Text

Troubleshooting Edge Banding Nightmares: Common Problems and How to Fix Them

Ah, the pursuit of the perfect edge. Edge banding, the process of applying a pre-veneered material to raw panel edges, elevates your woodworking projects with a touch of professionalism. But even the most seasoned woodworker can encounter occasional edge banding woes. Fear not, fellow crafters! This guide explores common edge banding problems and solutions, empowering you to troubleshoot these nightmares and achieve flawless results.

The Bane of Beautiful Edges: Common Edge Banding Nightmares

Let's delve into some of the most frequent edge banding challenges and how to overcome them:

Uneven Glue Application: This can lead to poor adhesion and visible gaps between the edging material and the panel.

Solution:

Manual Edge Banding: Ensure even glue spread with a dedicated glue spreader or a notched trowel.

Automatic Edge Banding Machines in India: Check the glue application settings and ensure proper roller pressure for consistent glue distribution.

Poor Adhesion: If the edging material peels off easily, the glue bond might be weak.

Solution:

General: Use a high-quality wood glue suitable for veneer application and ensure both surfaces are clean and free of dust before applying glue.

Manual Edge Banding: Apply sufficient clamping pressure to ensure a tight bond while the glue dries.

Rough or Chipped Edges: Uneven trimming can leave jagged edges or chipped veneer.

Solution:

Manual Edge Banding: Invest in a sharp, dedicated router bit for veneer trimming. Use a scrap piece of wood as a fence to guide your router for a straight cut.

Automatic Edge Banding Machines: Ensure the trimming blades are sharp and properly adjusted.

Wrinkles or Air Bubbles: These imperfections can detract from the overall finish.

Solution:

Manual Edge Banding: When using the glue and clamp method, carefully smooth out any air bubbles with a pressing tool before clamping.

Automatic Edge Banding Machines: Check the tension settings of the edging material feed system to avoid wrinkles.

Burning of Edging Material: Excess heat during trimming can scorch the veneer.

Solution:

Manual Edge Banding: Use a router with adjustable speed settings and a light touch while trimming.

Automatic Edge Banding Machines: Adjust the trimming speed or temperature settings to avoid burning the edging material.

Beyond Troubleshooting: Pro Tips for Flawless Edge Banding

Here are some additional tips to ensure a smooth edge banding experience:

Choose the Right Edging Material: Select a material compatible with your chosen glue and project requirements. Consider thickness and flexibility for curved edges.

Practice on Scrap Wood: Before tackling your final project, experiment with your edge banding technique on scrap pieces to perfect your application and trimming skills.

Clean Work Area: Dust and debris can interfere with glue adhesion. Maintain a clean workspace throughout the process.

Read the Manual (Seriously!): Whether using a manual or automatic edge banding machine, familiarizing yourself with the manufacturer's instructions ensures optimal machine performance and helps avoid common pitfalls.

Embrace the Challenge, Achieve Flawless Edges

Edge banding might present occasional challenges, but with the right knowledge and these troubleshooting tips, you can overcome these nightmares and achieve professional-looking results on your woodworking projects. Remember, whether you're using a manual edge banding machine, a high-tech automatic option in India, or a good old-fashioned DIY approach, patience, practice, and a touch of problem-solving go a long way in achieving flawless edges. So, don't let edge banding woes hold you back. Embrace the challenge, and watch your woodworking creations transform with the beauty of perfectly finished edges!

0 notes

Text

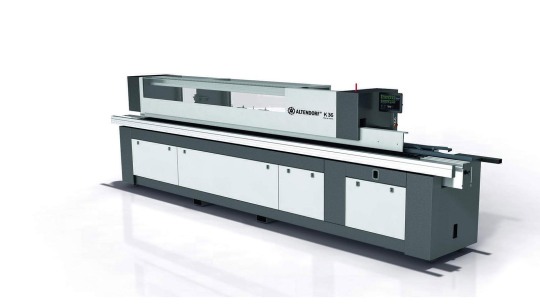

Efficiency Redefined: How Altendorf's K-34 Edge Trimming Machine Streamlines Woodworking Operations

For woodworkers, achieving flawless edges is a constant pursuit. The meticulous removal of excess material after applying edge banding, known as edge trimming, can be a time-consuming and potentially error-prone task. Enter Altendorf's K-34 edge trimming machine, a technological marvel designed to revolutionize efficiency in your woodworking operations.

The Edge Trimming Conundrum: Quality vs. Time

Traditionally, edge trimming relies on manual tools like routers or hand-held trimmers. While suitable for small projects, these methods present challenges:

Inconsistent Results: Manual trimming requires a steady hand and meticulous attention to detail. Even minor variations can lead to uneven edges and imperfections.

Time-Consuming Process: Manually trimming edges, especially on larger workpieces, can be a tedious and laborious task, impacting overall project completion times.

Safety Concerns: Using handheld trimming tools comes with inherent risks, such as accidental cuts or slips.

The K-34: A Precision Powerhouse

The K-34 tackles these challenges head-on, offering a perfect blend of precision, efficiency, and safety:

Unmatched Precision: The K-34 boasts a high-performance trimming unit featuring a carbide-tipped cutting blade. This combination ensures clean, crisp cuts with minimal material tear-out, eliminating imperfections and guaranteeing a professional finish.

Effortless Efficiency: Say goodbye to manual labor. The K-34 automates the entire trimming process, significantly reducing production time. This allows you to focus on other crucial aspects of your projects while the machine handles the repetitive task of edge trimming.

Repeatability and Consistency: Automation is key to achieving consistent results across multiple workpieces. The K-34 ensures uniform edge trimming, essential for professional-looking furniture and cabinetry, especially in production environments.

A Closer Look at the K-34's Features

The K-34 is packed with features that enhance the edge trimming experience:

Adjustable Trimming Height: Catering to various edging materials, the K-34's trimming head can be effortlessly adjusted to accommodate different thicknesses. This ensures precise trimming regardless of the material used.

Angled Trimming Capability: For projects requiring angled edges, the K-34 offers the flexibility of trimming at specific angles. This empowers woodworkers to tackle complex designs with confidence, expanding their creative possibilities.

Integrated Dust Extraction System: Maintaining a clean work environment is crucial. The K-34's dust extraction system ensures excellent visibility during operation and minimizes dust inhalation, promoting a safer and healthier workshop environment.

Seamless Workflow Integration

The K-34 is designed to integrate effortlessly into your existing woodworking workflow:

Compact and Efficient Design: Space-saving design makes the K-34 ideal for workshops of all sizes. Its portability allows for easy positioning within your workspace, optimizing workflow integration.

Intuitive User Interface: Operating the K-34 is a breeze. The user-friendly control panel allows for quick adjustments and effortless machine operation, minimizing setup time and maximizing productivity.

Compatibility with Other Altendorf Machines: For a truly streamlined workflow, the K-34 seamlessly integrates with other Altendorf machines like edge banding machines. This creates a complete edge finishing solution, eliminating the need for manual material handling between processes.

Beyond Efficiency: The Added Value of the K-34

The K-34 goes beyond just precise trimming, offering additional benefits for woodworkers:

Durable Construction: Built with top-quality materials and German engineering excellence, the K-34 is built to last. This translates to reliable performance and minimal downtime in your workshop.

Reduced Material Waste: The K-34's precision trimming minimizes edging material waste. This not only saves you money in the long run but also aligns with sustainable woodworking practices.

Enhanced Safety: Automation eliminates the risks associated with manual trimming tools. The K-34 promotes a safer working environment, giving you peace of mind while you work.

The K-34 Advantage: Elevate Your Craft

The K-34 edge trimming machine offers a compelling proposition for woodworkers seeking to elevate their craft:

Professional-Grade Results: Effortlessly achieve flawless edge trimming with the K-34. This elevates the overall aesthetics and perceived value of your woodworking projects, giving them a polished, high-end look.

Unmatched Workflow Efficiency: The K-34 automates the trimming process, freeing up valuable time for other crucial tasks. This translates to increased productivity and faster project completion times.

A Mark of Expertise: Utilizing a high-precision edge trimming machine like the K-34 signifies a commitment to quality and sets your work apart from the rest. It demonstrates your dedication to using the best tools to achieve exceptional results.

Investing in Efficiency: The K-34 for Today's Woodworker

In today's fast-paced world, efficiency is paramount. The K-34 edge trimming machine from Altendorf is more than just a machine; it's an investment in your woodworking future. It streamlines your workflow, minimizes material waste, and empowers you to achieve professional-grade edge trimming with remarkable consistency. With the K-34 by your side, unlock the true potential of your woodworking skills and transform your workshop into a hub of efficiency and precision. So, embrace the future of edge trimming and elevate your craft to new heights with the K-34.

0 notes

Text

Edge Banding Machines 101: An Introductory Guide for Woodworking Enthusiasts

Have you ever admired the flawless finish on professionally crafted cabinets or furniture? That seamless edge, where the material meets the core, is often the result of an ingenious tool called an edge banding machine. For woodworking enthusiasts, incorporating edge banding into your projects can significantly elevate their aesthetics, functionality, and overall quality. This beginner-friendly guide dives into the world of edge banding machines, empowering you to take your woodworking skills to the next level.

Understanding the Magic of Edge Banding

At its core, an edge banding machine applies pre-veneered edging material (think ABS, PVC, or melamine) to the raw edges of wood panels. This not only enhances the visual appeal by concealing the core material but also offers several practical benefits:

Improved Durability: Exposed edges are susceptible to moisture damage and chipping. Edge banding acts as a protective barrier, safeguarding the core material and extending the lifespan of your creations.

Enhanced Safety: Raw edges can be sharp and pose a splinter hazard. Edge banding eliminates this risk, creating a safer environment in your workshop.

Professional Finishing Touch: A flawlessly finished edge elevates the perceived value of your woodworking projects, making them stand out from the DIY crowd.

The Two Main Categories of Edge Banding Machines

As you embark on your edge banding journey, you'll encounter two primary machine types:

Manual Edge Banding Machines: These are ideal for hobbyists or workshops with occasional edge banding needs. The operator feeds the edging material and panel through the machine, offering greater control but requiring more physical effort.

Automatic Edge Banding Machines in India: Perfect for high-volume production environments, these machines automate most of the edging process. Features like automatic feeding, trimming, and buffing significantly enhance efficiency and consistency.

Choosing Your First Edge Banding Machine: Navigating the Options

The ideal edge banding machine for your needs depends on several factors:

Workshop Space and Budget: Manual machines are generally more affordable and require less space, making them suitable for smaller workshops. Automatic machines offer superior efficiency but require a larger budget and dedicated workspace.

Project Volume and Complexity: For occasional projects, a manual machine might suffice. However, if you envision high-volume production or intricate designs, an automatic machine might be a worthwhile investment.

Desired Level of Control: Manual machines offer greater control over the edge banding process. Automatic machines prioritize speed and consistency.

Portable Options: Edge Banding on the Go

For woodworking enthusiasts who require flexibility or work on-site installations, portable edge banding machines offer a compelling solution. These compact machines deliver surprisingly impressive results, often featuring functionalities like pre-milling and edge trimming.

Essential Considerations Before You Buy

Before diving headfirst into purchasing an edge banding machine, consider these additional factors:

Edging Material Compatibility: Ensure the machine you choose is compatible with the edging material you plan to use (thickness, type).

Safety Features: Look for machines with safety features like dust collection and emergency shut-off switches.

Availability of Replacement Parts and Customer Support: Reliable access to replacement parts and knowledgeable customer service can be invaluable in the long run.

The Learning Journey Begins: Resources for Budding Edge Banding Enthusiasts

The world of edge banding machines might seem intimidating at first. Here are some resources to equip you for success:

Manufacturer Manuals: Consult the user manual that comes with your chosen machine. It provides detailed instructions on operation, maintenance, and troubleshooting.

Online Tutorials: Numerous online tutorials demonstrate the edge banding process on various machines. These visual resources can be a great way to grasp the practical aspects.

Woodworking Communities: Online woodworking forums and communities are excellent platforms to connect with experienced woodworkers who can offer valuable advice and answer your specific questions.

Conclusion: Edge Banding – A Gateway to Professional Woodworking

By incorporating edge banding into your woodworking projects, you'll not only elevate their aesthetics and functionality but also demonstrate a commitment to detail and quality. With the knowledge gained from this guide and the vast array of edge banding machines available, from manual and portable options to automatic machines in India, there's a perfect machine waiting to empower you to achieve professional-grade finishes in your workshop. So, grab your woodworking tools, embrace the world of edge banding, and embark on a journey of creative exploration!

0 notes

Text

From Concept to Completion: Altendorf's F 5 Next PVC Edge Banding Machine Workflow

Transforming raw materials into stunning finished pieces is the essence of woodworking. However achieving seamless, professional edges often presents a challenge, especially when dealing with PVC edge banding. Enter the Altendorf F 5 Next PVC Edge Banding Machine, a revolutionary tool designed to streamline your workflow and elevate your results. Let's embark on a journey, exploring how the F 5 Next empowers you to bring your creative visions to life, from the initial concept to the final, polished masterpiece.

Step 1: Conception and Preparation

Every great project begins with an idea. Whether you're crafting elegant furniture, modern cabinetry, or innovative architectural elements, the F 5 Next adapts to your vision. Choose from a wide range of PVC edge banding tapes in various colors, textures, and thicknesses to perfectly complement your design. The machine's intuitive touch panel control allows you to easily define edge banding parameters, ensuring precision from the very start.

Step 2: Effortless Edge Trimming

With the F 5 Next, preparing your workpieces for edge banding is a breeze. The high-performance trimming unit features two independent motors, enabling you to achieve flawlessly flush or overhanging edges with unparalleled accuracy. Whether you're working with delicate veneers or thick solid wood, the machine effortlessly handles diverse materials, eliminating manual pre-milling and saving you valuable time.

Step 3: Precision Glue Application

The heart of the F 5 Next lies in its flexible glue application system. Choose from various options, including cartridge glue, PUR glue, and hot melt glue, to find the perfect match for your specific material and application. The machine's precise application ensures optimal bonding strength, preventing edge lifting or delamination, while minimizing glue waste for eco-conscious production.

Step 4: Bonding and Beyond

With glue applied, the F 5 Next seamlessly integrates the edge banding tape with your workpiece. The powerful motor ensures smooth, efficient operation, while the precision engineering guarantees consistent, high-quality results. But the F 5 Next doesn't stop there. Explore optional features like the corner rounding unit to craft professional-looking corners or the scratch removal unit to eliminate minor imperfections for a truly flawless finish.

Step 5: The Final Touches

For that extra touch of elegance, consider the optional buffing unit. This final step polishes the edge banding to a high-gloss sheen, adding a touch of luxury to your creations. With each stage completed, you'll witness your project transform from raw materials into a refined masterpiece.

The Altendorf Advantage: Efficiency and Innovation

The F 5 Next isn't just a PVC edge banding machine, it's an investment in your craft. Its automated processes and intuitive controls significantly boost your productivity, allowing you to complete projects faster and focus on what truly matters - your creativity. Moreover, the machine's energy-efficient design minimizes operating costs and environmental impact, making it a responsible choice for the modern woodworker.

Beyond the Machine: A World of Possibilities

With the F 5 Next in your workshop, the possibilities are endless. Explore the versatility of PVC edge banding to:

Elevate furniture design with clean lines and modern accents.

Enhance cabinet aesthetics with durable and visually appealing edges.

Create unique architectural elements for a touch of individuality.

Boost the value of your woodworking projects with professional-grade finishing.

Investing in Your Success

The F 5 Next represents a significant investment, but it's one that empowers you to take your woodworking skills to the next level. With its superior craftsmanship, versatility, and efficiency, you'll experience:

Increased productivity: Get more done in less time with automated processes.

Enhanced quality: Achieve professional-grade results consistently.

Reduced costs: Save time, materials, and energy with efficient operation.

Improved client satisfaction: Deliver projects that impress and exceed expectations.

Ready to streamline your workflow and unlock the full potential of PVC edge banding? Contact your local Altendorf dealer today and experience the F 5 Next PVC Edge Banding Machine firsthand. Let this innovative tool be your guide, transforming your creative concepts into stunning realities, one edge at a time.

0 notes

Text

Efficiency Redefined: Altendorf's K-34 Edge Trimming Machine for High-Volume Production

In the fast-paced world of manufacturing, edge trimming machines play a crucial role in ensuring precision, speed, and consistent quality. For high-volume production environments, where every second counts, choosing the right equipment is essential. That's where the Altendorf K-34 Edge Trimming Machine steps in, redefining efficiency like never before.

Unmatched Speed and Accuracy:

The K-34 boasts a powerful 11 kW motor, delivering lightning-fast cutting speeds of up to 60 m/min. This translates to significant time savings, especially for high-volume workloads. But speed without accuracy is meaningless. The K-34 addresses this concern with its innovative scoring unit, ensuring tear-free, clean cuts even on delicate materials. Additionally, the digital control panel allows for precise setting and adjustment of cutting parameters, guaranteeing consistent results throughout your production run.

Built for Versatility:

The K-34 isn't a one-trick pony. It caters to a wide range of trimming needs with its flexible design. The machine effortlessly tackles various materials, thicknesses, and angles, making it an invaluable asset for diverse production lines. The large trimming height of 120 mm opens up possibilities for thicker workpieces, while the adjustable trimming width of 0-60 mm offers customization for various edge profiles.

Ergonomics and Operator Comfort:

Production efficiency isn't just about the machine; it's about the operator too. The K-34 prioritizes operator comfort with its ergonomic design. The intuitive control panel simplifies operation, while the adjustable dust extraction system ensures a clean and healthy work environment. The foot pedal control further enhances workflow by allowing hands-free material feeding and activation, minimizing operator fatigue and maximizing productivity.

Advanced Safety Features:

Safety is paramount in any production environment. The K-34 incorporates advanced safety features to protect both the operator and the machine. The double-sided safety hood encloses the cutting area, while the emergency stop button ensures quick shut-off in case of any incident. Additionally, the machine adheres to stringent safety regulations, providing peace of mind for operators and managers alike.

Beyond Efficiency: Sustainable Design:

In today's eco-conscious world, sustainable practices are no longer optional. The K-34 is designed with sustainability in mind. Its energy-efficient motor reduces power consumption, while the dust extraction system minimizes waste and promotes a clean work environment. Furthermore, the machine's robust construction ensures long-lasting performance, reducing the need for frequent replacements and contributing to a more sustainable production cycle.

The Ultimate Investment for High-Volume Production:

The Altendorf K-34 edge trimming machine is more than just a machine; it's an investment in your production efficiency, quality, and sustainability. With its unmatched speed, accuracy, versatility, and operator-friendly design, the K-34 empowers businesses to achieve higher output, reduce costs, and gain a competitive edge in the market. So, if you're looking to redefine efficiency in your high-volume production, look no further than the Altendorf K-34. It's not just a trimming machine, it's a game-changer.

0 notes

Text

From Plain to Polished: Elevate Woodwork with Altendorf's F 5 Next

For discerning woodworkers, the finishing touch isn't just about aesthetics; it's about transforming the ordinary into the extraordinary. However achieving flawless, professional-grade PVC edge banding can be a time-consuming and challenging task, often requiring multiple machines and meticulous adjustments. Enter Altendorf's F 5 Next, a revolutionary PVC edge banding machine designed to elevate your woodworking process and take your creations from plain to polished with ease.

Effortless Mastery: Intuitive Design Meets Advanced Technology

Imagine a PVC edge banding tape machine that feels more like an extension of your creativity than a complex piece of equipment. With the F 5 Next, that's exactly what you get. Its user-friendly control panel boasts clear labeling, a responsive touch-screen interface, and an intuitive layout, making operation a breeze regardless of your experience level. Ditch the intimidating manuals and confusing settings; focus on your artistry and let the F 5 Next handle the technicalities.

Seamless Workflow: One Machine, One Flow, Perfection Every Time

Say goodbye to juggling separate machines and manual trimming tools. The F 5 Next integrates the entire edge banding process into a single, cohesive unit. It smoothly feeds and applies PVC edge banding tape with precise pressure, guaranteeing a flawless bond and eliminating alignment issues. Integrated trimming units then take over, delivering sharp, clean cuts and polished edges based on your exact specifications. This streamlined workflow saves you time, minimizes errors, and maximizes your production efficiency, allowing you to focus on what matters most - creating.

Precision Made Easy: Unwavering Quality at Your Fingertips

For flawless edge banding, precision is key. The F 5 Next doesn't disappoint. Its advanced feed system ensures consistent pressure and tape application, while the trimming units boast adjustable settings for achieving intricate or simple edge profiles with unmatched accuracy. Whether you're working with delicate curves or straight lines, this machine delivers unwavering quality, guaranteeing professional-grade finishes that consistently impress your clients.

Unleash Your Creativity: Adaptability Built for Diverse Designs

The F 5 Next understands that your projects are unique, and its versatility reflects that. This PVC edge band pressing cutting & trimming machine seamlessly handles a wide range of PVC edge band thicknesses (0.4mm to 3mm) and widths (10mm to 60mm), catering to your diverse design choices and material requirements. This adaptability empowers you to take on new challenges with confidence, knowing your machine can keep up with your creative vision and bring your ideas to life.

More Than a Machine: A Partner in Your Woodworking Journey

Investing in the F 5 Next goes beyond acquiring a high-quality machine; it's an investment in your long-term success. Altendorf offers comprehensive support to ensure you get the most out of your machine, including:

Expert training: Gain in-depth knowledge and master the functionalities of the F 5 Next with personalized training sessions tailored to your needs.

Reliable service: Enjoy peace of mind with readily available technical support and prompt parts replacement, minimizing downtime and ensuring smooth operation.

A vibrant community: Connect with fellow woodworkers, share knowledge, and gain inspiration through Altendorf's online community platform.

From Plain to Polished: An Investment in Excellence

The F 5 Next isn't just a machine; it's a transformative tool that elevates your woodworking experience in several ways:

Enhanced Efficiency: Streamline your workflow, minimize errors, and boost your production output, allowing you to take on more projects and grow your business.

Unleashed Creativity: Explore diverse design possibilities with the machine's versatility and precision, taking your craft to new heights.

Impeccable Client Satisfaction: Deliver consistently stunning results that showcase your professionalism and leave a lasting impression.

Sustainable Value: The F 5 Next is built to last, offering exceptional durability and performance, making it a valuable asset for years to come.

Ready to transform your woodworking process and elevate your creations from plain to polished? Contact your local Altendorf dealer today and discover how the F 5 Next PVC edge banding machine can empower you to achieve true excellence.

0 notes

Text

Solving Woodworking Challenges with Altendorf's Edge Banding Technology

From uneven edges to chipped veneers, every woodworker has encountered challenges with edge banding. But fear not, for the evolution of edge banding machines, and specifically Altendorf's innovative solutions, have transformed this once-laborious task into a streamlined and efficient process. Let's delve into how Altendorf's technology tackles common woodworking hurdles, empowering you to create flawless, professional-looking projects.

Uneven Edges: A Thing of the Past:

Manually applying edge banding often leads to inconsistencies in thickness and alignment. Enter automatic edge banding machines like Altendorf's K37. These marvels utilize advanced feeding and trimming systems, ensuring precise material application and a seamless finish, regardless of project complexity. For smaller workshops, manual machines like the WA 6 offer adjustable guides and pressure rollers, minimizing human error and delivering consistent results.

Chipped Veneers: No More Nightmares:

Chipped veneers can leave unsightly blemishes on your masterpiece. Altendorf's machines combat this issue with features like temperature control and pressure regulation. The WA 8, for instance, boasts pre-heating capabilities that ensure optimal adhesive activation, preventing veneer tearing during trimming. Additionally, dust extraction systems minimize chip accumulation, guaranteeing a clean and precise cut every time.

Time Constraints? Conquer Them with Speed:

Meeting deadlines can be stressful, especially with traditional edge banding methods. Thankfully, automatic edge banding machines like the WA 9 come to the rescue. With features like automatic feeding and high-speed trimming, these machines significantly enhance production speed, enabling you to complete projects faster without compromising quality. Even manual machines like the WA 6 offer improvements over handwork, allowing for quicker application and trimming, ideal for hobbyists and smaller workshops.

Material Versatility: Unleash Your Creativity:

Limited by material options? Think again! Altendorf provides a vast array of edgebanding materials, from classic wood veneers to cutting-edge laminates and functional edgebands. Whether you desire a timeless aesthetic or a modern touch, you'll find the perfect material to complement your vision. This versatility allows you to tackle diverse projects, pushing the boundaries of your creativity and catering to your unique design preferences.

Budgetary Concerns? Find Your Fit:

Investing in the right edge banding machine is crucial, but budget constraints are a reality. Altendorf understands this. They offer a diverse range of machines, from cost-effective manual options like the WA 6 to high-performance automatic solutions like the WA 9. By analyzing your project needs, workshop size, and budget, you can select the perfect machine that delivers optimal value and performance.

Beyond Technology: Expert Support at Your Fingertips:

Altendorf doesn't just sell machines; they offer a comprehensive support system. Their knowledgeable team provides invaluable training and resources, ensuring you maximize your machine's potential and overcome any challenges. Additionally, their commitment to seamless integration allows their machines to work harmoniously with other tools in your workshop, creating an efficient and productive workflow.

Conclusion: Embrace Efficiency and Excellence:

Edge banding no longer needs to be a source of frustration. With Altendorf's cutting-edge technology, diverse material options, and dedicated support system, you can conquer common woodworking challenges, elevate your efficiency, and achieve professional-looking results on every project. So, embrace the evolution of edge banding and unlock the full potential of your woodworking journey with Altendorf's innovative solutions.

0 notes

Text

K-34: Setting New Standards in Edge Trimming Efficiency

For woodworkers, time is precious, precision is paramount, and versatility is key. The Altendorf K-34 edge trimming machine shatters conventional standards, offering an unparalleled blend of these crucial elements. It's not just an edge trimmer; it's a productivity powerhouse designed to elevate your craft and streamline your workflow. Let's delve into the features that make the K-34 a game-changer for modern workshops:

Efficiency Unbound:

Turbocharged Performance: Experience the thrill of effortless trimming with the K-34's robust motor. Engineered for demanding tasks, it effortlessly handles diverse materials, allowing you to work faster and smarter. Imagine churning out flawlessly trimmed pieces at an impressive rate, meeting deadlines with ease and exceeding client expectations.

Dust Extraction Made Easy: Breathe easy and maintain a healthy, productive workspace with the K-34's integrated dust extraction system. This system effectively captures dust particles, enhancing visibility and minimizing respiratory concerns. Enjoy a cleaner work environment that fosters well-being and optimizes your creative flow.

Seamless Workflow Integration: The K-34 adapts effortlessly to your existing processes. Its user-friendly design and automated features allow you to quickly incorporate high-quality edge trimming into your workflow, boosting productivity without introducing unnecessary complexities. No more time wasted on intricate setups – focus on what truly matters: creating stunning woodworking masterpieces.

Precision You Can Trust:

German Engineering at its Finest: Experience unwavering accuracy and reliability with the K-34's core built on renowned German engineering. Achieve razor-sharp, chip-free edges on every type of material, from delicate veneers to robust solid wood. Whether you're crafting intricate furniture or tackling demanding projects, the K-34 delivers professional-grade results you can be proud of.

Beyond Straight Cuts: Unleash your creativity with a variety of trimming options. Choose from straight, chamfer, and radius trimming, all delivered with exceptional control. The K-34's adjustable fence and tilting trimming head adapt to your vision, allowing you to add unique details and personalized touches to your woodworking projects.

Micromanagement with Confidence: Take complete control with the user-friendly digital readout. This intuitive feature displays cutting depth and trimming angle in real-time, enabling you to make precise adjustments on the fly. Eliminate guesswork and achieve consistent, repeatable results that elevate your projects to the next level.

Comfort and Safety in Harmony:

Crafted for Comfort: Experience enhanced comfort and well-being with the K-34's ergonomic design principles. Intuitive control placement, ample workspace, and adjustable settings minimize fatigue, allowing you to work longer and more productively. Enjoy extended workshops without physical strain, focusing your energy on bringing your creative vision to life.

Safety is Paramount: Your safety is never compromised with the K-34. Essential safety features like emergency stop buttons and blade guards provide peace of mind and foster a safe working environment. Concentrate on your projects with confidence, knowing you're protected from potential hazards.

Built to Last: Invest in quality that endures. The K-34 boasts robust construction and high-grade materials, ensuring reliable performance and minimal downtime. Minimize maintenance needs and maximize your return on investment, knowing your machine is built to withstand the demands of your workshop for years to come.

Beyond the Machine:

Your Support Network: When you choose Altendorf, you gain access to a well-established dealer network across India. This translates to readily available support, spare parts, and expert advice, ensuring you have the resources and assistance you need to keep your K-34 running smoothly and maximize its potential.

Future-Proof Technology: Invest in a machine that grows with you. The K-34 embodies cutting-edge technology that remains relevant and efficient. By investing in this machine, you gain access to future-proof solutions, safeguarding your edge trimming capabilities for years to come.

A World of Learning: Expand your knowledge base with a wealth of online resources, including tutorials and user guides specifically for the K-34. Unlock the full potential of this versatile machine and push the boundaries of your creative vision through continuous learning.

The K-34 is more than just an edge trimming machine; it's a statement of excellence. It empowers you to work faster, smarter, and more creatively, delivering professional-grade results while prioritizing your well-being and safety. Remember, it's not just about owning a machine; it's about investing in your passion and setting new standards in edge trimming efficiency.

0 notes

Text

Innovations in Edge Banding: Altendorf's Cutting-Edge Technology

In the ever-evolving world of woodworking, edge banding machines play a crucial role in transforming raw edges into professional-looking finishes. But not all machines are created equal. Altendorf, a leading name in woodworking equipment, sets itself apart with cutting-edge technology that elevates edge banding to a whole new level. Let's explore the innovative features that make Altendorf's edge banding machines stand out:

Precision Engineering for Flawless Results:

Advanced Design: Altendorf machines are meticulously designed and crafted in Germany, renowned for their commitment to precision engineering. This translates to consistent edge banding applications, even with intricate curves and thick materials. Imagine achieving laser-sharp corners and seamless transitions for a truly professional finish, every time.

Automated Processes: Many Altendorf models incorporate intelligent technologies like automatic pre-milling and trimming. These features ensure perfect edge matching and effortless operation, minimizing human error and saving you valuable time. Imagine focusing on your creative vision while the machine handles the technical aspects with impeccable accuracy.

Material Versatility: Whether you work with delicate veneers, robust solid wood, or modern laminates, Altendorf machines boast exceptional adaptability. Their advanced material handling capabilities cater to diverse project demands, allowing you to explore any creative idea without limitations.

Efficiency Boosters for Streamlined Workflows:

Automated Edge Banding Machines: For high-volume projects, Altendorf's automatic edge banding machines are productivity powerhouses. Their automated processes significantly reduce production time, freeing you to focus on other aspects of your craft. Imagine churning out flawless edge-banded pieces with unmatched speed and efficiency.

Intuitive Interface: Designed with user-friendliness in mind, Altendorf machines feature intuitive control panels and efficient setup procedures. This minimizes time spent configuring the machine and maximizes your creative output. Imagine diving into your projects quickly and easily, without getting bogged down by complex settings.

Industry-Leading Features: Many Altendorf models come equipped with advanced features like multi-feed systems, corner rounding capabilities, and post-forming functionalities. These features streamline complex tasks and unlock creative possibilities, allowing you to take your edge banding beyond simple straight edges.

Pushing the Boundaries of Aesthetics and Functionality:

Unmatched Edge Quality: From razor-sharp corners to perfectly flush trims, Altendorf machines create visually stunning and aesthetically pleasing edges. Their innovative technologies ensure a seamless transition between the core material and the edge banding, elevating the overall look and perceived value of your projects.

Durable and Protective Edges: Edge banding adds an extra layer of protection, safeguarding your creations from wear, moisture damage, and chipping. This is especially crucial for frequently used furniture or exposed items. Altendorf machines ensure your projects stand the test of time, maintaining their keindahan for years to come.

Endless Creative Freedom: With a vast selection of edge banding materials available, you can unleash your creativity and personalize your projects like never before. Explore unique colors, textures, and thicknesses to match your design vision and bring your dream pieces to life.

Beyond the Machine:

Strong Support Network: Altendorf has a well-established dealer network across India, providing readily available support, spare parts, and expert advice. This ensures you have the resources and assistance you need to keep your edge banding journey smooth and successful.

Continuous Innovation: Altendorf is dedicated to ongoing research and development, constantly pushing the boundaries of edge banding technology. By investing in an Altendorf machine, you gain access to cutting-edge solutions and future-proof your woodworking capabilities.

Choosing the Right Altendorf Machine:

With a diverse range of models encompassing varying levels of automation, features, and capabilities, finding the perfect Altendorf edge banding machine that aligns with your specific needs is vital. Consider factors like:

Project volume and complexity

Desired level of automation

Types of materials you work with

Your budget and space constraints

By exploring the innovative features and functionalities of Altendorf's edge banding machines, you can unlock a world of possibilities in your woodworking journey. From precision and efficiency to creative freedom and professional-grade results, Altendorf empowers you to elevate your craft and create truly exceptional pieces that stand out from the crowd. Remember, it's not just a machine; it's an investment in your creative potential and woodworking excellence.

Additional Information:

Visit the Altendorf website or authorized dealers in India to learn more about their specific edge banding machine models and features.

Consider exploring online resources and tutorials to further understand the capabilities of Altendorf machines and how to utilize them effectively.

0 notes

Text

Altendorf Hand Guard

There can be no two ways about it when it comes to the highest level of safety. But a system: HAND GUARD. The unique, two-camera early-recognition system not only protects your employees but also safeguards your jobs and your cost estimation. We have done our job only when you have succeeded at your job.

1 note

·

View note