-sharp.

2 notes

·

View notes

Text

Why Waterproof & Washable Dog Beds Needed?

Our adored four-legged friends bring us boundless joy, coupled with their muddy footprints all over the place. Amidst games, it may seem like an endless mission to keep their bed clean and fresh. That’s why we need waterproof washable dog beds!

These beds are designed to be durable yet comfortable, while also being easy to maintain; this makes them perfect for lively dogs, untidy eaters, or senior pets who may have little accidents from time to time. So let’s take a closer look at what these best dog beds UK offer in terms of benefits — as well as how they could save you hours cleaning up after your furry friend!

Why Waterproofing Matters: Safeguard Your Bed Against Accidents & Spills

Peace Of Mind For Pet Owners: There will always be mishaps here and there — especially when dealing with puppies or older dogs whose control isn’t what it used to be. Therefore having that extra shield provided by a ‘waterproof’ dog bed that protects the inner cushion from any unforeseen leakages is truly life-saving; less stress for you, dryness for them.

Goodbye Stained Floors: Say goodbye once and for all to those nightmares about puddles seeping through onto carpets/rugs forever! These special beds have linings that act as barriers against water getting into contact with sensitive flooring materials like wool or cotton fibres — thus preventing damages such as rotting woodwork or unpleasant smells caused by mildew/mould growths underneath.

Washable Wonders: Easy Hygiene with Cleanable Materials

Fresh & Clean Beds For Happy Pups: Like our own beds, dogs’ beds need regular cleaning to keep them sanitary. Washable dog beds with removable covers make it easy to do this. Just throw the cover into the washing machine for a quick refresh — this will also help keep your furry friend’s bedding smelling fresh and free from allergens.

Fighting Doggy Odours: Regular washing helps to eliminate any doggy smells that may have built up over time. This will keep your house smelling nice and stop your pup from rolling around in a not-so-pleasant-smelling bed!

Perfect For Allergy Sufferers: If you or someone in your household suffers from allergies then having a washable dog bed is essential. Dust mites, dander, and other allergens can be removed during normal washes which could trigger allergy symptoms.

Keeping Your Dog Bed Fresh: Tips On Regular Cleaning And Odour Control

Even if you have got yourself a waterproof/washable dog bed there are still some things that should be done on a regular basis:

Shake things up: Shake out the bed regularly to get rid of the dirt that’s not attached, hair, and crumbs. This will prevent smells and keep the bed fluffy.

Clean spills on the spot: For small spills, use a damp cloth with a gentle pet-friendly cleaning solution and wipe away any mess immediately.

Wash cover often: Follow the instructions given by the manufacturer regarding washing the bed cover. Most washable beds can be machine washed using a mild detergent on a gentle cycle. Air-dry it completely before putting it back onto your dog’s bed.

Power of baking soda: Baking soda is a natural deodorizer. Sprinkle some over the top of your bed cover, leave for 30 minutes then vacuum off. This will help absorb and eliminate any lingering smells.

Also Read: Should You Use a Dog Harness or Collar?

In conclusion,

Waterproof and washable indestructible dog beds are perfect for keeping your furry friend comfortable as well as their sleeping area clean and fresh. These revolutionary new products provide protection against accidents or spills; they also have great hygiene due to easy-clean materials thus ensuring that you have a smelly-free zone around your dog’s resting place for longer periods of time. So buy the best dog bed today! Waterproof and washable indestructible dog beds are available now so why not invest in them? You’ll never look back!

0 notes

Text

Global Industrial Garnet Market Analysis and Growth Opportunities

Industrial Garnet: An Essential Raw Material for a Variety of Industries

What are Industrial Garnets?

Industrial garnets refer to varieties of garnet (naturally occurring silicate minerals) that are used for industrial purposes. Garnet possesses physical properties like hardness, chemical stability and fire resistance that make it suitable for industrial applications that require durable, long-lasting abrasives or filtration materials. The main factory garnet varieties used are almandine, spessartine and pyrope.

Garnet Mining and Production

Garnet deposits are mined through both open-pit mining and underground mining methods depending on the location and shape of the deposit. After mining, the raw garnet ore undergoes various physical and chemical processes of beneficiation which include washing, screening, crushing, heavy media separation etc to extract high purity garnet concentrates suitable for industrial uses. Leading garnet mining nations are India, Vietnam, China and U.S among others. The garnet industry offers steady employment and business opportunities in mining towns located near garnet deposits.

Uses of Factory Garnets

Abrasives: Garnet is a premier abrasive used for cleaning, blasting and grinding applications due to its high hardness. It is used for cleaning and surface preparation of metals, ceramics, glass, concrete etc. Precisely graded garnet grit is also used for waterjet cutting of metals and delicate materials.

Water Filtration: Highly durable garnet beads are used as filter media in water filtration plants to remove suspended particles from water. Its properties like rounded shape, hardness and specific gravity make it ideal for water filtration.

Blasting Abrasives: Garnet grit is a popular abrasive material used in various blasting applications for surface preparation and surface finishing. It is often used for removal of rust, paint and coatings prior to repainting of infrastructure like bridges and buildings.

Abrasive Blasting: Garnet is widely used in abrasive blasting equipment for surface preparation and surface finishing of various substrates like metal, concrete, glass etc. It is fed as an abrasive media in blasting machines.

Abrasive Powders: Precisely sized and graded garnet powders find applications as an abrasive additive in products like abrasive papers, sheets, cloths, polishing compounds, metal finishing and woodworking applications.

Waterjet Cutting: Ultra-fine garnet powder is used as the abrasive medium in waterjet cutting systems for precision cutting of even delicate materials like composites, glass, stone etc. without heat affected zones.

Other uses: Garnet finds other industrial applications as well in drilling muds, landfill liners, scouring pads, cleaning agents, anti-skid materials, etc leveraging its hardness and durability properties.

0 notes

Text

Mastering the Art of Drilling: A Comprehensive Guide to Drill Bits

Unveiling the Tools That Drive Precision and Efficiency

Drilling is an essential aspect of various industries, from construction to manufacturing, and even in the realms of DIY projects. At the heart of this fundamental process lie the unsung heroes known as drill bits. These small yet mighty tools play a crucial role in achieving precision, efficiency, and accuracy in drilling operations. In this comprehensive guide, we delve into the world of drill bits, exploring their types, uses, and key considerations for selection.

Understanding the Basics: What are Drill Bits?

Drill bits are cutting tools used to create cylindrical holes in various materials, including wood, metal, plastic, and masonry. They attach to a drill or drilling machine, utilizing rotational motion to penetrate surfaces. Despite their seemingly simple function, drill bits come in a myriad of shapes, sizes, and materials, each tailored to specific applications.

Exploring the Types of Drill Bits

Twist Drill Bits: Among the most common types, twist drill bits feature spiral grooves that aid in chip removal and enhance cutting efficiency. They are suitable for drilling holes in wood, metal, and plastic.

Masonry Drill Bits: Designed with a carbide tip, masonry drill bits excel in drilling through tough materials such as concrete, brick, and stone. Their robust construction enables them to withstand the rigors of heavy-duty applications.

Spade Drill Bits: Characterized by a flat, paddle-shaped blade, spade drill bits are ideal for drilling large-diameter holes in wood. They offer rapid drilling speed but may produce rough edges.

Forstner Drill Bits: With a flat-bottomed design, Forstner bits excel in creating precise, flat-bottomed holes in wood. They are favored for woodworking projects that demand accuracy and clean finishes.

Countersink Drill Bits: These specialized bits combine drilling and countersinking functions, allowing users to create recessed holes for screws and fasteners. They are indispensable in carpentry and metalworking tasks.

Step Drill Bits: Featuring multiple stepped diameters, step drill bits are versatile tools suitable for enlarging existing holes or drilling holes of varying sizes in thin materials like sheet metal.

Key Considerations for Selection

When choosing drill bits for a particular task, several factors come into play:

Material Compatibility: Select a drill bit that is compatible with the material you intend to drill. Different materials require different cutting geometries and coatings to achieve optimal results.

Drill Bit Size: Consider the desired hole diameter and depth when selecting the appropriate drill bit size. Using the wrong size can lead to inaccuracies and inefficiencies in drilling.

Speed and Feed Rates: Adjust drilling speed and feed rates based on the material being drilled to prevent overheating and premature wear of the drill bit.

Quality and Durability: Invest in high-quality drill bits made from durable materials to ensure longevity and performance consistency, especially for heavy-duty applications.

Safety Precautions: Prioritize safety by wearing appropriate personal protective equipment (PPE), such as safety goggles and gloves, when operating drilling equipment.

Conclusion

Drill bits are indispensable tools that form the backbone of drilling operations across various industries and applications. By understanding the different types of drill bits available and selecting the right one for the task at hand, professionals and DIY enthusiasts alike can achieve precision, efficiency, and safety in their drilling endeavors. Whether drilling through wood, metal, concrete, or other materials, the right drill bit can make all the difference in the success of a project.

For More Info:-

Drill Bits

Powerbuilt Tool Chest

0 notes

Text

Exploring the Benefits of PCD Tools Products for Industrial Machining

Introduction:

In the dynamic and demanding world of industrial machining, the efficiency and precision of the tools used are pivotal. Polycrystalline Diamond (PCD) tools have emerged as a frontrunner in high-performance machining applications.

Perfect Tools Industries, a prominent woodworking tools manufacturer in Ahmedabad, also specializes in advanced PCD tools products. These tools are revered for their exceptional durability and cutting accuracy, especially in complex machining tasks.

1. Unmatched Hardness and Durability: PCD tools products, known for their incredible hardness and wear resistance, can withstand high temperatures and abrasive materials that would typically wear down other types of cutting tools. This makes them particularly suitable for extended industrial applications, reducing downtime due to tool changes and maintenance. For industries focused on high-volume production, PCD tools from Perfect Tools Industries offer a longevity that is both cost-effective and efficient.

2. Enhanced Precision and Quality of Finish: The superior hardness of PCD allows for extremely sharp cutting edges that maintain their precision over long periods and numerous machining cycles. This sharpness is crucial for industries that require a high level of detail and a superb finish. Using PCD tools products from Perfect Tools Industries, businesses can achieve a consistently high-quality surface finish, reducing the need for secondary finishing processes and thereby speeding up production time.

3. Increased Productivity: PCD tools are significantly more resistant to wear than standard carbide or other diamond-coated cutting tools. This attribute allows machines to operate at higher speeds and feeds, significantly increasing throughput.

Perfect Tools Industries provides PCD tools products that are tailored to meet the demands of faster production cycles, thereby boosting overall productivity for users in sectors such as automotive, aerospace, and woodworking.

4. Wide Material Applicability: One of the greatest strengths of PCD tools products lies in their versatility across different materials, including highly abrasive composites, metals, and woods.

This adaptability makes them an invaluable asset in workshops and factories that work with a diverse range of materials. Perfect Tools Industries’ expertise as a woodworking tools manufacturer in Ahmedabad is complemented by their proficiency in creating PCD tools that excel in various industrial applications.

5. Cost Efficiency Over Time: While the initial cost of PCD tools products may be higher than traditional cutting tools, the long-term savings are substantial.

The durability and extended tool life of PCD tools mean fewer replacements, less machine downtime, and reduced tool inventory. For businesses looking to optimize their operating costs, investing in PCD tools from Perfect Tools Industries can lead to considerable financial savings over time.

6. Environmental Benefits: Using PCD tools also contributes to environmental sustainability. Longer tool life means fewer tools need to be produced, and less waste is generated.

Moreover, the efficiency of PCD tools can lead to lower energy consumption during machining processes. Perfect Tools Industries is committed to sustainability, providing PCD tools that not only enhance production efficiency but also support greener manufacturing practices.

Conclusion:

PCD tools products represent a significant advancement in machining technology, offering unparalleled benefits in terms of durability, precision, and efficiency. Perfect Tools Industries stands at the forefront of this innovation, integrating their deep expertise in woodworking tools with advanced PCD technology to serve diverse industrial needs.

For businesses aiming to elevate their machining capabilities and achieve cost-effective, high-quality production, exploring the PCD tools products offered by Perfect Tools Industries is a wise and profitable strategy. Whether you are engaged in woodworking, metal fabrication, or composite material processing, these tools promise to deliver performance that can transform your production processes.

0 notes

Text

Menahub: Your Ultimate Source for Grinder Machines

Explore the extensive range of grinder machines on Menahub, your premier destination for industrial equipment. From angle grinders to bench grinders, we offer top-quality products designed to meet the diverse needs of professionals and DIY enthusiasts alike. Whether you're looking for precision grinding for metalwork or tackling tough jobs in woodworking, our selection boasts durability, efficiency, and versatility. With user-friendly navigation and secure payment options, Menahub ensures a seamless shopping experience, backed by expert customer support to assist you at every step. Upgrade your workshop with the best grinder machines available, only at Menahub.

https://menahub.com/delonghi-la-specialista-ec9335-r-barista-pump-espresso-coffee-machine-with-integrated-grinder-red-132126030-mh-s8fici3p9h?queryID=4dcadaca176fed116743d1e9166e29be&objectID=42241&indexName=mh_default_products

0 notes

Text

Elevate Your Cutting Game with SawTrax Panel Saws

When it comes to crafting impeccable woodwork, the name that resonates with quality and precision is SawTrax Panel Saws by Saw Trax Manufacturing, Inc. These cutting-edge machines are the go-to solution for woodworkers who demand nothing but the best. Here's why:

Precision: SawTrax Panel Saws are engineered to deliver unparalleled precision with every cut. Featuring meticulous measuring and cutting guides, these saws ensure consistent results, minimizing wastage and maximizing efficiency for your woodworking projects.

Efficiency: Efficiency is the hallmark of SawTrax Panel Saws. Designed for swift operation, these machines effortlessly handle large sheets of material, slashing through them with accuracy and speed. Say goodbye to time-consuming cutting processes and hello to streamlined productivity.

Durability: Built to withstand the toughest of woodworking environments, SawTrax Panel Saws boast exceptional durability. Crafted from top-quality materials, these machines are engineered for longevity, promising years of reliable service even under heavy daily usage.

Versatility: From plywood to MDF, acrylic, and beyond, SawTrax Panel Saws excel in cutting a diverse range of materials. With the ability to make angled cuts and customizable features like dust collection systems and specialized cutting guides, these saws adapt to your unique woodworking needs effortlessly.

Safety: Safety is paramount, and SawTrax Panel Saws prioritize it with advanced safety features. Equipped with safety guards, emergency stops, and switches, these machines ensure operator safety, providing peace of mind during operation.

With a range of models to suit different requirements and budgets, including the Full Size Series, Compact Series, and Sign Makers Series, SawTrax Panel Saws offer tailored solutions for every woodworking enthusiast. Elevate your woodworking experience today with SawTrax Panel Saws and unlock a new level of precision and efficiency in your projects.

0 notes

Text

Mastering Precision: The Art of Miter Door Machines

In the world of woodworking, precision and craftsmanship are paramount. One tool that stands out for its ability to create seamless joints and elegant finishes is the miter door machine. This specialized equipment is designed to streamline the process of creating mitered doors, a task that demands accuracy and finesse. Let's delve into the world of miter door machines and explore how they elevate woodworking to new levels of excellence.

Understanding Miter Door Machines

Miter door machines are specifically engineered to cut precise angles on the edges of door components, allowing them to fit together seamlessly at the corners. These machines utilize advanced cutting techniques to ensure that each joint is perfectly aligned, resulting in a flawless finish that enhances the overall aesthetic of the door.

Benefits of Using a Miter Door Machine

Precision: Miter door machines offer unparalleled accuracy, ensuring that each cut is exact and consistent. This precision is essential for creating doors that fit together seamlessly and look professionally crafted.

Efficiency: By automating the mitering process, these machines significantly reduce production time and labor costs. Woodworkers can produce high-quality mitered doors quickly and efficiently, increasing overall productivity.

Quality: The precise cuts made by miter door machines result in high-quality joints that are durable and visually appealing. This level of craftsmanship adds value to the finished product and sets it apart from standard doors.

Versatility: Miter door machines can handle a variety of door sizes and materials, making them versatile tools for woodworking projects of all scales. Whether working on small cabinet doors or large entryway doors, these machines deliver consistent results.

Tips for Mastering Miter Door Machines

Calibration: Regularly calibrate your miter door machine to ensure that it is cutting angles accurately. Proper calibration is essential for achieving precise joints and seamless finishes.

Material Selection: Choose high-quality materials for your doors to complement the precision of the mitered joints. Quality wood enhances the overall look and durability of the finished product.

Maintenance: Keep your miter door machine well-maintained to prolong its lifespan and ensure optimal performance. Regular cleaning and lubrication will help prevent wear and tear on the machine.

Conclusion

Miter door machines are indispensable tools for woodworkers seeking to elevate their craft and produce exceptional doors with seamless joints. By mastering the art of using these machines, artisans can create doors that showcase precision, quality, and attention to detail. Embrace the precision of miter door machine and unlock a world of woodworking possibilities.

0 notes

Text

Joinery in Interior Designing: Importance & Benefits

Joinery is the craft of connecting or joining pieces of wood together to create sturdy and aesthetically pleasing structures. It has been an integral part of woodworking and construction for centuries, dating back to ancient civilizations. Joinery techniques vary widely, from simple but strong methods used in traditional carpentry to more intricate and precise techniques employed in fine woodworking and furniture-making

Types of Joinery:

There are numerous types of joinery techniques used by craftsmen and woodworkers to create strong and durable connections between wooden components. Some of the most common types include:

Dovetail joints: These interlocking joints are known for their strength and resistance to pulling apart. They are often used in drawer construction and box making.

Mortise and tenon joints: This classic joint consists of a projecting tenon on one piece of wood that fits into a corresponding mortise or slot in another piece. It is widely used in furniture making and timber framing.

Biscuit joints: Biscuit joinery involves cutting matching slots in two pieces of wood and inserting small, football-shaped wooden biscuits coated with glue to join them together.

Pocket hole joints: This modern joinery technique involves drilling angled holes into one piece of wood and joining it to another piece using special screws inserted into the pocket holes.

Finger joints: Also known as box joints, finger joints are created by interlocking alternating projections and recesses along the edges of two pieces of wood, forming a strong bond.

Tools and Equipment:

Joinery requires a variety of tools and equipment to accurately cut, shape, and assemble wooden components. Essential hand tools include chisels, hand saws, planes, marking and measuring tools, mallets, and clamps. Power tools commonly used in joinery include routers, table saws, jointers, biscuit joiners, and drill presses. Specialised equipment such as dowelling jigs, dovetail jigs, and mortising machines can also be used to streamline the joinery process and achieve precise results.

Materials Used:

Wood is the primary material used in joinery due to its natural beauty, versatility, and strength. Common types of wood used in joinery include hardwoods such as oak, maple, cherry, and walnut, as well as softwoods like pine, cedar, and fir. In addition to wood, joinery may involve the use of other materials such as metal fasteners, adhesives, and reinforcements to strengthen joints and enhance durability.

Joinery and Interior Designing: Importance and Benefits:

Joinery plays a crucial role in interior design, contributing to the functionality, aesthetics, and overall ambience of a space. Well-crafted joinery can enhance the visual appeal of interior spaces by adding architectural interest, texture, and character. Custom joinery solutions tailored to the specific needs and style preferences of clients can transform ordinary rooms into unique and inviting environments. Joinery also offers practical benefits such as maximising storage space, optimising workflow in kitchens and offices, and creating seamless transitions between different areas of a building.

Joinery companies in Dubai are at the forefront of delivering high-quality craftsmanship and innovative joinery solutions for residential, commercial, and hospitality projects in the region. With their expertise in traditional joinery techniques and access to state-of-the-art tools and materials, these companies are capable of meeting the diverse needs and design aspirations of their clients.

0 notes

Text

A Comparative Analysis of Bolts, Screws, and Nails: Understanding Their Differences and Applications

Fasteners Manufacturers in India

Introduction:

In construction and manufacturing, the selection of fasteners plays a crucial role in ensuring structural integrity and reliability. Among the most commonly used fasteners are bolts, screws, and nails. While they may appear similar, each serves distinct purposes and possesses unique characteristics. This case study aims to provide a comprehensive analysis of bolts, screws, and nails, highlighting their differences and respective applications.

Objective:

The primary objective of this case study is to elucidate the key differences between bolts, screws, and nails, and to elucidate their optimal applications in various industries. By understanding the distinctive features of each fastener type, professionals can make informed decisions when selecting the appropriate fastening solution for their projects.

Bolt Manufacturers in India

Brief:

Bolts, screws, and nails are all fasteners used in construction, manufacturing, and various other industries. However, they differ significantly in terms of design, function, and application.

Bolts:

Bolts are threaded fasteners characterized by a head on one end and a threaded shaft on the other. They require a nut to secure two or more components together. Bolts are commonly used in applications where a strong, durable connection is needed, such as construction, automotive, and aerospace industries. They provide high tensile strength and are suitable for heavy-duty applications where disassembly may be required.

Screws:

Screws are similar to bolts but differ in that they typically have a tapered, pointed end and may or may not require a nut. Screws create their own internal threads when driven into a material, providing a secure grip. They are versatile fasteners used in woodworking, furniture assembly, electronics, and general construction. Screws come in various types, including wood screws, machine screws, and self-tapping screws, each designed for specific applications.

Nails:

Nails are non-threaded fasteners with a sharp point on one end and a head on the other. They are driven into materials using a hammer or nail gun and rely on friction to maintain their grip. Nails are commonly used in woodworking, carpentry, framing, and general construction applications. They provide quick and easy installation and are ideal for temporary or non-load-bearing connections.

High Tensile Fasteners

Applications:

- Bolts:

- Structural steel construction

- Machinery assembly

- Automotive manufacturing

- Bridge building

- Screws:

- Woodworking and furniture assembly

- Electrical and electronic equipment

- Sheet metal fabrication

- Drywall installation

- Nails:

- Framing and carpentry

- Roofing and siding installation

- Flooring and decking

- Pallet and crate assembly

ASME Fastener Standards

Conclusion:

In conclusion, bolts, screws, and nails are fundamental fasteners with distinct characteristics and applications. Bolts offer high strength and reliability for heavy-duty connections, screws provide versatility and ease of installation in various materials, and nails offer quick and cost-effective solutions for light-duty applications. Understanding the differences between these fasteners is essential for selecting the most suitable option for specific project requirements, ultimately ensuring optimal performance and durability.

0 notes

Text

Efficiency Redefined: How Altendorf's K-34 Edge Trimming Machine Streamlines Woodworking Operations

For woodworkers, achieving flawless edges is a constant pursuit. The meticulous removal of excess material after applying edge banding, known as edge trimming, can be a time-consuming and potentially error-prone task. Enter Altendorf's K-34 edge trimming machine, a technological marvel designed to revolutionize efficiency in your woodworking operations.

The Edge Trimming Conundrum: Quality vs. Time

Traditionally, edge trimming relies on manual tools like routers or hand-held trimmers. While suitable for small projects, these methods present challenges:

Inconsistent Results: Manual trimming requires a steady hand and meticulous attention to detail. Even minor variations can lead to uneven edges and imperfections.

Time-Consuming Process: Manually trimming edges, especially on larger workpieces, can be a tedious and laborious task, impacting overall project completion times.

Safety Concerns: Using handheld trimming tools comes with inherent risks, such as accidental cuts or slips.

The K-34: A Precision Powerhouse

The K-34 tackles these challenges head-on, offering a perfect blend of precision, efficiency, and safety:

Unmatched Precision: The K-34 boasts a high-performance trimming unit featuring a carbide-tipped cutting blade. This combination ensures clean, crisp cuts with minimal material tear-out, eliminating imperfections and guaranteeing a professional finish.

Effortless Efficiency: Say goodbye to manual labor. The K-34 automates the entire trimming process, significantly reducing production time. This allows you to focus on other crucial aspects of your projects while the machine handles the repetitive task of edge trimming.

Repeatability and Consistency: Automation is key to achieving consistent results across multiple workpieces. The K-34 ensures uniform edge trimming, essential for professional-looking furniture and cabinetry, especially in production environments.

A Closer Look at the K-34's Features

The K-34 is packed with features that enhance the edge trimming experience:

Adjustable Trimming Height: Catering to various edging materials, the K-34's trimming head can be effortlessly adjusted to accommodate different thicknesses. This ensures precise trimming regardless of the material used.

Angled Trimming Capability: For projects requiring angled edges, the K-34 offers the flexibility of trimming at specific angles. This empowers woodworkers to tackle complex designs with confidence, expanding their creative possibilities.

Integrated Dust Extraction System: Maintaining a clean work environment is crucial. The K-34's dust extraction system ensures excellent visibility during operation and minimizes dust inhalation, promoting a safer and healthier workshop environment.

Seamless Workflow Integration

The K-34 is designed to integrate effortlessly into your existing woodworking workflow:

Compact and Efficient Design: Space-saving design makes the K-34 ideal for workshops of all sizes. Its portability allows for easy positioning within your workspace, optimizing workflow integration.

Intuitive User Interface: Operating the K-34 is a breeze. The user-friendly control panel allows for quick adjustments and effortless machine operation, minimizing setup time and maximizing productivity.

Compatibility with Other Altendorf Machines: For a truly streamlined workflow, the K-34 seamlessly integrates with other Altendorf machines like edge banding machines. This creates a complete edge finishing solution, eliminating the need for manual material handling between processes.

Beyond Efficiency: The Added Value of the K-34

The K-34 goes beyond just precise trimming, offering additional benefits for woodworkers:

Durable Construction: Built with top-quality materials and German engineering excellence, the K-34 is built to last. This translates to reliable performance and minimal downtime in your workshop.

Reduced Material Waste: The K-34's precision trimming minimizes edging material waste. This not only saves you money in the long run but also aligns with sustainable woodworking practices.

Enhanced Safety: Automation eliminates the risks associated with manual trimming tools. The K-34 promotes a safer working environment, giving you peace of mind while you work.

The K-34 Advantage: Elevate Your Craft

The K-34 edge trimming machine offers a compelling proposition for woodworkers seeking to elevate their craft:

Professional-Grade Results: Effortlessly achieve flawless edge trimming with the K-34. This elevates the overall aesthetics and perceived value of your woodworking projects, giving them a polished, high-end look.

Unmatched Workflow Efficiency: The K-34 automates the trimming process, freeing up valuable time for other crucial tasks. This translates to increased productivity and faster project completion times.

A Mark of Expertise: Utilizing a high-precision edge trimming machine like the K-34 signifies a commitment to quality and sets your work apart from the rest. It demonstrates your dedication to using the best tools to achieve exceptional results.

Investing in Efficiency: The K-34 for Today's Woodworker

In today's fast-paced world, efficiency is paramount. The K-34 edge trimming machine from Altendorf is more than just a machine; it's an investment in your woodworking future. It streamlines your workflow, minimizes material waste, and empowers you to achieve professional-grade edge trimming with remarkable consistency. With the K-34 by your side, unlock the true potential of your woodworking skills and transform your workshop into a hub of efficiency and precision. So, embrace the future of edge trimming and elevate your craft to new heights with the K-34.

0 notes

Text

Revolutionizing Woodworking: The Advancements of Auto Edge Banding Machines

In the realm of woodworking, precision and efficiency are paramount. With the rapid advancements in technology, the traditional methods of edge banding have evolved significantly. One such innovation that has revolutionized the industry is the Auto Edge Banding Machine. This marvel of engineering has streamlined the process of applying edge banding to wooden panels, offering unparalleled accuracy and speed. In this article, we delve into the workings of auto edge banding machines, exploring their benefits, applications, and the future they herald for woodworking professionals.

Evolution of Edge Banding:

Traditionally, edge banding involved manual application of thin strips of veneer or PVC to the edges of wooden panels using adhesives and rollers. While effective, this method was labor-intensive and prone to human error. As demand for efficiency and precision grew, the need for automated solutions became apparent. Enter the auto edge banding machine.

How Auto Edge Banding Machines Work:

Auto edge banding machines automate the entire process of edge banding, from adhesive application to trimming and buffing. These machines are equipped with advanced mechanisms such as conveyor belts, glue application systems, pressure rollers, trimming units, and buffing wheels. The process begins with the feeding of the wooden panel into the machine, where it is guided along the conveyor belt. The machine applies adhesive to the edge of the panel and precisely attaches the edge banding material using pressure rollers. Subsequently, the excess banding material is trimmed and buffed to perfection, resulting in a seamless finish.

Advantages of Auto Edge Banding Machines:

Precision: Auto edge banding machines ensure consistent and precise application of edge banding material, eliminating human error.

Efficiency: These machines significantly reduce production time, allowing woodworking professionals to increase their output.

Versatility: Auto edge banding machines can handle various types of edge banding materials, including veneer, PVC, and ABS, making them versatile for different woodworking projects.

Quality: The automated process results in high-quality finishes that enhance the aesthetics and durability of the wooden panels.

Cost-effectiveness: While initial investment may be higher, the long-term cost savings from increased efficiency and reduced labor make auto edge banding machines a cost-effective solution.

Applications:

Auto edge banding machines find applications across various sectors of the woodworking industry, including furniture manufacturing, cabinetry, interior design, and architectural woodworking. Whether it’s producing custom furniture pieces or mass-manufacturing kitchen cabinets, these machines cater to the diverse needs of woodworking professionals.

Future Outlook:

The future of auto edge banding machines looks promising, with ongoing advancements in technology enhancing their capabilities further. Integration of artificial intelligence and machine learning algorithms may lead to even more precise and adaptive edge banding solutions. Additionally, advancements in materials science may result in the development of innovative edge banding materials with enhanced properties.

In conclusion, auto edge banding machines represent a significant leap forward in the field of woodworking. Their ability to automate and streamline the edge banding process offers numerous advantages, including increased precision, efficiency, and versatility. As technology continues to evolve, these machines will play a pivotal role in shaping the future of woodworking, empowering professionals to achieve new heights of craftsmanship and productivity.

0 notes